Introduction 2/36

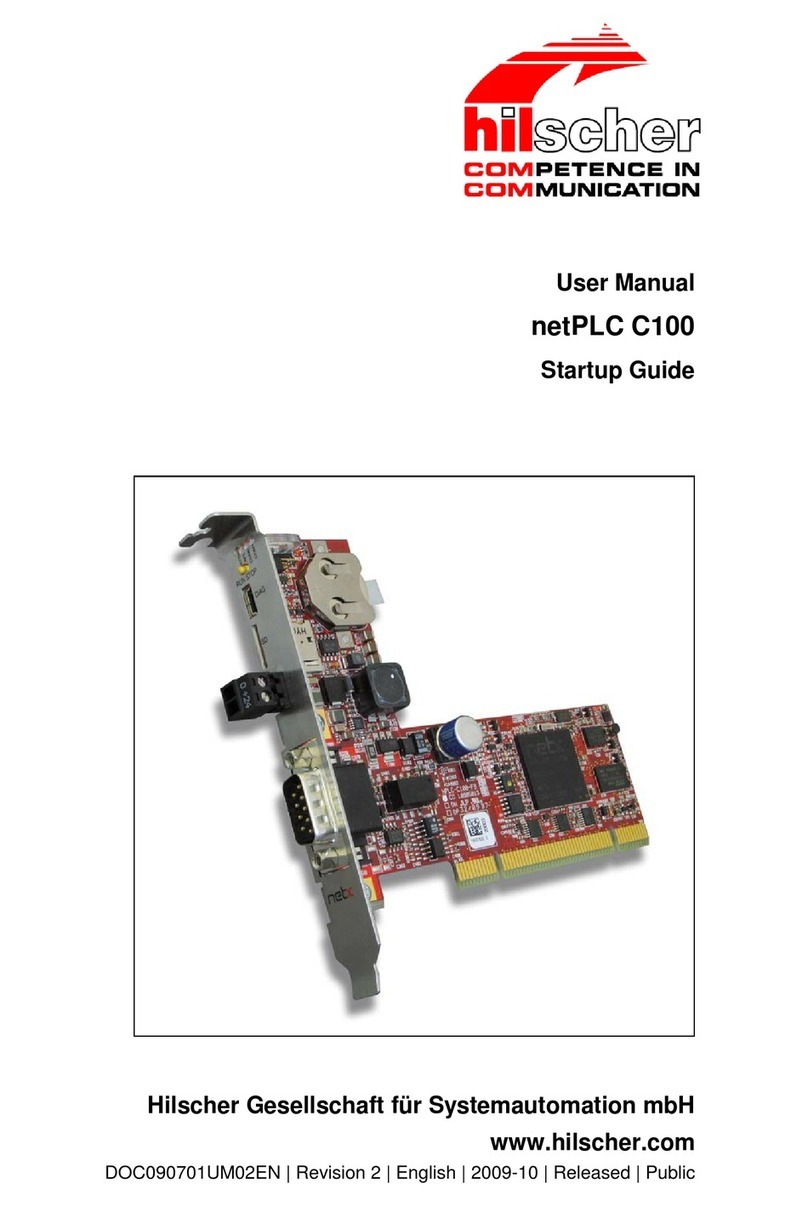

Slot PLC NPLC-C100 | Hardware Installation

DOC120112UM02EN | Revision 2 | English | 2014-01 | Released | Public © Hilscher, 2009-2014

Table of Contents

1INTRODUCTION.........................................................................................................4

1.1 About the User Manual...............................................................................................4

1.1.1 List of Revisions ...................................................................................................4

1.1.2 Reference to Hardware, Firmware, Driver and Software.....................................5

1.1.3 Conventions in this Manual..................................................................................6

1.2 Legal Notes.................................................................................................................7

1.2.1 Copyright..............................................................................................................7

1.2.2 Important Notes....................................................................................................7

1.2.3 Exclusion of Liability.............................................................................................8

1.2.4 Warranty...............................................................................................................8

1.2.5 Export Regulations...............................................................................................9

1.2.6 Registered Trademarks........................................................................................9

1.3 Licenses......................................................................................................................9

2SAFETY ....................................................................................................................10

2.1 Safety Instructions....................................................................................................10

2.2 Intended Use ............................................................................................................10

2.3 Personnel Qualification.............................................................................................10

2.4 References Safety....................................................................................................10

2.5 Commitment to read and understand the Manual ....................................................11

2.6 Safety Instructions to avoid Personal Injury..............................................................11

2.6.1 Electrical Shock Hazard .....................................................................................11

2.7 Labeling of Safety Instructions..................................................................................12

2.8 Safety Instructions....................................................................................................13

