Notifier®and FlashScan®are registered trademarks of Honeywell International, Inc. Testifire®is a registrered trademark of SDi, LLC.

TESTING

Before testing, notify the proper authorities that the system is undergoing

maintenance, and will temporarily be out of service. Disable the system to

prevent unwanted alarms.

All sensors must be tested after installation and periodically thereafter. Test-

ing methods must satisfy the Authority Having Jurisdiction (AHJ). Sensors

offer maximum performance when tested and maintained in compliance with

NFPA 72.

The sensor can be tested in the following ways:

A. Functional: Magnet Test (P/N M02-04-01 or M02-09-00)

This sensor can be functionally tested with a test magnet. The test magnet

electronically simulates smoke in the sensing chamber, testing the sensor

electronics and connections to the control panel.

1. Hold the test magnet in the magnet test area as shown in Figure 3.

2. The sensor should alarm the panel.

Two LEDs on the sensor are controlled by the panel to indicate sensor

status. Coded signals, transmitted from the panel, can cause the LEDs to

blink, latch on, or latch off. Refer to the control panel technical documen-

tation for sensor LED status operation and expected delay to alarm.

B. Smoke Entry

Sensitivity readings are available through the FACP. Refer to the manufac-

turer’s published instructions for proper use.

Additionally, canned aerosol simulated smoke (canned smoke agent) may

be used for smoke entry testing of the smoke detector. Tested and ap-

proved aerosol smoke products include:

Manufacturer Model

HSI Fire and Safety 25S, 30S (PURCHECK)

SDi SMOKE CENTURIAN, SOLOA4,

SMOKESABRE, TRUTEST

No Climb TESTIFIRE 2000

When used properly, the canned smoke agent will cause the smoke detec-

tor to go into alarm. Refer to the manufacturer’s published instructions for

proper use of the canned smoke agent.

Canned aerosol simulated smoke (canned smoke agent) formulas will vary

by manufacturer. Misuse or overuse of these products may have long term

adverse effects on the smoke detector. Consult the canned smoke agent manu-

facturer’s published instructions for any further warnings or caution statements.

A sensor that fails any of these tests may need to be cleaned as described

under CLEANING, and retested.

When testing is complete, restore the system to normal operation and notify

the proper authorities that the system is back in operation.

CLEANING

Before removing the detector, notify the proper authorities that the smoke

detector system is undergoing maintenance and will be temporarily out of

service. Disable the zone or system undergoing maintenance to prevent un-

wanted alarms.

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover by pressing firmly on each of the four removal

tabs that hold the cover in place. (See Figure 4.)

3. Vacuum the screen carefully without removing it. If further cleaning is

required continue with Step 4, otherwise skip to Step 7.

4. Remove the chamber cover/screen assembly by pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove dust and debris from

the sensing chamber.

6. Reinstall the chamber cover/screen assembly by sliding the edge over the

sensing chamber. Turn until it is firmly in place.

7. Replace the cover using the LEDs to align the cover and then gently push-

ing it until it locks into place.

8. Reinstall the detector.

9. Test the detector as described in TESTING.

10. Reconnect disabled circuits.

11. Notify the proper authorities that the system is back on line.

SPECIAL NOTE REGARDING SMOKE DETECTOR GUARDS

Smoke detectors are not to be used with detector guards unless the combina-

tion has been evaluated and found suitable for that purpose.

