HMS-VILGO LIFTY 5 User manual

1

LIFTY 5 user guide

Version 11/2020

250Kg / 40 stones

5

5

L

Li

if

ft

ty

y

2

LIFTY 5 user guide

Version 11/2020

3

LIFTY 5 user guide

Version 11/2020

November 2020 edition:

All rights reserved. Reproduction of these instructions in whole or in part in any form without express written

permission from HMS-VILGO is strictly prohibited except for private use.

Information is regularly updated in the latest instructions versions. This can not engage the responsibility of

HMS-VILGO in any way.

Warning :

The pics on this leaflet are not under contract.

Therefore, HMS-VILGO has the right to change the products inside anytime.

TABLE OF CONTENTS

1. PREAMBLE

………………………………………………………………………

page 4

2. DESCRIPTION

……………………………………………………………………

page 4-7

2.1. Where to use Lifty5

2.2. General description

2.3. Technical description

2.4. Dimensional characteristics

2.5. Labelling

3. LIFTY5 ASSEMBLING

………………………………………………………

page 7-14

3.1. Package contents

3.2. Lifty5 assembling (page 13)

3.3. Plugging

4. UTILISATION

…………………………………………………………………………

page 14-17

4.1. First use

4.2. Lifty5 use

4.3. Safety

4.4. Control box operating, battery charge

4.5. Storage instructions

5. ENTRETIEN ET MAINTENANCE

……………………………………………..

page 17-18

5.1. Weekly maintenance

5.2. Annual maintenance

5.3. Warranty

5.4. Recycling

Removable central leaflet.:

RECOMMENDED CHECKS

………………………………………………………

page 9

EVALUATION OF THE NUMBER OF HOIST OPERATING CYCLES

……

page 10

MAINTENANCE BOOK

………………………………………………………..…

page 11

SPARE PARTS LIST

…………...…………………………………

page 12

4

LIFTY 5 user guide

Version 11/2020

1. PREAMBLE

Only entitled staff who has read and understood these complete instructions can use Lifty5.

Always use Lifty5 with a person who can belay the patient in case of blackout of the patient or failure of the

hoist.

Use Lifty5 following the maintenance instructions (see Lifty5 maintenance paragraph). If you have any doubt

about Lifty5 operating, please call HMS-VILGO After Sales Service for a diagnostic before using the hoist on a

patient.

HMS-VILGO will not be responsible for damage if these warnings are not followed.

This manual contains all the technical information you need to make a good use of this product. This

information has been carefully checked by HMS-VILGO. This is not an exhaustive list and HMS-VILGO is not

responsible for any kind of mistakes or omissions.

2. DESCRIPTION

2.1. WHERE TO USE LIFTY5

The Lifty5 is a lifting device. It is used to transfer disabled or elderly people in:

- - home medical care for the transfer of a person toward an armchair, a WC seating or chair,

- - medical care small structure,

- - communities (old people’s home, convalescent home).

Do not use Lifty5 outdoors or on a surface whose declivity could make the patient fell down (>5°).

Before any use of the product :

1- Read the leaflet : It will inform you how to use the product securely and must

be at the disposal of the caring personnel.

2- Product cleaning and disinfection : Please see chapter 5.

3- Connection of the Lifty5 to the electrical network : Please see chapter 4.5

4- Make sure of the good working of all functions.

