5

ENGLISH

1

PMML0277A - rev.0 - 12/2012

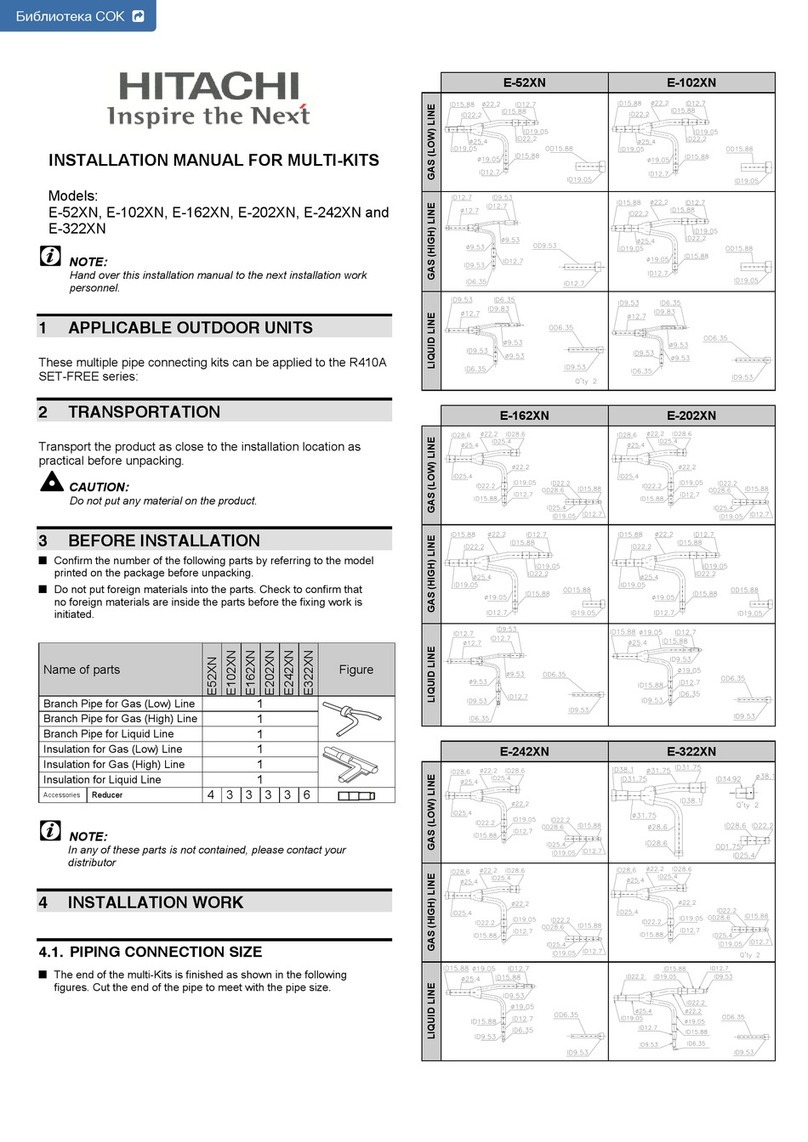

4.4 PIPING CONNECTION

INSTALLATION MANUAL FOR

MULTI-KITS

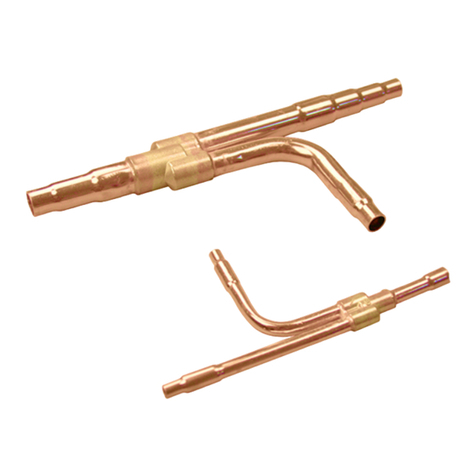

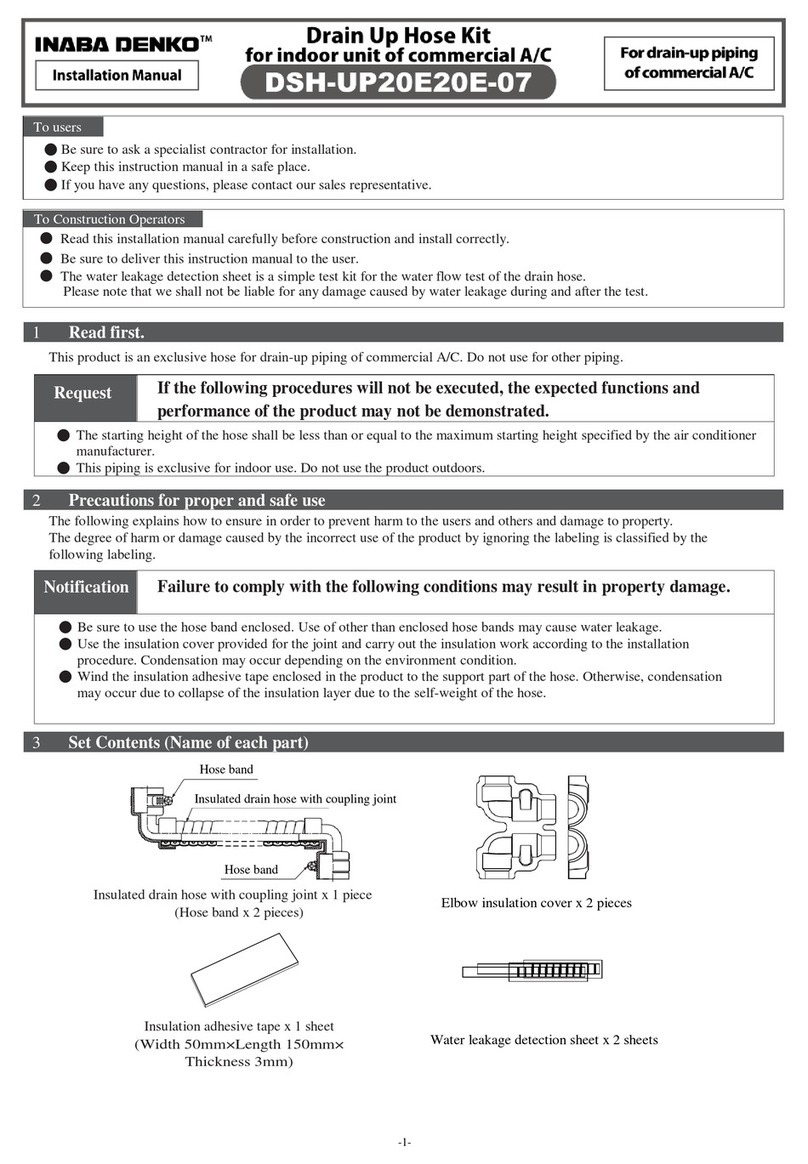

1 When the branched pipe size is smaller than 22.2mm of in-

ner diameter, a mini pipe cutter (eld-supplied) as follow is

required.

(mm)

Recommended mini pipe cutter Cleavable

size

Rotating

radius

(21)

(43)

(70)

less than 70mm

Ø5 - 28 (50)

2 Use clean copper pipes without any moisture or foreign mate-

rials on inner surface of pipes. When connecting refrigerant

pipe, cut the copper pipes with a pipe cutter as shown below.

Also blow the pipes with nitrogen or air to remain no dust insi-

de the pipe. Do NOT use a saw, a grindstone or others which

causes a large amount of cutting powder.

Pipe cutter

Pipe

Burring

Connection part

3 When cutting the pipe, secure the adequate depth for brazing

as shown in the following table.

(mm)

A: Outer diameter B: Minimum

depth

A

Over 5, Below 8 6

Over 8, Below 12 7

Over 12, Below 16 8

Over 16, Below 25 10

Over 25, Below 35 12

Over 35, Below 45 14

• Caution for Refrigerant Piping

When installing pipe through the wall, secure a cap at the end of

the pipe. INCORRECT

CORRECT

Attach a cap

or vinyl tape.

Hole

Do NOT place the pipe directly on the ground.

Attach a cap

or vinyl tape.

CORRECT INCORRECT

Attach a cap or

vinyl tape with

rubber band.

Rain water

can enter.

INCORRECT

CORRECT

4 Make sure that all stop valves of the outdoor unit are closed

completely.

5 Blow the inside of the pipes with nitrogen gas when brazing.

DANGER

Make sure that the refrigerant leakage test should be per-

formed. Refrigerant (Fluorocarbon) for the indoor unit is

non-ammable, non-toxic and odorless. However, if the re-

frigerant is leaked and is contacted with re, toxic gas will

generate. Also, because the uorocarbon is heavier than

air, the oor surface will be lled with it, which could cause

suffocation.

6 The air tight test pressure of this product is 4.15MPa.

7 Apply the insulation supplied with this multi-kits to each

branch (liquid side and gas side) with a tape. Also apply the

eld-supplied insulation to the eld-supplied pipes.

NOTE

When polyethylene foam is applied, a thickness of 10mm for li-

quid piping and 15mm to 20mm for gas piping is recommended.

(Use the insulation with heat resistance of 100oC for gas piping.)

Wrap the insultation tape without gap between

accessory insulation and eld-supplied insulation.

Insulation tape

(Field-Supplied)

Insulation for gas and

liquid line (Accessory)

Insulation (Field-Supplied)

Do NOT leave a

gap between the

insulation.

Fix the insulation with tape

(accessory) completely

after taping temporary.

CAUTION

• Perform the insulation work when the pipe surface tempera-

ture decreases to the room temperature. If insulation work

is performed immediately after brazing, insulation may melt.

• If the ends of pipe are open to the atmosphere for a while after

performing piping work, securely put caps or plastic bags over

the pipe ends for avoiding moisture or dust.

After installation, it is recommended to keep this manual by a

customer.