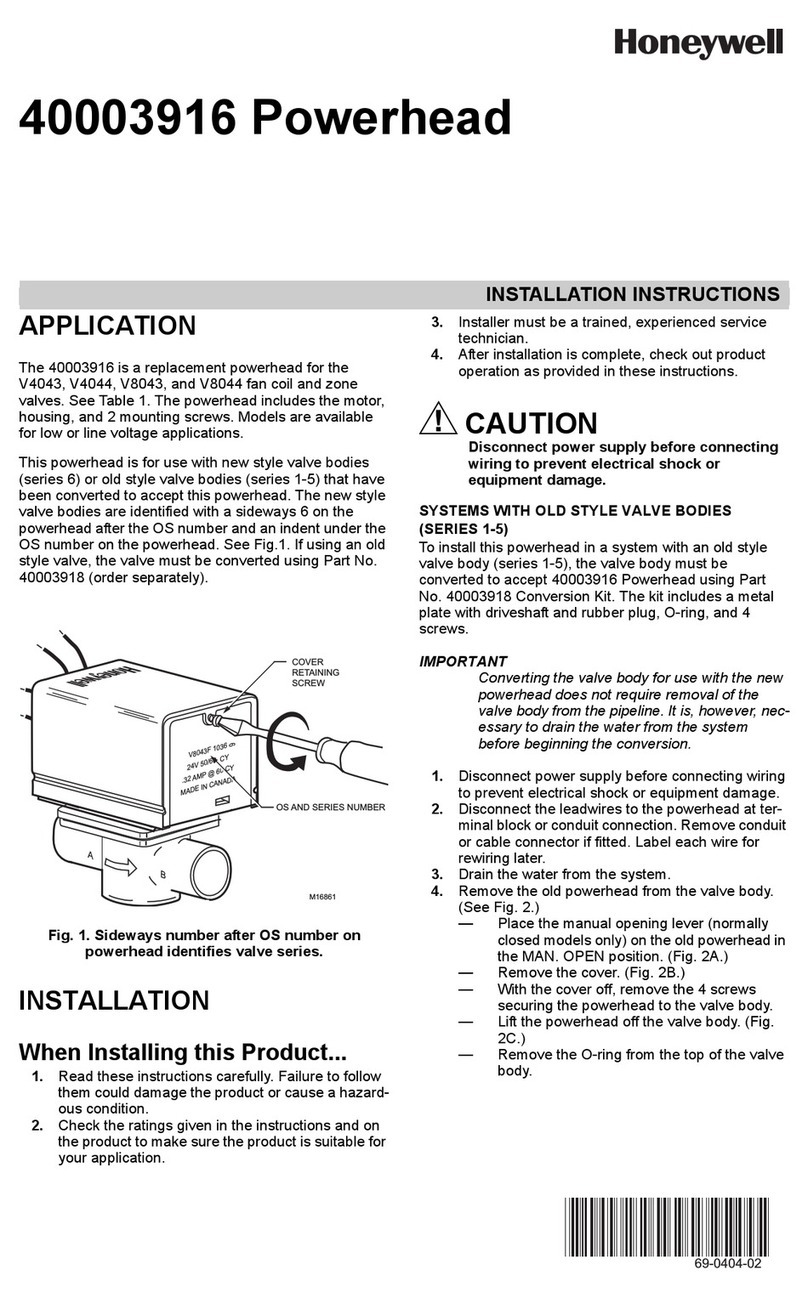

FIGURE 3: FEATURES OF THE PHOTO DETECTOR

Magnet

Test

Marker

LED

Base

Notch

Magnet Test Marker

Base Alignment Notch

LED C2021-00

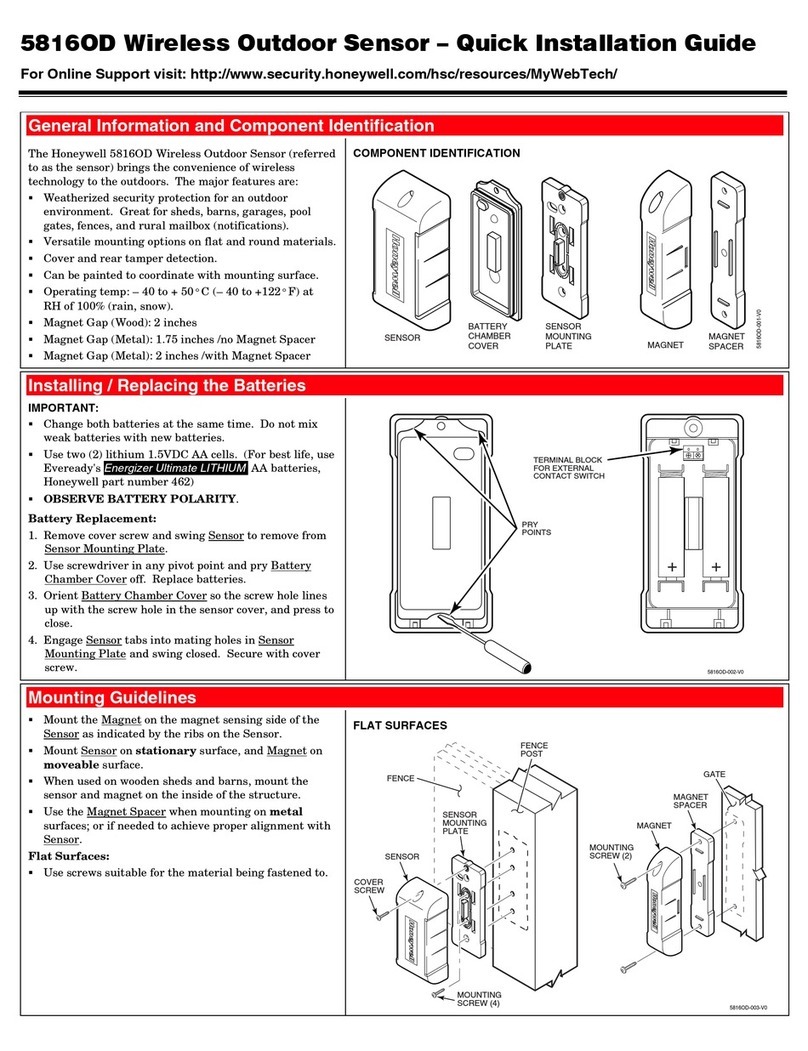

FIGURE 4: CLEANING THE PHOTO DETECTOR

Cover

Removal

Tabs

Sensor Cover

Sensing Chamber

Cover and Screen

Sensing Chamber

C2022-00

FCC STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

Please refer to insert for the Limitations of Fire Alarm Systems

DEVICE AND SYSTEM SECURITY

Before installing this product ensure that the

tamper seal on the packaging is present and

unbroken and the product has not been tampered

with since leaving the factory. Do not install this

product if there are any indications of tampering.

If there are any signs of tampering the product

should be returned to the point of purchase.

It is the responsibility of the system owner to

ensure that all system components, i.e. devices,

panels, wiring etc., are adequately protected to

avoid tampering of the system that could result

in information disclosure, spoofing, and integrity

violation.

2 I56-4281-001

©2018 Notifier. 07/25/2018