Hikari HW740TA Owner's manual

CONTENTS 目錄

目錄目錄

目錄

1

Installation

安裝

1.1

Table dim ensio ns

桌板尺寸

1.2

Adjusting presser foot lift

調整抬壓腳

1.3

Motor and belt

馬達和皮帶

1.4

Other Parts

其它部份

2

Sewing speed and rotating direction of pulley

馬達轉速和皮帶輪轉動方向

3

Lubication

潤滑

3.1

Lubricating oil

潤滑油

3.2

Lubricating

潤滑系統

3.3

Priming oil

啟動注油

3.4

Priming

補充油

3.5

Changing oil

更換油

4

Proper operation

使用說明

4.1

Needle system

車針系列

4.2

Installing needle

針的安裝

4.3

Threading

線

4.4

Thread tension

線鬆緊

4.5

Pressure of presser foot

調整壓腳壓力

4.6

Up-and-down position of presser foot

調整壓腳高低

4.7

Adjusting differential feed dog

調整差動

4.8

Adjusting stitch length

調整針距

4.9

Adjusting lapped width of upper fabric

調整切布刀

4.10

Sp device

過線油組

4.11

Use of lap former

導布器

5

Adjustments

調節裝置

5.1

Needle thread tension

針線鬆緊

5.2

Looper thread tension

下底線

5.3

Top cover thread te nsion

上網線

5.4

Height of needle

針位高度

5.5

Top cover thread carrier and hook

上勾針

5.6

Looper

下勾針

5.7

Needle guard (front)

前針檔

5.8

Needle guard (rear)

後針檔

5.9

Height of feed dog

狗齒高度

5.10

Replacing presser foot

置換壓腳

5.11

Replacing presser foot spring plate

置換壓腳彈簧片

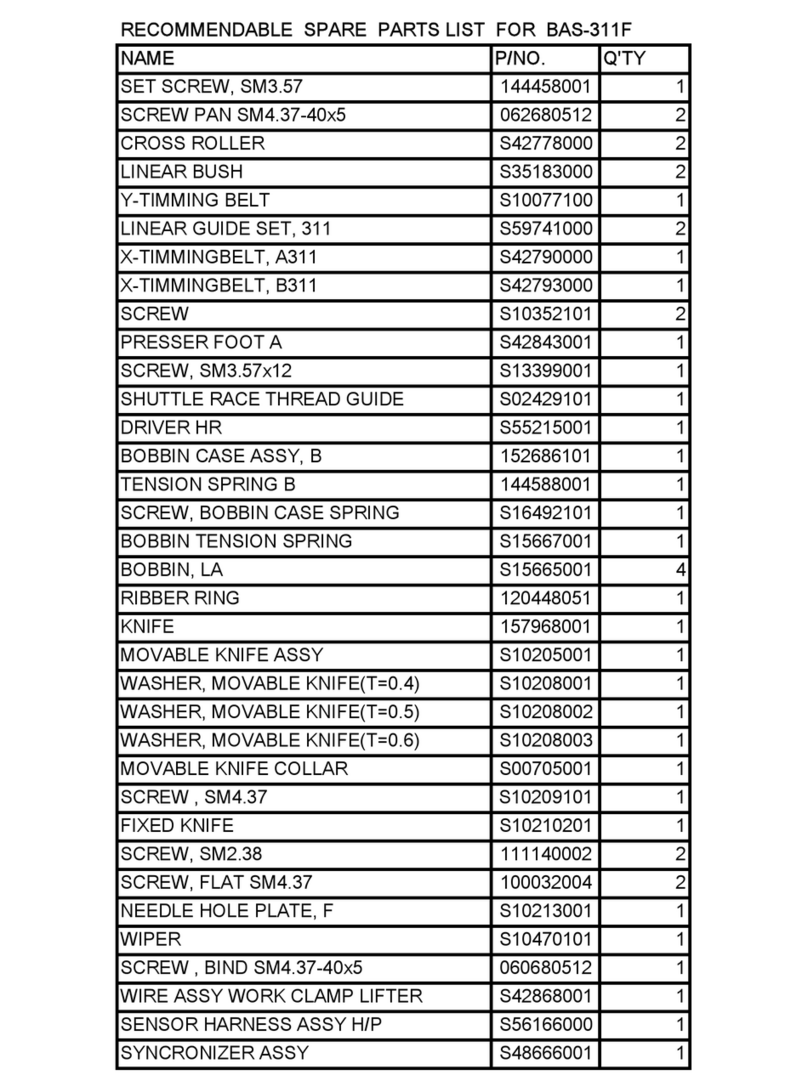

5.12

Replacing and adjusting knives

置換和調整位置

6

Specifcations

規格

1.

