8 Care and maintenance

8.1 Cleaning and drying

1. Blow dust off the lenses.

2. Donottouchtheglasswiththefingers.

3. Use only a clean, soft cloth for cleaning. If necessary,

moisten the cloth slightly with pure alcohol or a little

water.

NOTE Do not use any other liquids as these may

damage the plastic components.

4. Observe the temperature limits when storing your

equipment. This is particularly important in winter

/summeriftheequipmentiskeptinsideamotor

vehicle (30°C to +60°C / -22°F to +144°F).

8.2 Storage

Remove the tool from its case if it has become wet.

The tool, its carrying case and accessories should be

cleaned and dried (at maximum 40°C / 104°F). Repack

the equipment only once it is completely dry.

Check the accuracy of the equipment before it is used

after a long period of storage or transportation.

8.3 Transport

Use the Hilti toolbox or packaging of equivalent quality

for transporting or shipping your equipment.

Never transport the tool in an unpacked state. Always

ensure that it is well packed.

8.4 Hilti Calibration Service

We recommend that the tool is checked by the Hilti Cal-

ibration Service at regular intervals in order to verify its

reliability in accordance with standards and legal require-

ments.

Use can be made of the Hilti Calibration Service at any

time, but checking at least once a year is recommended.

The Calibration Service provides confirmation that the

tool is in conformance, on the day it is tested, with the

specifications given in the operating instructions.

The tool will be readjusted if deviations from the man-

ufacturer’s specification are found. After checking and

adjustment, a calibration sticker applied to the tool and

a calibration certificate provide written verification that

the tool operates in accordance with the manufacturer’s

specification.

Calibration certificates are always required by companies

certified according to ISO 900x.

Your local Hilti Center or representative will be pleased

to provide further information.

8.5 Checking and adjusting the tool

In order to ensure compliance with technical specifica-

tions, the tool must be checked at regular intervals (at

least before each relevant major job).

NOTE

All tools are checked and calibrated before shipping.

Nevertheless,thetoolmustberecheckedandadjusted

if necessary before use.

