1

C23UE004-2109

Content

1. TRANSPORTATION AND INSTALLATION ...................................................2

1.1 TRANSPORTATION ................................................................................................................ 15

1.2 INSTALLATION...................................................................................................................... 25

1.3 CONNECTION WITH THE CONTROLLER....................................................................................... 27

1.4 GROUNDING ....................................................................................................................... 29

1.5 ENVIRONMENTAL CONDITIONS................................................................................................ 30

1.6 STANDARD AND OPTIONAL EQUIPMENT LIST.............................................................................. 31

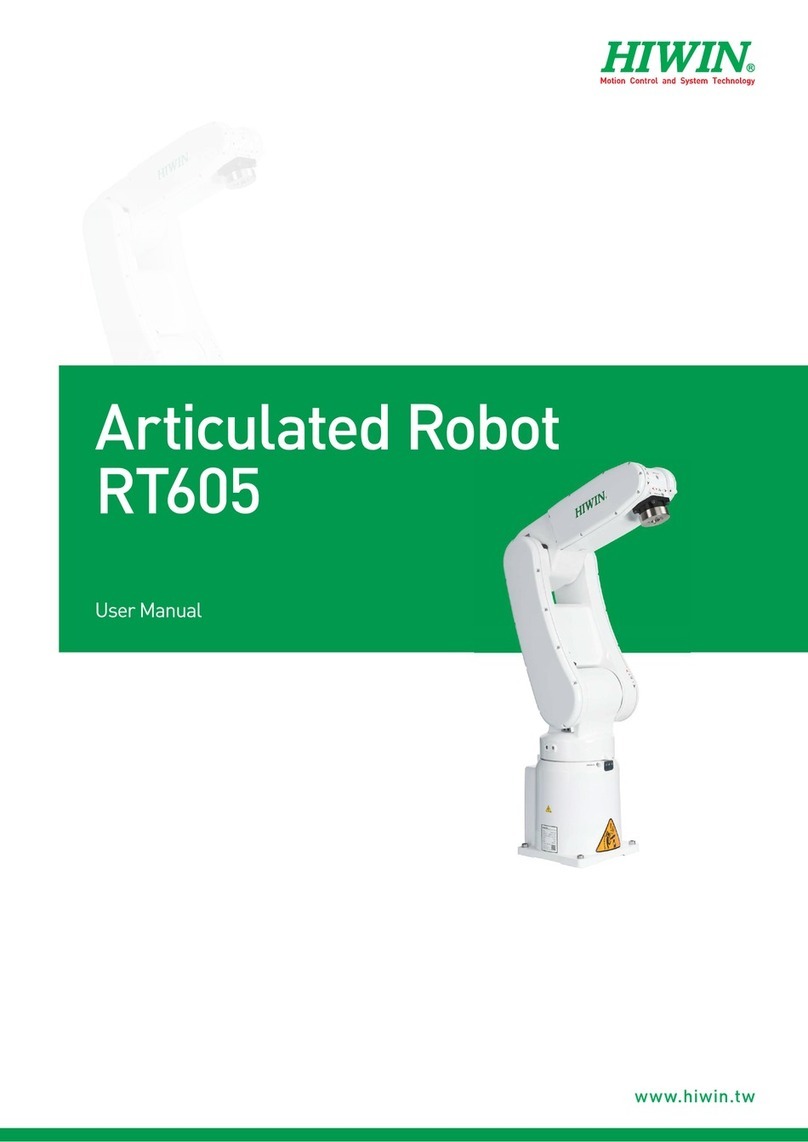

2. BASIC SPECIFICATIONS ...........................................................................34

2.1 DESCRIPTION OF MODEL NAME .............................................................................................. 34

2.2 LABELS ............................................................................................................................... 35

2.3 ROBOT SPECIFICATIONS ......................................................................................................... 37

2.4 OUTER DIMENSIONS AND MOTION RANGE ............................................................................... 39

2.5 WRIST LOAD CONDITIONS...................................................................................................... 44

3. EQUIPMENT MOUNTING INTERFACE......................................................49

3.1 END-EFFECTOR INTERFACE...................................................................................................... 49

3.2 MOUNTING SURFACE ON THE ROBOT ....................................................................................... 50

3.3 PNEUMATIC INTERFACE.......................................................................................................... 53

3.4 R-I/O INTERFACE ................................................................................................................. 55

4. CALIBRATION .........................................................................................59

4.1 ZERO-POSITION SETTING ....................................................................................................... 59

5. MANUAL BRAKE RELEASE DEVICE (OPTIONAL).......................................64

5.1 SAFETY PRECAUTIONS ........................................................................................................... 64

5.2 CONFIRMATION BEFORE USING ............................................................................................... 64

5.3 OPERATION ......................................................................................................................... 66

6. MAINTENANCE AND INSPECTION...........................................................68

6.1 MAINTENANCE ITEMS ........................................................................................................... 68

6.2 MAINTENANCE METHODS ..................................................................................................... 72

6.2.1 Backup Batteries Replacement ............................................................................................ 72

6.2.2 Timing Belt Replacement..................................................................................................... 73

6.2.3 Grease Replacement ............................................................................................................ 77

7. SAFETY CERTIFICATION ..........................................................................79