Hollywood Racks HR3000-E User manual

Other Hollywood Racks Automobile Accessories manuals

Hollywood Racks

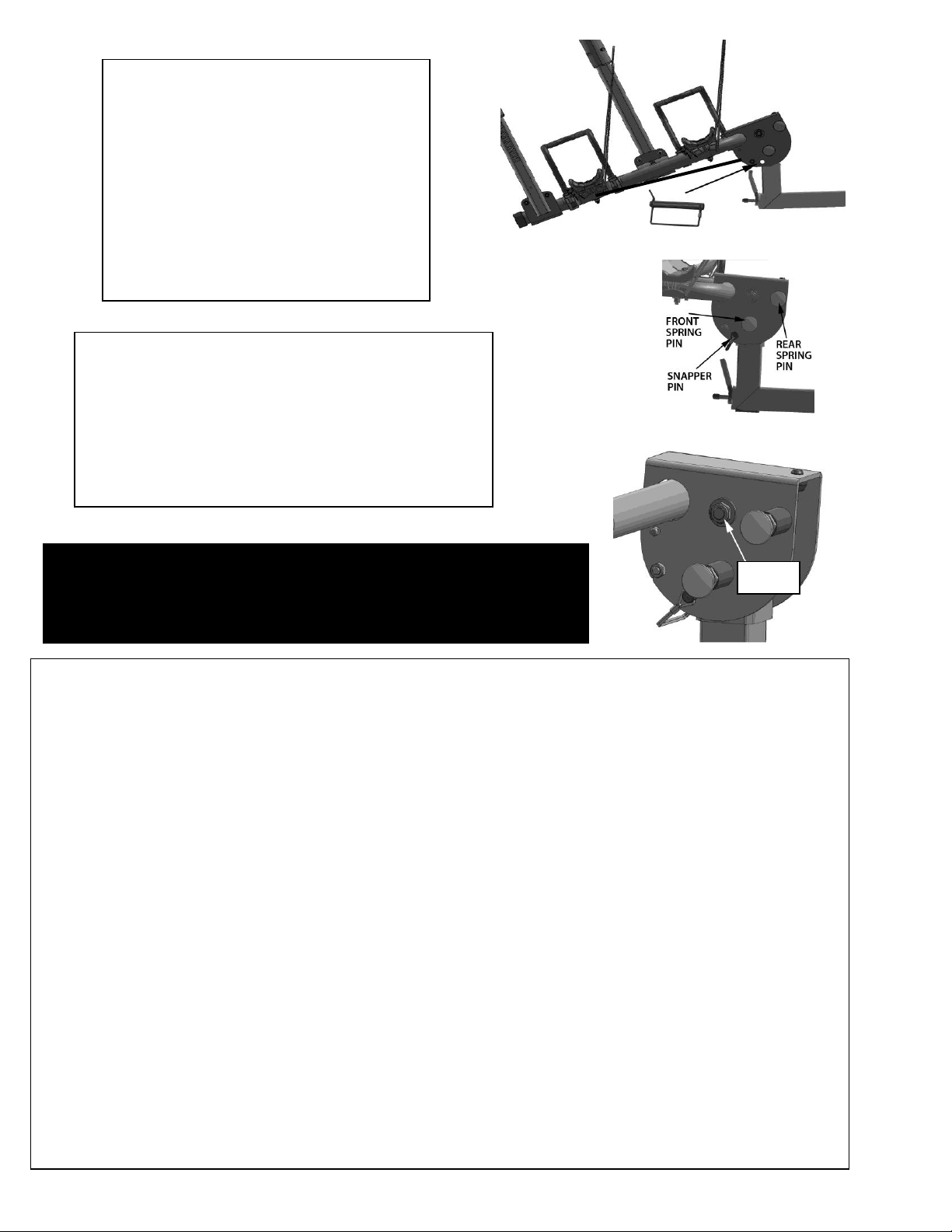

Hollywood Racks HR135 Quick setup guide

