SIROCCO Self Closing System

Fitting Instructions

for sliding doors up to 80kg.

SLIDING & FOLDING DOOR HARDWARE

November 2008

Self closing system for a single door between 800 to 1200mm wide. For metal or timber doors with a thickness between 30mm and

46mm. Complete with a hydraulically controlled soft close feature, and a brake to reduce opening speed to prevent damage to the door

and system. Consistent hydraulic closing operational range between temperature ranges of -10°C to 40°C.

(Read instructions thoroughly before commencing installation).

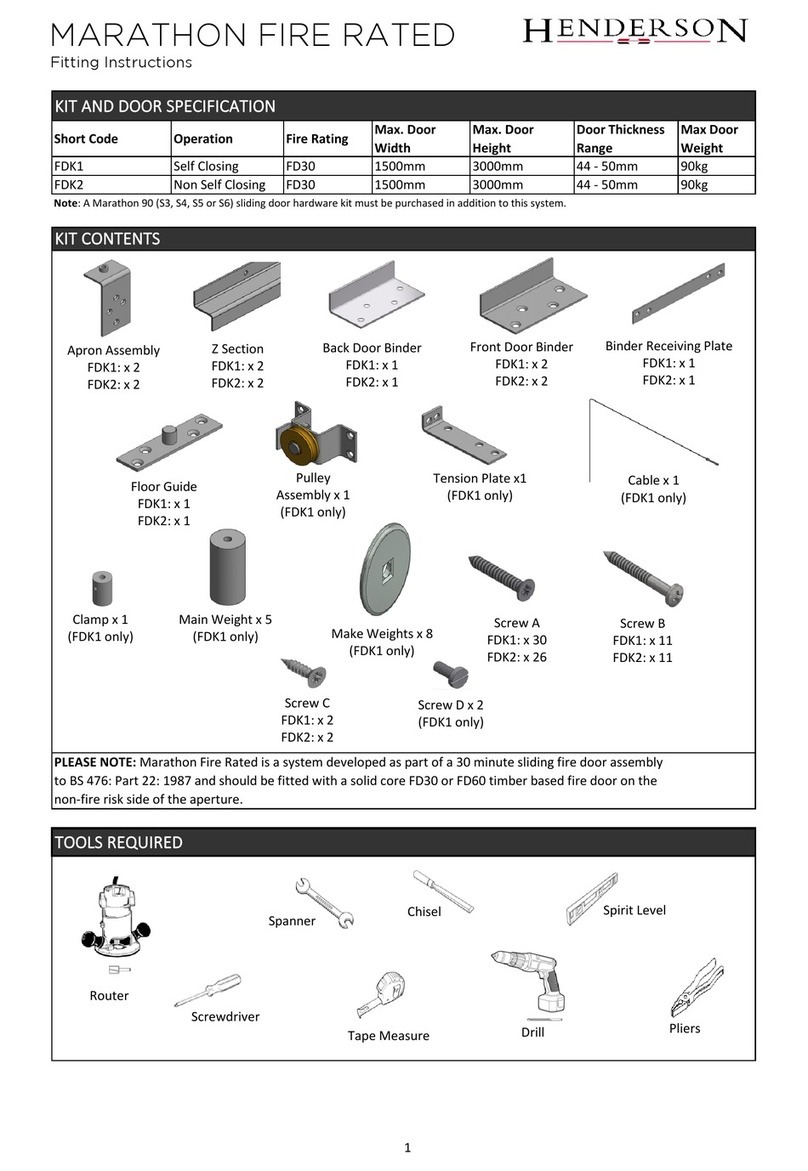

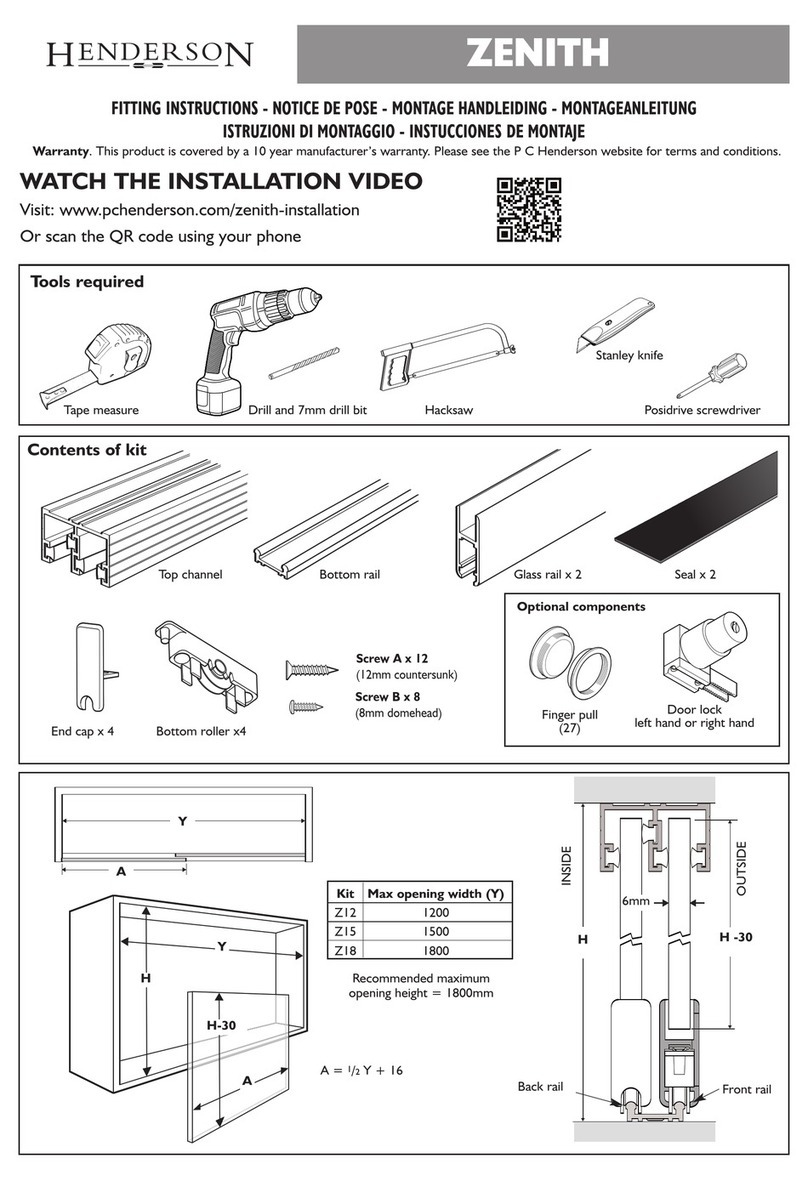

Parts List

Tools Required

General Elevation of

Completed Installation

The elevation view is showing right hand

opening of the door. Left hand opening is

simply a mirror image. Right hand closing is

shown in all images.

Spirit level, Posi-drive screwdriver, Flat head screwdriver, Metal cutting saw, Drill

with metal and masonry drill bits and a Tape measure

9. Installation of the Opening Brake

Slide the door to the fully open position, insert

the Opening Brake Rack into the groove on the

track as shown in diagram 9a. Then align the

front edge of the leading hanger with the

aligning mark on the brake rack as shown on

diagram 9b. Screw the rack to the wall through

the four holes in the rack with suitable fixings.

Remove all debris from the track as this will

damage the track and the rollers.

Diagram 9a. Diagram 9b.

11. Adjusting the Closing Power and Speed

Adjust the closing power by firstly removing the

fixing screw. Adjust the Power Spring Unit as

shown in the diagram 11a. When complete re-

tighten the fixing screw back into its original

position as shown in diagram 11a.

Diagrams shown are for right handed sliding

doors, for left handed sliding doors the

procedures are the opposite.

To adjust the door closing speed as shown in

