Contents

List of Figures................................................................................................................................. 5

1 Preamble....................................................................................................................................... 6

1.1 List of the Symbols Used in this Manual...............................................................................6

1.2 Qualified personnel................................................................................................................ 6

1.3 Storing the manual.................................................................................................................7

1.4 Regulatory information...........................................................................................................7

1.5 Terms of Warranty.................................................................................................................7

1.6 Liability....................................................................................................................................7

1.7 Terms and abbreviations........................................................................................................8

2 Safety.............................................................................................................................................9

2.1 Pictograms on the Machine...................................................................................................9

2.2 General Warnings.................................................................................................................. 9

2.3 Warnings During Use...........................................................................................................10

2.4 Warnings for Operating Personnel.......................................................................................11

3 Introduction.................................................................................................................................12

4 Description of the Machine.......................................................................................................13

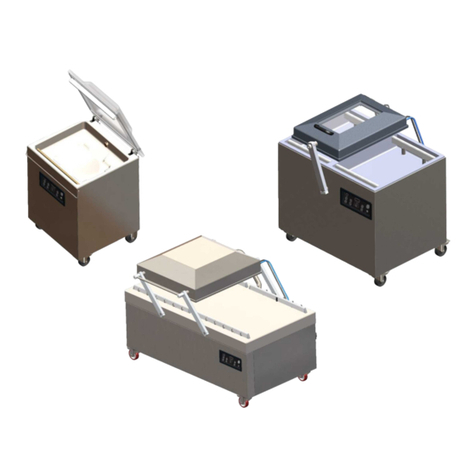

4.1 Jumbo series........................................................................................................................13

4.1.1 Overview of the Main Components..............................................................................14

4.2 Description of the Packaging Process/Machine Functions..................................................15

4.2.1 Packaging Process/Machine Functions........................................................................15

4.2.2 General Functions........................................................................................................15

4.3 Sealing System.................................................................................................................... 16

5 Installation...................................................................................................................................17

5.1 Transportation and Installation.............................................................................................17

5.2 Connecting the Machine...................................................................................................... 17

5.3 Prior to the First Use........................................................................................................... 18

6 Operation.....................................................................................................................................19

6.1 1-Programme Control System (1-PCS)................................................................................19

6.1.1 Operating Elements......................................................................................................19

6.1.2 Starting the Machine....................................................................................................20

6.1.3 Starting the Packaging Cycle.......................................................................................20

6.1.4 Proceeding to the Next Step in the Cycle....................................................................20

6.1.5 Terminating a Programme............................................................................................20

6.1.6 Changing the Programme Settings..............................................................................21

6.1.6.1 Vacuum.................................................................................................................21

6.1.6.2 Vacuum+ time (only for sensor control)...............................................................21

6.1.6.3 Seal.......................................................................................................................22

6.1.6.4 External Vacuum (optional)..................................................................................22

Contents 3