Hollywood Racks

Hollywood Racks Sport Rider HR1475 User manual

Hollywood Racks

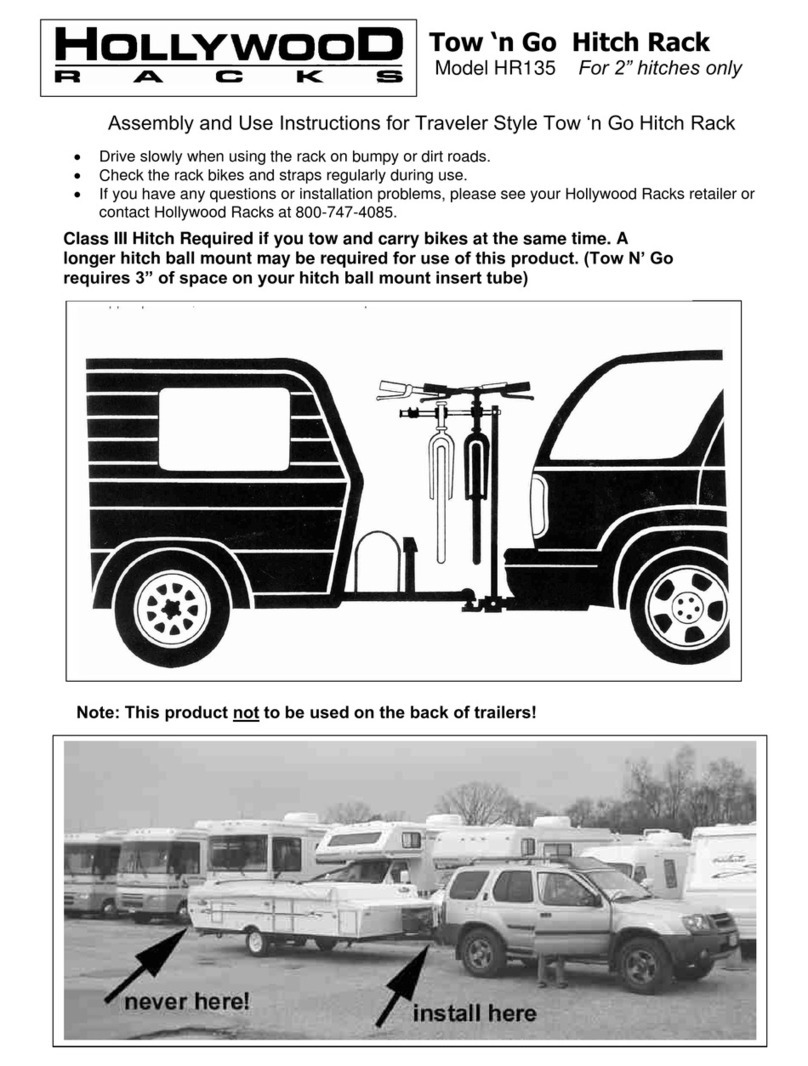

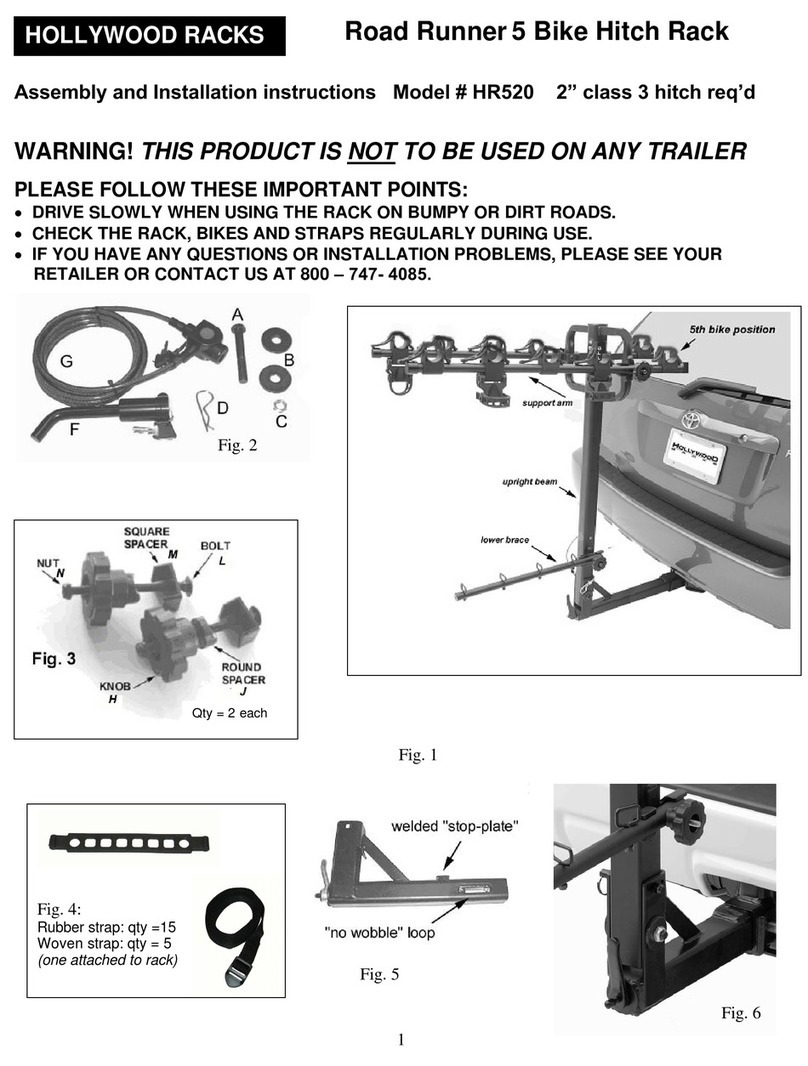

