Hikari HW762T Owner's manual

ell£m:~

Jt:$~?:

~

w

*1'ffi'tJU1f~Gf-t:vZ:1H~

~

'§1

45

oo

~~,

~~~m~~45~~m~-m*o

~45

oom~~~~~~*~*fi~--~~-•~-

l&

*

~.>fo

~~

l:r££

/_)(./I]J"

..l.6._']1=1.--:J o

·~~m~~45mhl•~~3R~~•~m~~

§

~'

:ff:$ili5rm~~~~~~o

~~~®m~*~'§J~~ff~~ffo

~~'

~~~m~~45~~*1fm~~~~~~hl~,

*~'§J~~~ff~~ff-~*ffiff~m*o

·~

Ll1*1'ffi'tJU1f~Gf4VZ::ff~~~'§J

Si';%'7

IA~7t*~

vz:*,

ll£~~~~~¥~~~tt~-~m~~

~0

~~,

~m*~i±rrm~~~m,

~*~~

~0~~~*45~c~m)-~~hl•m1r~

-'%

R~~-'%~~~1f~~o

*~~45~R.~h*~'

~T~ffl~~~~~~

~~~~*H~fflWi5~~om~m~~3,

r;t;

ill[~

~L±.

+b

~

)IlL;' 'if"

i§

I=! 1

C!

7J\

0

.t!Ui~JJtJL

~

~~1HI~~J;Jili'!~i'1Fi1UD

!±.~!%

~Jli±r,

~11Xim~1)'i'l~~j;Jili'!rm~li*~o

i-!F

m•~~ffl~~m~~45~~,·~~-~~

n:~iA~ffiu5E¥t1tY:nX:.

r~il?JT1f1Jilt!~o¥t1$~&,

~~1tt,

~R.?JT1fllf±i1~t?~J;JillJ1Uo

~i-!Fi'!

-~Jf!ffl~I

fp:~1Jw~U~1~~B:~~5frf!J;Jil1J1U,

~&

~:t-fu~R1f~mn&tJL~ffiu5E~1Jilmu

0

Be

sure

to

study very

carefully

for

safety

Copyright

eThis

instruction

manual

may

not

be reproduced,

trans

-cribed,

transmitted,

distributed

or

translated

into

any language,

in

whole

or

part,

in

any form

or

thro

-ugh a paper

or

electronic

medium,

without

the

prior

written

permission from Hikari

Precise

Machin

-ery

Science & Technology

Co.

Ltd.

eDisclaimer

The

contents

described

in

this

instruction

manual

are

intended

for

giving

information and

subject

to

change without

notice.

We

assume

no

responsibility

for

these

information, and any

errors

and/or

incor

-rect

descriptions

that

may

appear

in

this

instruc

-tion

manual.

eHikari

Precise

Machinery Science & Technology

Co,

Ltd. has a

policy

that

we

always modify

the

performance and/or

specifications

of

this

product

introducing

the

state-of-

the-art

technology.Accor

change

the

specifications

and/or

design without

notice.

eThis

instruction

manual

is

valid

for

all

the

models

and

subclasses

listed

in

the

chapter

"Specfication"

Directives

This machine

is

constructed

in

accordance with

the

European

regulations

contained

in

the

conformity and

manufacturer' s

declarations.

In

addition

to

this

instruction

manual,

strictly

observe

all

the

generally

accepted,

statutory

regulations,

legal

requirements

and

all

the

environmental

protection

regulations.Also

rigidly

adhere

to

the

regionally

valid

regulations

of

the

social

insureance

society

for

occupational accide

-nts

or

other

supervisory

organizations.

ft~~~~~~&~~~,

~T~~~ffl;~,

@~~~~~~-~*~*~~fflo~~*~

mJtr*J~,

:%-&':il~~~~tlt~o

-~~~@Mft~~m~~~B~~ili*~~

tfo

~~®~~~~~~~~,

@&~~~,

M~

¥JT~tlF~o

~~~~ffl~~~~'

~~~~~~~~~~

f'iD]j:**"

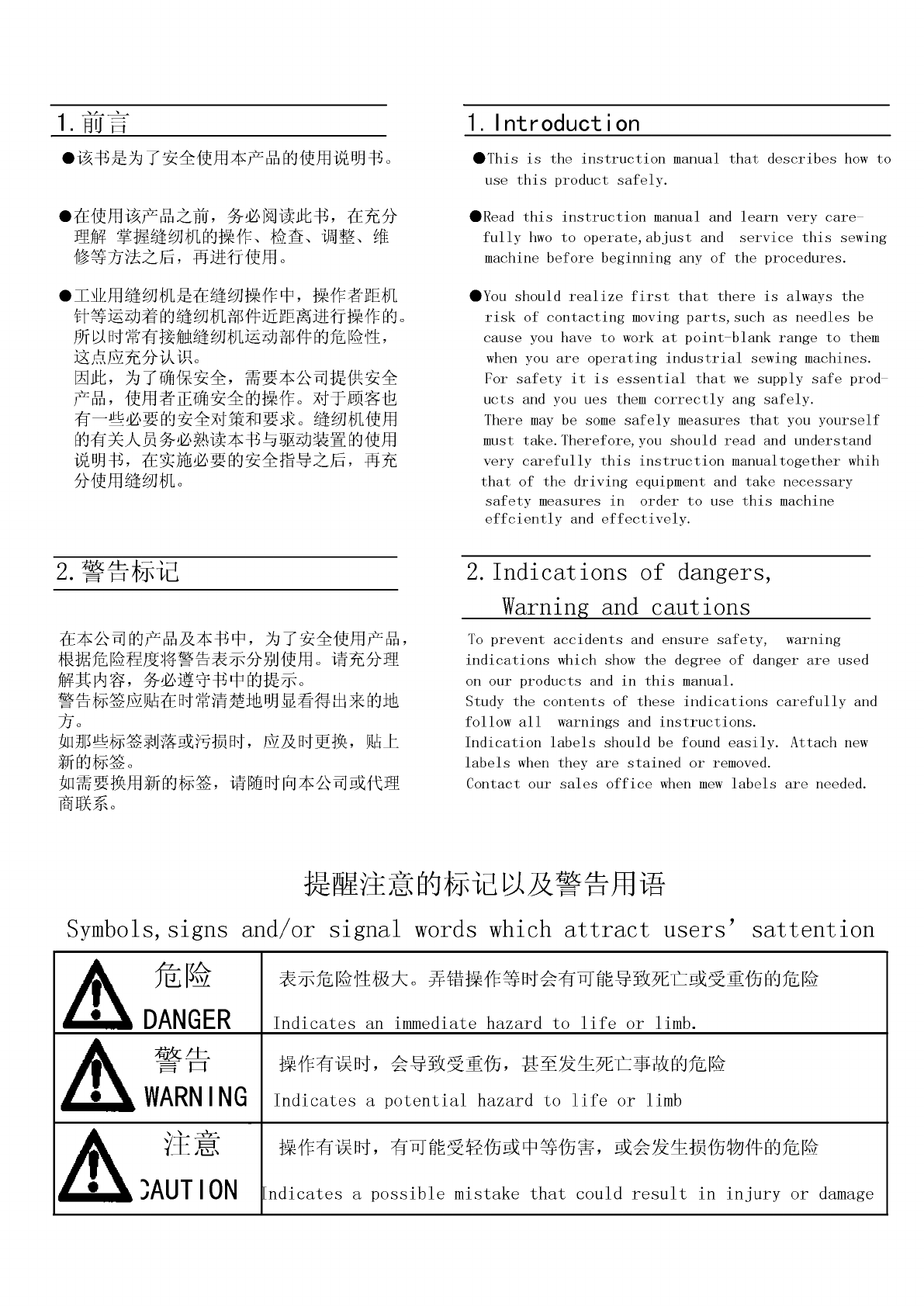

1.

Introduction

4tThis

is

the

instruction

manual

that

describes

how

to

use

this

product

safely.

4tRead

this

instruction

manual and

learn

very

care-

fully

hwo

to

operate,abjust

and

service

this

sewing

machine

before

beginning

any

of

the

procedures.

4tYou

should

realize

first

that

there

is

always

the

risk

of

contacting

moving

parts,

such as

needles

be

cause

you have

to

work

at

point-blank

range

to

them

when

you

are

operating

industrial

sewing machines.

For

safety

it

is

essential

that

we

supply

safe

prod-

ucts

and you ues them

correctly

ang

safely.

There

may

be

some

safely

measures

that

you

yourself

must

take.

Therefore,

you

should

read

and

understand

very

carefully

this

instruction

manualtogether

whih

that

of

the

driving

equipment and

take

necessary

safety

measures

in

order

to

use

this

machine

effciently

and

effectively.

2.

Indications

of

dangers,

Warning and

cautions

To

prevent

accidents

and

ensure

safety,

warning

indications

which

show

the

degree

of

danger

are

used

on

our

products

and

in

this

manual.

Study

the

contents

of

these

indications

carefully

and

follow

all

warnings and

instructions.

Indication

labels

should

be found

easily.

Attach

new

labels

when

they

are

stained

or

removed.

Contact

our

sales

office

when

mew

labels

are

needed.

Symbols,

signs

and/or

signal

words which

attract

users'

sattention

~

frt~ft

*~~~ttm*"*m~~~~~~m~~~~~~~mm~~~

DANGER

Indicates

an immediate

hazard

to

life

or

limb.

~

~LL

~~~w~,

~~~~mm,

~~~~~~-$~~~

WAR~I

NG

Indicates

a

potential

hazard

to

life

or

limb

~

"·~·

1r}fi1,

~~~w~,

~m~~~m~~~m~,

~~~~~m~#~~~

~AUT

I

ON

ndicates

a

possible

mistake

that

could

result

in

injury

or

damage

~~~

~n

iw7t1f~

1J?J

ig;

in

S)j

[!!*i2%

Be

sure

to

study

very

carefully

for

safety

Symbols

and

messages

~

&/m:il~1b~

'/1), 'if"

C!

7J\'

}_Ill

Be

;It

pg

~~it

Wll

1*

fp:

)';]

~

0

Be

sure

to

follow

the

instructions

when you

operate

the

machine

and/or

labor

saving

device.

&

Jj

-f*fP:~i!R,

~

1U!l!

~

Efl

frt

~B:

o

If

you

use

the

machine

and/or

labor

saving

device

incorrectly,

you

may

get

an

electrical

shock

&

f*fP:~-i!R,

~~~Y:'¥1~'3t1%

0

If

you

use

the

machine

and/or

labor

saving

device

incorrectly,

you

hands

and/or

fingers

may

be

injured.

1f

11(

~!!!

~

~_ffi\3~

'¥

'3t

1%

Etj

frt

~B:

0

&

Indicates

a

danger

of

bum

injury

due

to

hightemperature.

(9

~TI

xt

::f

PJ

1tY:

Never

do

this

'*<!It

itt"

-1~

:@_

-rm~

1T

~;;,.

,

im]~~~i1~I

fP:Si,

g!G:ffPJ~~jij

~Si,

@~7tre~~M~~~~EflM~~~,

~JG~3J~o

~

Unplug

the

machine

or

shut

off

the

power when

checking,

adjusting

and/or

repairing

the

machine

and/or

labor

saving

device,or

when

lightning

may

strike.

&,~NJi11(:1:-fui~,

~

1~1?

)';]

~

0

e

Be

sure

to

ground

the

machine

and

labor

saving

device

securely.

*

7J\

~ii

~JJ

tJL

1t

i)J

~

JJJE

~

:1f

rl:iJ

0

-+

Denotes

the

normal

rotating

direction

of

the

machine

pully.

ICDffl~,

§

B"J

I

**~Efli~m~wm,

~~•~m~~Eflm

;~~~$7'1§Efl®M~H~Eflm~,

~~~

~_tmJi~3J~,

ifi~Tixt::f~1~m

0

l®1~ffl£fit

I

**~Efli~m~wm,

~r~mEfl~~,

:ffPJ

~~~WmEfl%~,tt~&~~ttm*::f~~~o

2.

r"'~~~~fCE!j:l:-fu:1f,

&'3t~~

lS'!~:I:-fu:1f

1~fflM1~1ro

3.

ffij~,

~~_fiji_~~~'

]~j1(Sj:SjlljE!j:l:-fu:1f

o

4.

)jlfj!JE!j~_g,~t,

~~lt1tt:7c,

~~~ii~JJtJLm*w

~

QrPJ

Etj

:1:-fu

:1f

0

5.

