Maintenance Filter & Fryer Vat Cleaning (continued)

FM08-720A ©McDonald’s Corporation · Planned Maintenance Manual · Revised August 2020 Page 2 of 4

nny Penny Corp.Open Fryer Electric LVE 30X

FR 25 D01

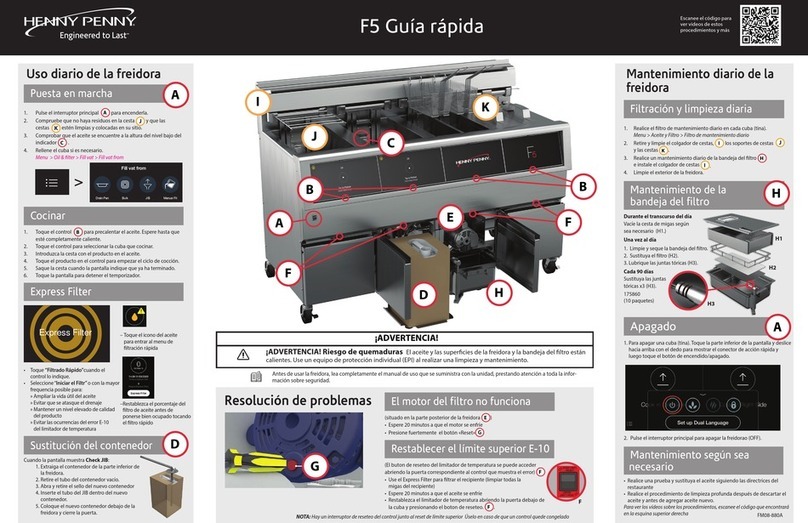

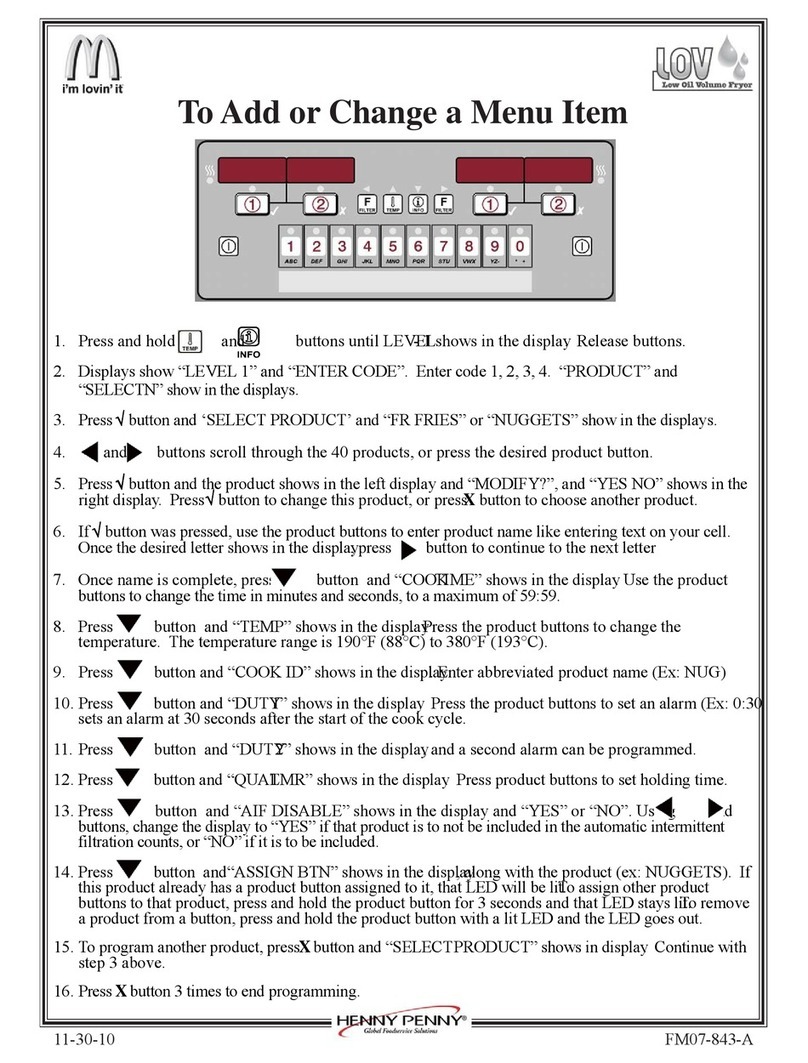

Follow prompts to start the

Daily Filter.

-For split vats, choose left

or right side.

-As prompted skim the vat

to remove floating

crumbs.

- Tap Start Filter to drain

the oil. Draining displays.

-Tap X to exit the Daily

Filter screen and return to

normal operation.