Hollywood Racks Road Runner 5 Bike Hitch Rack Instruction manual

Hollywood Racks

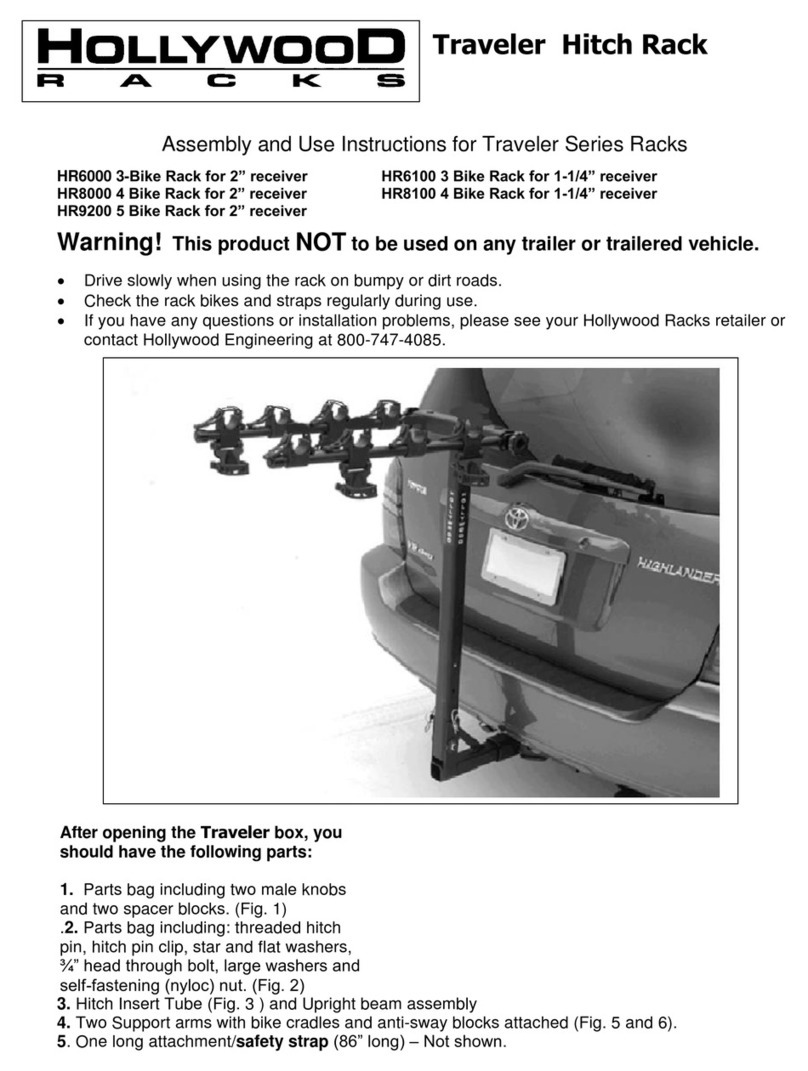

Hollywood Racks HR6000 Quick setup guide

Hollywood Racks