~9!5E

~ff';%~)1±

10%~_tE!j

~ff1E~)J~JJJ'@:

Etj

:1:-fu

:1f

0

6.

~~~

;x~tW!l1~~ffiu

~itsJJilt!

_tpfiffi~

Efl

3.Safety

precautions

ICDApplication.purpose

I

Our

industrial

sewing machines have been developed

in

order

to

increase

quality

and/or

produ

ction

in

the

sewing

industry.Accordingly

never use our prod

-ucts

for

other

than

intened

use

described

above.

!®Circumstances

I

The

environment

in

which our

industrial

sewing

mach

-ines

are

used

may

seriously

affect

their

lives,

functions,performance

and/or

safety.

(S;)

For

safety,

to

not

use

the

machine under

the

circumstances

below.

l.Do

not

use

the

machine

near

objects

which

make

noise

such as a

high-frequency

welder,

etc.

2.Do

not

use

or

store

the

machine

in

the

air

which

has vapor from chemicals,

or

do

not

expose

the

device

to

chemicals.

3.Do

not

leave

the

machine

outside,

in

high

tempera

-tures

or

the

dirct

sun.

4.Do

not

use

the

machine

in

the

places

of

high

ambient

temperature

and humidity

that

seriously

affects

sewing machines.

5.Do

not

use

the

machine

on

the

condition

that

the

voltage

fluctuation

range

is

more

than±

10%

of

the

rated

voltage.

®1Z~m~

~

(1)

Jt!:1-JM!d~1~*'

,fft~S1Eflidt1~1?

·~~~wmJtJ:fifft~-~~-m~~~~~~

~,

~~~~~H~,

~~~M~MM~~~

T,

*~~R~wm•~~~~~~~€,~

Jt!:1-Jf*fp:

0

@~,

~~~~~~~Jt!:fif*~~'

~~~~

~~wm•*~~~f*~~m~oo~~~~Efl

idtf*fP:i1tlJ1U,

#:iJ!~-tJJidt~1?1J\llJ1U

o

0

)Jp~ffi

0

~i~

.

1H3

~iiiJJ

tJL

0

:jj(

tJL

'tf

.

Jt!:1-J1it~ffi5G1£t1~13~PJ!:jj(Si

o

.

J!

:jj(

tJL

~rn

e~Jt!:fi~Tf*~~,

~*~~~~~H~~

€Jtl:1fo

.

iml

11

'tf

H!il

Si

.

im]

11

&

Z:)J

tt

Si

-~~~Mfft~-~*~'

@~~~*~~~

j]

%t'i:

~

RJiiiJJ

tJL

Efl

Mid~

I

fp:

Efl

~

1'1

VZ::;f

~

*Jtl:if0

-~~~~~Etjff·~~®~~~~~J!~,

~

~

~)C$i&

EfJ@:

l!L

t<:\

*izP~e~~~J!e~Eflffi~,

@~J1:**?&'ff'g

\:::1

m~~~'§']'§f~?JTimi'PJ

0

~

(2)

tJL~H~i1~~1WEflfft~1JrN

·~*~f*~~~~wm~,

m~fft~~wm

~~~~~~~,

~~~~~m-~~~~

l:r££

':;1

"'"'

>:t

I

Pj

!Eli

0

•*~ffl~~-*~~'tf~~~~~~o

(Fig. 1)

(~1)

6.Do

not

use

the

machine

in

the

place

where

the

supply

voltage

specified

for

the

control

motor

cannot

be

properly

obtained.

@Safety

measures

~

(1)

Safety

precautions

when

you perform

~

maintenance

on

the

machine.

eAlways

turn

off

the

power,unplug

the

machine

and

then

make

sure

that

the

machine does

not

run

by

pressing

the

treadle

before

performing

any maintenance, such

as

checking,repairing,

cleaning,

etc.

However,

if

you need

to

perform

these

procedures

with

the

power

on,

to

prevent

accidents

due

to

the

unexpected

start

of

the

machine and

users'

misoperation,

estabish

your

oun

procedures

for

safety

and

follow

them.

~

4tAlways

turn

off

the

power and unplug

the

~

machine

before

performing

the

procedures

shown

below.

.Lubrication

. Treading

. Cleaning

.Replacing

the

needle

.Checking/replacing

the

oil

element

.Replacing

the

oil

4tAlways

turn

off

the

power

before

performing

the

procedures

shown

below.

.Adjusting

the

stitch

length

.Adjusting

the

differential

feed

ratio

4tOnly

well-trained

people should perform

routine

daily

maintenance

and/or

repair

the

machine.

4tDo

not

modify

the

machine

yourself

t<:-\~Consult

your

local

Pegasus'

sales

office

\:::1

or

representative

for

modification.

~

(2)

Before

operating

the

machine

4tCheck

the

machine head and

unit

for

any

damage

and/or

faulty

function

at

the

start

of

each day.

If

there

should be something wrong

with

the

machine, immediately perform

repairs

and/or

other

necessary

procedures.

4tCheck

by

hand

to

see

if

the

needle

holderis

secured.

~Be

careful

of

the

needle

point.

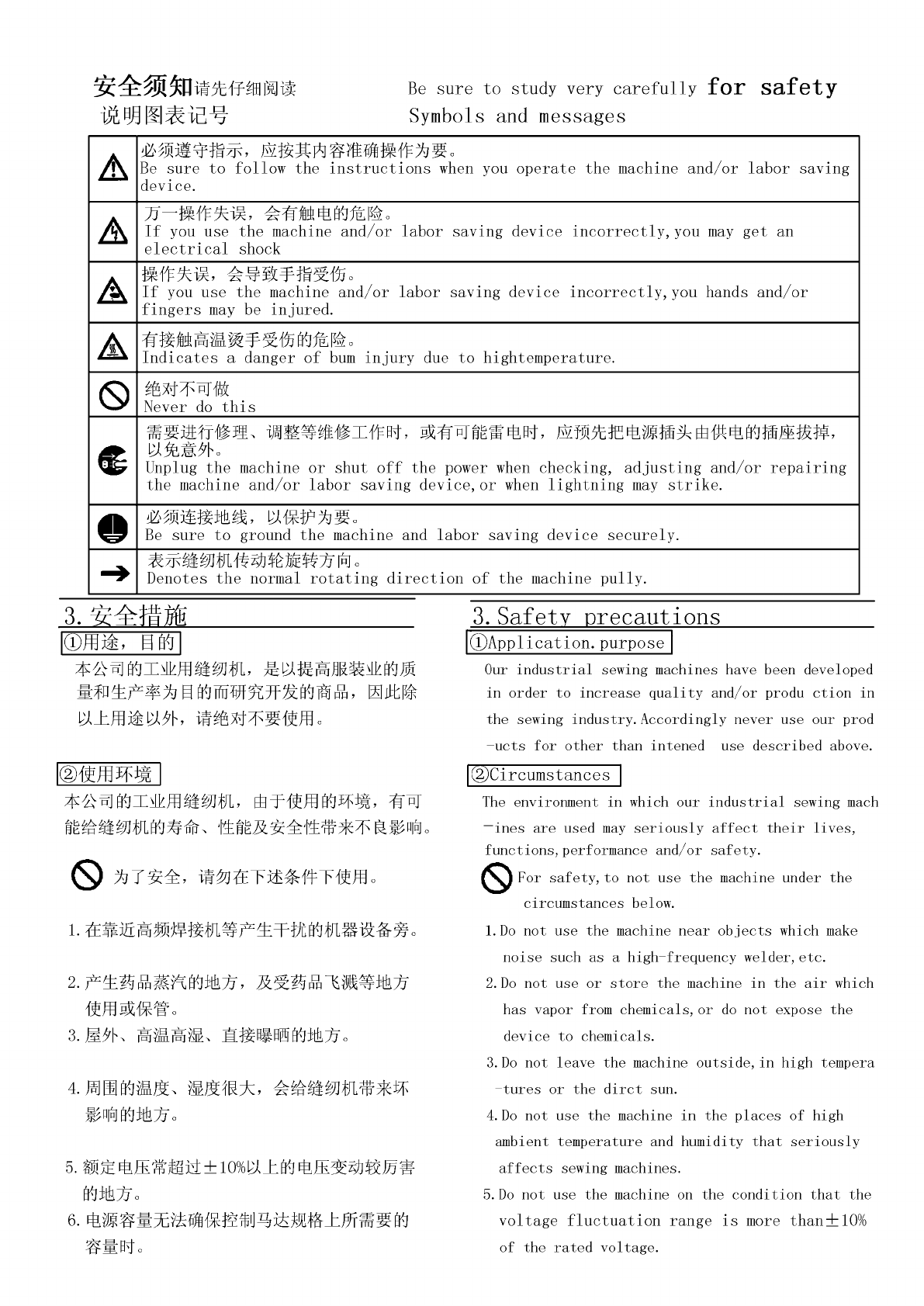

4tBefore

starting

the

machine,

make

sure

that

the

presser

foot

is

positioned

correctly

(turn

the

machine

pulley

slowly

by

hand

to

see

if

the

needle

point

is

centered

in

the

needle

dorp

hole

on

the

presser

foot).

(Fig.

1)

~

~

~jl

m

iff7t1f~

,'#,]

ig;

e

*&,1ft

1"f

£EJ!p

~

~

4-

[!I!]

Efl

[!I!]

5E~f

o c

1~JiHil'

ff~m~~~ff~,

m~~€~~~M,

1ft

1"f:WffH!p~~tt~JJ)

(~2)

_&

(3)

±~iJII.

n!:1~

(~2)

(Fig

2)

e~T~K$~,

~wmm~M~W*~Efl~

~A~&~~~~~~,

m7t~~m~~~

m~~~~~'

*~~I~Efl~~o

~~'

iff

E8~

P

Efl1fJJ.l'J!1lz:~~tR11'J~flF:hffiJ!I

it:JGU,

rm

*J1fu

JE

7J\.

Efl

v

!I

t~

0

A\

,;±

:Ir.

~

i-=c}~,

I

CD3Tt§

l

1.

~ii~JJ

tJLtJL~:fr

t±:l}

Si

~*~f

€

%tAt~;f§

~

t±:l

Efl,

JJ-f=~!rjliJ:frt~;f§_tt1Ficr¥fcfWiliA_t

T

€,

iff

}J__t~iJTEcJI[fJV~lf;f§

o

2.

1E~ii~JJtJLtJL~£iirr~*M*-lEI!.*t±:l

Si,

~'@xt

~~m*~mn~~Mrl~~~~~Efl~~o

~

1J1U~bt!±.frt~B:M1fl11%t!L~o

3.

:frltZt±:l~Ji~JJtJLtJL~Si,

iff~i~]~>l,'Efl1lz::'i:,

!J\Jl,\ilt~EflllZt±l

0

4.

3f;f§fflrlE!jt~;f§izp*~€~fflE!ji!,

iff*~

1~f¥J])(:~f

0

~**H4Efl~~

·~*M*-4~115*~'

t~5-!C

t~;f§,

VCE

HML

~~~~~~~ffEfl~~*M~~~~~Efl

JttiT~~o

;jig!JJ

~Jl~

1m

a~

~J~

1.

~ii~JJtJLEfl~~,

iff~l'iD~~Jt!:1-J~~o

2.

ffiiJmjJi~JJtJL?JT1~ffl

Efl:f~H-4~~,

'f§L

ff&~

*rf1~*4o

3.

~ii~JJ

tJL

Etj

~~@if~~

:1:-fulf

~

1~1?

Etj

~

~j;Jil

5EJt!:1-J~~o

&,~Si~f£;~1'1

Efli%Jt1:1-J~

~0

*~~~Etj~#*~:il~~~lf~~~Etj~~

j;Jil)E,

JJ\.:'fJijJt!:iT~~o

•

:tt~~~~~3M~wm~~~Efl~~**

~&~~ffo3M~~7~~~wm~~~

w,

iff~i~~~{~~4~Ji~J}fJLo

Be

sure

to

study

very

carefully

for

safety

4tCheck

to

see

if

the

presser

foot

is

secured

(raise

the

presser

foot

by

the

foot

lifter

and

press

it

by

hand

front

to

back and

left

to

right.

)

(Fig

2)

,&(

3)

Tr a in i

ng

4tTo

prevent

accidents,

operators

and

service/mainte

-nance

personnel

should

have

proper

knowledge and

skills

for

safe

operation.

To

ensure

so, managers

must

design

and conduct

training

for

these

people.

4.Notes

for

each

procedure

_&

CAUTION

l

CD

Unpacking

I

1.

The

machine

is

packaged

in

a

cardboard

box

before

shipping.

Unpack your machine

in

orderly

sequence

while

checking

them

right-side

up

by

referring

to

the

indications,

such

as

logo,

etc.

printed

on

the

boxes.

2.Never

hold

the

area

near

the

needle

and/or

thread

guide

related

parts

when

taking

out

the

machine

from

the

cushion.Otherwise

it

may

cause

injury

and/or

damage

to

the

machine .

3.

Take

out

the

machine

very

carefully

while

checking

the

position

of

the

center

of

the

gravity.

4.Keep

the

cardboard

box and

packing

carefully

in

case

secondary

transport

is

needed

in

the

future.

Disposal

of

the

packaging

4tThe packaging

material

of

the

machine

consists

of

wood

,paper,

cardboard

and

VCE

fiber.

The

proper

disposal

of

the

packaging

is

the

responsibility

of

the

customer.

Disposal

of

machine

waste

1.

The

proper

disposal

of

machine

waste

is

the

respon

-sibility

of

the

customer.