5

LIFTY 5 user guide

Version 11/2020

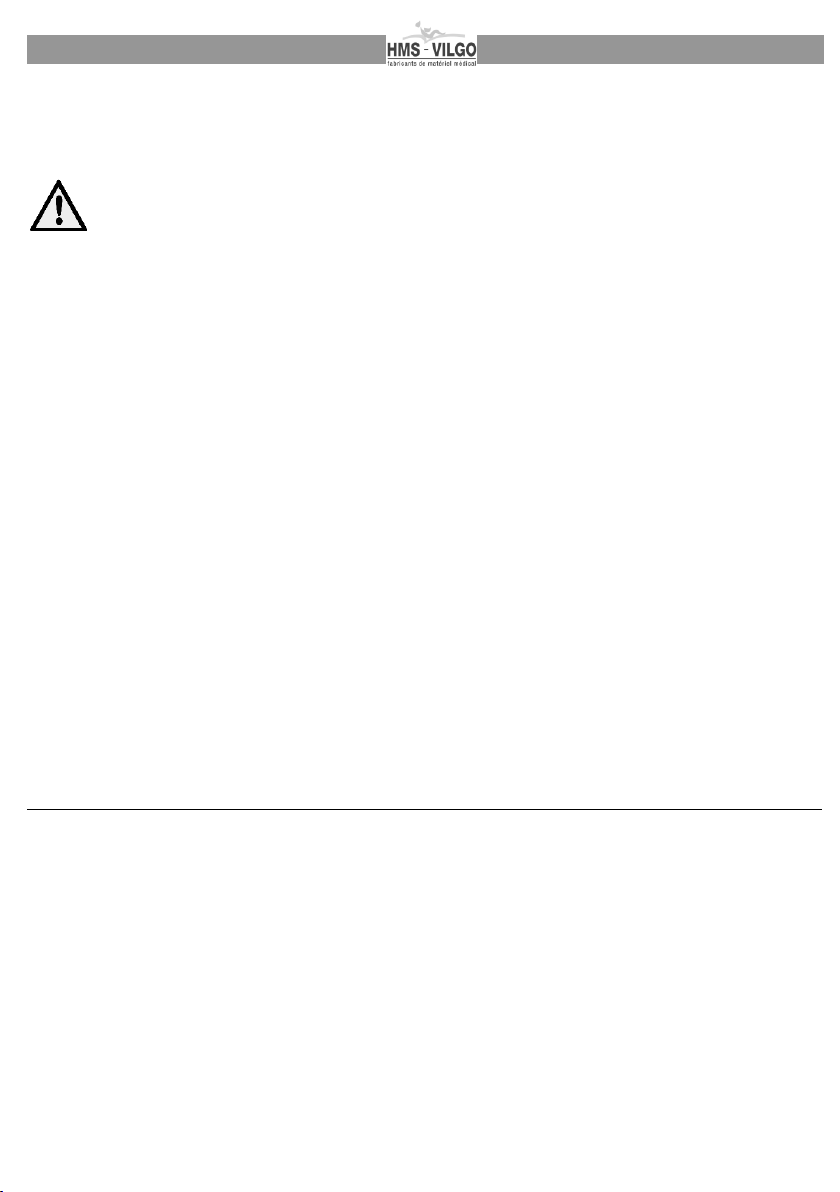

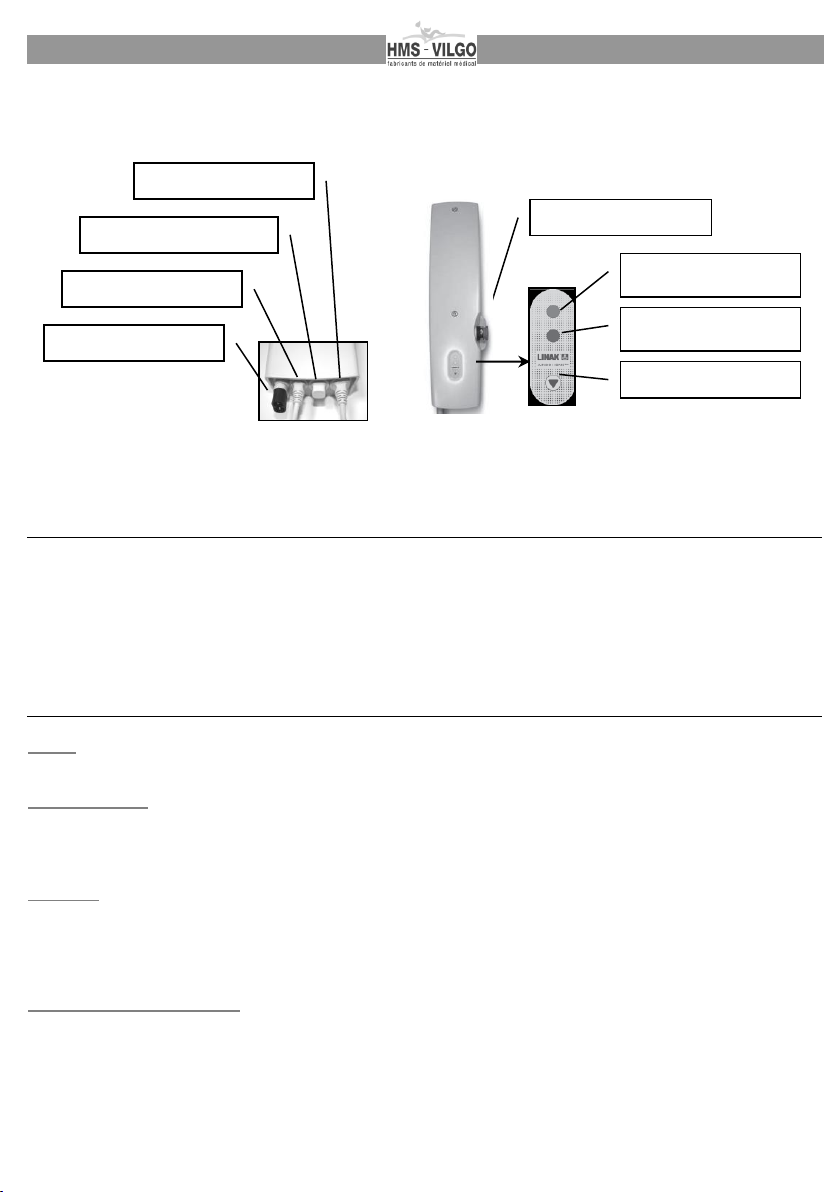

2.2. DESCRIPTION GENERALE

2.3. CARACTERISTIQUES TECHNIQUES

Materials : steel

Finish : Epoxy paint coating

Class: I

Weight (without support device): 68 kg / 150 lbs

Maximum patient weight to be transferred: 250 kg / 40 stones

Electrical equipment conformed to NF EN 60 601-1 and to NF EN 60 601-1-2

Electric protection classification : Class II

Applied parts : Type B

Duty cycle: 2 min./18 min. (10%)

Input: 230V ~ 50 HZ

Actuator input : 24 V CC

Battery charge required time : 15 h

Battery autonomy: ± 20 cycles

Electrical equipment protection : Remote control : IP X6

Control box : IPX4

Actuator : IP X4

Pole

Control box

Driving handles

Support beam

Beam

Side foot

Electric actuator

4 in wheels

5 in wheels with

brake

Side foot Electric

actuator

6

LIFTY 5 user guide

Version 11/2020

2.4. DIMENSIONAL CHARACTERISTICS

Dimensional characteristics of the base

1 - Maximum external length : 55 in

2 - Maximum internal length 35.8 in

3 - Minimal internal width : 22.8 in

4 - Minimal external width : 29.5 in

5 - Maximum internal width : 45.3 in

6 - Maximum external width : 51.2 in

7 - Minimum ground clearance : 2.3 in

8 - Maximum front height : 5.1 in

9 - Maximum back height : 5.9 in

Total lift / lifting radius / overall dimension :

1 - Lifting radius at the highest CSP : 32.3 in

2 - Total lift (3-4): 51 in

3 - Maximum CSP height : 77.2 in

4 - Minimal CSP height : 26.2 in

5 - CSP height at maximum lifting radius : 63.8 in

6 - Lifting radius at lowest CSP : 30.3 in

7 - Maximum lifting radius : 38.6 in

8 - Low position floor/hooks height : 17.7 in

9 - High position floor/hooks height : 68.9 in

10 - Low position overall dimension height : 53.5 in

11 - High position overall dimension height : 81.1 in

12 - Overall dimension length : 57 in

13 –Floor/handles height : 51.2 in

* CSP : Central Suspension Point

8

4

6

10

12

11

9

3

CSP*

1

13

6

5

2

1

4

3

9

8

7

7

LIFTY 5 user guide

Version 11/2020

2.5. LABELLING

This label allows you :

To have all the necessary information to make any intervention request for the after sales service thanks to

the serial number and to the reference.