Installation

安裝

1

1.1 桌板尺寸

1.1 Table dimensions

Fig.1

1.2 調整抬壓腳

1.2

Adjusting presser foot lift

1.2.1 抬壓腳連接桿

1.2.1

Presser foot connecting lever

設置壓腳連接軸

○

1螺絲

○

2。(Fig.2)

Set the presser foot connecting lever

○

1with the

screw

○

2

.

(Fig.2)

Fig.2

1.

Installation

安裝

2

1.2.2 抬壓腳

1.2.2 Presser foot lift

1.當壓腳緊貼在針板上時,在抬壓腳連接軸

○

1跟壓腳連接托架

○

2留1mm 的間隙。(Fig.3,4)

註:壓腳主體跟壓腳彈片之間要有 0.3mm 的間隙。

1. As standard, makethe clearance between the presser bar lifter lever

○

1 and the presser bar

connecting bracket

○

2 to 1 mm when the presser foot touches the stitch plate closely.(Fig. 3,4)

Note: The clearance between the body of the presser foot and presser foot spring plate has 0.3mm

Fig.3 Fig.4

1.

Installation

安裝

3

調整:

(1) 移除油塞

○

3

○

4才可以檢查間隙。(Fig.5)

(2) 放鬆壓腳連接桿螺絲

○

5。(Fig.6)

(3) 移開壓腳連接桿(短)

○

6右邊或左邊去調整間隙。

Adjusting :

(1) Remove the seal plugs

○

3

○

4to check the clearance.(Fig. 5)

(2) Loosen the screw

○

5 of the presser foot lifter lever link (long). (Fig. 6)

(3) Move the presser foot lifter lever link (short)

○

6right or left to adjust the clearance.

Fig.5 Fig.6

注意:

在調整抬壓條連接軸

○

1之後,調整抬壓腳在壓腳的最低位置,如果沒有調整,會導致上網線勾損壞。

WARNING

After adjusting the clearance of the presser bar lifter lever

○

1 , adjust the presser foot lift at the lower

point of the presser bar. If not adjusted, it can cause damage to the top cover thread hook.

1.

Installation

安裝

4

2.當針柱在最低位置和壓腳完全抬舉時,針鎦

○

1和上

網線勾

○

2需留間隙 0.3mm。(Fig.7)

2. As standard , make the clearance between the

notch of the needle clamp

○

1 and the top cover

thread hook

○

2 to 0.3mm when the needle bar is

at the lowest point and the presser foot is raised

by pressing the presser foot pedal fully. (Fig. 7)

Fig.7

調整:

1. 放鬆螺母

○

3。(Fig.8)

2. 移動抬壓腳停止插銷

○

4或再調整外面間隙。

Adjusting :

1. Loosen the lock nut

○

3 .(Fig.8)

2. Move the presser foot lifter stop plunger plunger

○

4 in or out to adjust the clearance.

Fig.8

1.

Installation

安裝

5

1.2.3 過線組

1.2.3Tension release unit

不踩踏板時鬆線器

○

1和鬆線器座之間要有 0.5mm

的間隙。

當踩下踏板時,六個鬆線器

○

1會向上推,之後上夾線

片

○

2開始離開下夾線片。(Fig.9)

As standard, make the clearance between the

tension release pins

○

1 and the tension release

shaft

○

3 to 0.5mm when six tension release pins

○

1 are pushed up slightly and the upper thread

tension disc without pressing the presser foot pedal.

(Fig.9)

Fig.9

調整:

(1) 放開提昇擺臂(大)的螺絲

○

4。(Fig.10)

(2) 翻轉鬆線器座

○

3用螺絲起子。(Fig.9)

註:

順時針旋轉,減間隙。

逆時針旋轉,增加間隙。

Adjusting:

(1)

(1)(1)

(1) Loosen the screw

○

4of the presser bar lifter lever

(large).(Fig. 10)

(2)

(2)(2)

(2) Turn the tension release shaft

○

3with a Fig.10

screwdriver.(Fig. 9)

●To decrease the clearance, turn it clockwise.

●To increase the clearance, turn it counterclockwise.

1.