2.

The

materials

used

on

the

machine

are

steel,

aluminum,

brass

and

various

plastics.

3.

The

machine waste

is

to

be

disposed

of

in

accordan

-ce

with

the

locally

valid

environmental.

protection

regulations.

A

specialist

should

be

commissioned

if

necessary.

~The

parts

contaminated

with

lubricants

should

be

disposed

off

separately

according

to

the

locally

valid

environmental

protection

regulations.

Transport

within

the

customer'

s

premiss

eThe

manufacturer

assumes

no

liability

for

transport

within

the

customer'

s

premises.Careshould

be

taken

to

transport

the

machine

in

an

upright

position

avoiding

it

from dropping

or

falling

down

to

the

ground

when

it

is

moved.

~

¥15

I®DiE I

1.

~ii~JJtJLtJL~Efl1M~-5E~VJJ1'

A~_LJt!:if

o

:13

*'

mA~~•~mR~~-tt~wm~~~

~~$o~M-~*~~ffl~~$Jtl:fio

2. ;j$

~;Mii~JJ

tJLtJL~

si, m

k1

:f-tJJH±

1t~JJ

~,

1e

'¥

~~m~~,

~~*~Efl-~o~wm_t~~

~~~-~~3~m~~$,

-~~~~~•

i¥tJL~LEfJ~ffJ~o

(~3)

(~3)

(Fig

3)

3.

~11~ii~JJtJL

~t)Z_t~,J\~$_L1M~Si,

ilf~1~

~~M*~*~RM,

~~~Wm~~~~~

4.

izP*~~=ij(~*~ii~JJtJL:3f~~*Si,

iJ-)E

•

T-i¥tJL~_tE!j~ffi~

o

~lJlU,

1M~s1~11U£~

$tJL~~~ffi~{t~~**H41EJ9i~

Jf£

o

' '

.:Ir.

~

1£}~~

I®

1Z*·

it~

I

gitJHJl

E'

tP.

1.

iw1~ffl

~~JE)J\.7f~'3t~ii~JJtJLtJL~!ItS.R.1M~Si?"'

~Efl&~fflnEfl~Wm~~c~~,~~)o

2.

mJE

7J\.~

m~ii~JJ

tiL*

we

'lr!Wt

~o

1*

fp:

:lt~~

Efl

a)j

~

~'

~~~3~:f*~Etj~m~o~*:lt~~~

+*ajj~~'

@@~~~~*~a)j~no

3. ~

~ ~

~ii

~JJ

tJL

Si

,

7'11))]

lt:f*

11:

1'r

~*lfMJZ

Si

H!il

1l'f

~~~-~,

-5E~~~wm•~_t~*I))]Jt

11'r

n£

Efl

m

~

0

4.

~~m1*1t:i'r~~Etj~:JttT,

~5E~t1ZTIITEfli'1'11

~

CI

11:SiE!ji'1'1J~)

o

A\

~&.

.l.!.}.

i="'i

l=t

~~

1.

iii$~

Efl1m~Hii~JJtJLtJL~~

~tJLJit1(~~Efl1m~o

~wmm~~~mmJt~~JtJ:fiii~~,

*~

~~~*~~~~EfJ~~TJt!:fi:f*~o

2.

~1~ffl

~ilf~~~Jit1(~~M$Eflh

o

3

<S)

iw~~tt~~a±JJtt1(~~

4.11(Jli~~JJ'Iffl1tt

cizo1t~JJ~,

v~lt'fff~)

Eflii

11(~~,

JffuHr2/l16@~25mm~Jtl:1f~*o

~

WARNING

I®

Transportation

!

1.

The

machine

should

be

carried

by

at

least

more

than

two

people

when

it

is

mounted

on

the

table

and/or

a hand

truck.Be

sure

to

use hand

truck

for

other

transportation.

2.

To

carry

the

machine

,hold

the

machine

pulley

tightly

with

your

right

hand and

the

machine

arm

with

your

left

upper

arm.

If

the

machine

and/or

your hands

are

stained

with

oil,

the

machine

may

be

easy

to

slip

out

of

your hands and

fall

to

the

floor.Therefore,

wipe

off

the

oil

carefully.

(Fig

3)

3.Care

should

be

taken

to

avoid

excessive

shock and

shake

when

the

machine

is

mounted

on

the

table

and/or

transferred

using

a hand

truck.Otherwise

the

machine

may

fall

down.

4.

Wipe

off

the

oil

from

the

machine

before

packaging

it

again

for

secondary

transport.

Otherwise

the

machine

may

easily

slip

out

ofyour

hands

or

the

bottom

of

the

box

may

come

off

while

in

transit.

~

CAUTION

I®

installation,

preparation

I

Machine

table

1.

Use

the

machine

table

(table

board. metal

legs)

that

completely

carries

the

machine and

is

fully

resistant

to

warping

while

the

machine

is

running

.

2.Arrange

the

working environment

for

easy

operation

by

considering

where

to

place

the

machine and

the

brightness

around working

area

if

the

illumination

is

insufficient,control

or

change

lighting

as

requ

-ired.

3.Attach

a

non-slip

pad

to

the

treadle

(foot

switch).

Otherwise

the

operator

may

slip

off

the

treadle

while

running

the

machine,causing

trouble.

4.Adjust

the

height

of

the

table

according

to

a

working

posture

of

the

operator.

~

WARNING

Cables

1.

When

connecting

the

cables

between

the

machine and

the

motor, be

sure

to

turn

off

the

power and

connect

each

cable

connectors

securely

.

2.Do

not

strain

the

cables

in

use.

~-

{S)

Do

not

bend

the

cables

escessively

4.

When

connecting

the

cables

that

are

close

to

the

moving

parts.

such

as

pully

or

V

belt,

keep a

distance

of

25mm

at

least

between them.

5.Protect

each

cable

using

a

cover

or

adjusting

its

position

if

necessary.

~~~

~n

iff7t1f~

1J?J

ig;

5.

&,

~

s1

~

mJtt1(£~

11r::'i:WG1JP

iJtt?

mHI~1~t?

Jt

:J'~£~o

6.

{S)

[!ll]5EJit1(i~Si~Tixt::f~1~JiHJi=HL

~Jr.

btl±.

1,m

~MJ<.xo

A\

,;±

:Ir.

~

ii}ff.J,

~±-fu

1.

:J'1(:1:-fui~~~4lt-El~iiiJJ]UJE7J\.:'fJ'J*i3t~

JtJ

Ef1t1(

:1:-fui~

,

::f@

~

Jt1tMJl

~~

JtJ

o

2.

e

:fr~iiiJJ

tfltfl~

Etj

j;Jil)E:I:-fu

,8

i'i

Wll

:1:-fu*

i)t

11(

:1:-fui~

7'1

~

0

~

~15

I@

1~m

g)i~J],ffl11B

I

1.

:tt~rn:m:

r*J

;~Jt:ff1iA~rn

~IW~Tixt::f~JtJ:1-r~~

0

m~~~mm5EEf1~mm~m~m~cffi~

~IS0f~nt~~VG22)o

2.

tfl~ffiJti:A§~~~1~§~~/5t:ik_,

?JT

~:fr1~ffl

Si

iffmi))Jt?§~lt

~Jc.tfl~rnJtJ:A§~~

0

*-li

-Jti:A§~~,

iff

JtJ

T-i¥7kirF~15)J\.~rfl~

iff

~!±.Jtl:if~r'lfi

0

3.

f}1}ffj:j:1(~!l!Bl~Jcf§'

iff

~_t}tJJ](~p~~!g~Tf¥o

4.

(S)

~Tixt::f~1~tfl~ffiJt!:A

Q

~~0

5.

tfl~rniff1~1f:tt~.:=t-m::f~u

Ef1:t-fu:1f

0

*-li-Jti:AQ~,

::f~~tt~~,

~_t~~!±.

JtJ:1-r

~a

rr

0

6.

~~rn,

~~~Ef1~Jm:1f~t:ff

&,~N:il~~t~Ef1

2*'~@~~~~Wil~Jmo~::f~m~~

~1Jll;j~tfj)i'1J1:**J§'

~WIJJttiT~:@.o

7.

l'JTI))]Jttk~,

7](7J\.Ef11rtA,

1~ffl5GJ§1~1f

m~~~m~~~m,

~:fr;~Jt:ff~~~MEf1

IW&:~1~1f

o

A\

~&..

~

i="'i

l=t

I®

)E~g)i~J],ffl!WB"Jli~$JUf

I

gji

t)]

~Jl

E'

tP.

1.

1J7f~iJj!W'

iffW!liAt1(£~gl(;:j:1(~~~:fftfl11%,

~£~,

tt~JJ~j~,XJrl_LE!j:ff';%

0

2.

:tEH

7f

~iJj

Siiff::f~~:it:f-

J])(:frtfl'ff

JYftJliWG1t

~)J~JYffJlio

3.

~f}]lf~il~~~JiiJJtJlSi,

1J7f~iJjW!JiA

1t~)J

~Ef1~~:1frJ:iJ

o

~iiiJJtflEf1~~~JA1t~JJ~11JlU

*:W~[Q]k]JJJE~

0 (

~4)

(~4)

(Fig

4)

Be

sure

to

study

very

carefully

for

safety

5.Protect

cable

using

a cover

of

adjuting

its

position

if

necessary.

6.

{S)

Never

use

staples

to

fasten

the

cables.Othe

-rwise

it

causes

a

short

circuit

and/or

a

fire.

~

CAUTION

Ground

l.Connent

each

of

the

ground

wires

in

the

sewing

machine system

to

the

ground

terminal.Do

not

connect

to

another

devices'

.

2.

~

Connect

the

ground

wires

securely

to

the

indicated

ground

points

on

the

machine head.

~

WARNING

I®Handing machine

oil

l.Never

start

the

machine

with

no

oil

the

reservoir.

Use

HIGH

SPEED

SEWING

MACHINE

OIL

(Equivatent

of

ISO

requirements:

Viscosity

index

of

Vg22).

2.

If

machine

oil

gets

in

your eyes,

it

may

cause

eye

irritation.

To

prevent

the

machine

oil

from

getting

in

your eyes, wear a

pair

of

protective

glasses.

~

Shonld machine

oil

gets

in

your eyes,wash them

with

fresh

water

for

15

minutes and

then

go

to

see

a

doctor.

3.Avold

skin

contact.

Immendatelywash

contacted

areas

completely

with

water

and soap

4.

~

Never

swallow machine

oil.

5.Keep machine

oil

out

of

the

reach

of

children.

~If

swallowed,

do

not

induce vomiting.

Immediately

go

to

see

a

doctor.

6.Dispose

of

the

waste

oil

and/or

containers

properly

as demanded

by

law.

If

you have

further

questions

on

its

dispasal,

consult

the

store

or

shop

at

which you

purchased

it.

7.After

opening

the

oil

container,

be

sure

to

seal

it

to

prevent

dust

and

water

from

getting

into

the

oil

and keep

it

in

the

dark

to

avoid

direct

unlight.

~

WARNING

I®

Before

starting

the

machine I

Machine

table

l.Before

turning

the

power

on,visually

check

the

cables

and

connctors

for

defective

conditions

,

such as

damage

,

disconnection

and/

or

loosening.

2.Never

bring

your hands

close

to

the

needle.

and/or

pulley

when

turning

on

the

power.

3.When

the

machine

is

used

for

the

first

time,

turn

on

the

power and

then

check

the

rotaing

direction

of

the

machine

pulley.

The

machine

pulley

should

turn

clockwise

as

seen from

the

machine

pulley.

(Fig

4)

4.

1*

11:

~ii

~JJ

tJL

1't

mz

J';J

'3t

u:lf!

'3v

11

t~,

JE

7J\.

;@_m

*~ffl~~~~~3~€,

~*fif*~~m"

5.

~r~ii~JJtJLtJL~_t~frt~:~L

Wi5t1FitillZ~Mg;

:3f:@.m

c

"2"

Wi5*~'

&,.~simzxt1~m

1'r*1fiz:~~F'f

0

6.

~fJJ1~ffl

~-1'

}j

JIIZ~11£J!lto

iff1~fflft~

n'lJ~J!~3/4~

T~~J!o

!@:

ili~~~iif9HJl$

s~5i~~r.w

I

1.

(.S}

:tE1~1EPT[))J1?tJZ,

1?1~~,

1tiJJ~1?'!'J

~iz:~~~~~~T,

~~~~~~Wm"

2.

(9

~ii~JJtJL:tt~~9="

~1~trt~B:~,

?;Tixt~~

~~

'¥

nJ<:AtJL

'ITT"

3.