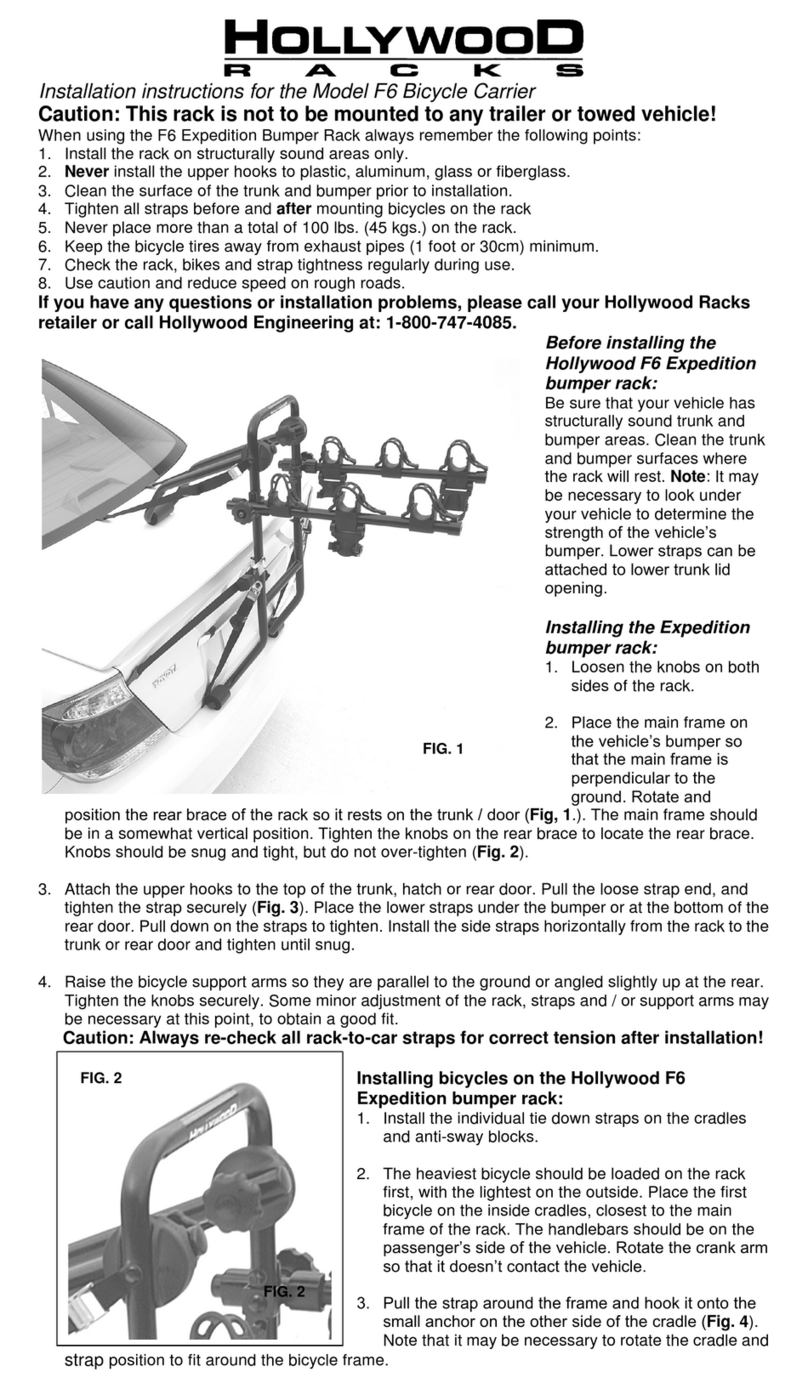

Hollywood Racks F6 User manual

Hollywood Racks

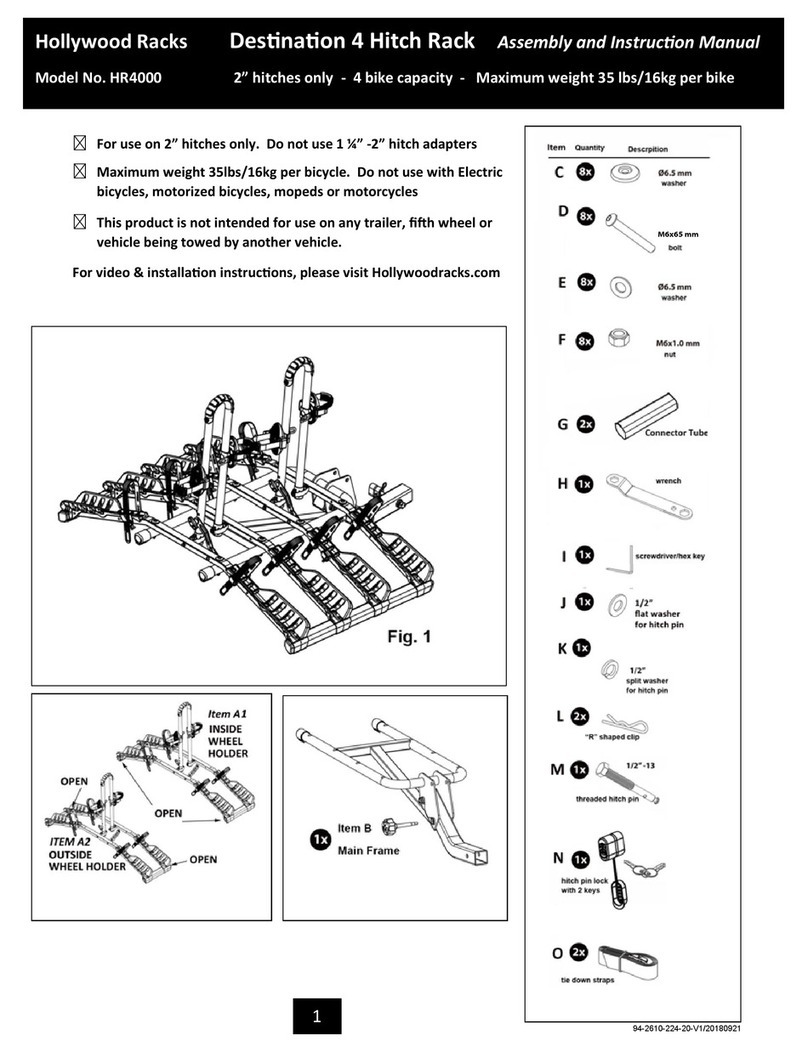

Hollywood Racks HR4000 User guide

Hollywood Racks