To ensure the follow up of the medical disposal.

It also gives to you the security loading charge for a good use.

There are 3 labels : One on the basis of the Lifty5, one on the electric actuator, and one on the control box.

Standards :

By this label, HMS-VILGO ensures that Lifty5 hoist is conformed to European directive

89/336 referring to electromagnetic compatibility and to European directive 93/42 referring

to medical devices.

8

LIFTY 5 user guide

Version 11/2020

3. LIFTY5 ASSEMBLING

3.1. PACKAGE CONTENTS

The following parts are in the package:

1 Lifty5 hoist :

1 box containing:

Control box (x1)

Remote control

(x1)

Main cable

(x1)

Actuator cable

(x1)

Fixing screw

CHC 6x80 (x2)

Anti-pulling up

Cable kit (x1)

Spanner 6 section 5

(x1)

9

LIFTY 5 user guide

Version 11/2020

R

RE

EC

CO

OM

MM

ME

EN

ND

DE

ED

D

C

CH

HE

EC

CK

KS

S

Item to check

Check

Periodicity: at least once a year and before renting it.

* Replacement

after 11 000 cycles

1

Pole / beam support

connection

- Check brass ring wear

- Check fixing screw wear

- Check stop-nut presence and assembling

✓

2

Control box

- Check emergency stop operating

- Check battery charging

3

Electrical cables

- Check cables (pinching, plug state, cut …)

4

Actuator

- Check charging operating

5

Actuator / pole

connection

- Check fixing screw wear

- Check stop-nut presence and assembling

✓

6

Side feet moving

- Check actuator operating

- Check screw and stop-nut presence, assembling and wear

7

Wheels

- Check braking system

- Check tightening and screw assembling

8

Side foot / cross piece

connection

- Check fixing screw wear (screw nut + brass rings)

✓

9

Actuator / beam

support connection

- Check fixing screw wear

✓

10

Emergency release

- Check electrical and manual release operating

11

Beam support / beam

axle connection

- Check stop-nut presence and assembling

- Check fixing screw wear

- Check fixing metal tongue welding

✓

12

Beam hooks

- Check fixing screw wear

- Check control and operation of safety springs

13

Sling

- Check seams

14

Pole / cross piece

connection

- Check screw / stop-nut connection (presence, wear and assembling)

- Check pole welding

✓

*See table on page 10 to list necessary spare parts

Réf. Document : IB 7.5.1. 706 indice B

Hoists are conformed to EN 10 535 standard which means that they can run 11 000 complete cycles under

the conditions of uses they are designed for. Please, carefully consider how important it is to evenly check

and maintain it in order to make sure that it is used under the standard specifications and under ours

recommendations. We will not be responsible for any damage due to an abnormal use or to a too high

number of cycles. You will find all the information you need for your checking and maintenance steps on

pages 9, 10, 11 and 12.