2.8.1 Electrical Shock Hazard .....................................................................................13

2.9 Property Damage Messages ....................................................................................13

2.9.1 Electrostatically sensitive Devices......................................................................13

3DESCRIPTION AND REQUIREMENTS ...................................................................14

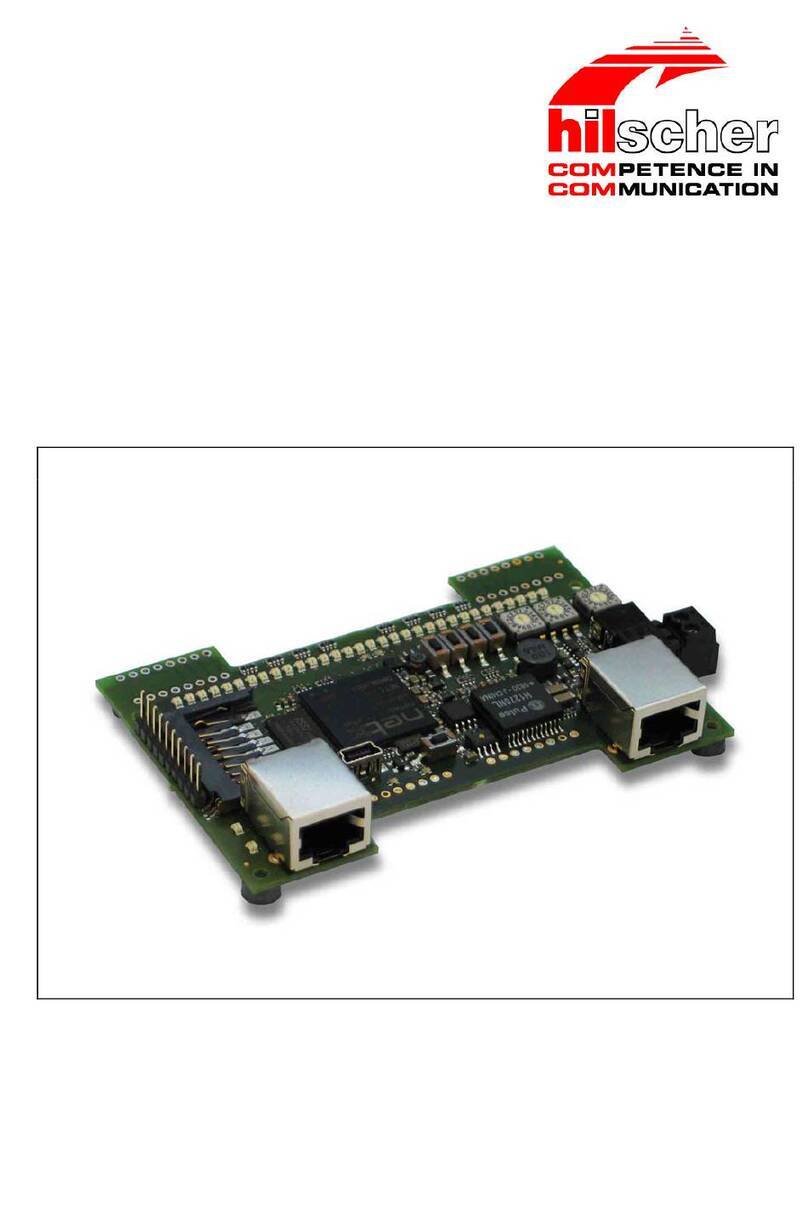

3.1 Description................................................................................................................14