Installation

安裝

6

1.3 馬達和皮帶

1.3

Motor and belt

使用 M型之 V皮帶。安裝馬達時,機器皮帶輪和馬達

皮帶輪的中心線需成一直線。(Fig.11)

To install the clutch motor, align the center of the

machine pulley with that of the motor pulley when

the motor pulley shifts to the left with toeing down

the pedal.(Fig. 11)

Fig.11

提醒:表格一為縫紉機轉數和馬達皮帶輪之外徑對照

表,當使用第 3個階段,2-皮帶輪的尺寸適合

400W 的離合器馬達(1/2HP)。

皮帶輪增大尺寸為每 5mm 一個單位。

Note:

Table 1 shows the outside diameter of the

motor pulley, rpm of the machine, and size

of the belt when using the clutch motor of

3-phase, 2-pole, 400W(1/2HP).

The outside diameter on the table shows the

nearest size to the calculated values based on 表格一

the commercial pulleys at intervals of 5 mm.

注意:

只可使用適合之皮帶輪,如果使用速度超過最大上限機器會有損壞的可能性。

CAUTION

Use only those motor pulleys applicable to the machine. If not, the sewing speed will be over

maximum and it can cause the machine damage.

皮帶輪

外徑 機器轉速 皮帶尺寸

50Hz

60Hz

離合器馬達

45 2600

M21

50 2900

M21

55 2700 3200

M21

60 2900 3500

M21

65 3150 3800

M21

70 3400 4100

M21

75 3650 M22

80 3900 M22

85 7500 M22

1.