5

8

6

3

7

4

2

1

9

14

12

11

10

4

13

10

LIFTY 5 user guide

Version 11/2020

E

EV

VA

AL

LU

UA

AT

TI

IO

ON

N

O

OF

F

T

TH

HE

E

N

NU

UM

MB

BE

ER

R

O

OF

F

H

HO

OI

IS

ST

T

O

OP

PE

ER

RA

AT

TI

IN

NG

G

C

CY

YC

CL

LE

ES

S

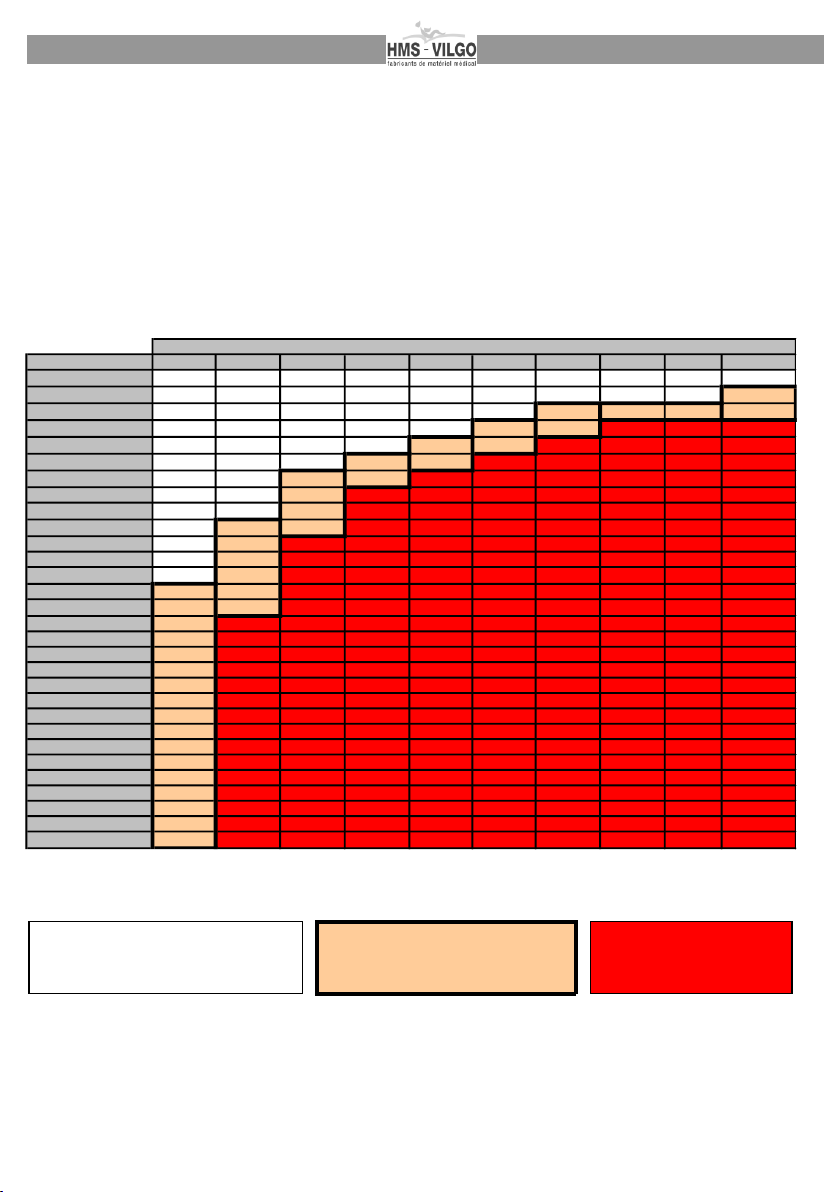

This table below, indicates if the replacement of actuator, axis and spare parts is necessary, in function of the

number of runs a day.

number of runs / a day 1 2 3 4 5 6 7 8 9 10

1365 730 1095 1460 1825 2190 2555 2920 3285 3650

2730 1460 2190 2920 3650 4380 5110 5840 6570 7300

31095 2190 3285 4380 5475 6570 7665 8760 9855 10950

41460 2920 4380 5840 7300 8760 10220 11680 13140 14600

51825 3650 5475 7300 9125 10950 12775 14600 16425 18250

62190 4380 6570 8760 10950 13140 15330 17520 19710 21900

72555 5110 7665 10220 12775 15330 17885 20440 22995 25550

82920 5840 8760 11680 14600 17520 20440 23360 26280 29200

93285 6570 9855 13140 16425 19710 22995 26280 29565 32850

10 3650 7300 10950 14600 18250 21900 25550 29200 32850 36500

11 4015 8030 12045 16060 20075 24090 28105 32120 36135 40150

12 4380 8760 13140 17520 21900 26280 30660 35040 39420 43800

13 4745 9490 14235 18980 23725 28470 33215 37960 42705 47450

14 5110 10220 15330 20440 25550 30660 35770 40880 45990 51100

15 5475 10950 16425 21900 27375 32850 38325 43800 49275 54750

16 5840 11680 17520 23360 29200 35040 40880 46720 52560 58400

17 6205 12410 18615 24820 31025 37230 43435 49640 55845 62050

18 6570 13140 19710 26280 32850 39420 45990 52560 59130 65700

19 6935 13870 20805 27740 34675 41610 48545 55480 62415 69350

20 7300 14600 21900 29200 36500 43800 51100 58400 65700 73000

21 7665 15330 22995 30660 38325 45990 53655 61320 68985 76650

22 8030 16060 24090 32120 40150 48180 56210 64240 72270 80300

23 8395 16790 25185 33580 41975 50370 58765 67160 75555 83950

24 8760 17520 26280 35040 43800 52560 61320 70080 78840 87600

25 9125 18250 27375 36500 45625 54750 63875 73000 82125 91250

26 9490 18980 28470 37960 47450 56940 66430 75920 85410 94900

27 9855 19710 29565 39420 49275 59130 68985 78840 88695 98550

28 10220 20440 30660 40880 51100 61320 71540 81760 91980 102200

29 10585 21170 31755 42340 52925 63510 74095 84680 95265 105850

30 10950 21900 32850 43800 54750 65700 76650 87600 98550 109500

Oldness of the hoist (years)

Foresee axis and spare parts

replacement.

* Replace axis and

spare parts.

Keep using the hoist.

*See spare parts list page 12

11

LIFTY 5 user guide

Version 11/2020

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

B

BO

OO

OK

K

HOIST REFERENCE:

Serial number :

Serial number :

Serial number :