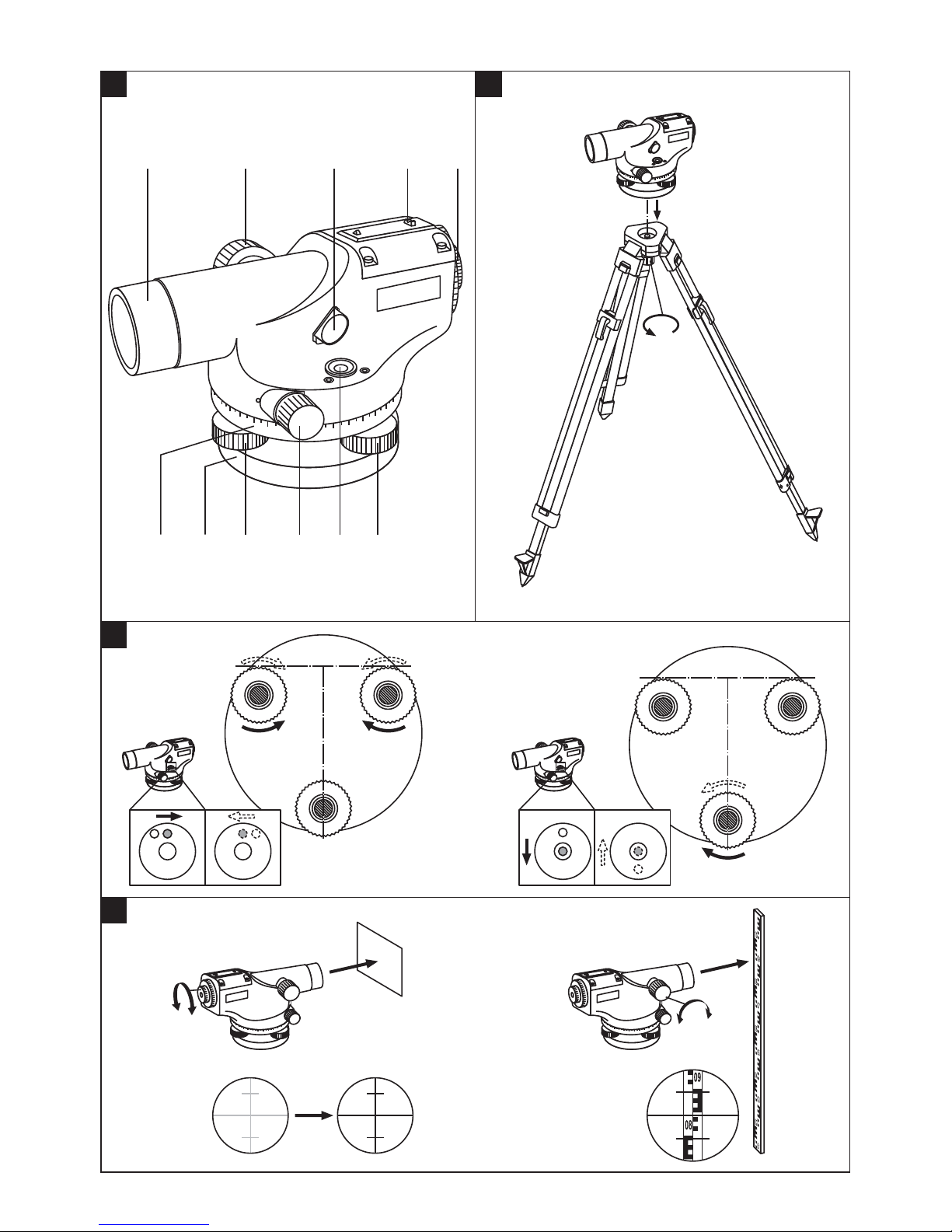

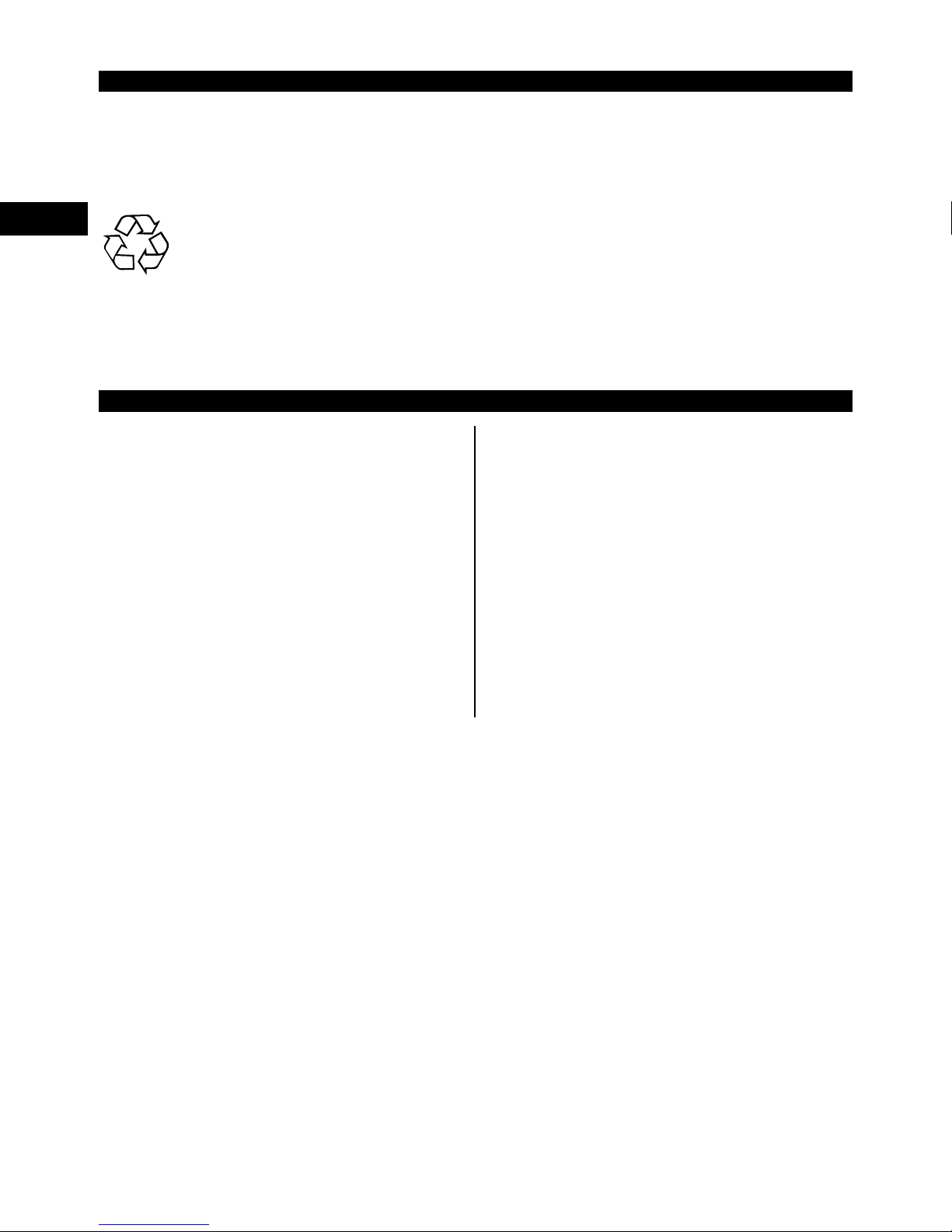

8.5.1 Adjusting the circular bubble level 8

1. Set up the tripod with the tool fitted as described in

sections 6.1 and 6.2.

2. Rotate the POL 10/15 through 180° and check

whether the bubble in the circular bubble level is

still centered.

If the bubble is no longer centered, the bubble level

must be readjusted.

3. Use an Allen key to turn the screws on the circular

bubble level until the error is corrected by half.

4. Level the tool by turning the footscrews until the

bubble is centered.

5. Repeat steps 2-3-4 several times until the bubble

remains centered even after rotating the POL 10/15.

NOTE Depending on the degree of misadjustment,

it may be necessary to repeat this procedure several

times.