1~ffl

ll16il~J'\

~tJLSi~1ljl:~iJj~€

~tJL1JJ~

~~~U~JJJE

~-~

J

L"

J25:

Si

~JiHii~JJ

tJLlftUJZ€

~ii

~JJtJL~~z:JJ~i~trt~B:~,

iff*f:'IJ'J'J\.c,,"

4.

<9

~ii~JJtJL:tt~~9="

~1~trt~B:~,

?JT

~?;Tixt

~~~~'¥1~,

~'JY:.,

:;&~JH1(Jli:f-~,

V~it

m,

~m~M~,m~~,'tf$"

~~"~

~~~~n,m~,IA~~:fr~_tm~"

5.

&

1~mm1rtJJn~~~~ii~JJtJLsi,

iff~~

~'¥-m~aJlimnm~,!Mf~:tt~mm9="~

3~'JY:.!±.$i0/:,

~1~m~B:~"

6.

iff~

1~ffl

~ii~JJ

tJL

Si

giG

:i'rf*11:

1'r

r'l16

3Hii~JJ

tJL

Si,

-}E~~~~iJjJf~~1lj[o

7.1~~Si*IJZ\~~~iJj~1ljl:o

8.

:frf*11:~ii~JJtJLSi,

iff~~~~*ffi:tJL~~A~

~J....~o

9.

c:Y

~ii~JJtJL:fr~~9="'

iff~~:tE~ii~JJtJL

-EltJZ

_t~~IA&~m~~Wx~~~~"

I

C7)

~1H?'

~~'

fi~!l

I

1.

Mid~,

fft1"f,

1~:@.~11:~JIIZE8'3trl~~iJllt~

~A:3f:tE1E*:@.m*~m~~~~~3~€

'

~*1J11:~o

2.

~

J';JTMH?,

fft1"f,

1~:@.~~~~ii~JJtJLtJL~

~~~,*~~~iJjlf~~~,

re~iJjM~

MM~_t~r,

:3f~~~~R~mm•~~

:{'Jlifl~~~~Z:)J~€~*1Tf*1"Fo

3.

C

:ttiz:~M1~1EPV~ltmsi,

*&'~~~iJj

lf~~~,

re~iJjM~MM~_t~r,

:3f~

~~~R~mm•~,

~wm~~~~M~

€

~

*11'1*11:

0

4 .

xtr~ii~JJtJLtJL~

~

B

';%{ft1"t~D

)E;ItJ]{ft1"t,

mz~~*~&~m~~~~m~,

m~~~

~*iTo

4.

Well

trained

operators

should

use

the

machine

after

studying

these

precautions

and

the

instruction

manual

carefully.

5.Regarding

symbols

that

indicate

a danger

or

a warn-

ing

,read

and

study"

2.

Waning

indications"

carefully

and

give

training

on

safety

to

the

operators

as

required.

6.Run

the

machine

at

the

speed

less

than

3/4

of

its

maximum

for

the

first

one month.

_&

WARN

lNG

~

Precautions

while

you

are runn1ng

the

machine

1.

(S;)

Do

not

run

the

machine

with

the

safety

devices

removed, such

as

eye guard

,finger

guard,

pulley,

cover

etc.

2.

{S)

Never

bring

your hands under

the

needle

while

running

the

machine.

3.A

cluth

motor keeps

on

running

for

a

while

after

the

power

is

turned

off.

Therefore,

be

careful

even

after

the

power

is

turned

off

as

the

machine

could

start

running

by

pressing

the

machine

treadle.

4.

(S;)

To

prevent

accidents.

never

bring

any

part

of

your

fingers.

hair

and

clothes

near

the

machine

pulley

,

thread

take-up

and

needle

bar. Also

never

leave

sclssors,

tweezers,

tools,etc.

around

these

areas.

5.

~

If

you

use

the

machine

with

knife

device

,

do

not

bring

any

part

of

your hands and

fingers

too

close

to

the

knife

during

sewing. Otherwise

it

may

cause

accidents

and

physical

in

jury.

6.Always

turn

off

the

power

while

the

machine

is

not

used

or

before

leaving

the

machine

table.

7.

In

the

event

of

a power

failure,

be

sure

to

turn

off

the

power.

8.

While

operating

the

machine,wera

clothes

that

cannot

be

caught

in

the

machine.

9.

~

Do

not

put

any

tools

or

other

unnecessary

obj-

ects

on

the

machine

table

while

running

the

machine.

_&

CAUTION

I

CO

Maintenance,

check,

repa1r

1.

Well

trained

people

should

perform maintenance,

check and

repiar

of

the

machine

after

studying

these

~

autions

and

the

instruction

manual

carefully.

2.

:

If

it

is

necessary

to

lay

the

machine backward

for

maintenance, check and

repair,

always

turn

off

the

power,unplug

the

machine and

press

the

treadle

to

make

sure

that

the

machine does

not

operate

before

hP~inning

any

of

the

procedures.

3.

~

Before

installing/removing

the

V

belt

,always

turn

off

the

power,unplug

the

machine and

press

the

teradle

to

the

make

sure

the

machine does

not

operate.

4

..

Carry

out

daily

maintenance work and

periodical

inspections

propperly

by

folloeing

these

precautions

and

the

instruction

manual.

~~~§~~7~**m~m~~~~~~~

:'§':,

:3fic~7

~tm7J\.Er-J~i~1Jr1JL

A\

,j±:TL.

~

ii}ff.J,

1Z~15!HP

*][

r

1)

1?§1H1Z

{9

::f~Hlf

~rmdEr-J~~,

~~::f~~Hlf~m~Er-J~

~T-~~wmo~m~~~7~~W~~~

Si,

1~~~/F~lSA§~drm~~

EfJ1J'1§~'§Jo

(2)

1?1~~

0

::f~1E:f-1~1$A

~7~~~T~MEr-Jm~~A~~rm~~~~,

~m~ffl~~~7~m~o@~,

~~m~~

~~7~~~~rmm~~~,

~*~'f-mM~

~~A,

m~~~~~~m'¥-m~~~~o

(3)

1t~)J~

m~~~wm~M~Er-J~~~~,

tt~Er-J~~

~~~1t~JJ~1~~~Si~ki~Er-J

o

r4)

ffH!il

(S)

::f~1E:f-1~1$A

M~~*OOff~Er-J~*;~sm~~'

~~~

~~~:f-mEr-J~~o~m~mlf~~*ff~~

~m•~~M~*ff~~,

m::f~~:f-m~A

ffH!!JT~

o

r~)

!W1?m

<S>

::f~

1T

7f

qftEr-J~MM~WmttOO~~,

~*fi~kitt

~Er-J~W~Mo

~7M~*fi~W~MEr-Jq~

~A~~,

*~m~!Wm~~~Er-J~~T•~

~)i~J}fJLo

(f))

tSfftJZ

(S)

::f~Hlf

T~m~B~~W~~7mili-~;Er-JT~~

M~~~M,

~7M~*fi~~~MEr-JT~m

~ft~A~~,

*~m~M~~~Er-J~~T

fp:

~ii

~JJ

tJL

0

6.

Protectors

for

safety

This

chapter

describes

each

protector

for

safe

-ty.

Therefore,

read

and

study

the

following

carefully.

~

CAUTION

Protectors

for

safety

(11Eye

guard

{S)

Never

leave

the

eye guard open.

For

the

safety

of

eyes,

do

not

operate

the

machine

with

the

eye guard open.

The

eye guard

will

prevent

any

pieces

of

the

broken

needle

from

getting

into

your eyes

if

the

needle

should

break

during

sewing.

(2)

Finger

guard

0 Never

insert

any

of

your

fingers.

To

prevent

the

needle

that

moves

up

and

down

from

contacting

any

of

your body,

the

finger

guard

is

installed

close

to

the

needle.

However,

there

is

clearance

above

the

finger

guard

for

easy

threading.

Be

careful

that

the

needle

may

penetrate

any

of

your

fingers

if

you

insert

it

into

this

clearance.

(3)

Pulley

Check

the

direction

in

which

the

machine

pulley

rotates.

It

should

rotate

clockwise

as

seen

from

the

pulley.

(4)

Presser

foot

(9 Never

insert

any

of

your

fingers.

There

is

a

clearance

of

more

than

5mm

between

the

top

surface

of

the

needle

plate

and

the

press

-er

foot.Be

careful

that

none

of

your

fingers

are

caught

in

this

clearance.Never

insert

any

of

your

fingers

under

the

presser

foot

when

raising

the

presser

foot

with

the

knee

switch

or

automatically

raising

it

with

the

treadle.

( 5)

Front

cover

(S)

Never

leave

the

front

cover

open

The

looper

travels

left

to

right

while

drawing

an

arc

as

seen

from

the

front

of

the

machine.

To

prevent

the

looper

from

contacting

any

part

of

your body, be

sure

to

operate

the

machine

whith

the

front

cover

closed

securely.

(6) S I i

ding

pI

ate

0 Never I

eave

the

s I i

ding

pI

ate

open

The

looper

thread

take-up

rotates

in

order

to

supply

the

required

amount

of

looper

thread

during

sewing.

To

prevent

the

looper

thread

take-up

from

contacting

any

of

your body, be

sure

to

operate

the

machine

with

the

front

cover

closed

securely.

Ei'~:bUIOO

Schematic

diagram

of

the

machine

table

Cut

the

table

referring

to

the

diagram.(Fig6)

~18

5 -

4

~25

5

cr.>

I I

~l

I I I I

:i:

I

I

II

I I

I,

I I

I

4-~13

I

300

=

r-

70

038

73

0

2-R10

2-R10

234

409

1------+--+---+--+---+---+--+--+----+------+900

8::

1.

:fr1Z*

-05M8Cw:fft:JJ7J*][)

B"Jg}i~JJ,fJUrt.

i~~WAa

2.

:fr1Z*

-1

UTD*lCS1,

i~~WBa

~

oj

Q)

;....,

oj

+-'

;:::l

u

Q)

u

.,.-,

>

Q)

'"d

00

::2:

LD •

oo:l

I

oj

~

,...c::

Q)

(.0

+-'

;....,

bJJ

.,.-,

oj

.,....,

~

+-'

~

'"d

;:::l

'-.../

Q) u

0,

Q)

0,

.,.-,

u

(.0

;:::l

.,.-,

0'

>

till

Q) Q)

'"d

-~

Cl

I'-<

Q)

~.

~,......,

.,.-,

I

,...c::

u Q)

oj

rJl

a

;:::l

Q)

;:::l

,...c::

0

+-'

>..

'+-< '+-<

.,.-,

,.._.,

,_......,

N

..

+-'

0

z

IE'imUipi!I~

£

1

1~

Qt

~~;iig!JJ~Jla1,

*&:

'

~%

;jig!JJ

~Jl

a~

~

7JJt~

1~,

~%

tffi

~

;.;._

~

7JJHffi

!~

...t

Mtl'

Z.

!§"{I}

i1H:r

o

;ji

g!JJ

~Jl

a~

7l.fE~~

1J

loJ

;.;._

-¥~t-f9!1J~~

JoJ

tJ

J].fE

~~a~o

£11~

~

:fr)Jp

tfl

~ffi

Si

QX:

:jj(

tfl

~ffi

Si,

iff*

&Ht~ffl

~

~

~m~~m~o~*~fflm~~*~m~,

~

PJ

~~tfl1

W~ii~JJtfl

o

1.

f!ffls"J

~rn

~

iJ1~ffl~~~t~~~

(HIGH

SPEED

SEWING

MACHINE

OIL)

Cn'l]J!

11£;f~,lt~ilJ1l'Hffi

ISO;f~,ft~&',&

/VG22) o

2.

f~~rn

s"JJJ~!

mH~~Q~m~1,

~~~~oo~~~~R~

H~~~ou~~

rBJ

0

1JP5c~rnJ§,

iwm~t~~rn

Q

~m

~1.

3.