DATE

/

Number of cycles

evaluated

MAINTENANCE AND QUALITY CHECKING

NAME &

APPROVALS

12

LIFTY 5 user guide

Version 11/2020

S

SP

PA

AR

RE

E

P

PA

AR

RT

TS

S

L

LI

IS

ST

T

Part

Description

Item code

Qty

Location

Replacement

After 11 000

cycles

Vérin de levée Lifty5-6

LA44 - 12000N

A501359

1

/

Vérin écarteur pieds Lifty5-6

LA31 -

A501360

1

/

Boîtier de contrôle Lifty5-6

CBJH1

A501361

1

/

Télécommande Lifty5-6

A501362

1

/

Vis TH 12x100

Ecrou frein Ø12

A001087

A001080

2

pole / cross piece

connection

✓

Vis TH 12x80 classe 10.9

Ecrou frein Ø12

Rondelle Ø 12 ZI

Axe de Fléau D28 Lg135 Lifty 4

Bague laiton Ø 28/22 LG 5

Chape potence fléau Lifty5-6

Vis métaux TH12x80 classe 10.9

écrou frein diam. 12

A501251

A001080

A001088

A501420

A501421

A501356

A501251

A001080

1

1

2

1

1

1

1

1

support beam /

beam connection

✓

Vis TH 12x90 classe 10.9

Ecrou frein Ø12

Rondelle Ø 12 ZI

Patte pied de vérin Lifty5-6 drte

Patte pied de vérin Lifty5-6 gche

écrou frein diam. 12

Vis métaux 12x70 classe 10.9

Rondelle Ø 12 ZI

A501250

A001080

A001088

A501417

A501418

A001080

A501250

A001088

2

2

4

1

1

1

1

2

actuator / pole

connection

✓

Rondelle laiton Ø 40-14.2-e2

Axe Ø14-M12-Lg69/101

Ecrou frein Ø 12

Rondelle Ø12 ZI

Patte mât/potence Lifty5

écrou frein diam. 12

Vis TH 12x90 classe 10.9

A501404

A501411

A001080

A001088

A501415

A001080

A501434

2

1

2

2

2

2

2

pole / support

beam connection

✓

Vis TH 12x60 classe 10.9

écrou frein diam. 12

A501249

A001080

1

1

actuator / support

beam connection

✓

Vis TH 10x100

écrou frein diam. 10

Douille D16-di 10-lg76 pied Lifty5

A501375

A001072

A501407

2

2

2

Side foot / cross

piece connection

✓

Roue sans frein D100 –av Lifty5 -6

Vis métaux TF BTR 12x80 inox

A501364

A501388

2

2

Roue frein D125 –ar Lifty5-6

Vis métaux TF BTR 12x80 inox

A501365

A501388

2

2

Beam hook spring

A501665

4

beam

13

LIFTY 5 user guide

Version 11/2020

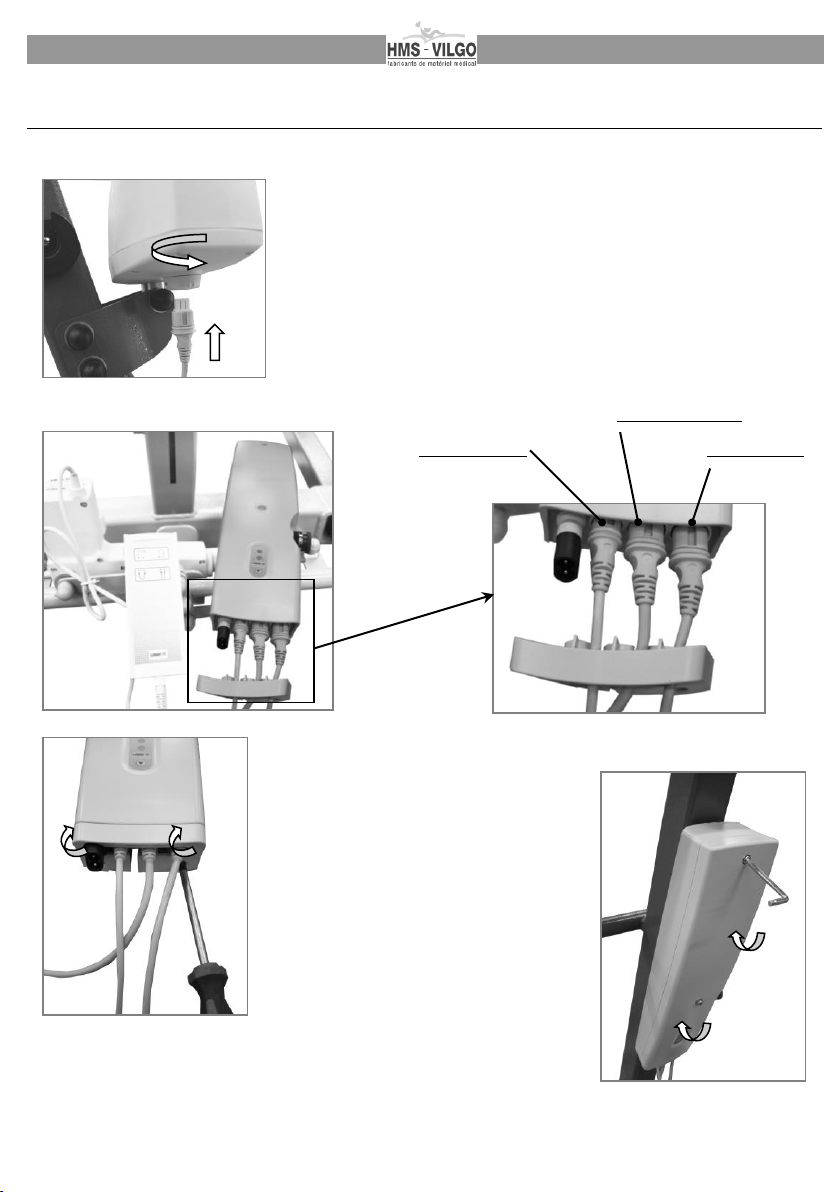

3.2. LIFTY5 ASSEMBLING

Fix the control box to the pole in

screwing the 2 CHC 6X80 screws.

Your Lifty5 hoist is now ready to

run.

Plug the remote control and the actuators cables in the

control box. Put the anti-pulling up hood in placing the cables

through the opening.

Screw the hood to the control

box with a crossed screw-driver.