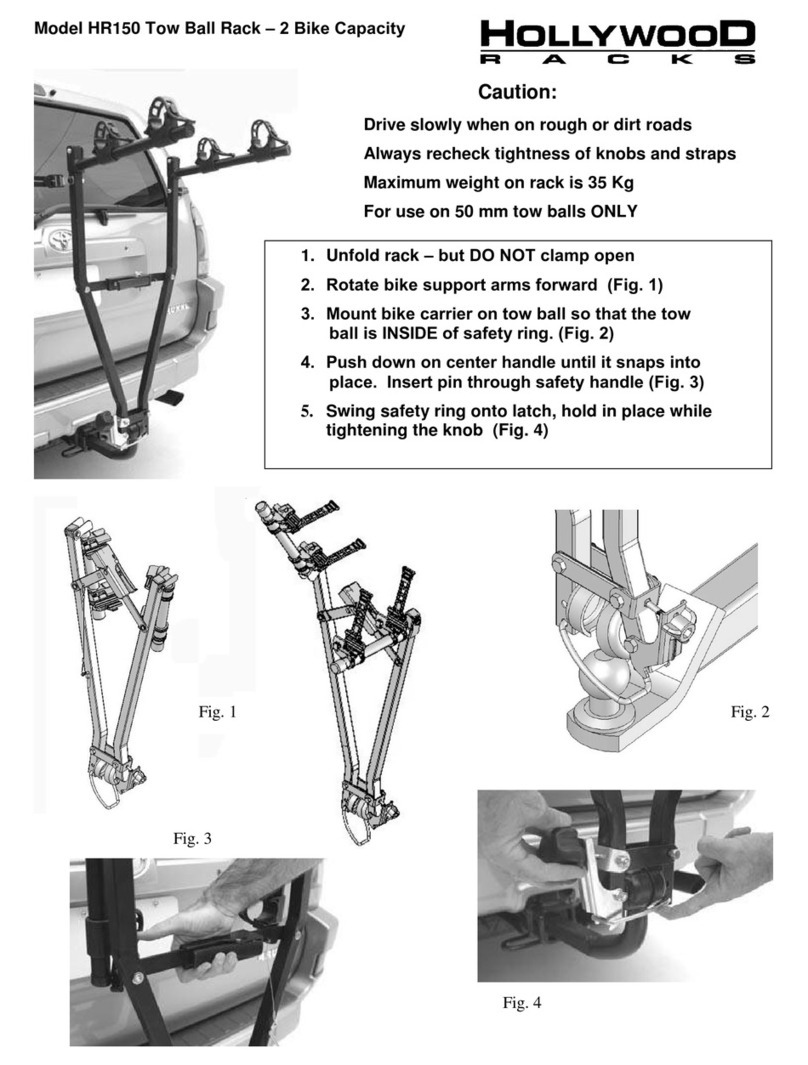

Hollywood Racks HR150 User manual

Hollywood Racks

Hollywood Racks HR1200 User manual

Hollywood Racks

Hollywood Racks Sportrider HR1500 Instruction manual