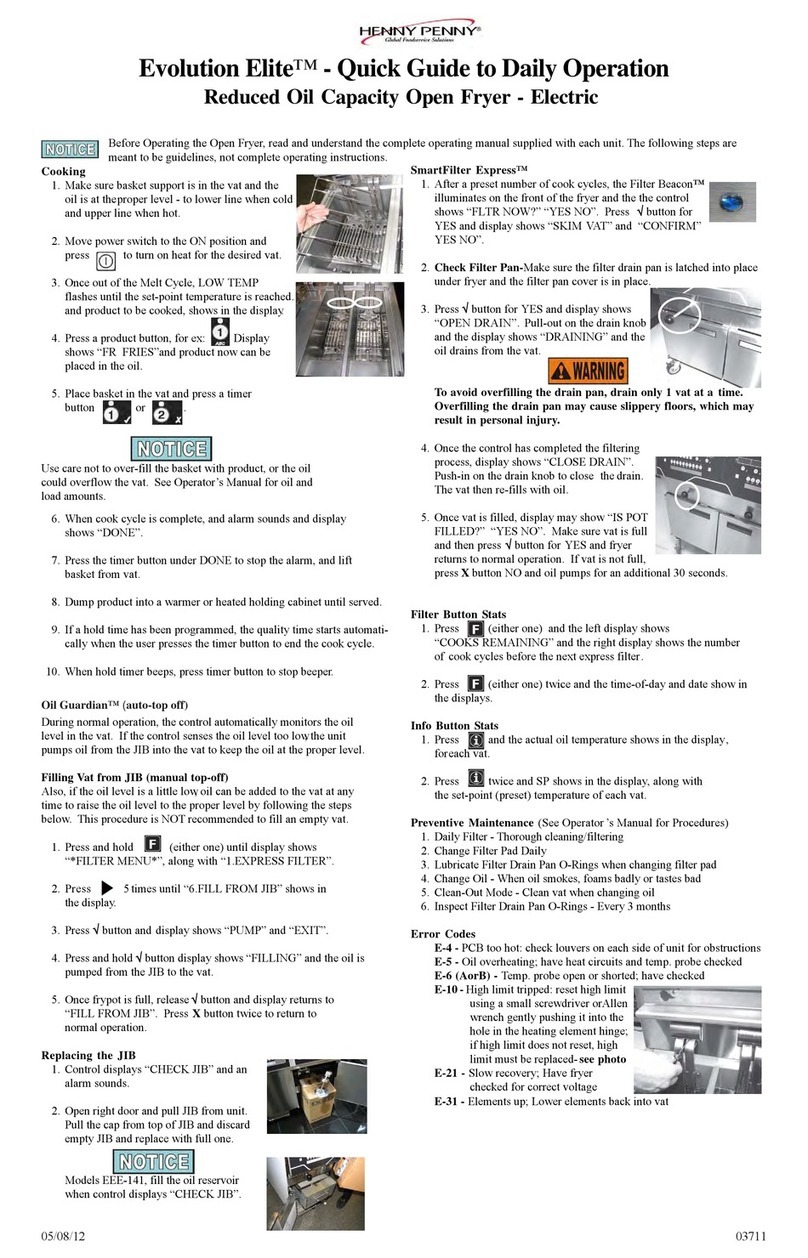

Once oil has drained, remove

basket support, and use lift

tool to raise the hinged

elements from the vat.

Use heat-resistant gloves

when lifting elements or

burns could result.

Be careful not to damage high

limit probe(s) in center of

elements.

Attach thePad to theHi-

Temp Pad Holder and

moisten with shortening.

Sprinkle KAY®QSRFryer

Cleanser on the Pad and scrub

the walls, corners, and bottom

oftheinside of the vat. Use

the Hi-Temp Detail Brush to

remove soil built up and

debris fromheating element

coils, corners and bottom of

vats and other hard-to-reach

areas.

Be careful not to damage the

sensing probes and DO NOT

scrub elements or breading

will stick and burn.

KAY®QSRFryer Cleanser

Once the vat is clean, Drain

Complete displays.

Lower the elements and then

tap the Start Wash, play

button. Washing displays. Oil

is circulated through the vat.

Once wash cycle is complete,

Wash Complete displays.

Buttons for Repeat Wash or

Start Rinse are available. If

vat is not yet clean, tap the

Repeat Wash arrow and step

If vat is clean, tap the Start

Rinse, play button. Rinsing

displays. The oil is pumped

into the vat and rinses it.

Once completed, Rinse

Complete displays with

buttons for Repeat Rinse or

Start Polish. If vat is not yet

clean, tap the Repeat Rinse

arrow and step 11 is repeated.

If vat is clean, tap the Start

Polish, play button and oil is

circulated through the filter

system for 5 minutes.

-A Skip Polish action

button is available to exit

the polish step at any

point in the process.

Once the polish cycle is

complete, Refilling displays

and the vat fills with oil.