Installation

安裝

7

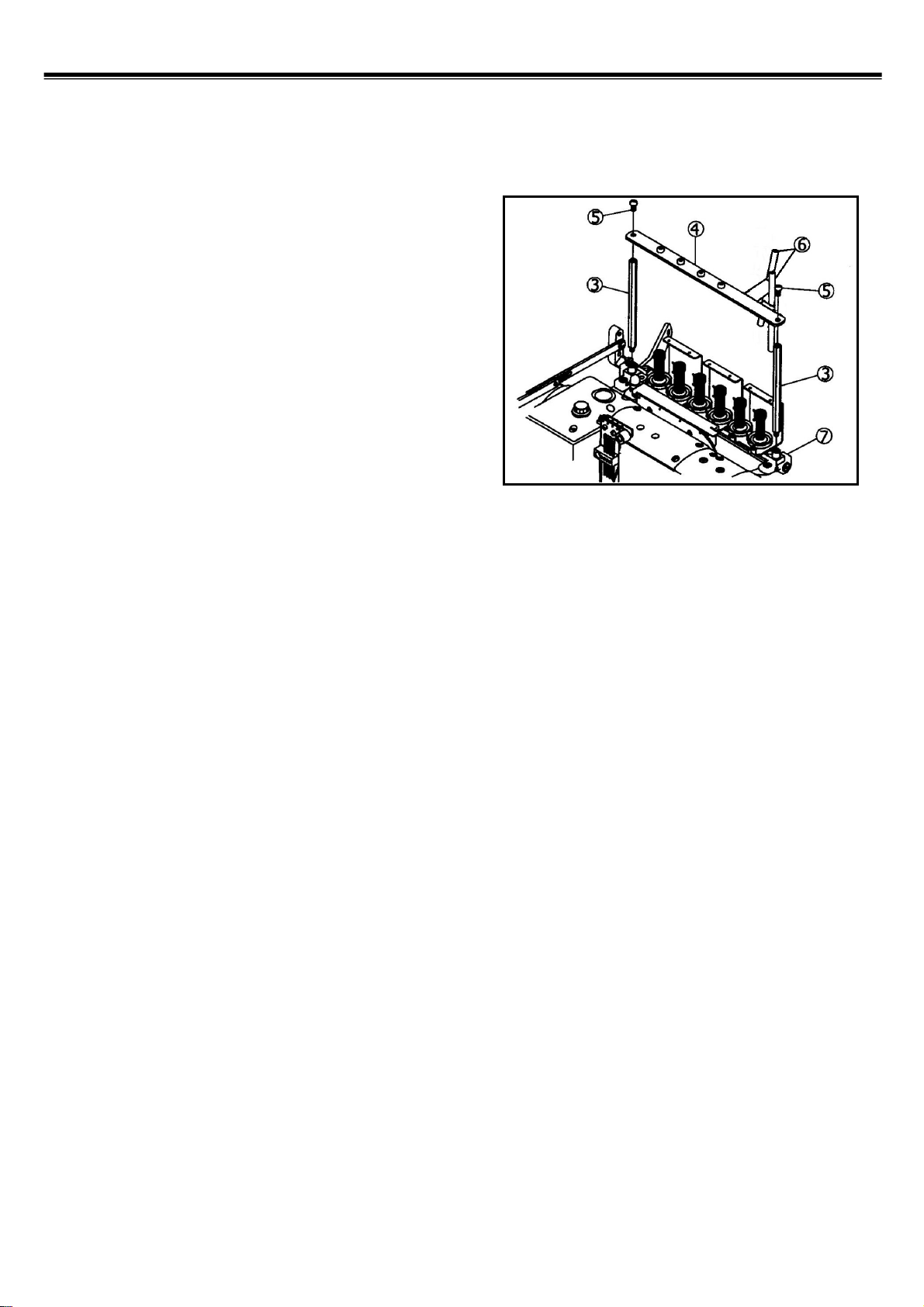

1.4 其它部份

1.4

Other parts

機頭線架

將線架支柱

○

3裝在線架固定座

○

7,再將過線架

○

4用

螺絲

○

5鎖在線架支柱

○

3,調整過線桿

○

6,使穿線平

順,不致於線會糾結在一起。(Fig.12)

Setting thread eyelets:

Stand the thread guide plate supports

○

3on the

thread tension support

○

7and fix the thread guide

plate

○

4on the supports

○

3with the screws

○

5.

Adjust the thread pipes

○

6to thread smoothly without

entangling. (Fig. 12) Fig.12

2.

Sewing speed and rotating direction of pulley

馬達轉速和皮帶輪轉動方向

8

機器轉速最高速為 4200R.P.M,平常使用 3800R.P.M。

在前 200 個小時(約一個月)使用 3000-3360R.P.M 左右的速度,這樣機器使用時間可以延長。

The sewing speed is 4200 rpm at the maximum and3800rpm is usual.

Run a new machine at a speed of 15-20% lower than maximum sewing speed during the first 200

hours(for about one month) so that the machine can offer

a long service life in good condition.

注意:

如果運轉方向相反,油無法供應,會造成機器損壞。

CAUTION

If rotaing in reverse direction, oil can not be supplied properly. It can cause the machine damage.

3.

Lubrication

潤滑

9

3.1 潤滑油

3.1

Lubricating oil

注意:

絕對不要在油內加入任何添加物(劑),否則將惡化

油的品質,並損害機器。

CAUTION

Never add additives to the oil.

If added, it can cause the deterioration of the oil and the machine damage.

3.2 潤滑系統

3.2

Lubricating

(1) 旋開油塞螺絲

○

1和

○

2然後加油。(Fig.13)

(2) 從油孔

○

1加油直到油量到

○

3最上方的紅線,從

油孔

○

2加油直到油量到

○

4最上面的紅線。

(Fig.14)

(3) 使用機器前檢查油水平。如果沒到水平線要加油

。

(4) 當機器在使用中時,從油鏡

○

5和

○

6檢查油有無

供應。

Fig.13

(1)Remove the plug screws

○

1and

○

2indicated

”OIL”and supply oil.

(2)From the plug screw

○

1,supply oil until the oil level

indicator top reaches the upper line in the oil sight

gauge

○

3.From the plug screw

○

2,supply oil to the

upper line in the oil sight gauge

○

4.(Fig.14)

(3)Check the oil level between the lines in the oil sight

gauge

○

3and

○

4before running a machine. If it is

under the lines, supply oil.

(4)Check the oil splashes from the nozzle inside the

oil sight top windows

○

5and

○

6when starting to run Fig.14

a machine.

3.

Lubrication

潤滑

10

注意:

太多或太的油會造成機器漏油和機器故障。維持油的水平在 2條紅線之間。

CAUTION

Too much oil or not enough oil can cause oil leakage and machine trouble. Be sure to keep the oil

level between the lines.

3.3 啟動注油

3.3

Priming oil

裝新機器或使用久未使用的機器,如果油沒有循環完

整,需移除幫浦上的油塞螺絲

○

1,注入油後裝回螺

絲再使用機器。(Fig.15)

Prime oil if oil does not circulate completely when

installing a new machine or running a machine which

has not been used for a while.

