User Manual of XRotor Series Controllers for Multi-rotors HW-SM909DUL-V2-20160614

Thank you for purchasing this HOBBYWING product! Brushless power systems can be very dangerous. Any improper use may cause personal injury and

damage to the product and related devices. We strongly recommend reading through this user manual before use. Because we have no control over the use,

installation, or maintenance of this product, no liability may be assumed for any damages or losses resulting from the use of the product. We do not

assume responsibility for any losses caused by unauthorized modifications to our product.

01 Warnings

Ensure all wires and connections are well insulated before connecting the ESC to related devices, as short circuit will damage your ESC.

Ensure all devices are well connected to prevent poor connection that may cause your multi-rotor to lose control or other unpredictable issues such

as damage to the device.

Read through the manuals of all power devices and ensure the power configuration is rational before using this unit.

Please use a soldering iron (ensuring it’s connected to a GND wire) with the power of at least 60W to solder all input/output wires and connectors.

Stop using the ESC when its casing temperature exceeds 100℃, otherwise your ESC will get destroyed and may also get your motor damaged.

Please swap any two ESC-to-motor wires if the motor runs in reverse.

02 Features

Special core program for multi-rotor controllers greatly improves throttle response.

Specially optimized software for excellent compatibility with multi-rotor motors.

Microprocessor powered by independent DC regulator has better anti-interference performance greatly reduces the risk of losing control.

Separate signal wires for reminding user of RPM output & error states.

All settings except the timing are preset, making usage simple, high intelligent and adaptive.

Compatible with various flight-controller and supports a signal frequency of up to 621Hz.

DEO (Driving Efficiency Optimization) technology for better throttle linearity and higher driving efficiency.

PWM frequency of 18KHz.

Firmware upgrade via HOBBYWING multifunction LCD program box or WIFI module (item sold separately).

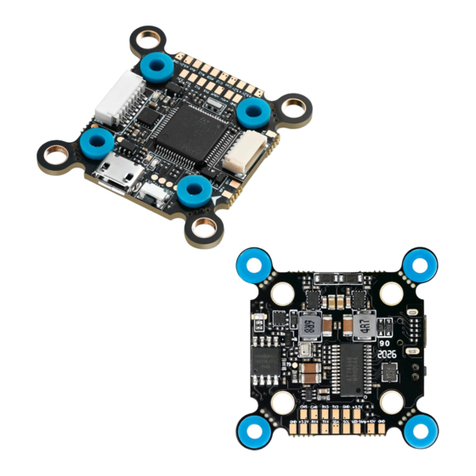

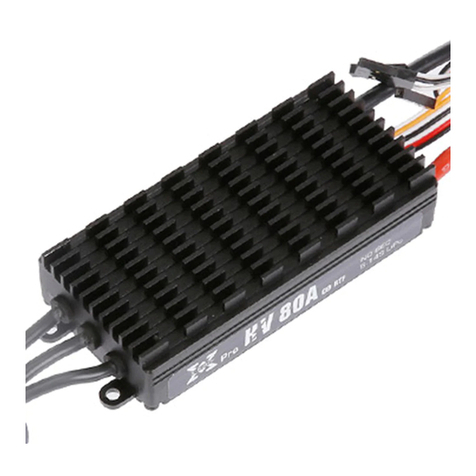

03 Specifications

86.1*42.0*20.5mm

(Length w/o ears)

XRotor

Pro-100A-HV-V3-RTF

86.1*42.0*22.6mm

(Length w/o ears)

04 User Guide

Throttle Calibration

Attention! Users need to calibrate the throttle range when they start to use a new XRotor brushless ESC or another transmitter.

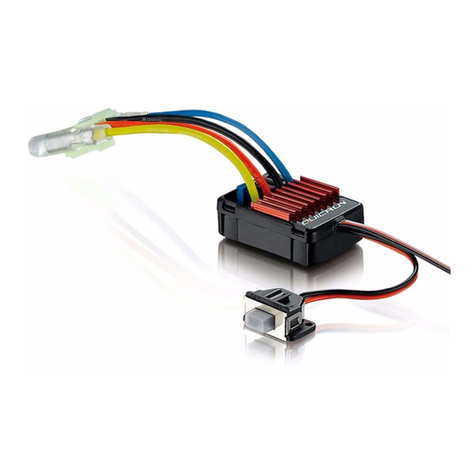

Step 1: Wiring

Notes:

6) The tri-color (Black/Red/White) cable is the programming cable.