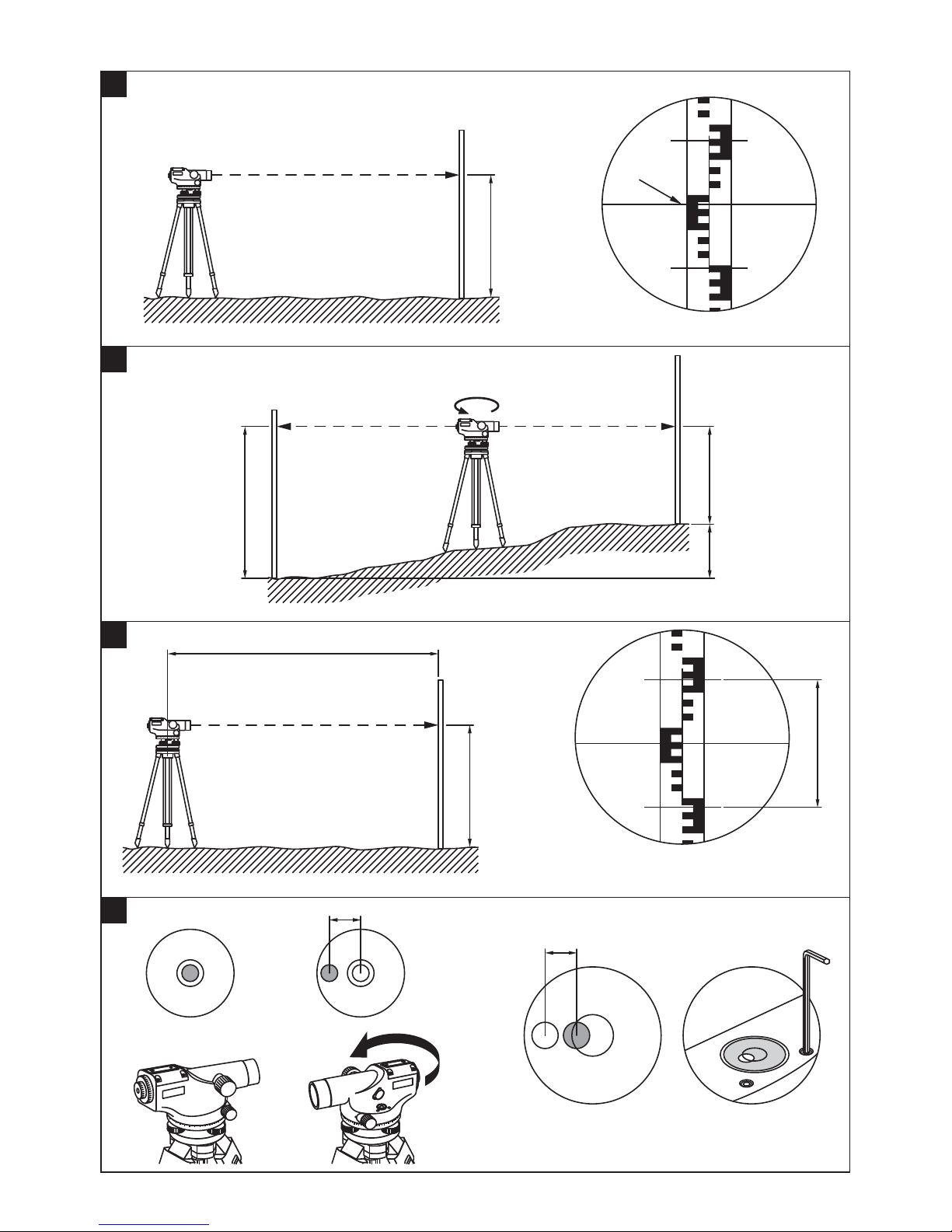

8.5.2 Checking the target line 9

NOTE

Before checking the target line, make sure that the bubble

level has been adjusted in accordance with section 8.5.1.

1. Select two points (A and B) at a distance of approx.

30 m (98 ft) from each other.

2. Set up the tripod with the tool fitted as described in

sections 6.1 and 6.2.

3. Check that the POL 10/15 is set up at the mid point

between points A and B.

4. Stand the leveling staffs on the measuring points.

5. Read the heights of points A and B from the lev-

eling staffs and calculate the difference in height

(ΔH₁ = A₁-B₁).

