Hochiki Europe (UK) Limited 2-3-0-345/ISS7/OCT10 Hochiki Europe (UK) Limited 2-3-0-345/ISS7/OCT10

Certain actions can cause permanent damage to the detector. If the detector is subjected to any of the following it should not

be used:

Dis-assembly and re-assembly, apart from chamber replacement in the case of photoelectric smoke detectors (the

detectors cannot be repaired and must be replaced in their entirety).

Impact or shock.

Suspected damage following a fire.

In the case of heat detectors, touching the thermistor element.

These detectors must be subject to periodic maintenance during regular service visits. This period should be outlined in the

appropriate standards or recommendations. If there are no such standards existing, Hochiki recommend that the minimum

period of maintenance should be 1 year and that the following should be taken into account:

A regular operation test should be performed using suitable test equipment (certain types of test equipment should not be

used in flammable/combustible atmospheres).

A visual check for staining and mechanical damage should be made.

A magnetic test facility is incorporated into both detectors which can be operated using a suitable magnet.

A dust cover is included with these detectors to prevent contamination during installation and prior to commissioning. The dust

cover must be removed for the detectors to operate.

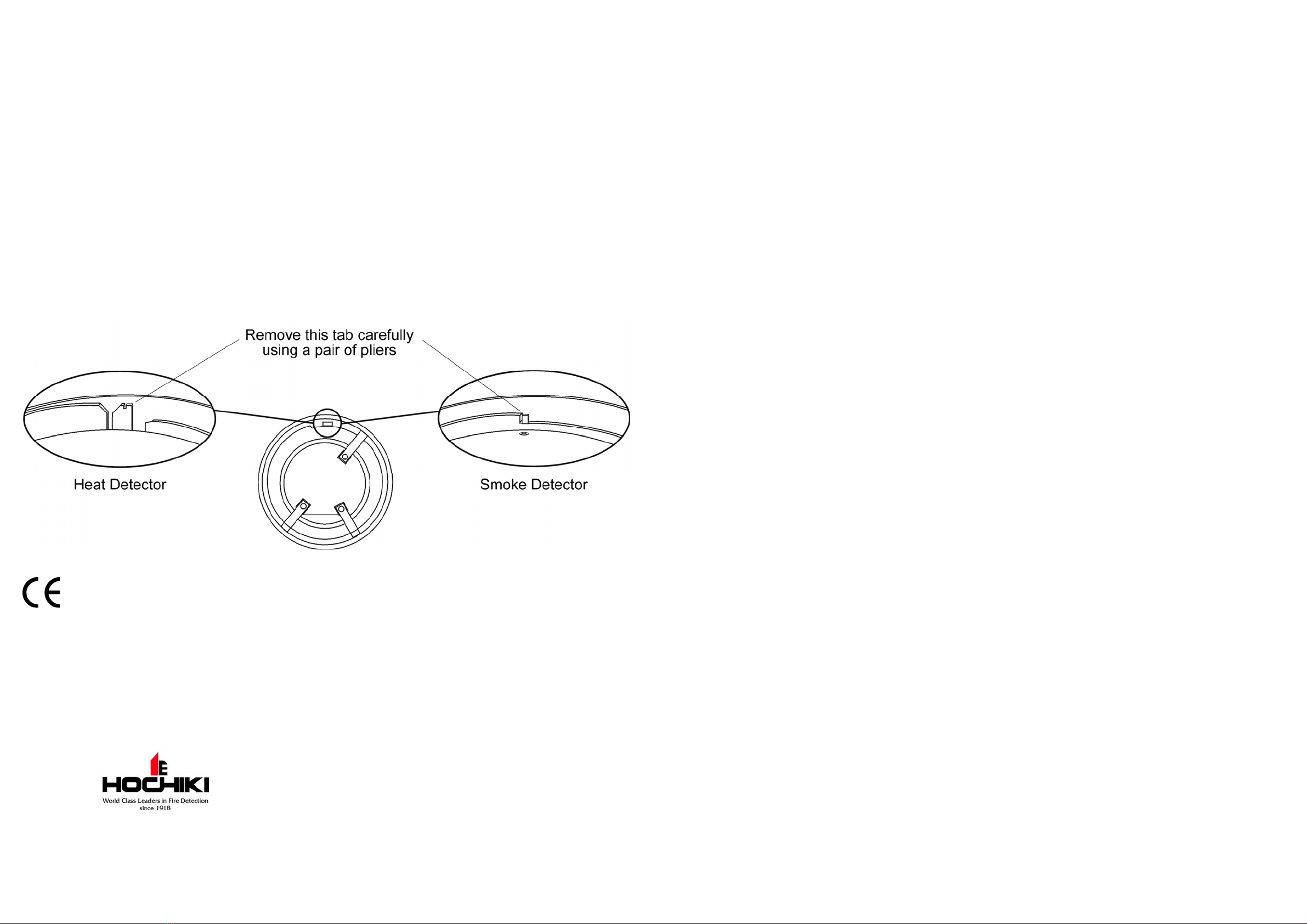

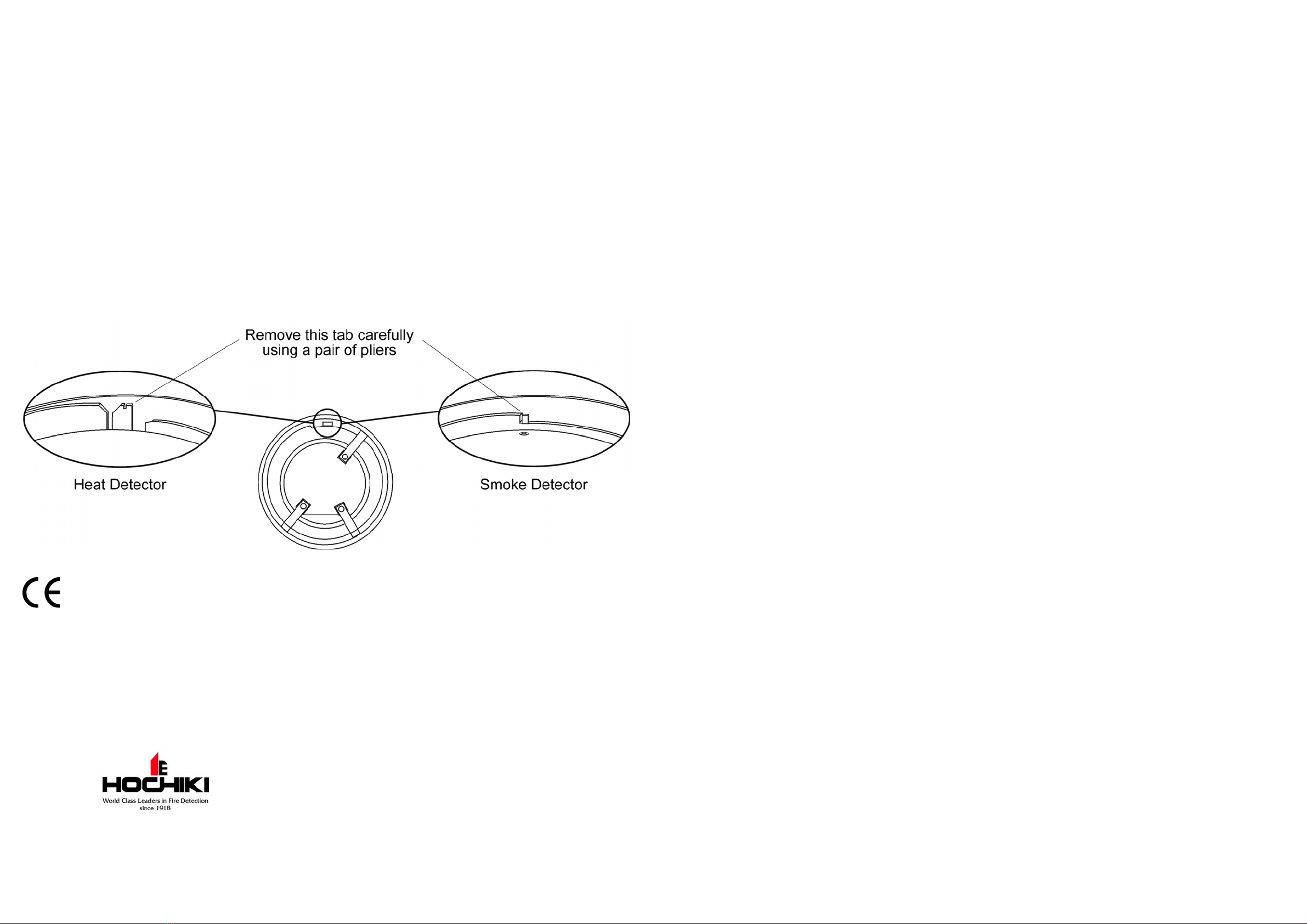

The detectors can be locked on to the base by removing a plastic lug on the underside, please refer to the diagram below. The

locked detector can then only be removed by using a special removal tool which is available from Hochiki Europe (UK) Ltd

(part number TSC-A100/ALG).

DCD-1E-IS 0832-CPD-0121 05 EN54-5 Point type heat detectors

SLR-E-IS 0832-CPD-0113 05 EN54-5 Point type heat detectors

Hochiki Europe (UK) Ltd

Grosvenor Road, Gillingham Business Park,

Gillingham, Kent, ME8 0SA, England

Telephone: +44(0)1634 260133 Facsimile: +44(0)1634 260132

Email: sales@hochikieurope.com

Web: www.hochikieurope.com

Hochiki Europe (UK) Ltd. reserves the right to alter the specification of its products from

time to time without notice. Although every effort has been made to ensure the accuracy of

the information contained within this document it is not warranted or represented by

Hochiki Europe (UK) Ltd. to be a complete and up-to-date description. Please check our

web site for the latest version of this document.

HOCHIKI INTRINSICALLY SAFE SMOKE AND HEAT DETECTORS (AND

MOUNTING BASE) INSTRUCTIONS

Products Covered: SLR-E-IS Photoelectric Smoke Detector, DCD-1E-IS Combined Rate of Rise

Heat Detector, YBN-R/4(IS) Electronics-Free Mounting Base

Introduction

These Detectors are certified by BASEEFA as suitable for use in hazardous atmospheres as detailed below. It is essential that

the detectors and base are installed and operated in conformance with the certification in order to remain safe. It is the

responsibility of the installer to ensure that the detectors and base are installed according to the certification requirements, and

it is recommended that the installation only be carried out by qualified personnel.

The YBN-R/4(IS) Base may only be used with Hochiki Intrinsically Safe specified detector heads. The use of other detector

heads is expressly forbidden and may cause fire or explosion.

Classification - SLR-E-IS

This Detector has BASEEFA certification classification according to EN 60079-11:2007 and an ATEX Classification of

II 1 G Ex ia IIC T5 -20°C<Ta<55°C. Areas suitable for installation: Category 1, 2 or 3 hazardous atmospheres, with a

maximum ambient temperature of up to 55°C.

Classification - DCD-1E-IS

This Detector has BASEEFA certification classification according to EN 60079-11:2007 and an ATEX Classification of

II 1 G Ex ia IIC T5 -20°C<Ta<55°C. Areas suitable for installation: Category 1, 2 or 3 hazardous atmospheres, with a

maximum ambient temperature of up to 55°C.