7) The Black wire is the GND wire.

8) The bi-color (White/Black) cable is the throttle control cable

9) The Yellow wire is the RPM signal output wire.

10) The White wire is the signal wire for warning user of error states.

Step 2: ESC Programming

Warning! This is an extremely powerful brushless motor system. We strongly recommend removing your propellers for your own safety and the safety of

others around you before performing calibration with this system.

05 Normal Start-up Process

06 Protections

This ESC is specially designed for multi-rotors/drones; it has no low-voltage cutoff protection function.

Start-up Protection: The ESC will shut down the motor if it fails to start the motor normally within 2 seconds by increasing the throttle value. In this

case, you need to move the transmitter throttle stick back to the bottom position and restart the motor. (Possible causes of this problem: poor connection/

disconnection between the ESC and motor wires, propellers are blocked, etc.)

Motor Lock-up Protection: The ESC will cut off its output and stop trying to restart the motor when it detects the motor is locked up. It won’t resume

the output until you move the throttle stick to the bottom position first and then push the stick upward.

Over-current Protection: The ESC will cut off its output immediately when the peak current gets close to 350A (the short-circuit current). It only

restarts after you power it off and then back on.

Throttle Signal Loss Protection: When the ESC detects loss of signal for over 0.25 second, it will cut off the output immediately to avoid an even

greater loss which may be caused by the continuous high-speed rotation of propellers or rotor blades. The ESC will resume the corresponding output after

normal signals are received.

07 Trouble shooting

The ESC was unable to start

the motor.

Please set the throttle direction to “REV”

on the transmitter.

The ESC was unable to start

the motor.

“B, B, B …”

(The motor beeped rapidly.)

The throttle stick is not moved to

the bottom position or the throttle

range is too narrow.

Move the throttle stick to the bottom

position or recalibrate the throttle range.

The ESC was unable to start

the motor.

“B-, B-, B-….”

(The interval is 1 second.)

No output signal from the throttle

channel on the receiver.

Check if the transmitter and receiver are well

bound, if the throttle control cable has been

properly plugged into the TH channel on the

receiver.

The power-on voltage is

below 18V.

“BB-, BB-…”

(The interval is 1 second.)

The battery voltage is too low.

Change another suitable battery that is fully

charged.

The power-on voltage is

above 65V.

“BB-, BB-…”

(The interval is 1 second.)

The battery voltage is too high.

Change another suitable battery that is fully

charged.

Explanations for errors/warnings

Overheat issue happened to the ESC.

Land the multi-rotor immediately and stop using it until the ESC cools down.

Over-current issue happened to the ESC.

Stop using the multi-rotor, check if the ESC has the over-current issue.

The power-on voltage is below 18V.

Change another suitable battery that is fully charged.

The power-on voltage is above 65V.

Change another suitable battery that is fully charged.

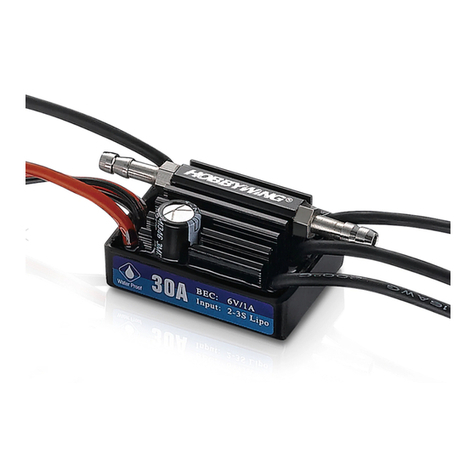

Connect the ESC to a battery;

the motor emits “♪123”

indicating the ESC is powered

on normally.

Turn on the

transmitter, move

the throttle stick to

the bottom position.

Turn on the

transmitter, move the

throttle stick to the

top position.

Connect the receiver to the battery,

ensure the transmitter and receiver

are well bound, and then turn on

the ESC.

“Beep-beep-”Throttle Calibration;

“Beep-beep-beep-”DEO ON;

“Beep-beep-beep-beep-” DEO OFF;

If the throttle stick is moved to

the bottom position 3 seconds after

you hear the corr esponding

beeps, then the programming of that

item is complete.

The motor will

beep different

tones circularly

Programming is completed;and

the ESC is ready.