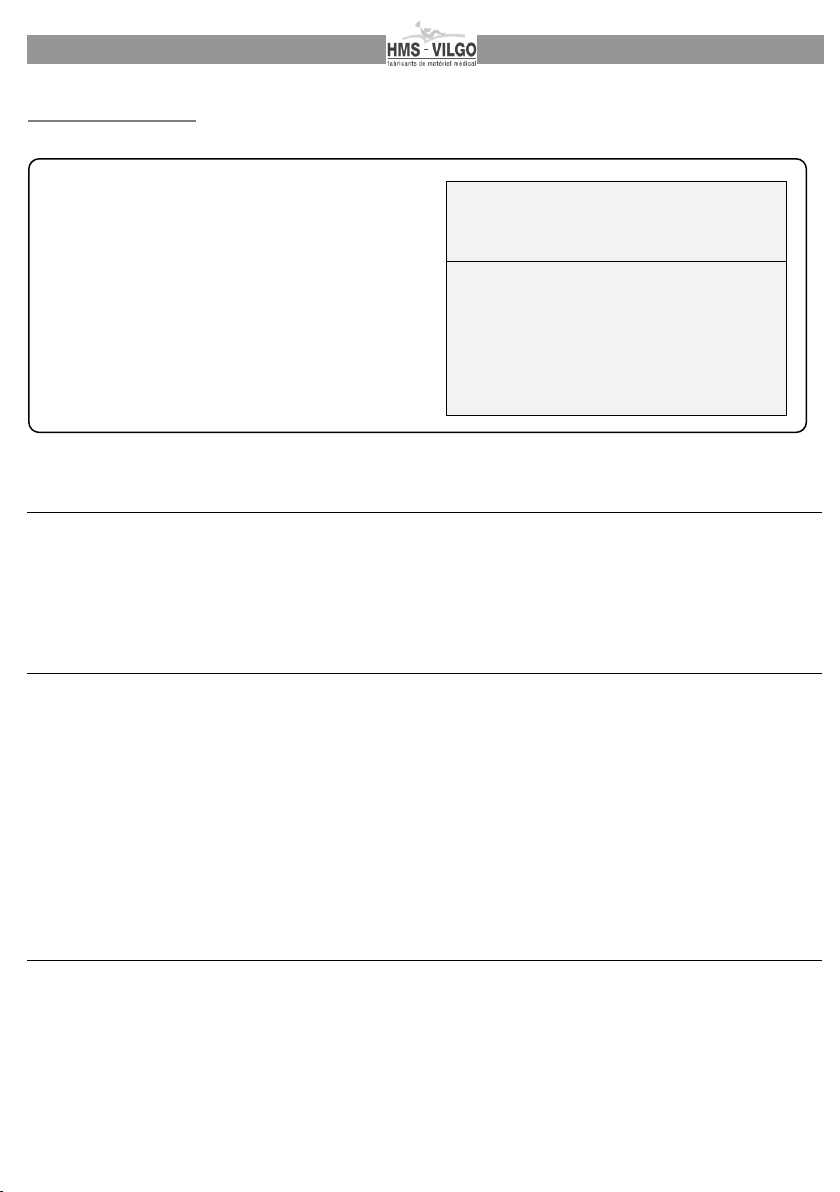

Remote control

.

Side feet actuator

Main actuator

Plug main actuator cable.

Block the actuator cable (see chap.3.3).

14

LIFTY 5 user guide

Version 11/2020

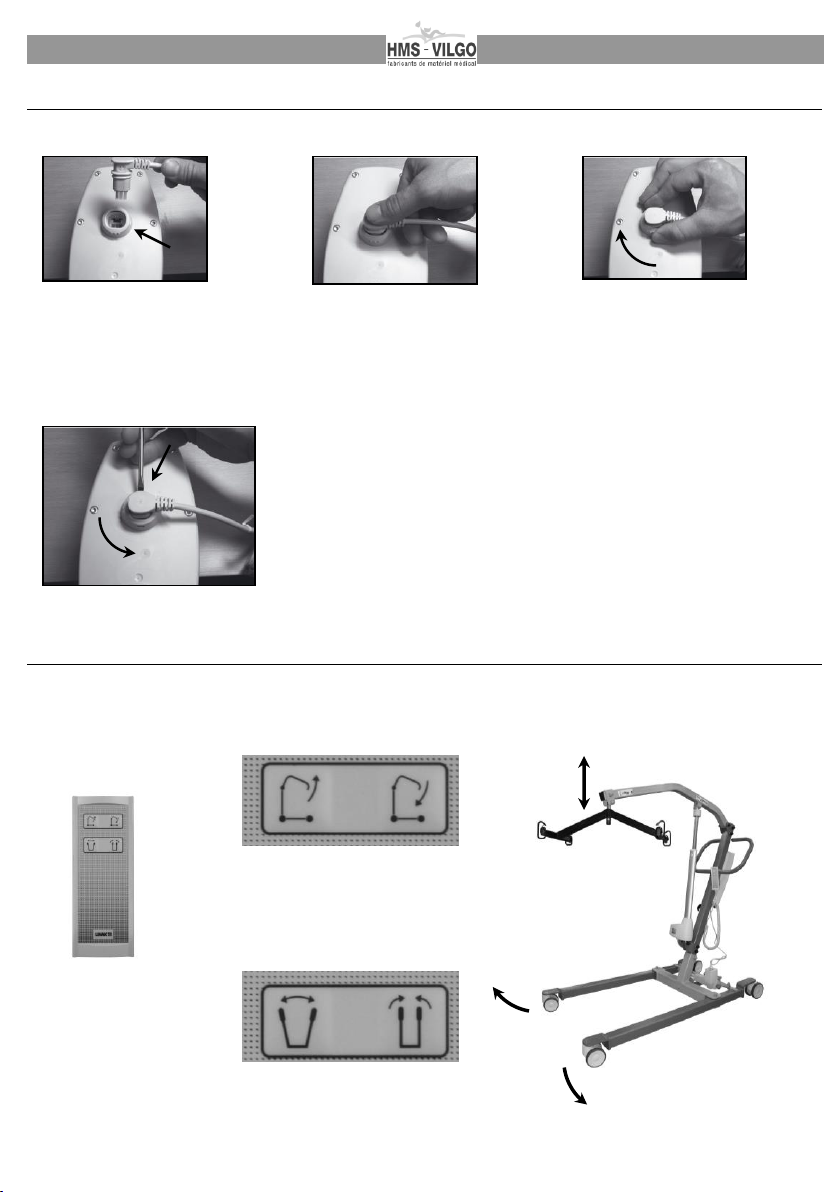

3.3. BRANCHEMENTS

3.3.1 Plugging/blocking the actuator cable

3.3.2 Unlocking of the actuator cable plug

Unlock with a screw-driver (as shown here), leaning in the notch. In the

same time, turn the ring from the left to the right to unlock the plug.