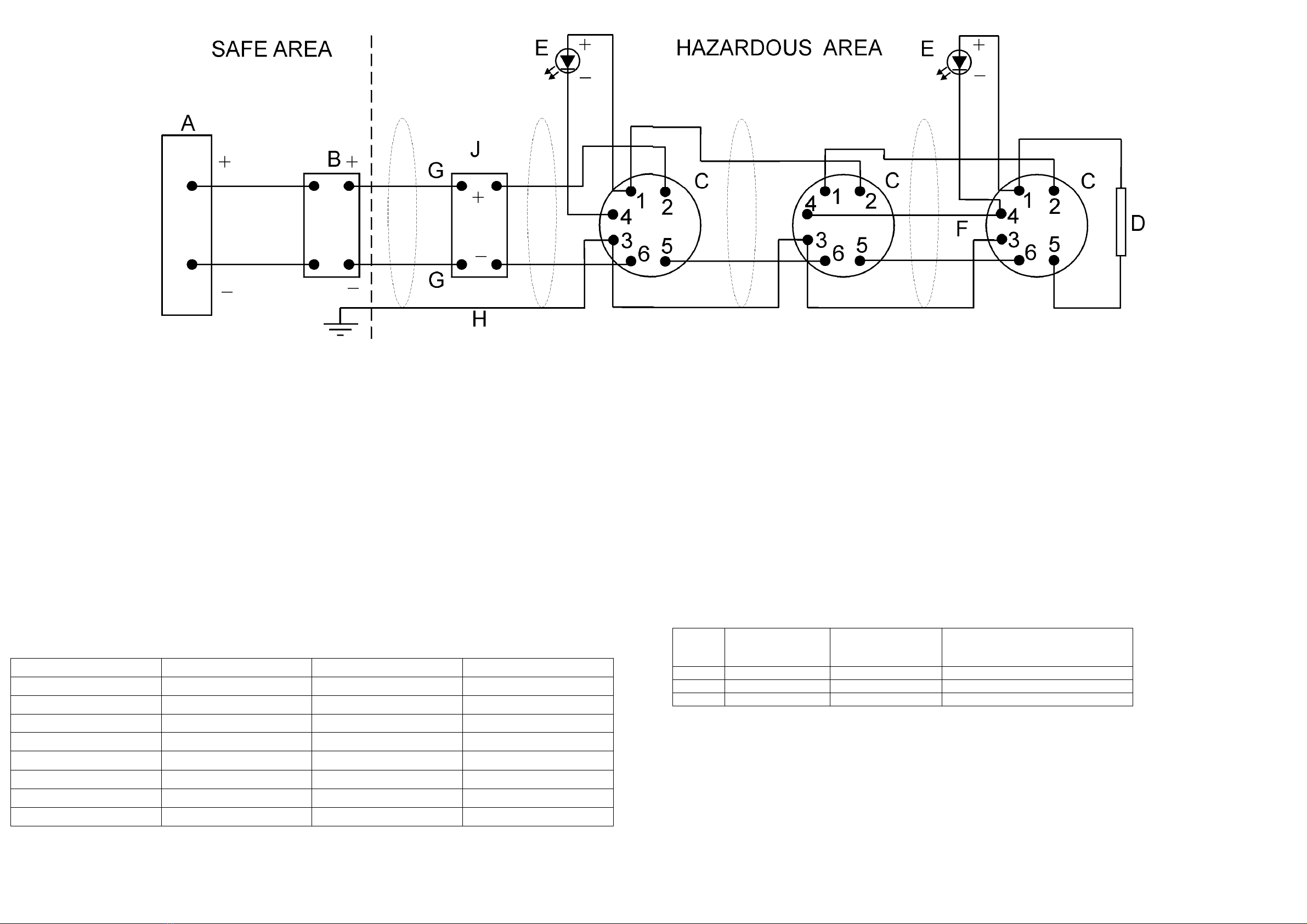

Refer to the system drawing overleaf for important information concerning installation/wiring requirements which must be

strictly observed in order to comply with BASEEFA certification. These detectors and base MUST be used with either a Zener

Diode Barrier or a Galvanic Isolator, using suitable models as detailed in the system drawing overleaf. The Zener Diode

Barrier or Galvanic Isolator should be installed according to the manufacturer's instructions.

Note

These products have been designed to

Avoid physical injury or harm by direct or indirect contact

Not produce surface temperatures of accessible parts or radiation which could cause danger

Eliminate any non-electrical dangers

Not give rise to dangerous conditions in the event of overload

Precautions

Hochiki smoke and heat detectors cannot be used to prevent a fire itself, they are intended only to detect certain characteristics

of fire. When installing the detectors, check that the location of each one has been planned according to appropriate fire

regulations and recommendations.

Hochiki detectors are suitable for indoor use only. A detector should not be installed in the following environmental conditions:

Excessive ambient temperature.

Where excessive condensation or moisture is present.

Where corrosive gas or any other harmful agent is present.

Where flammable dust or steam is present.

Where obstructions are present which could impede the flow of air to the detector.

Where mechanical stresses could affect the detector when fitted in accordance to these instructions.