INDUSTRIE 4.0 Best Partner

Multi-Axis Robot

Pick-and-Place / Assembly /

Array and Packaging / Semiconductor /

Electro-Optical Industry /

Automotive Industry / Food Industry

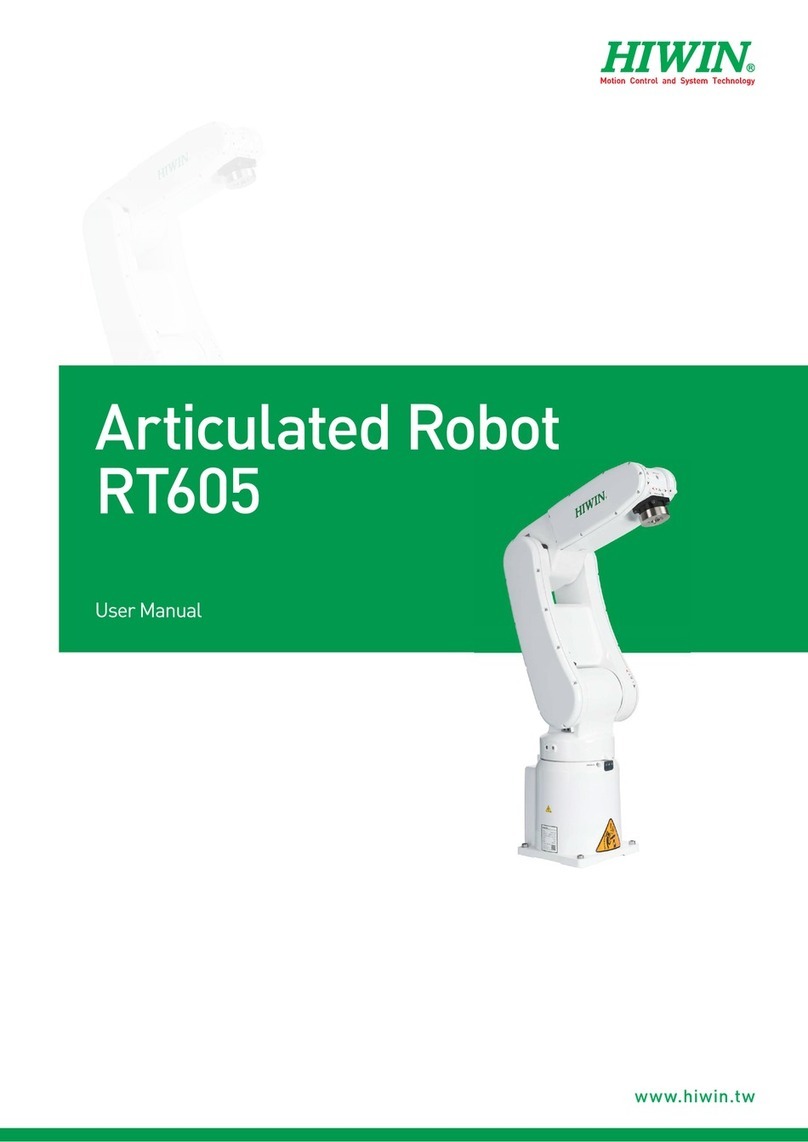

• Articulated Robot

• Delta Robot

• SCARA Robot

• Wafer Robot

• Electric Gripper

• Integrated Electric Gripper

• Rotary Joint

Single-Axis Robot

Precision / Semiconductor /

Medical / FPD

• KK, SK

• KS, KA

• KU, KE, KC

Torque Motor

Rotary Table

Medical / Automotive Industry /

Machine Tools / Machinery Industry

• RAB Series

• RAS Series

• RCV Series

• RCH Series

Ballscrew

Precision Ground / Rolled

• Super S Series

• Super T Series

• Mini Roller

• Ecological & Economical

Lubrication Module E2

• Rotating Nut (R1)

• Energy-Saving & Thermal-

Controlling (Cool Type)

• Heavy Load Series (RD)

• Ball Spline

Linear Guideway

Automation / Semiconductor / Medical

• Ball Type--HG, EG, WE, MG, CG

• Quiet Type--QH, QE, QW, QR

• Other--RG, E2, PG, SE, RC

Bearing

Machine Tools / Robot

• Crossed Roller Bearing

• Ballscrew Bearing

• Linear Bearing

• Support Unit

DATORKER®Robot Reducer

Robot / Automation Equipment /

Semiconductor Equipment / Machine Tools

• WUT-PO Type

• WUI-CO Type

• WTI-PH Type

• WTI-AH Type

AC Servo Motor & Drive

Semiconductor / Packaging Machine

/ SMT / Food Industry / LCD

• Drives--D1, D2T/D2T-LM, E1

• Motors--50W~2000W

Medical Equipment

Hospital / Rehabilitation Centers /

Nursing Homes

• Robotic Gait Training System

• Robotic Endoscope Holder

Linear Motor

Automated Transport /

AOI Application / Precision /

Semiconductor

• Iron-core Linear Motor

• Coreless Linear Motor

• Linear Turbo Motor LMT

• Planar Servo Motor

• Air Bearing Platform

• X-Y Stage

• Gantry Systems

Torque Motor &

Direct Drive Motor

Machine Tools

• Torque Motor--

TM-2/IM-2, TMRW Series

Inspection / Testing Equipment / Robot

• Direct Drive Motor--

DMS, DMY, DMN Series