~rn

s"J

1Jtl

IE

_m

1hH1FR2

~H~~~DU~*~~~ffi

£

~

_1JlUDT

~~

o

J';J1~~rn00?&1t1~M':tEH~~~ou~zJBJ,

iw1t1tfft

;i''H:E~)Jp~ffi

o

C~

·

8)

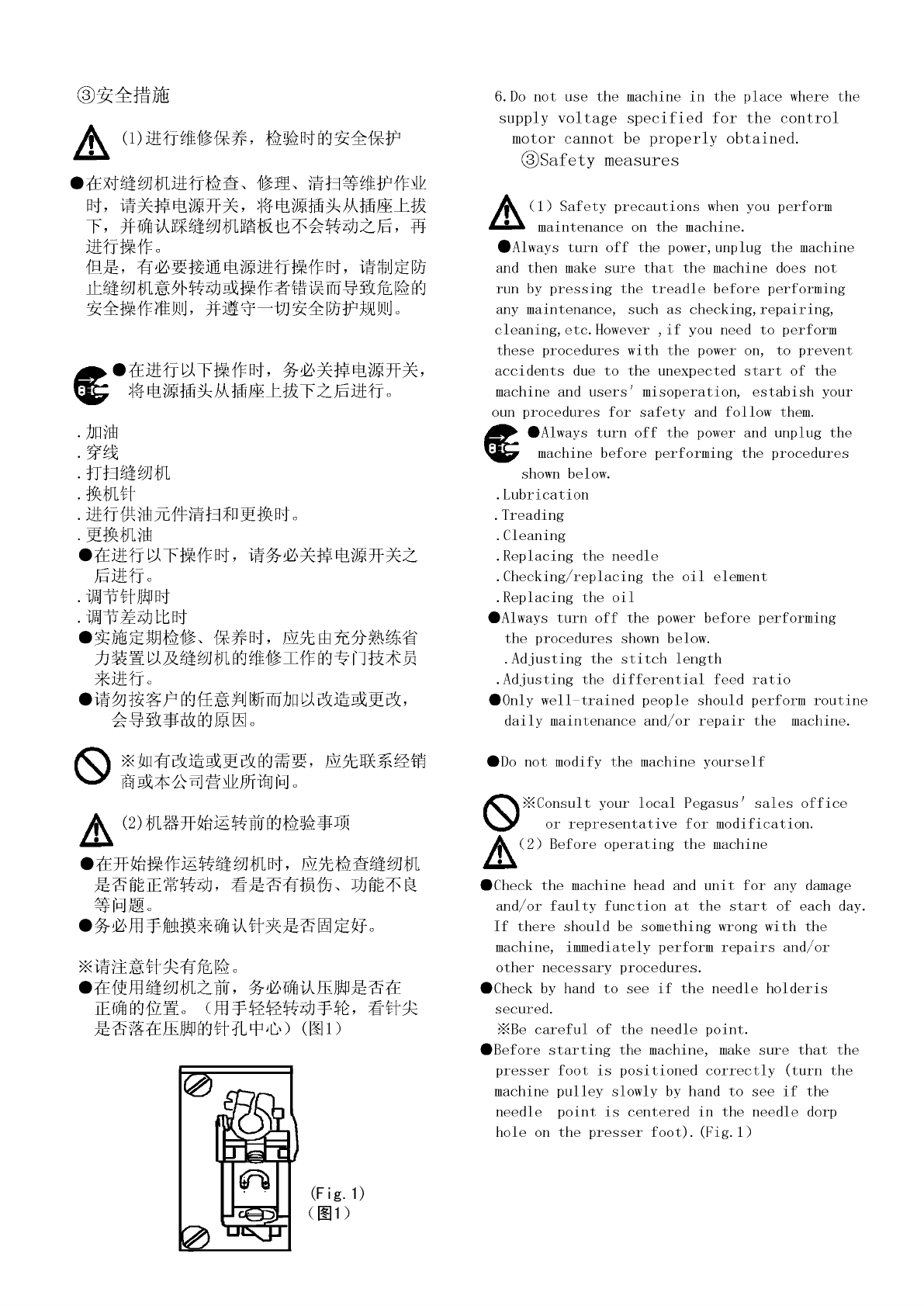

Assembling the machine

rest

board

Assemble

the

components comprising

the

machine

rest

board

by

referring

to

the

illustration

below.

Be

sure

to

secure

all

rods,

nuts

and

bolts

firmly

with

no

shake.

(Fi

g

7)

Sewing

machine

installation

£

CAUTION

C Alaways

tu

rn

off

the

power,

un

plug

the

m

achine

and

then

wei

lqual

ifi

ed

tech

nicians

sh

ould

i

nstal

I

the

machi ne.

Operating

direction

of

the

machine

pulley

the

machine

pulley

rotates

clockw

ise

as

seen

from

the

end

of

th

e

mach

ine

pu

I ley.

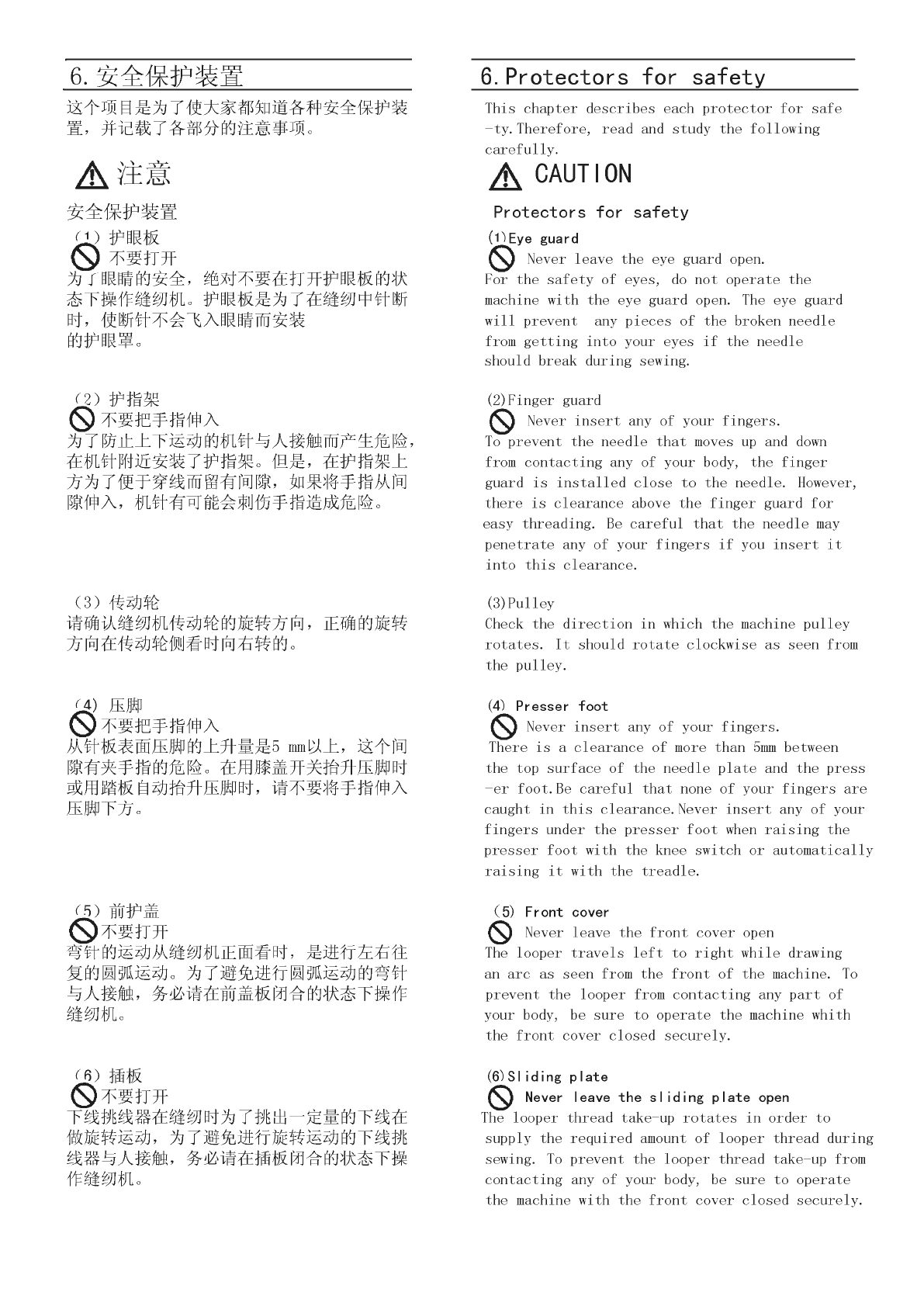

Lubrication

£

CAUT

ION

~When

lubricating

the

machine

and/or

replaceing

the

oil

,use

Pegasus recommended

oil.

Using

other

oils

may

damage

the

machine.

1.

Oil

Use

the

following

oil.

Pegasus

designated

oil:

(HIGH

SPEED

SEWING

MACHINE

OIL)specified

by

our company(ISO

Viscosi

-ty

Grade

22.

)

2.

Tofill

the machine

with

oil

Remove

cap l.Add

the

oil

until

the

oil

level

(see

oil

gauge

2)

reaches(H).

After

filling

the

tank

with

oil,replace

cap

1.

3.Required amount

of

oil

(H)

on

oil

gauge 2:Upper

limit.

(L)

on

oil

gauge 2:Lower

limit.

The

oil

level

should always

lie

between

(H)

and

(L).

(Fig

8 )

1!1

8 (

Fig

8)

4.

Jil¥

:1Jo

~rn

~

11~

C:frffl'¥

)Jp

~ffi

Si,

~&'

~:iHii~JJ

tJL

Efl

~

iJj

~

~,

~M~M~iJjM~~~T*~€~*fi"

:tEH~~ffl~Wm~,

~~~ffl*M*~ffl

Efl

~ii

~JJ

tJL

si,

JtJ

~rn

w

~'IT

tt

31'5-

1JP

2-

31i'lii

~rn

"

(~9)

s.

1ft~

~;urn

s"J

tm

:Ef~

m.

~:tt~~~€,

RT~mm•~,

~~wm

~~"~M~$4~~m~Efl~~~~~~~

~fo

(~10)

~10

(Fig

10)

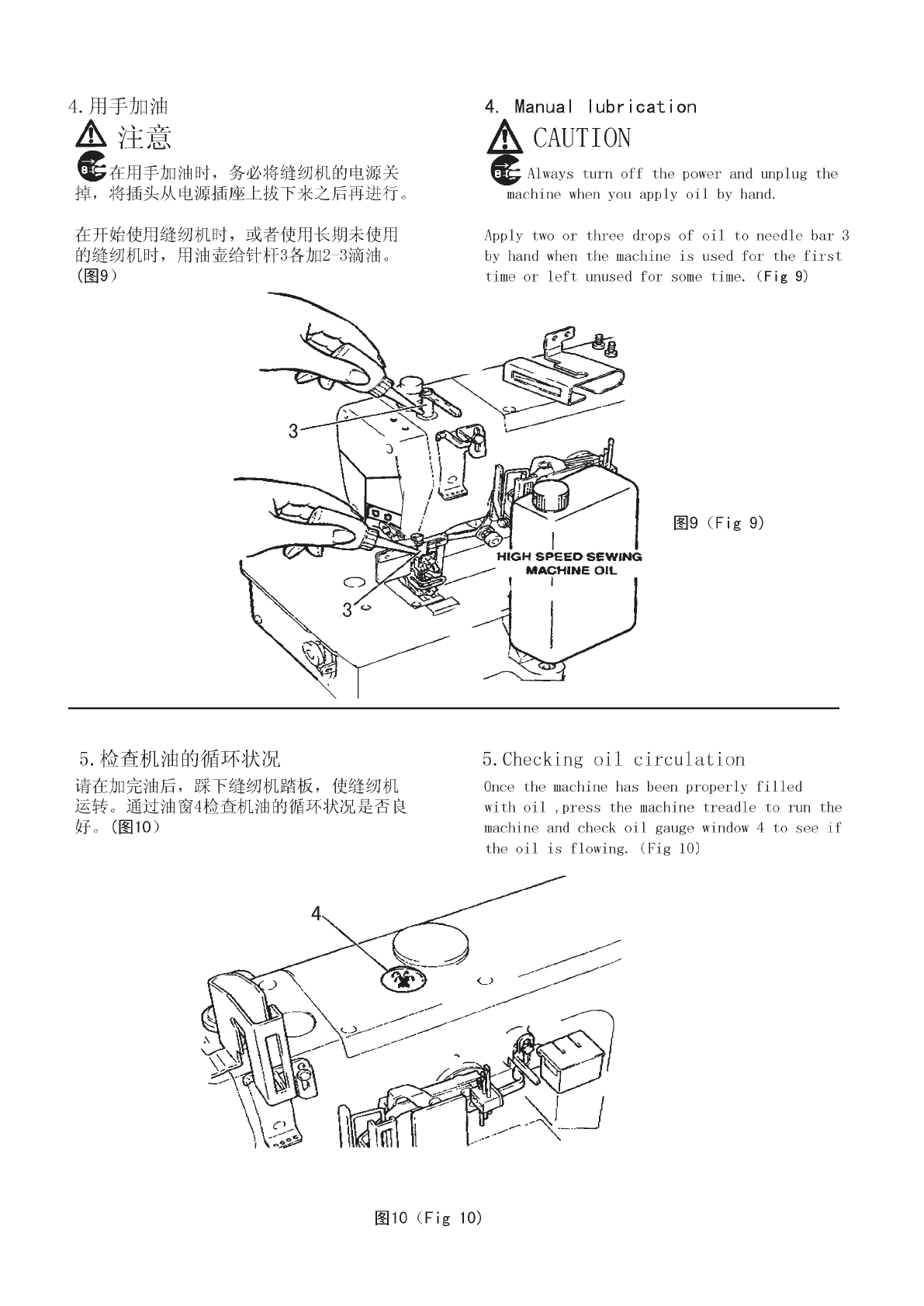

4.

Manual

lubrication

Li

CAUTION

CAlways

turn

off

the

power and unplug

the

machine

when

you apply

oil

by

hand.

Apply

two

or

three

drops

of

oil

to

needle

bar

3

by

hand

when

the

machine

is

used

for

the

first

time

or

left

unused

for

some

time.

(Fig

9)

I

HIGH

SPEED

SEWING

MACHINE

OIL

I

~9

(Fig

9)

5.Checking

oil

circulation

Once

the

machine has been

properly

filled

with

oil

,press

the

machine

treadle

to

run

the

machine and check

oil

gauge

window

4

to

see

if

the

oil

is

flowing.

(Fig

10)

A.

...

.:::6:::.

Lll

/.I,~

..

Gt

:frJt!:iT

~

i~

Si,

:%-&'

~~

~JiiJJ

tfl

EfJ

~

iJj

~

tljl:,

~~tm~JJ.~iJjtSff~_tf&:rzJ§~JtJ:if.

1.

iwtT3ft?§~'!'JUDt?.ffir:2,

3,

4.

2.

iwBcilZ:¥5.

J25:SiT

£~1;/t£~~6~1;/tt±:l

*o

