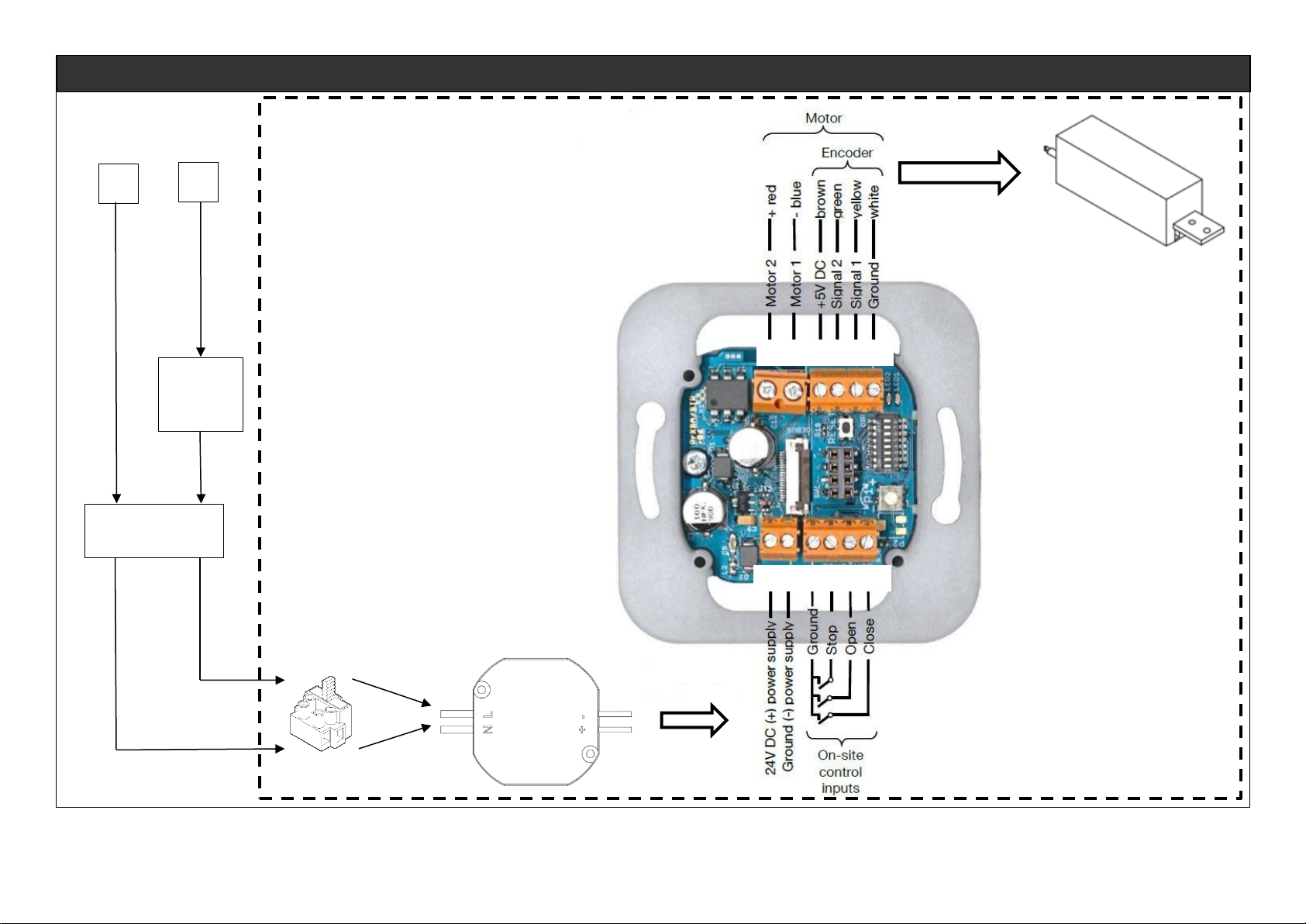

For detailed operation and programming instructions please consult separate Evolve Motor and Wiring Instructions

supplied.

1. Operation Mode Semi-Automatic/Automatic

When semi-automatic mode is set the drive will not close automatically - the potentiometer is without function.

When the automatic mode is set the drive closes automatically.

2. Dead Man’s Control

When dead man’s control is activated the drive will lonely operate, as long as an input is applied. Switch 1 is inactive

when dead man’s control is selected.

3. Push & Go

With push & go enabled the drive starts to move, as soon as the door is pushed manually.

4. Reaction on Obstruction

When reverse is set the drive stops and starts to move in the opposite direction as soon as an obstruction is

detected. If this isn’t set it will stop until a new command is given. This is only possible in semi-automatic mode.

5. Closing Speed

By default the closing speed is slower than the opening speed. The closing speed can be set as fast as the opening

speed, by setting this switch to ON>

6. Maximum Door Speed

The maximum speed has to be set via these switches

Maximum speed is dependent on the door weight according to DIN EN 18650

Weight of door is up to 80kg - maximum speed is 20cm/s

Weight of door is up to 80kg - maximum speed is 23cm/s

Weight of door IS up to 80kg - maximum speed is 26cm/s

When no switch is activated, the slowest speed is set (20cm/s)

When more than one switch is activated, a reduced speed is set (12 cm/s)

PERFORM RESET

1. Switch Power Supply On

Control device in delivery status or after power cut

Red LED blinks continuously twice with a short break of 1.5sec

2. Press RESET for About 2 Seconds

Red LED blinks continuously

3. Check Driving Direction of Motor with Control Keys

When pressing OPEN, door has to open and when pressing CLOSE, door has to close

When driving direction is wrong - swap motor cables (terminals MA and MB), check driving direction again.

4. Move Door in Middle Position by Pressing and Holding the Control Keys

5. Press RESET for About 2 Seconds

Red LED lights up permanently

Green LED lights up during motor activity

Door moves in the open position

Door moves in the closed position

Door moves in the open position

LED’s go out

CHECK FUNCTIONALITY

1. Test, if the door shows desired behavior

2. In case of malfunction check electrical connections and configurations

for electrical connection refer to chapter 5.3 of the Evolve Motor and Wiring Instructions supplied

for configuration refer to chapter 6.1 of the Evolve Motor and Wiring Instructions supplied

Repeat initial operation, if necessary

3. Initial operation is completed when function is correct