3.2 System Requirements ..............................................................................................15

3.2.1 System Requirements PC..................................................................................15

3.3 Requirements for Operation .....................................................................................15

3.3.1 Slot PLC NPLC-C100-XX...................................................................................15

4DEVICE DRAWINGS................................................................................................16

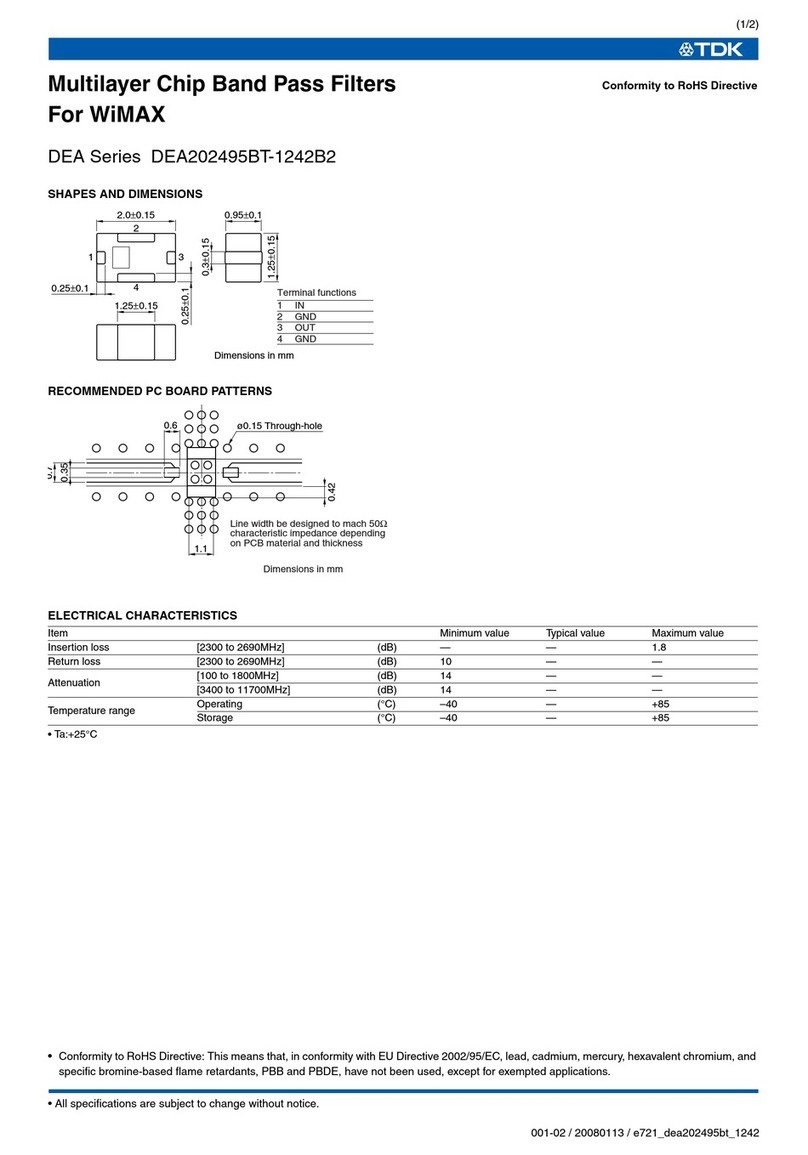

4.1 Device Drawing NPLC-C100-DP..............................................................................16

4.1.1 Cover NPLC-C100-xx.........................................................................................17

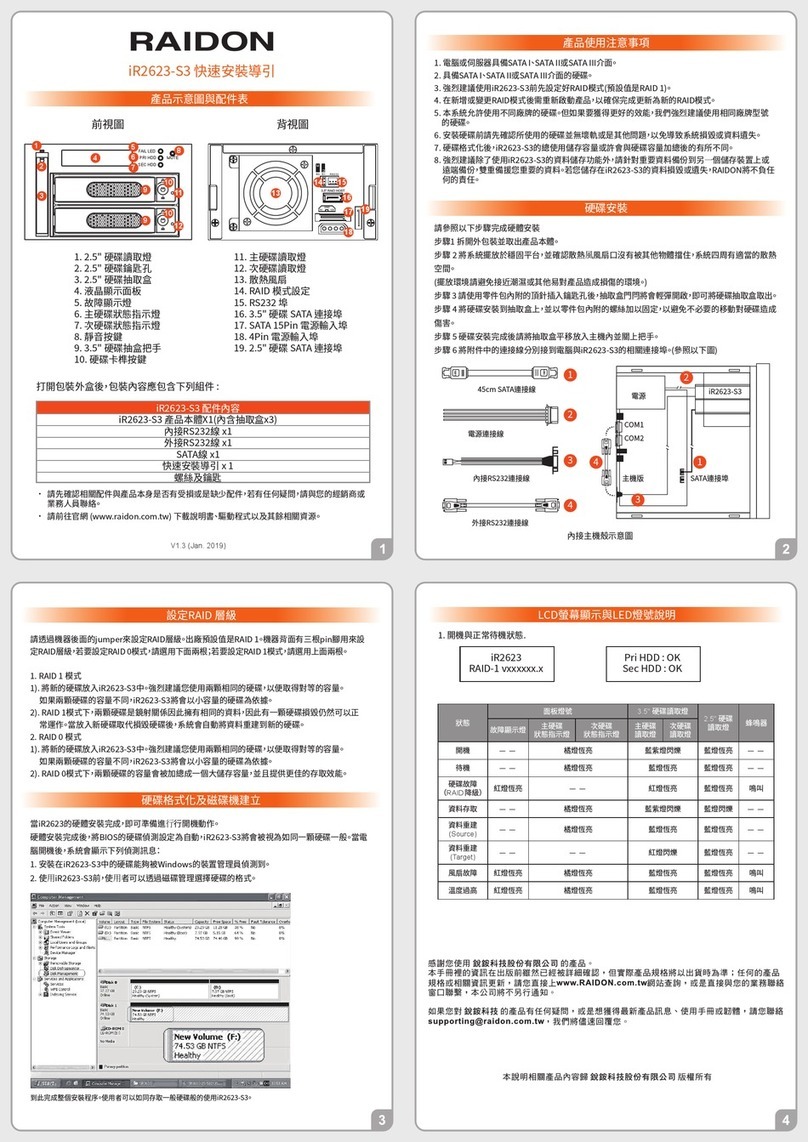

5INSTALLING HARDWARE (SLOT PLC)...................................................................18

5.1 Safety Messages on Personal Injury........................................................................18