~~~J§,

:fr~~~*Efl~~~,

~BeT

T£~1;/ti~~-

C~

12)

~12

CF

ig

12)

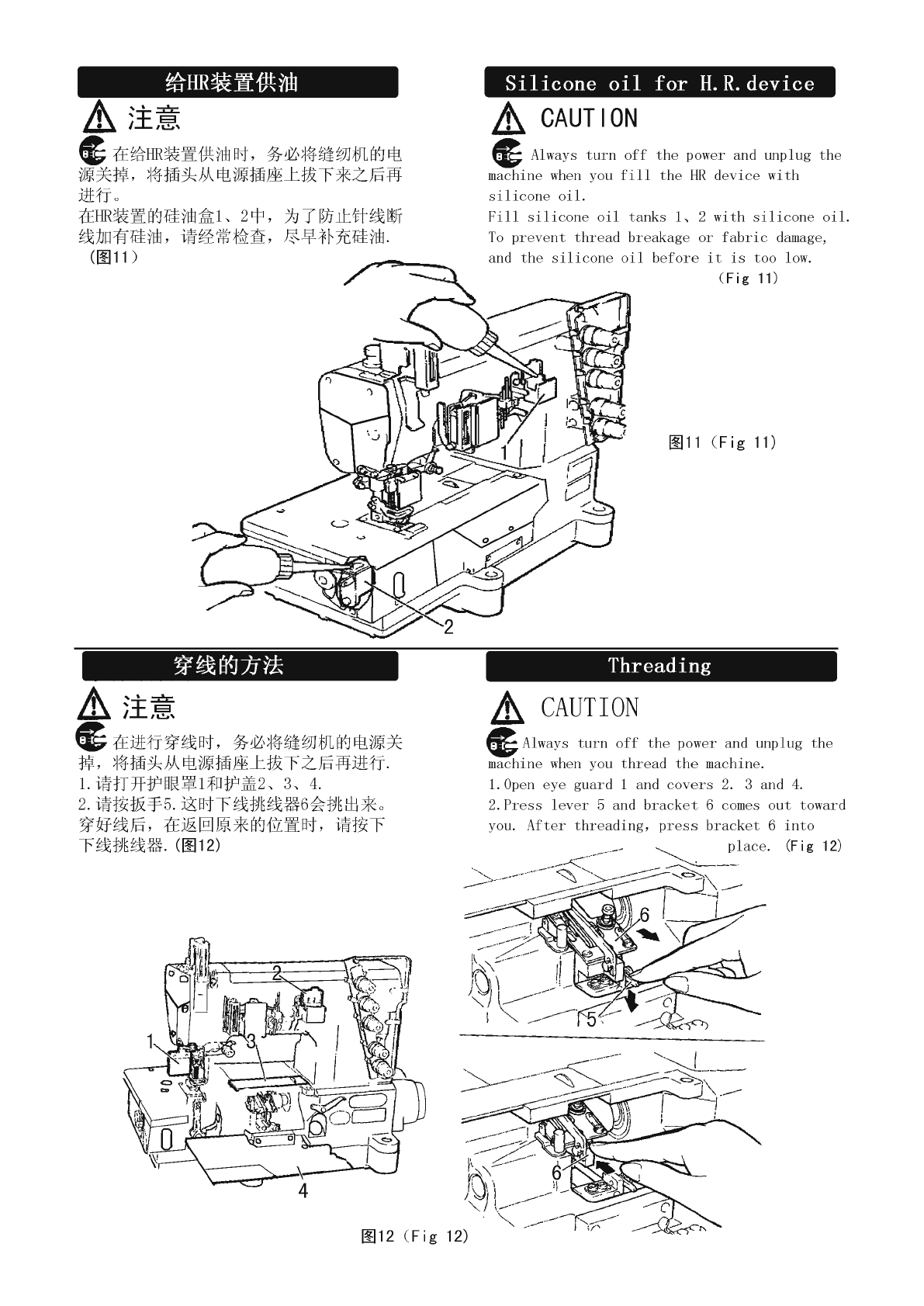

Silicone

oil

for

H.R.device

~

CAUTION

~

Always

turn

off

the

power and unplug

the

machine

when

you

fill

the

HR

device

with

silicone

oil.

Fill

silicone

oil

tanks

l,

2

with

silicone

oil.

To

prevent

thread

breakage

or

fabric

damage,

and

the

silicone

oil

before

it

is

too

low.

(Fig

11)

~11

(Fig

11)

Threading

~

CAUTION

Qt

Always

turn

off

the

power and unplug

the

machine

when

you

thread

the

machine.

l.Open eye guard 1 and

covers

2.

3 and

4.

2.Press

lever

5 and

bracket

6

comes

out

toward

you.

After

threading,

press

bracket

6

into

(Fig

12)

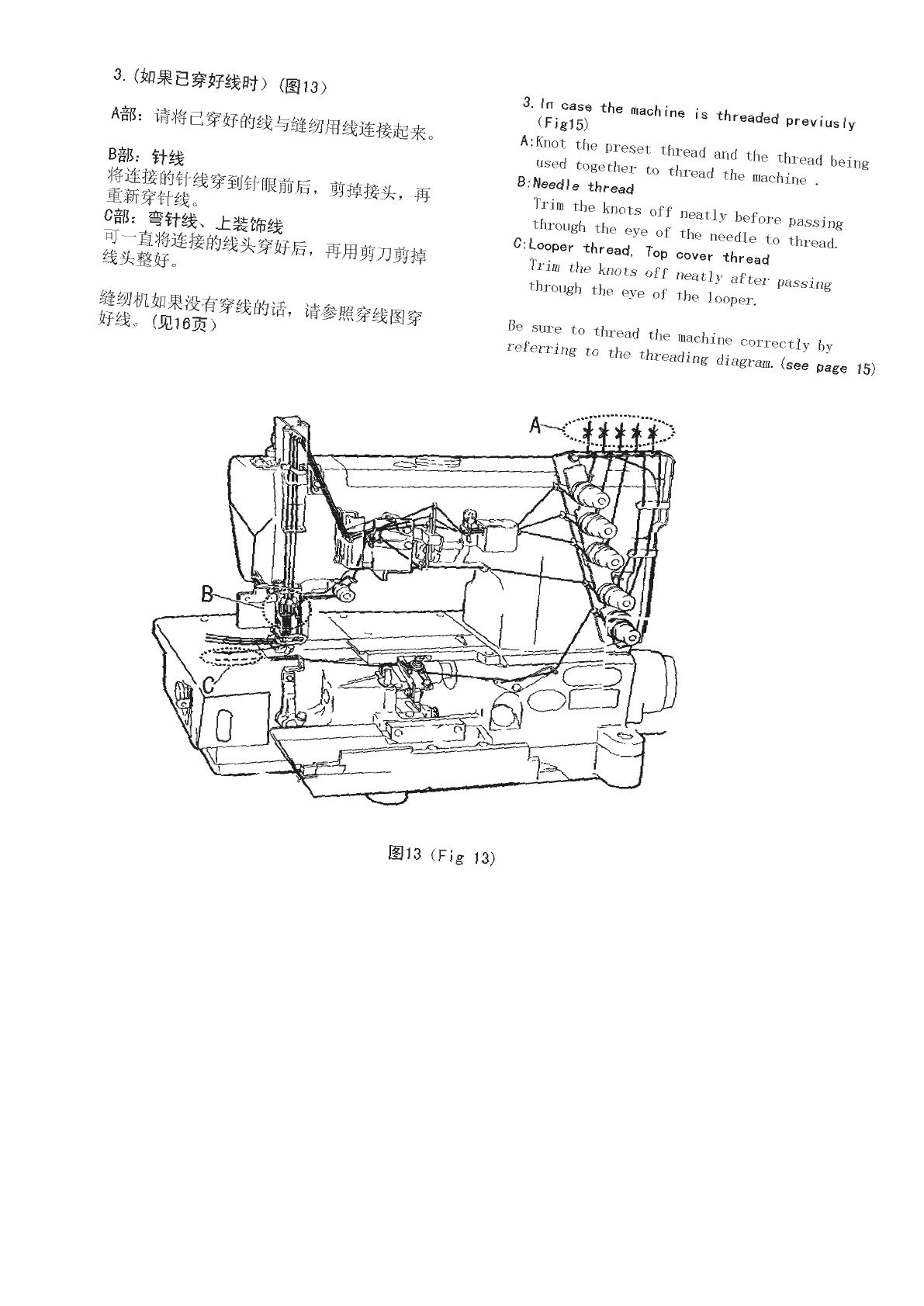

3.

(:${Q~B~~H

:

U1

)

(1!1

13

)

A~:

~~B~M

~

~~-Wffl~~~~*

·

8~~:

lt!i;

~~~

~

#~~~#~~€

,

~*~~'

~

lfff#T~#~.

c~~=

~lt!i;,

L.~itn~i;

ey

-

B~~~

~

~~~M€

,

~m~n~*

~t~l'lfH

.

•wm~~&~~~

~

~

,

~~~~~oo~

PJ~.

(!Ji!.

16

Di)

1!113

(

Fig

13)

3. In

case

the

machine

is

threaded

prev

ius

Iy

(

Fig15

)

A:

Kn

ot

t he p

reset

th

rea

d and the th

rea

d be

in

g

u

se

d

toget

her

to

th

rea

d t he mac

hin

e .

B:Needle

thread

Tri

m t he

kn

ots

off

n

eat

l y b

efore

p

assing

t h

ro

ugh the eye

of

the nee

dl

e

to

th

rea

d.

C:Looper

thread,

Top

cover

thread

Tr

im

the

kn

ots

off

n

eat

l y af t er p

assi

ng

th

ro

ugh the eye

of

t he l oop

er

.

Be su

re

to

th

rea

d the mac

hin

e

correct

l y by

referr

in

g

to

the th

rea

d

ing

d

iagr

am

. (

see

page

15)

~

1$i:lil::k:8{]~

at

ffl

,~;i;:~A::If

iP:J

o

~:

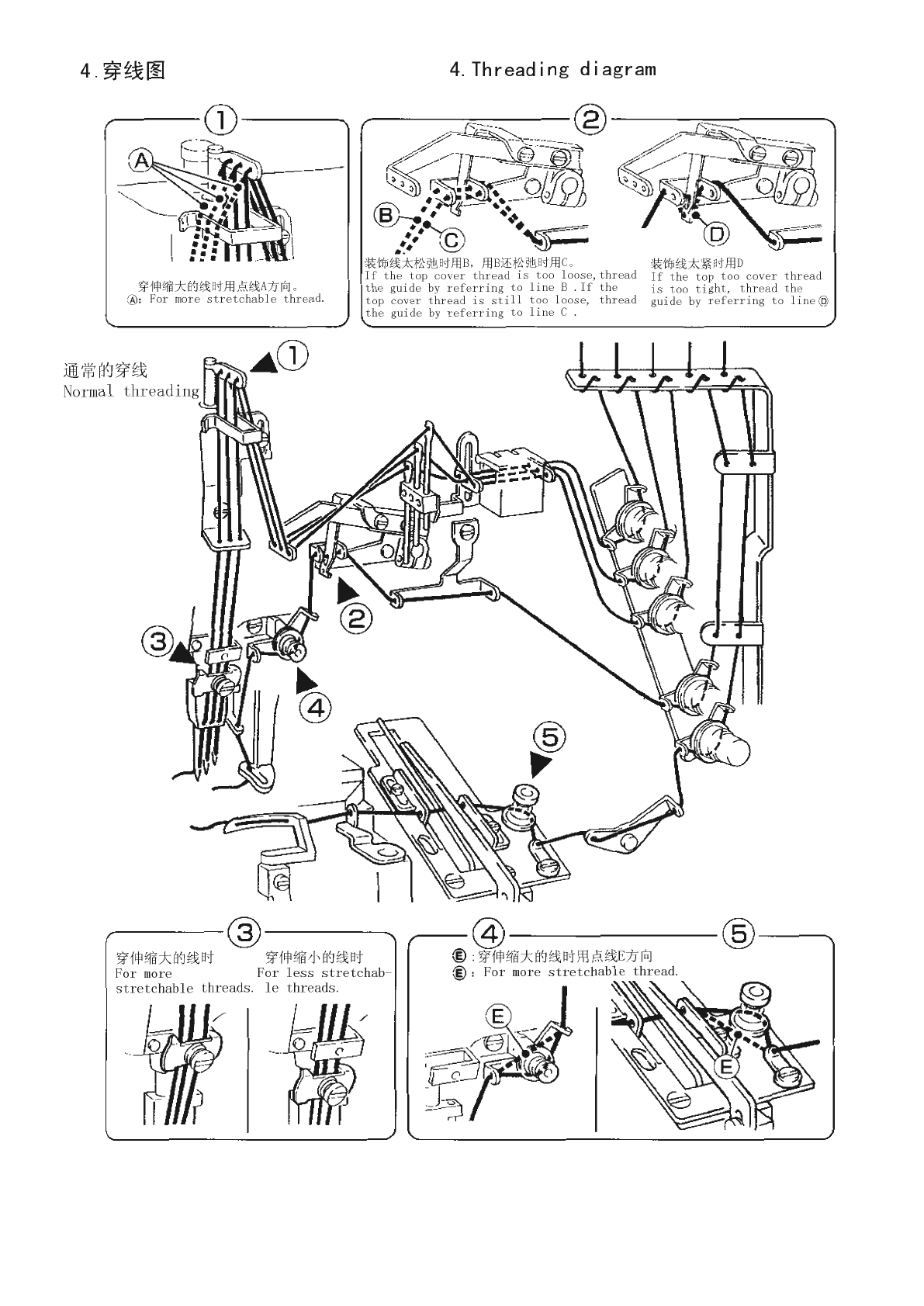

For more

stretchable

thr

ead.

4.

Threading diagram

{'·

-·

-. ®

--

,

-

_-:

-

---::

-~

::::::-

-

-

~

--

:;.

··

--

-

---

- ._

-

_

~

s~~~

~~!j

_

.•

:

..

·"'@

·~

~~

-----

~'dii

~il:fl9iJ1MfflB

,

fflB:kE

;fl91J1M

ffl

Co

~'dii

~il:~

a

tfflD

If

the

top

cover

thr

ead

is

too

loos

e,

thread

If

the

top too

cover

thread

the

guid

e

by

refe

rri

ng

to

line

B .

If

the

is

too

tight,

thread

the

top

cov

er

thread

is

still

too

laos~

thread

guide

by

referr

ing

to

line@

the

guide

by

refe

rrin

g

to

line

C .

,--@------.....

,.---@----@-----...

~

1$

~:k

a"J~Bt

~

1$

~

1

H"J~Bt

@ :

~1$

~:ka"J

~BtJtL

8~E/7r'iJ

For

mor

e For l

ess

stretc

hab- @ :

Fo

r

mo

re

st

ret

chable thread.

stretc

hable

threads.

le

threads.

~

ff~~ffh~*~~~~~*fi,

#~~~ili