Remove the plug screws

○

1of the pump driven gear

to prime oil. Run a machine after reseting them

○

1. Fig.15

(Fig.15)

3.

Lubrication

潤滑

11

3.4 補充油

3.4

Replenishing oil

在箭頭處需滴一些油潤滑。如果油漏在壓腳和上刀周

圍會導致沾汙布,要確實的把油擦乾淨。

(Fig.16,17,18)

Replenish a drop of oil from the points indicated

arrowswith an oiler (accessories) if needed.

If oil leaks around the presser foot and the upper knife,

it can cause oil stain on the material. Be sure to wipe

it completely. (Fig.16,17,18) Fig.16

Fig.17 Fig.18

3.5 更換油

3.5

Changing oil

3.5.1 換油時機

新機使用 200 小時(約使用一個月)後,要更換新油,之後每年換新油 1-2 次。

3.5.1Period of changing :

When using a new machine, change the lubricating oil after running for 200 hours(for about one

month). After that, change the oil once or twice a year.

3.

Lubrication

潤滑

12

3.5.2 換油程序

(1) 分別在螺絲

○

1和

○

2下面放置接油容器。

(2) 拆下螺絲

○

1和

○

2後油會自行流出。

(3) 裝回螺絲

○

1和

○

2。

(4) 注入新油。

(5) 裝上皮帶蓋。

Procedrue for changing :

(1) Set containers received the oil under the screws

○

1and

○

2respectively.

(2) After removing screws

○

1and

○

2,the oil is drained. Fig.19

(3) Reset the screws

○

1and

○

2.

(4) Fill the new oil.

(5) Reset the belt cover.

注意:

勿使油弄髒皮帶以及機器轉輪。

NOTE

Be careful not to soil the V-belt and the machine

pulley with the oil.

Fig.20

4.

Proper operation

使用說明

13

4.1 車針系列

4.1 Needle system

4.1.1 縫紉機用針

4.1.1

Sewing needle :

格洛茲貝克牌(Groz-Beckert) UY118GKS

風琴牌(Organ) FLX118GCS

表格二

提醒:

請選用適合的針給不同的材料。有些尺寸並沒有販售,請從目錄上確認尺寸。

4.1.2 假針

4.1.2

Retainer needle :

四支針配合一支假針。

One retainer needle is used with four sewing needles.

格洛茲貝克牌(Groz-Beckert) 36211 , 36211A

風琴牌(Organ) FLG-1 , FLG-8

表格三

提醒:

請選用適合的假針去使用不同的材料。有些尺寸並沒有販售,請從目錄上確認尺寸。

Note:

Select the proper sewing needle in size depending on thickness and type of material.

Japanese

standard

日本規格

8 9 10

11

12

14

Metric

Standard

公制規格

60

65

70

75

80

90

Japanese

standard

日本規格

8 9 10 11 12

Metric

Standard

公制規格

60 65 70 75 80

4.

Proper operation

使用說明

14

4.2 針的安裝

4.2

Installing needle

(1) 旋轉轉輪將針抬到最高點。

(2) 放鬆螺絲

○

1。(Fig.21)

(3) 平面擺在前方將新針放入針鎦內最頂端,然後鎖

緊螺絲

○

1。

(1) Rotate the handwheel to raise the needles at the

highest point.

(2) Loosen the screws

○

1and pull the needles down.

(3) Face the flat parts front, insert new needles into

the needle clampas far as they will go. Tighten Fig.21

them with the screws

○

1securely.

注意:

安裝針之前一定要先把馬達關掉,並確定馬達不會轉動。

WARNING

Before installing the needles, always turn the motor switch OFF and check that the motor has already

stopped.

4.

Proper operation

使用說明

15

4.3 線

4.3

Threading

先用易穿的線從 ABCDEF 孔穿至針鎦前,然後結上要用的線拉到針前,把結剪掉。

線正確位置(Fig.28)。

A , B , C , D:針線

E:上飾線

F:下勾針線

When threaded, pull the thread out until it is in front of the needles. Then cut off the knot before needle

eye to rethread. When threaded, pull the thread out until the knot is out. Then cut off the knot.

A, B, C, D : Needle thread

E : Top cover thread

F : Lower looper thread

提醒:

當抬起壓腳時,線架組會平穩的放開,此時可輕鬆的將線拉過。

穿下鉤針線時不須把針板拆掉。

Note:

When raising presser foot, thread tension will be released to take up smoothly.

Improper threading can cause thread breakage, skip stitch, and uneven stitch.

注意:

穿線前一定要先把電源關掉,並確定馬達完全停止。

WARNING

Before threading, always turn the motor switch

OFF and check that the motor has already

stopped.

Fig.22

4.

Proper operation

使用說明

16

4.4 線鬆緊

4.4

Thread tension

調整線架上的鬆緊度是靠螺母

○

1-

○

6取決於布線寬度

和其它狀況。(Fig.29)

○

1-

○

4:針的線(

○

1:右針,

○

4:左針)

○

5:上網線

○

6:下網線

!如果調緊線時,以順時間方向調下

○

1-

○

6螺絲。

!如果調鬆線時,以逆時間方向調上

○

1-

○

6螺絲。

Adjust the thread tension with the tension adjusting

nuts

○

1-

○

6depending on fabric type, thread type, Fig.23

seam width, stitch length, and other sewing conditions.

○

1-

○

4: needle threads (

○

1: right needle,

○

4: left needle)

○

5 : top cover thread

○

6 : looper thread

● To tighten the thread tension, turn the nuts

clockwise.

● To loosen the thread tension, turn nuts counter-

clockwise.

4.5 調整壓腳壓力

4.5

Pressure of presser foot

放鬆螺母

○

7然後用壓腳柱螺帽

○

8來調壓力。(Fig.24)

!增加壓腳壓力時,順時間調整螺帽

○

8。

!減壓腳壓力時,逆時間調整螺帽

○

8。

Loosen the lock nut

○

7and turn the adjusting screw

○

8

to adjust the pressure.

● To increase the pressure, turn the adjusting screw

○

8clockwise.

● To decrease the pressure, turn the adjusting screw

○

8counterclockwise. Fig.24

提醒:

儘可能保持壓腳壓力在最鬆的狀態,使布在針板上更加平穩。

Note:

Keep the pressure as low as possible for stable stitches.

4.

Proper operation

使用說明

17

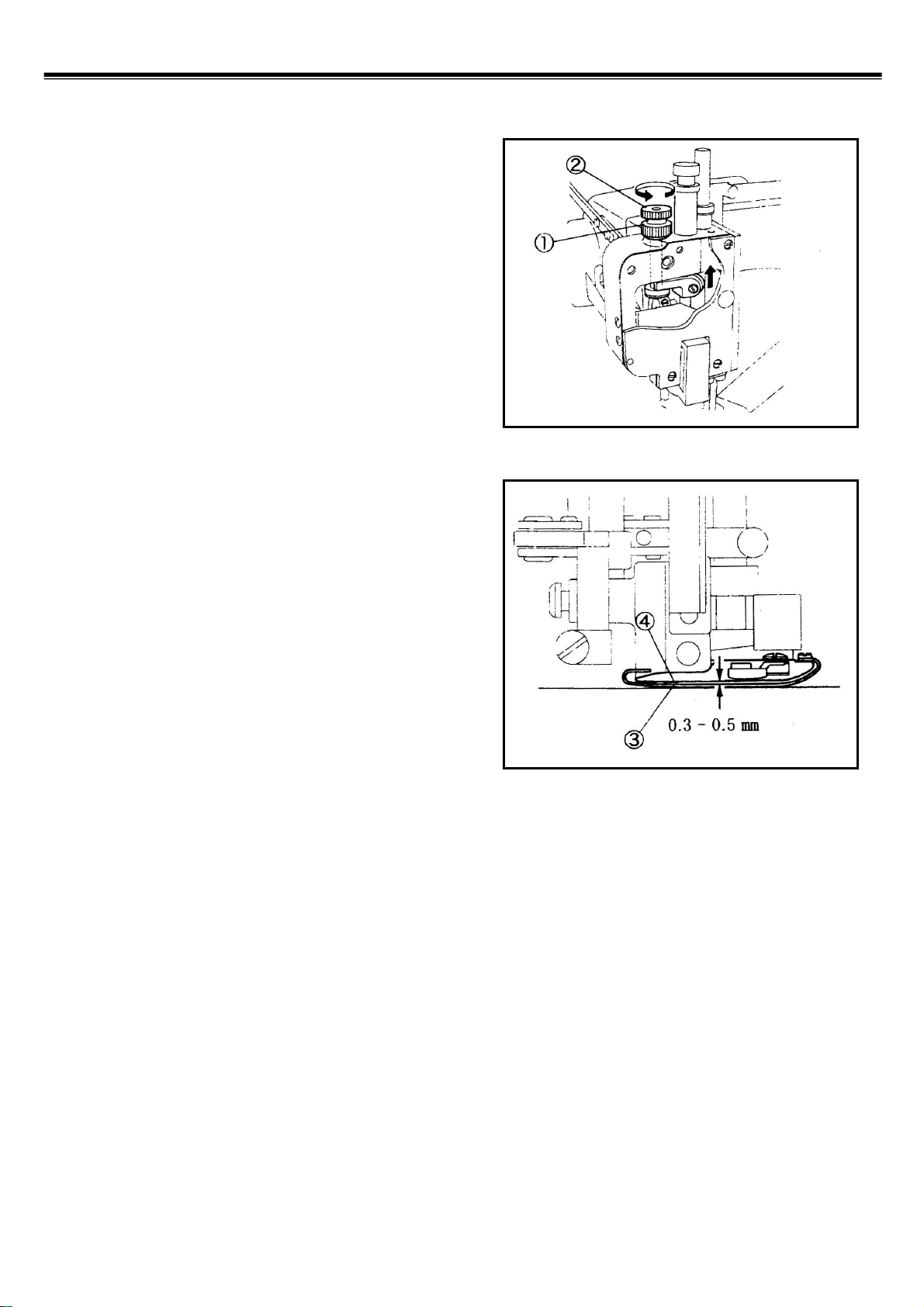

4.6 調整壓腳高低

4.6

Up-and-down poition of presser foot

輕微的調高或降低壓腳會有明顯的成效。

Following effective points will be obtained by slightly

raising the presser foot.

!預防勾齒抓痕。

!改善壓腳彈片的耐久度。

!增減壓腳彈片的壓力度。 Fig.25

!減噪音和振動。

!可細微的調整針織的寬度。

!Prevention of fabric jam

!Prevention of feed scratch mark

!Improvement of durability of presser foot spring

plate

!Reduction of vibration and noise

!Available for fine adjustment of lapped fabric width

(1) 針在最底點的位置。

(2) 鬆開螺絲

○

1,然後逆時間旋轉調整螺母

○

2抬起 Fig.26

壓腳。(Fig.25)

(3) 在壓腳

○

4和壓腳彈片

○

3之間調整出 0.3-0.5mm

的間隙。(Fig.26)

(4) 把螺母

○

1鎖回去。

(1) Position the needle at the lowest point.

(2) Loosen the lock nut

○

1and run the adjusting nut

○

2counterclockwise to raise the resser foot

(3) Adjust the clearance between the botton

○

4

of the presser foot and the presser foot spring

plate

○

3to 0.3-0.5 ㎜

(4) Tighten the lock nut

○

1securely.

4.

Proper operation

使用說明

18

4.7 調整差動

4.7

Adjusting differential feed dog

(1) 移動調整桿向右或左去調整差動桿

○

5在刻度“4”

和刻度“5”之間是相同的動作和差動。即主牙和

差動牙的運作相同。(Fig.27)

(2) 螺絲

○

6是用來固定調整桿

○

5和保持差動的多或

。

(1) Move the differential feed operating lever

○

5right or

left to adjust differential feed dog.

The lever

○

5between the graduations”4” and “5”

makes the equal movement of the main and the

differential feed dogs. Fig.27

(2) The screw

○

6is for fixing the lever

○

5and keeping

the differential movement adjusted.

!一般差動比:調整桿

○

5調到刻度“9”的位置。

!反差動比:調整桿

○

5調到刻度“1”的位置。

!To make normal differential, move the lever

○

5 to “9” .

!To make reverse differential, move the lever

○

5 to “1”

注意:

在調整機器之前,一定要先把電源關掉,並確定馬達完全停止。

WARNING

Before adjusting, always turn the motor switch OFF and check that the motor has already stopped.

Table of contents

Other Hikari Sewing Machine manuals

Hikari

Hikari H8800E User manual

Hikari

Hikari H99S User manual

Hikari

Hikari H9300 Series User manual

Hikari

Hikari HX68S Series User manual

Hikari

Hikari HX8V Serles User manual

Hikari

Hikari HX6800TD User manual

Hikari

Hikari HW782TA Owner's manual

Hikari

Hikari HW762T Owner's manual

Hikari

Hikari H9990 User manual

Hikari

Hikari H8800-7P User manual