Hollywood Racks

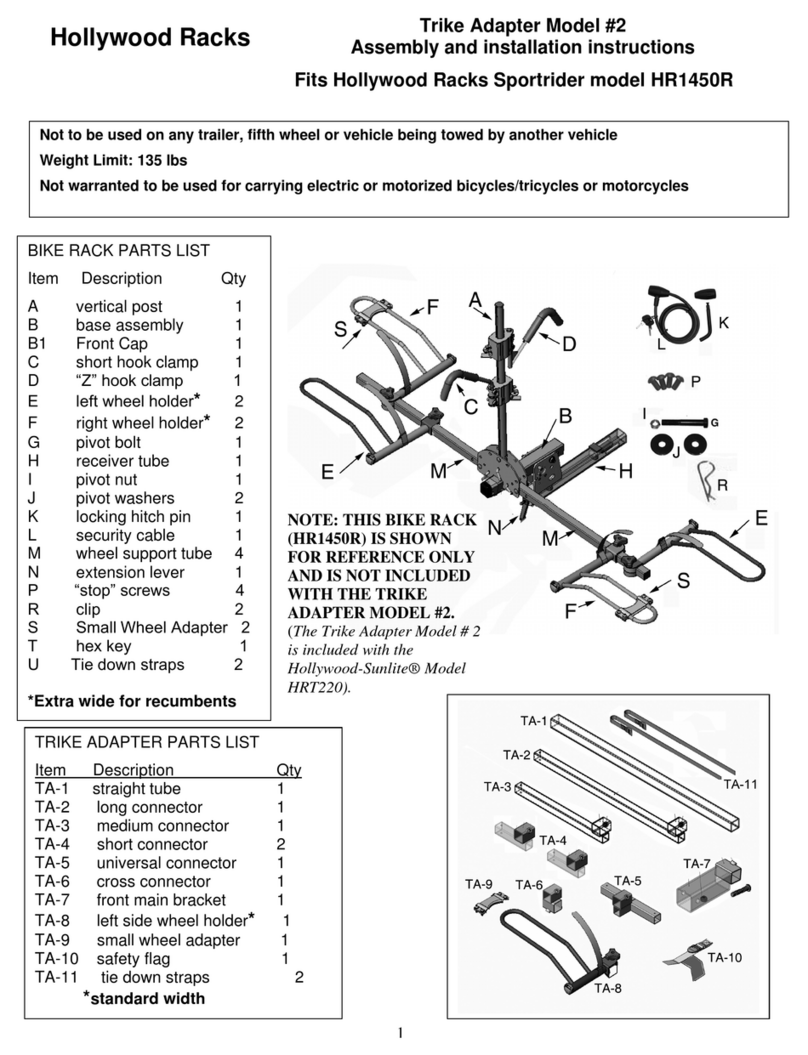

Hollywood Racks Trike Adapter 2 Instruction manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction