2 NEW PRODUCT GENERAL DATA

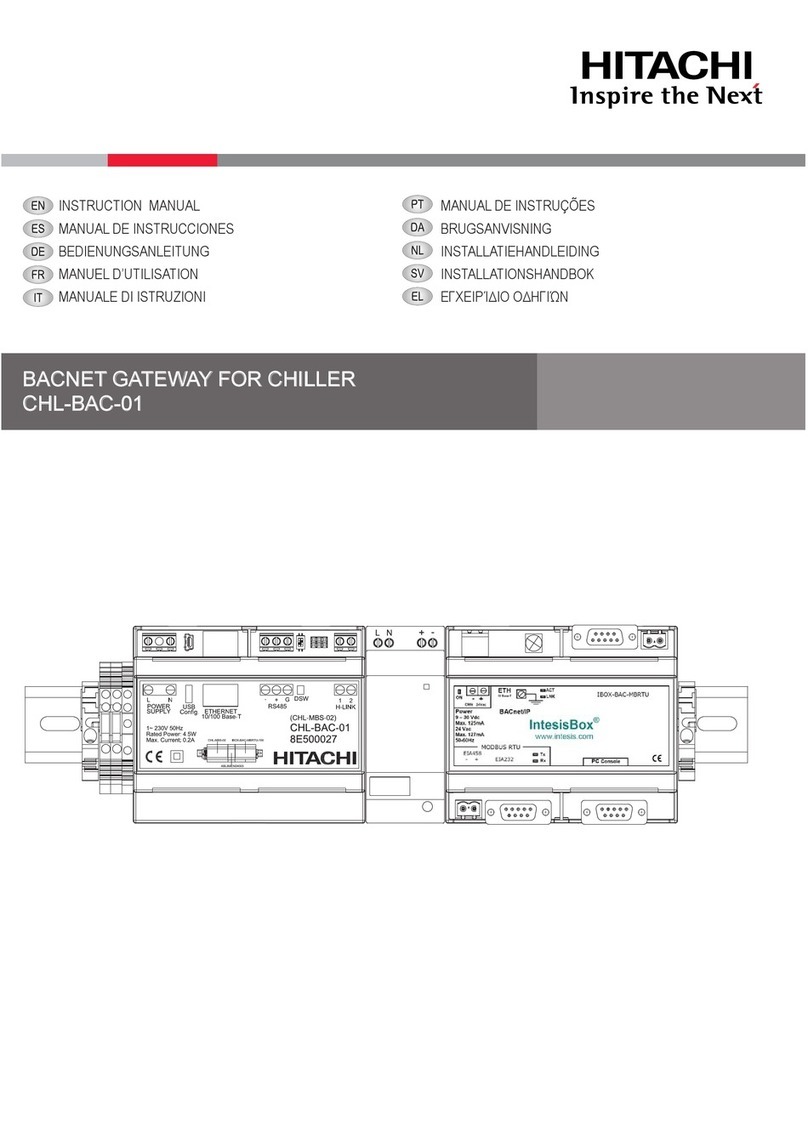

2.3.1 Hardware specications

Item Specications

Power supply 1~ 230 V ±10% 50 Hz

Consumption 4.5W (maximum)

Outer dimensions Width: 106 mm, Depth: 90 mm, Height: 58 mm

Weight 165 g

Assembling conditions Indoors (installation inside an enclosure with restricted access by a tool)

Ambient temperature 0~60 ºC

Humidity 20~85% (Without condensation)

2.3.2 Communication

RS485

Item Specications

Type Modbus RTU for HC-A(8/16/64)MB

Not available for HC-A64NET

Connector Serial Port RS485 (3 screw terminals)

Communication line Shielded twisted pair cable, with third wire (for the common), with polarity.

Communication system Half-duplex, multipoint serial connection

Communication method Non parity or odd/even parity selection. Data length: 8 bits – 1 stop bit

Baud rate transmission 19200/9600 Baud

Length Max. 1200 m according EIA-485

Ethernet

Item Specications

Type Modbus TCP for HC-A(8/16/64)MB

TCP/IP communication for HC-A64NET

Connector Ethernet (RJ45)

Communication line Two twisted pair cable CAT5 or better (T-568A/T-568B)

Communication system Full-duplex

Length Max. 100 m according IEEE 802.3

H-LINK

Item Specications

Communication with HC-A(16/64)MB: SET FREE, UTOPIA, CENTRIFUGAL and HEATING systems

HC-A8MB and HC-A64NET: SET FREE, UTOPIA and CENTRIFUGAL systems

Communication line Twisted pair shielded cable, non-polarity

Communication system Half-duplex

Communication method Asynchronous

Speed of transmission 9600 Bauds

Length of wiring 1000 m maximum (total length of H-LINK I/O bus)

Maximum number of gateways 1 Gateway (HC-A(8/16/64)MB) / H-LINK SYSTEM

Maximum number of IU

HC-A64MB → up to 64 * Indoor Units

HC-A16MB → up to 16 * Indoor Units

HC-A8MB → up to 8 * Indoor Units

HC-A64NET → up to 64* Indoor Units

NEW PRODUCT GENERAL DATA

PMML0351A rev.4 - 04/2020

2