e.g. ΔH₁= 2.137 m – 1.845 m = 0.292 m

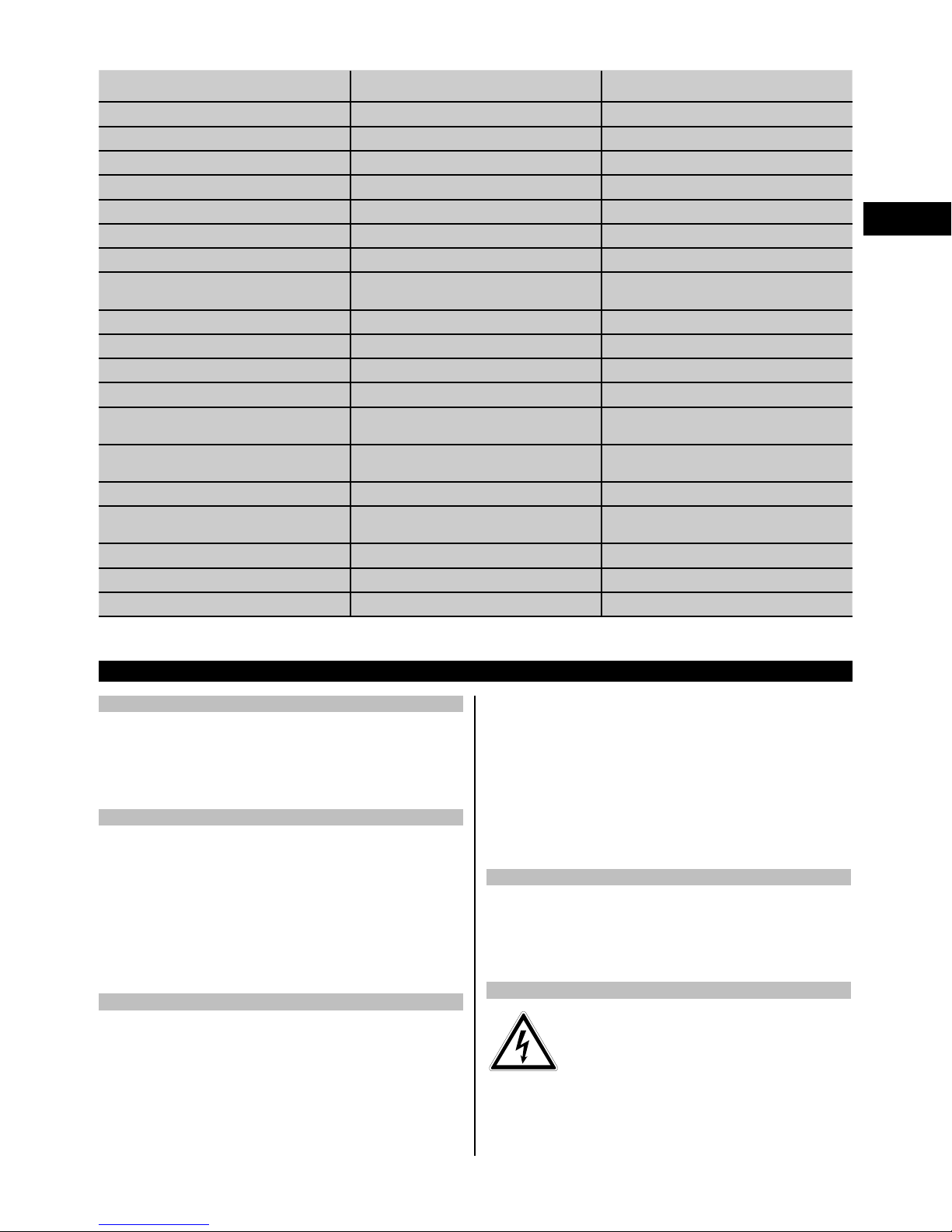

6. Now set up the tripod with the POL 10/15 at a

distance of 1 m (3.3 ft) from point A, as described in

sections 6.1 and 6.2.

7. Read the heights of points A and B from the lev-

eling staffs and calculate the difference in height

(ΔH₂ = A₂-B₂).

e.g. ΔH₂= 2.025 m – 1.755 m = 0.270 m

IfΔH₁-ΔH₂>3mm(0.12in),thenthetargetline

must be adjusted.

e.g. 0.292 m – 0.270 m = 0.022 m ΔH₁ - ΔH₂ > 3

mm (0.12 in)

Adjust the target line until B2 = A2 - ΔH₁.

e.g. nominal value B2 = 2.025 m - 0.292 m = 1.733

m

8.5.2.1 Adjusting the target line

1. Remove the cover from the eyepiece.

2. Aim the POL 10/15 at staff B and adjust the cross

hairs by turning the knob until the middle line indic-

ates the nominal value (e.g. B2 = 1.733 m).

3. Repeat the checking and adjustment procedure until

ΔH₁ - ΔH₂ < 3 mm (0.12 in).

en

11

Printed: 08.07.2013 | Doc-Nr: PUB / 5070116 / 000 / 02