4. USE

4.1. FIRST USE

Even if battery box is immediately ready to run as it is charged when delivered, make sure the hoist

installation has been strictly done as shown on paragraph 3. Test it off load first to get used to it.

3/ Grip the notches and turn

the ring from left to the right.

The cable is locked when the

ring is turned to 90°.

1/ The 3 notches of this

ring show that the griping

device of the cable plug is

unlocked.

2/ Put the cable plug in

position and lean on it

to plunge into the

lodging.

15

LIFTY 5 user guide

Version 11/2020

4.2. LIFTY5 USE

4.2.1 Sling installation and operating :

Reminder: Sling is adjustable. User is responsible for adjusting it in order to not hurt the patient. Lifty5 hoist is

delivered with a 20041 sling. See the user instruction bellow.

1/ Put the back of the sling (largest part of the sling) on the patient back in order to have the 2 hanging-up

straps on both sides of the patient.

2/ Hang up each hanging-up strap to the beam hooks (A1 and B2)

3/ Softly lift up the patient right thigh to put the right thigh support underneath.

4/ Softly lift up the patient left thigh to put the left thigh support underneath.

5/ Cross the two thigh support sling.

6/ Hang up each strap to the beam hooks (C3 and D4)

→You can adjust the patient tilt with the different hanging-up holes. Make sure to always hang-up the

A and B straps at the same hole level (same colour). Act the same way for C and D straps.

Cautions :

- This sling is designed for HMS-VILGO hoists only.

- Always hang-up the 4 straps at the same level.

- Never adjust straps while the hoist is running.

- Always make sure that straps are well-attached on the beam before lifting the patient up.

- Never exceed the maximum running load.

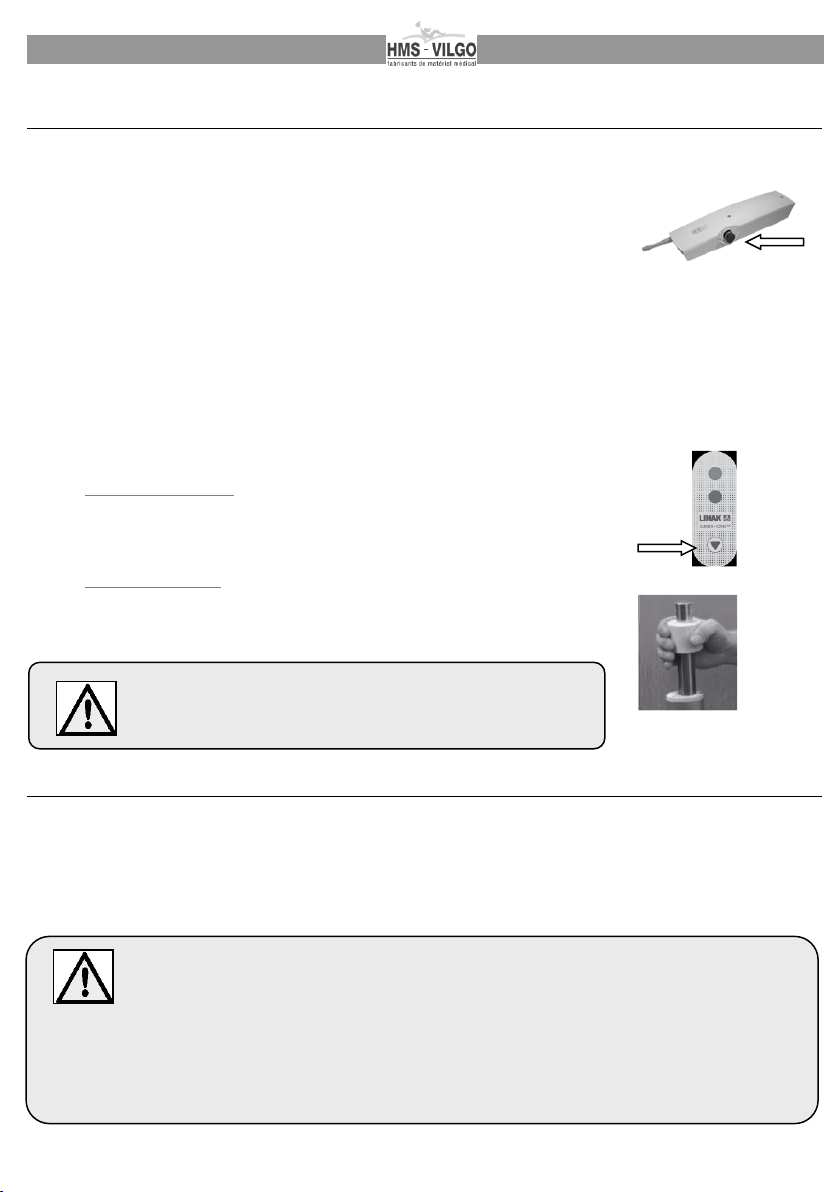

4.2.2 Transferring the patient:

1/ Set the hoist in a way that the beam stands above the patient (if

necessary, open or close side foot to get closer to the patient).

2/ Lock brakes

3/ Set the sling

4/ Push up button of the remote control to lift the support beam (make

sure the strap does not get stuck and does not hurt the patient while lifting him).

5/ Unlock brakes to transfer the patient.

6/ Lock brakes again when transfer done.

7/ Push down button of the remote control to go down

A

B

C

D

Back of the sling

thigh support straps

1

3

4

2

16

LIFTY 5 user guide

Version 11/2020

4.3. SAFETY

crushing safety: Lifty5 runs with a single-acting actuator. Any obstacle on its way will automatically stop its

going-down.

Emergency stop : the Lifty5 emergency stop button is located on the control box.

Push it to stop the lifting or going-down. Push it again to unlock it.

Electric safety : lifting and going-down are locked when Lifty5 is connected to charge battery.

Alarm : a red led lights on when the actuator is running while battery is low.