~~~~~m~~,

~~;~m~~~ffh~

'§:o

ttJf~J-BJ:l,

JJJE~~~f'f'2*1-JiJ1W1J

o

imJlJfG

J§rr~~~-BJ:L

c~14)

1.

tt7f~J-BJ:3,

~:iHlZ:¥4

rJ:iJ

TillL

lJlU&~JJ

tt1E

J:-:,

~ii~t~~*-l~t&mr

0

~:it:t&'¥4rJ:iJ_Lf&,

lJlU&~JJ

rt1E!J\'

~Ji~f~~*-l~1$*o

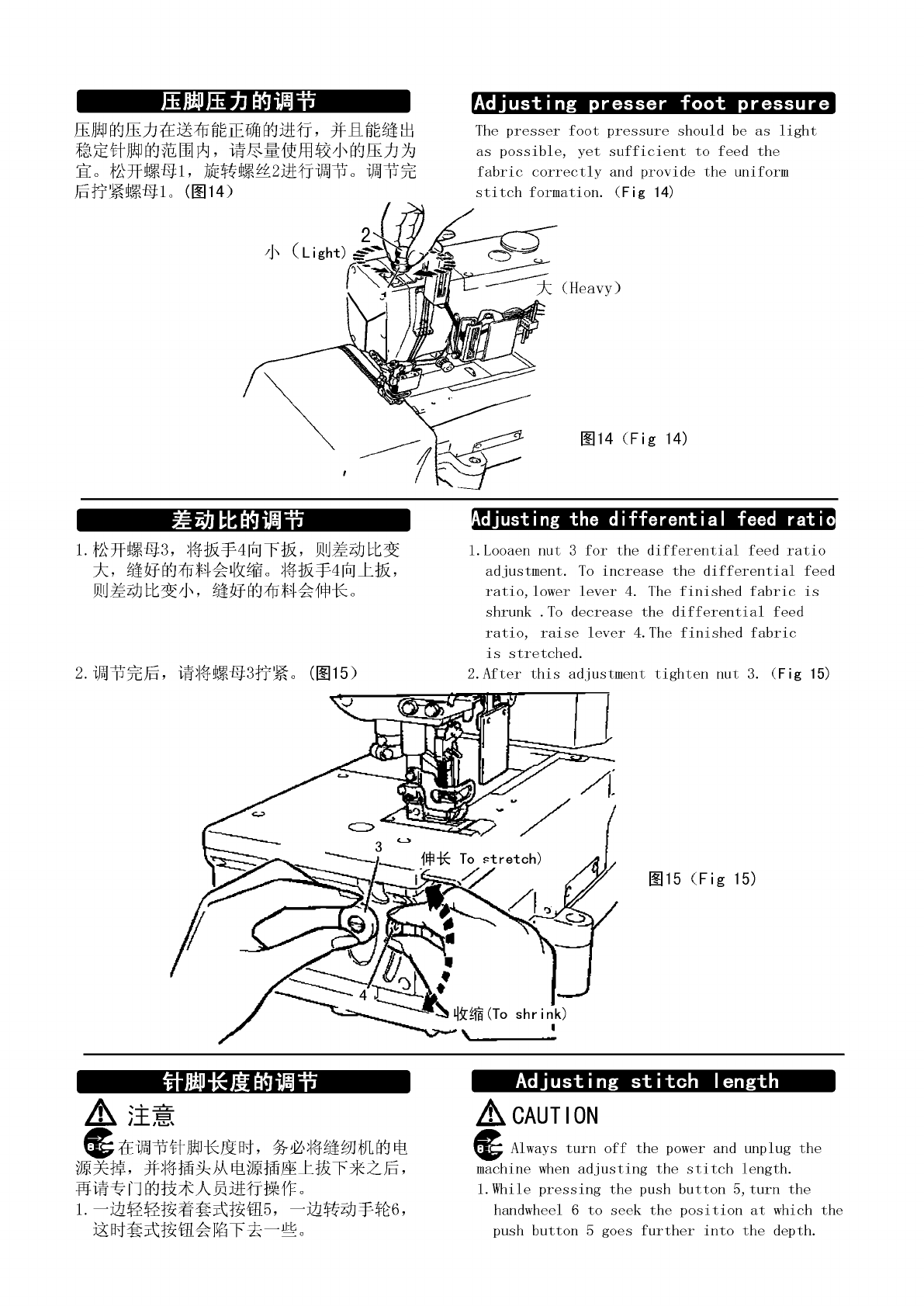

Adjusting

presser

foot

pressure

The

presser

foot

pressure

should

be

as

light

as

possible,

yet

sufficient

to

feed

the

fabric

correctly

and

provide

the

uniform

stitch

formation. (Fig

14)

~14

(Fig

14)

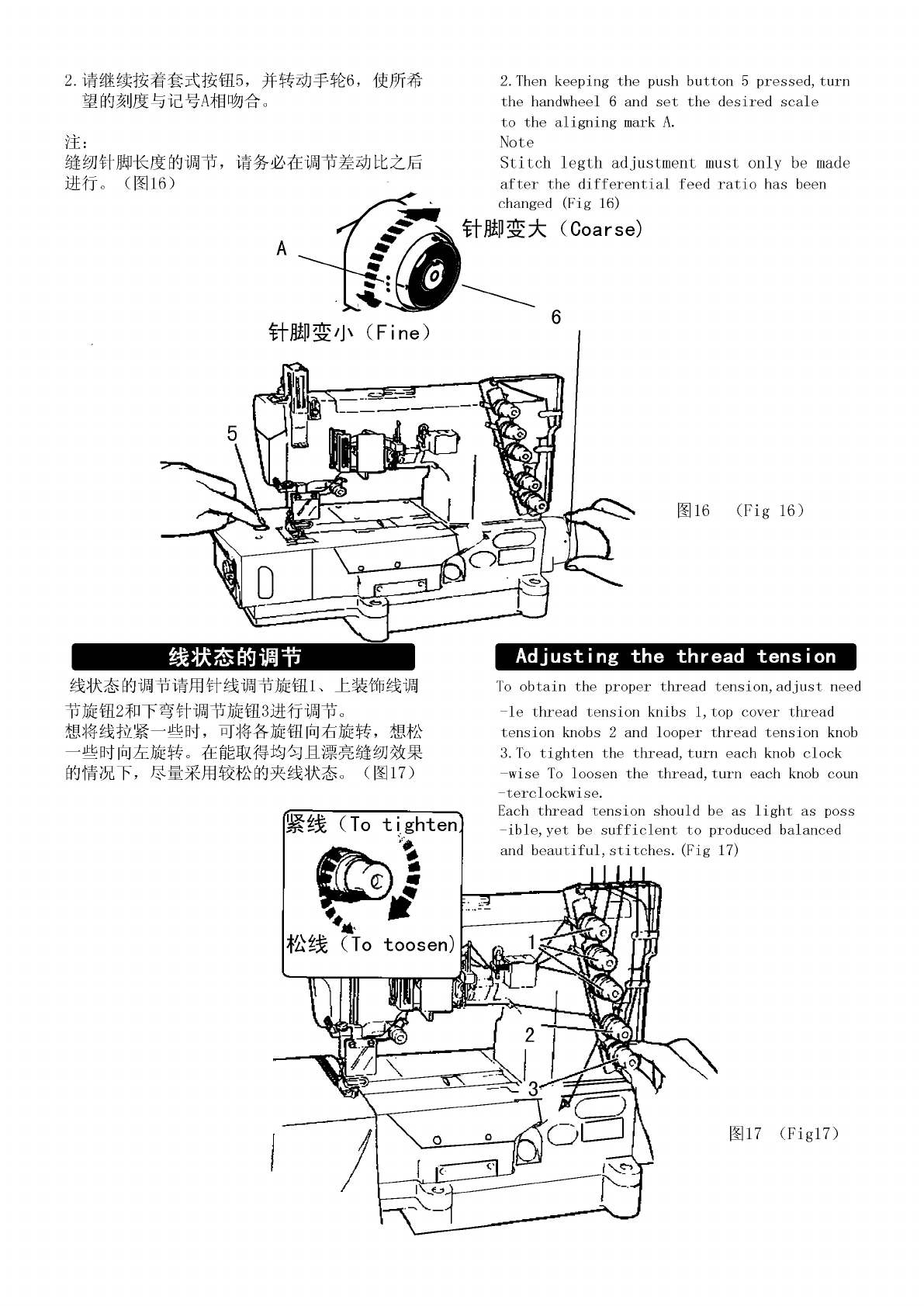

djusting the

differential

feed

ratio

l.Looaen

nut

3

for

the

differential

feed

ratio

adjustment.

To

increase

the

differential

feed

ratio,

lower

lever

4.

The

finished

fabric

is

shrunk .

To

decrease

the

differential

feed

ratio,

raise

lever

4.

The

finished

fabric

is

stretched.

2.After

this

adjustment

tighten

nut

3.

