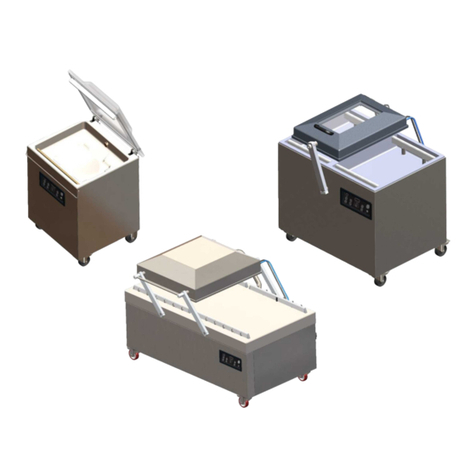

Boxer / Lynx / Toucan Version: BLT-EN-0 10-12-14

TABLE OF CONTENTS

LIST OF FIGURES.................................................................................................................................. 6

EC DECLARATION OF CONFORMITY (COPY) ................................................................................... 7

LIST OF SYMBOLS................................................................................................................................ 8

ICONS ..................................................................................................................................................... 9

1. TECHNICAL INFORMATION........................................................................................................ 10

2. DESCRIPTION OF THE MACHINE............................................................................................... 13

2.1. DESCRIPTION OF THE PACKAGING PROCESS /MACHINE FUNCTIONS ....................................... 14

2.1.1. THE PACKAGING PROCESS /MACHINE FUNCTIONS................................................................. 15

2.1.2. GENERAL FUNCTIONS.......................................................................................................... 18

2.2. THE SEAL SYSTEM............................................................................................................... 19

2.3. THE VACUUM PUMP ............................................................................................................. 20

2.4. GAS FLUSHING (OPTIONAL).................................................................................................. 22

2.5. ELECTRICAL INSTALLATION.................................................................................................. 22

2.6. MULTI PROGRAM DIGITAL CONTROL (MPDC)...................................................................... 24

2.7. ADVANCED CONTROL SYSTEM (ACS).................................................................................. 26

2.7.1. SETTINGS ACS GENERAL.................................................................................................... 27

2.7.2. IMPORT /EXPORT DATA ....................................................................................................... 29

2.7.3. HAZARD ANALYSIS AND CRITICAL CONTROL POINTS (HACCP).............................................. 29

2.7.3.1. SET UP AND USE HACCP.................................................................................................... 29

2.7.3.2. EXPORT THE HACCP DATA LOG.......................................................................................... 30

3. SAFETY ......................................................................................................................................... 32

3.1. GENERAL............................................................................................................................ 32

3.2. DURING NORMAL OPERATION............................................................................................... 33

3.3. OPERATIONAL STAFF........................................................................................................... 33

4. INSTALLATION............................................................................................................................. 34

4.1. TRANSPORT AND PLACEMENT.............................................................................................. 34

4.2. CONNECTING THE MACHINE ................................................................................................. 34

4.3. START THE MACHINE FOR THE FIRST TIME............................................................................. 34

5. OPERATION.................................................................................................................................. 35

5.1. STARTUP ............................................................................................................................ 35

5.2. PRODUCTION ...................................................................................................................... 35

5.3. CONTINUE TO THE NEXT STEP OF THE CYCLE ........................................................................ 36

5.4. STOP PROGRAM .................................................................................................................. 36

5.5. CHANGING THE PROGRAM SETTINGS .................................................................................... 37

5.5.1. MULTI PROGRAM DIGITAL CONTROL (MPDC)...................................................................... 37

5.5.1.1. VACUUM+OPTION (MPDC) ................................................................................................. 38

5.5.1.2. GAS+OPTION (MPDC)........................................................................................................ 39

5.5.1.3. LIQUID SENSOR CONTROL (MPDC)...................................................................................... 39

5.5.1.4. RED MEAT OPTION (MPDC) ................................................................................................ 40

5.5.1.5. MULTI CYCLE OPTION (MPDC)............................................................................................. 40

5.5.1.6. EXTERNAL VACUUM OPTION (MPDC)................................................................................... 42

5.5.2. ADVANCED CONTROL SYSTEM (ADC).................................................................................. 43

5.5.2.1. PROGRAMMING THE ACS CONTROL ON YOUR PC................................................................. 44

5.5.2.2. OPTIONS (ACS).................................................................................................................. 45

5.5.2.3. EXTERN VACUÜM OPTIE (ACS)............................................................................................ 46

5.6. DIRECTIVE FOR FUNCTION VALUES ....................................................................................... 47