Emergency going-down (only use when patient is stuck above and that it is impossible to go down using the

remote control): There are two actuator release systems:

1/ Electrical release :

To go down, push the blue switch located under the emergency stop.

2/ Manual release :

Push down (1) and turn to the right (2) the red ring of the actuator.

This function can be used if the electrical system is not efficient.

4.4. CONTROL BOX OPERATING, BATTERY CHARGE :

If the charging level is too weak, an alarm sounds (in a constant way) when the control box is activated. The

charging of the battery is then necessary.

The control box has its own integrated charger. To charge batteries, connect the control box to the 220 VAC

main power line, until the green led turn on indicating batteries are charged (approximately 12 hours).

A third person must assist the patient during the

entire emergency going-down process.

The Lifty 6 must be connected to a network which is in accordance with the NFC 15-100

and NFC 15-211 ( 230 V Electric plug + ground connection) for France and CEI 364 for

other destinations.

Make sure that the power supply of the control box (you can find it on the label), is in

accordance with the establishment power supply.

It is advisable to connect the device on a power fitting protected by a differential circuit

breaker of 30 mA Maximum, in accordance with the CEI 364-5-53 publication.

17

LIFTY 5 user guide

Version 11/2020

Main cable connection

Warning, the loading of the batteries works only if the emergency button is out of power (put it on the position

‘on’ to load the batteries).

To make batteries last longer, they must be recharged every night.

4.5. STORAGE INSTRUCTIONS:

Do not expose to moisture.

Store in a temperate dry place (5°C to 40°C).

Charge battery before using it after a long time off.

Handling and stocking of the lift has to be done in order to avoid any impact, falling or damage of the material

5. LIFTY5 MAINTENANCE

5.1 WEEKLY MAINTENANCE

Sling :

Check the sling by looking at its seams condition: immediately replace a sling that starts to show any tear.

Electrical parts:

Test the emergency stop switch while lifting and lowering the support beam.

Look at the electrical cables cover.

Test crushing safety system by placing an item on the support beam going-down way.

Chassis :

Check the brake of the back wheels.

Look at the global geometry on the Lifty5 (no bent item).

Make sure that the 4 wheels are well positioned on the ground.

Make sure that there is no play between the support beam and the pole.

Strap cleaning instructions:

86°F (or 30°C) machine wash - Do not dry clean - Do not iron

Main actuator connection

Remote control connection

Emergency stop

LED green color when the

control box is activated

vert / rouge

Yellow charging LED

Emergency going down

Connection feet actuator

18

LIFTY 5 user guide

Version 11/2020

Cleaning of the Lifty5:

Before any intervention on the Lifty5, disconnect it from the power and take out the control box.

Follow this cleaning protocol:

5.2 ANNUAL MAINTENANCE

It is recommended to do a complete checking once a year.

You will find on pages 9-12 the checking list and the maintenance book to write down the different

maintenance steps.

5.3 WARRANTY

Lifty 6 hoist has a serial number. You will find it on the chassis and on each electronic item.

To make a claim under warranty, you need to return the defective item with its serial number label to your

retailer who will contact us.

The warranty of this product is valid for 5 years (except battery: 1 year).

ANY RETURN WITHOUT SERIAL NUMBER LABEL WILL NOT BE COVERED BY THE WARRANTY.

Warranty does not cover breakdown due to a wrong use or maintenance (shock on the battery charger, cut

cable …).

Any breakdown of dysfunction which could be imputable to a modification or replacement by any other spare

part than original ones will affect the warranty.

5.4 RECYCLING

Recycling must be done according to the type of materials and components and in compliance with the

current recycling regulations. Disposal and destruction of the faulty parts must be handled by an agreed

recycling company.

1- Impregnate a clean non-weaved tissue with

an appropriate cleaning solution (Anios

cleaning and disinfecting high surface solution

or other same solution).

Make sure to respect the right dosage

indicated on the product notice.

2- Clean the all product with the impregnated

non-weaved tissue.

3- Let dry the product.

WARNING:

- Avoid abrupt cleaning and rinsing.

- No high pressure water cleaning.

IMPERATIVELY AVOID:

- Pure alcohol

- Acetone

- Perchlorethylene and trichloroethylene.

- Any solvent or detergent.

- Abrasive cleaning products.

- Any kind of wax.

19

LIFTY 5 user guide

Version 11/2020

20

LIFTY 5 user guide

Version 11/2020

Distributor stamp

Site de Lille : Parc Eurasanté –243 Rue Allendé

59120 LOOS LEZ LILLE

Tél : +33 (0)3 20 84 81 50 –Fax : + 33 (0)3 20 59 58 08

Site de Beregrac : Rte de Sainte Alvère - Creysse BP 212

24102 BERGERAC Cedex

Tel. : +33 (0)5 53 74 45 50 –Fax : +33 (0)5 53 63 06 07

5

5

L

Li

if

ft

ty

y

Table of contents

Other HMS-VILGO Lifting System manuals

Popular Lifting System manuals by other brands

EZ-ACCESS

EZ-ACCESS TRANSITIONS Angled Entry Mat instructions

Prowise

Prowise iPro Toddler Lift user manual

EDMA

EDMA EDMAPLAC MEGA INSTRUCTION AND SECURITY MANUAL

Oshkosh Corporation

Oshkosh Corporation JLG H600SJ Service and maintenance manual

Holmatro

Holmatro HLB Series manual

Nuvo

Nuvo Navigator Lift 180 Single operating instructions

Columbus McKinnon

Columbus McKinnon Yale HTP Series Translated Operating Instructions

Upright

Upright SL26SL Service manual

IMER

IMER TR 225 2V Operating, maintenance, spare parts manual

Genie

Genie SX-180 Operator's manual

Anthony Liftgates

Anthony Liftgates SM Series parts book

Sinoboom

Sinoboom GTJZ0612E Maintenance manual