(Fig

15)

~15

(Fig

15)

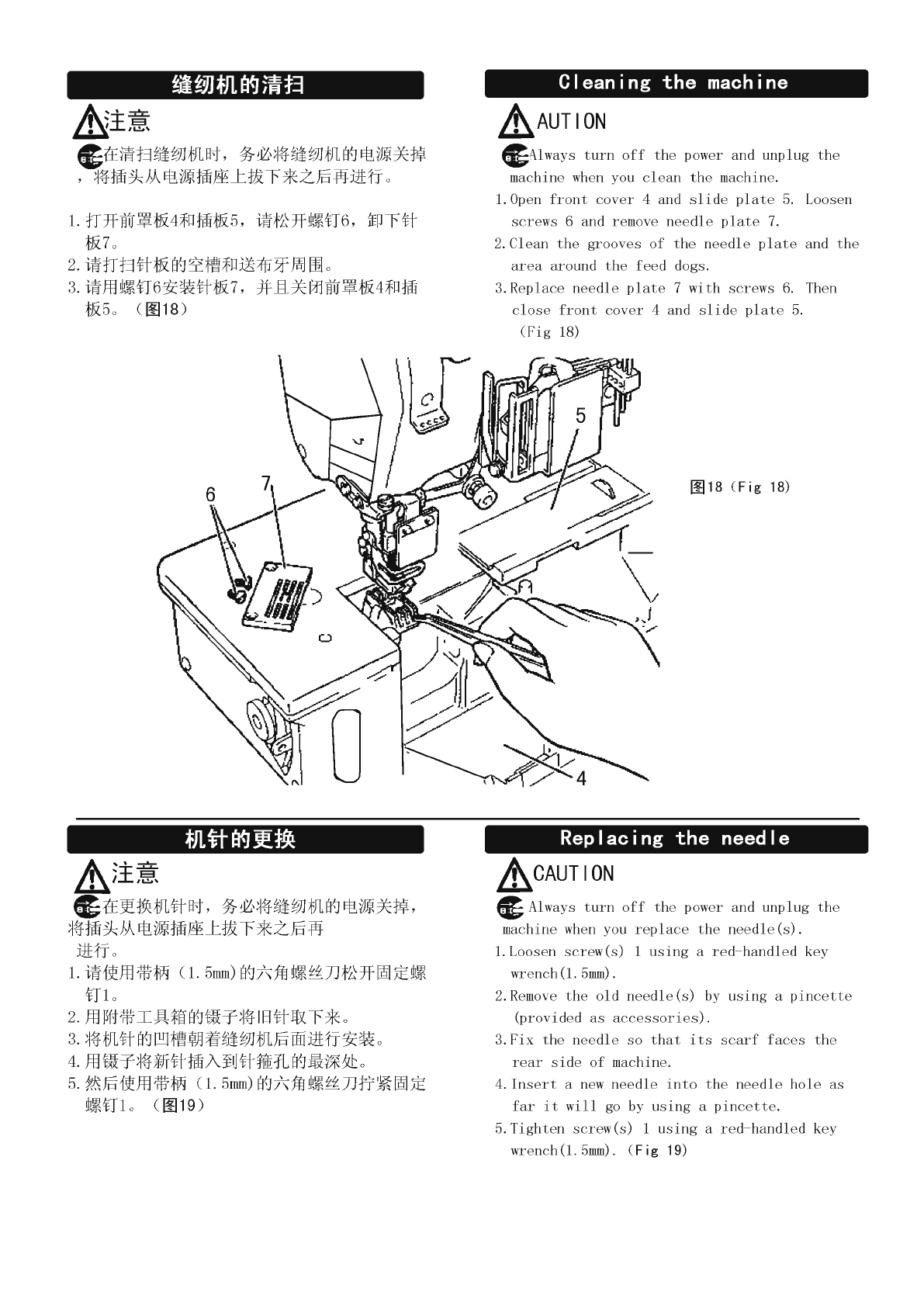

Adjusting

stitch

length

A

cAUTION

~

Always

turn

off

the

power and unplug

the

machine

when

adjusting

the

stitch

length.

1.

While

pressing

the

push

button

5,

turn

the

handwheel 6

to

seek

the

position

at

which

the

push

button

5 goes

further

into

the

depth.

2.

iJ~!*~~~~~:r\:~~Rs,

:3f~~)J:f-~6,

1~?JT$

-tfl

Efl

~u

tt

E1

ic

-5

Affi

om

il

0

~i:

~w~~*ltEfl~~,

~*~~~~~M~~€

Jtl:if

0 (

~

16)

2.

Then

keeping

the

push

button

5

pressed,

turn

the

handwheel 6 and

set

the

desired

scale

to

the

aligning

mark

A.

Note

Stitch

legth

adjustment

must

only

be

made

after

the

differential

feed

ratio

has been

~

changed (Fig

16)

71

,...

~t~PS£*

(Coarse)

~

A

..

• 0

.

~:

------

6

~t~PS£1j\

(Fine)

~~~Efl~~~m~~~~~m1.~~~~~

~JJJE~R2~DT~

~iJlll~JJJE~R3Jtl:1fiJlll~

o

m~~~~-®~,

ey~~~m~~~~,

m~

-@~~~~~o~~~~~~~~~~W~*

Efl'twiJGT,

~£*ffl~ttEfl:'k:iiAfi:~o

C~17)

~~~

(To

t i

ghten

~

·

-..

~i

..

-

•·

*]}~~

(To

too

sen)

~16

(Fig

16)

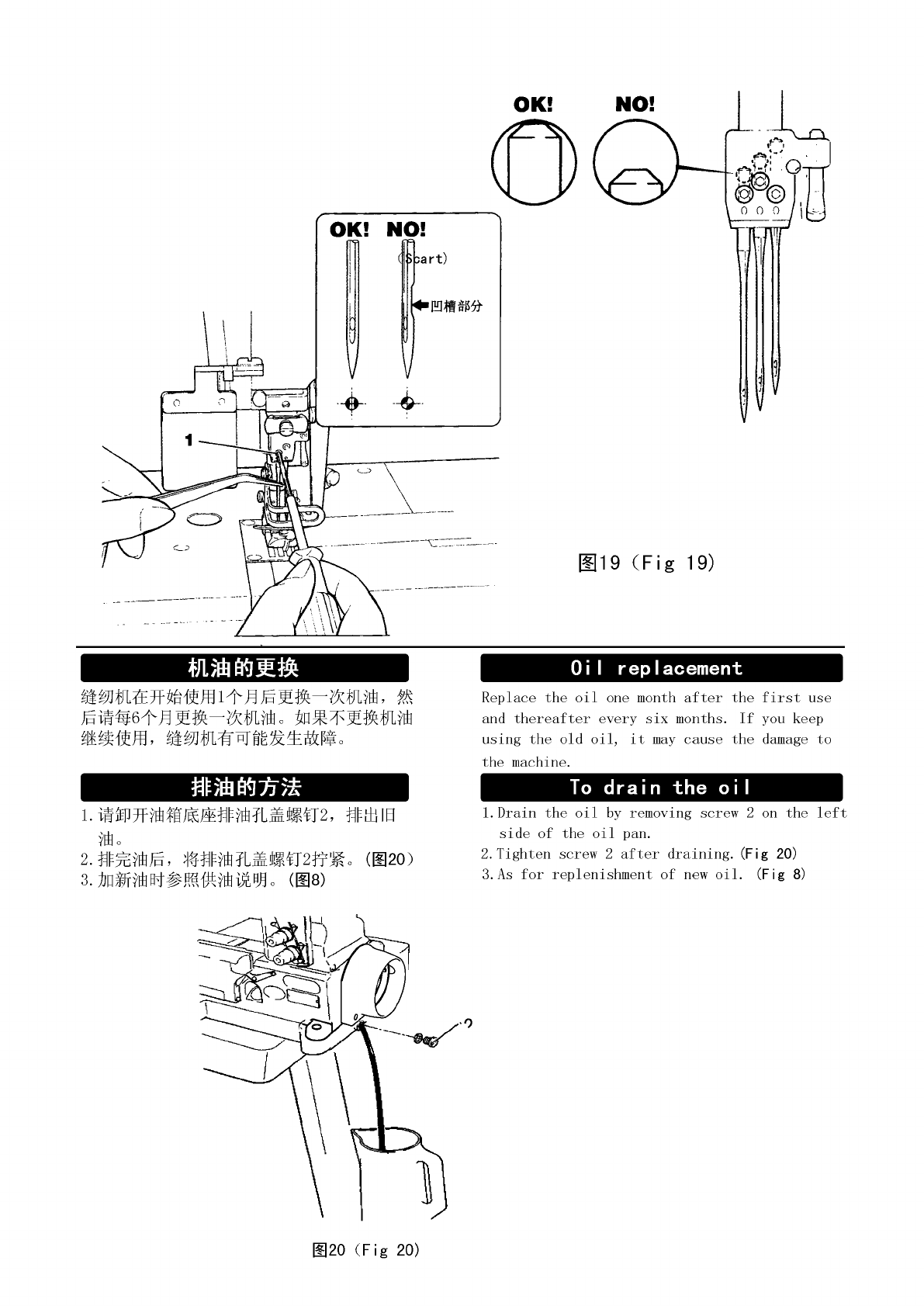

Adjusting

the

thread

tension

To

obtain

the

proper

thread

tension,adjust

need

-le

thread

tension

knibs

1,top

cover

thread

tension

knobs 2 and

looper

thread

tension

knob

3.

To

tighten

the

thread,

turn

each

knob

clock

-wise

To

loosen

the

thread,turn

each

knob

coun

-terclockwise.

Each

thread

tension

should be as

light

as poss

-ible,yet

be

sufficient

to

produced balanced

and

beautiful,

stitches.

(Fig

17)

~17

(Fig17)

1.

1J3f!W'!'J;fJZ4~DtSfi;fJZ5,

iritt7f~JtJ6,

iEPT'tt

;fJZ7

0

2.

iff

1H3

'tttJZ

Efl

2tJIUD*

::tH

3f

)jlfJ

II

o

3.

iJJtJ~JtT6iz:*'tt;fJZ7,

:3f

ll~i~IW'!'J;fJZ4~Dtm

fJZ5o

(~18)

A..

'"'

__.__

L.ll

/I~

El!;

:tt~~tfl'ttSi,

~&'~~Hii~JJ;fJlE!j

~iJj~j:ljl:,

~~Hm~JA

~iJjtSff~_LW:T

*ZJ§

~

Jtl:if

0

1.

ii1~fflwfr3

c1.

smm)

EfJ;\}MJf'f'JJtt7f[llli5E~J

tTL

2.

JtJ

JYft

wI~

;f§

EfJ

tl.:=t"

~:it

IB

'tt

.!lZ

T *o

3.

~:it

tfl

'tt

Efl

[!I]

tl!l!

~jj

~

~ii

~JJ

tfl

J§

00

Jt!:

if

iz:

* o

4.

JtJtl.:=t-~:it¥JT'tttmA~U'ttfiT!FJLEfl~~~L

s.

~J§1~fflwfr3

c1.

smm)

EfJ;\ftl~Jf'f'JJrr~[llli'!E

~Jtrlo

(~19)

Cleaning

the

machine

Li

AUTION

El!;

~lways

turn

off

the

power

and

unplug the

machine

when

you

clean

the machine.

1.0pen

front

cover 4

and

slide

plate

5.

Loosen

screws 6

and

remove

needle

plate

7.

2.Clean the grooves of the needle

plate

and

the

area

around the feed dogs.

3.Replace needle

plate

7 with screws

6.

Then

close

front

cover 4

and

slide

plate

5.

(Fig

18)

~

18

(Fig

18)

Replacing

the

needle

Li

CAUTION

EI!;

Always

turn

off

the

power

and

unplug the

machine

when

you

replace

the

needle(s).

1.Loosen screw(s) 1 using a red-handled key

wrench (1.

5mm).

2.Remove

the old needle(s)

by

using a

pincette

(provided as

accessories).

3.Fix

the needle so

that

its

scarf

faces the

rear

side

of machine.

4.

Insert

a

new

needle

into

the needle hole as

far

it

will

go

by

using a

pincette.

5.

Tighten screw(s) 1 using a red-handled key

wrench (1.

5mm).

(Fig

19)

OK!

NO!

·+··+·

.

---

-

----

~wm~H~~m~~~€~~-~m~,

~

€~~6~~~~-~m~o~*~~~m~

~JH~1~ffl,

~ii~JJtfl1fPJ~~bt!±.iOI:Il!iio

1.

iJiEPH~ffi;f§Jf£~flF~ffi:JL.ffirJJ!fJ2,

flFt±:liB

~rn

0

2.

flF5c~rn€,

~:itflF~ffi:JL.ffirJJtr2rr~

0

c~2o)

3.

1JP¥JT~ffiSi~~'(jt~ffii£a)j

o

(~8)

~20

(Fig

20)

OK!

NO!

0

~19

(Fig

19)

0 i I

rep

I

acement

Replace

the

oil

one month

after

the

first

use

and

thereafter

every

six

months.

If

you keep

using

the

old

oil,

it

may

cause

the

damage

to

the

machine.

To

drain

the

o i I

l.Drain

the

oil

by

removing screw 2

on

the

left

side

of

the

oil

pan.

2.

Tighten

screw 2

after

draining.

(Fig

20)

3.

As

for

replenishment

of

new

oil.

(Fig

8)

Table of contents

Other Hikari Sewing Machine manuals

Hikari

Hikari H9199 Product guide

Hikari

Hikari H99S User manual

Hikari

Hikari HX6800TD User manual

Hikari

Hikari HW740TA Owner's manual

Hikari

Hikari H9300 Series User manual

Hikari

Hikari HK2900 User manual

Hikari

Hikari H8800E User manual

Hikari

Hikari H93SF-7D User manual

Hikari

Hikari H9990 User manual

Hikari

Hikari H8800-7P User manual

Popular Sewing Machine manuals by other brands

Singer

Singer 4423CL instruction manual

Duerkopp Adler

Duerkopp Adler 524-101 Spare parts

frister & rossmann

frister & rossmann EURO-21 instruction manual

Dürkopp Adler

Dürkopp Adler 884-xxx-M series Service instructions

Brother

Brother KE-430D Service manual

Singer

Singer 119W2 Instructions for using and adjusting