diagram 11b. Perform this calibration about

250mm from the fully closed position with a flat

head screwdriver, and then ensure that the door

closes with an appropriate and safe speed from

the fully opened position. Do not turn the

speed adjustment valve more than two full

revolutions.

Diagram 11a.

Diagram 11b.

Part Qty

1 Aluminium track 2200mm 1

2 Leading hanger 1

3 Trailing hanger 1

4 Hydraulic Control Unit 1

5 Closing brake rack 1

6 Opening brake rack 1

7 Power spring mounting bracket 1

8 Height adjustment plates 7

9 Power spring unit 1

10 M5 X 16 pan head screw 10

11 M8 x 35 hexagon bolt 4

12 M5 x 12 pan head screw 2

13 Anti rise bolt 2

14 Spring washer

(Countersunk 10mm dia)

2

15 M5 X 12 pan head screw 2

16 M4 X 6 pan head screw 2

17 Guide roller 1

Opening door stop 1

Door stop roller 1

M6 X 20 Hexagon bolt 1

M5 X 12 pan head screw 2

19 Closing door stop 1

Wooden door plate 2

Ø5 X 30 screws

(Countersunk flat head)

8

Delayed timer body

(optional)

1

Time adjusting plate

(optional)

1

22 Guide channel

(optional) 1

18

20

21

To make pulling power stronger To make pulling power weaker

10. Installation of the Hydraulic Control unit

With the door in the closed position fix the

Hydraulic Control Unit to the leading hanger as

shown in diagram 10a with the M5 x 12 screws

provided. Pull the control wire from the Power

Spring Unit and hook the wire loop on to the

leading hanger body as shown in diagram 10b.

Diagram 10a. Diagram 10b.

8. Hanging the Door

With the track and the hangers firmly fixed in

position, hang the door on to the track whilst

locating the floor guide into the guide channel in

the bottom of the door. Carefully check the

door can slide smoothly and that there are no

clearance problems.

Install the hanger anti-rise bolts to both of the

hangers as shown in diagram 8. Diagram 8.