NI-285 Index 1 February 2022

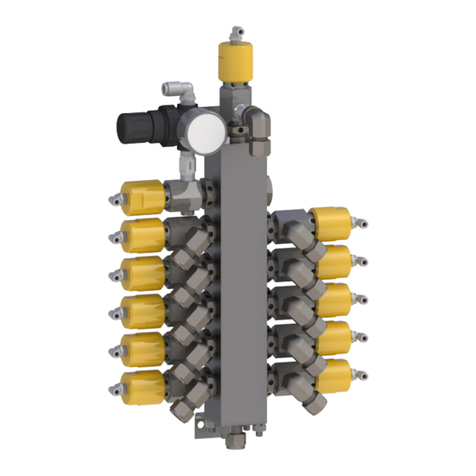

On mechanism "14" and upper body "10". Position the upper body "10" on the mechanism and mount with screws "14".

Take the valve "3", place the valve seal "4", add the spacer "5", place the valve seal "6", add the sleeve "7".

Place the assembly onto the mechanism "15", taking care not to damage the seal and the segment "13", then screw and

tighten the valve using the flats on the valve (use thread locker), then (N.C. assembly, supply the mechanism "15", N.O.

assembly, cut off the air). Position the lower body "1" paying attention to the seal and tighten the nuts "9" on the dowel

pins "2". Then (N.C. assembly, turn off the air, N.O. assembly, supply the mechanism "15") and check the correct

centring of the valve by the lower track. When using for the first time, check for leaks of the lower section in the low

position, then of the upper section(s) and of the lantern in the high position.

N.B.:

−We recommend the use of a medium thread locker glue to secure the valve when reassembling on the mechanism.

−During sawing operations, please avoid the introduction of chips or filings inside the pipes and rinse the pipes with

a generous amount of water to avoid damage to the seals during commissioning.

8) STORAGE

We advise you to store your valves protected as much as possible from the pollution of the site (abrasive dust, impacts,

acid, or chlorinated products, U.V...) and if possible assembled to avoid the mixing of components.

9) EEC COMPLIANCE

A-All our valves comply with European regulations (EEC) within the limits of use described in paragraph B.

The CE mark on the valve indicates compliance with the following directives:

B-Use limits:

According to Directive 2014/68/EU

The valve accepts a maximum operating pressure of 40 bar on liquids and gases of group 2, a

maximum temperature of 140°C, a permissible vacuum of 0.4 bar.

The use of hazardous gases of group 1(1) is not permitted.

The use of hazardous liquids of group 1(1) is limited to a pressure of 20 bar.

For usage outside these limits, please consult our technical service

(1) hazardous gases/liquids: Group 1 gases/liquids identified by a letter which you will find on the label and

on the product safety data sheet:

E (for explosive gas), O (for oxidizer), F+, F and R10 (flammable), T+ and T (toxic), Xn (Harmful), C

(Corrosive), Xi (Irritant), (non-exhaustive list)

For more details, see regulation 1272/2008 "Labelling of dangerous products".

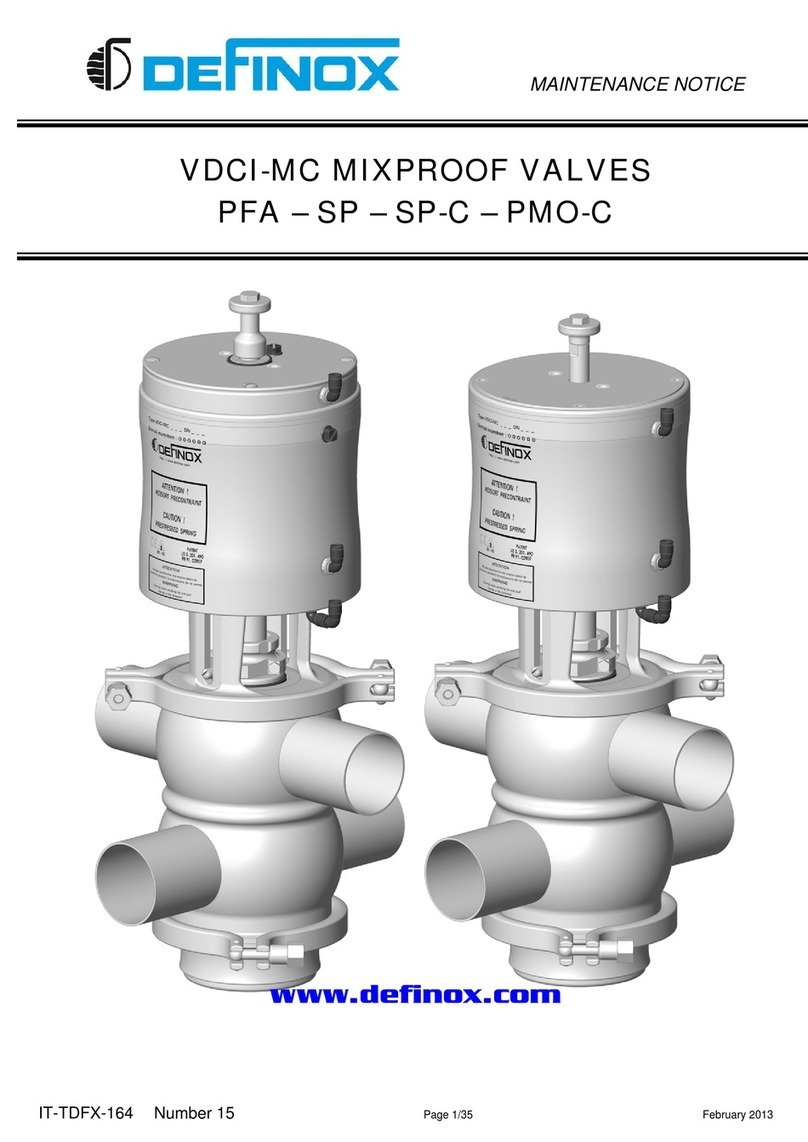

10) SPARE PARTS AND ACTUATOR DISASSEMBLY

Note the identification number on the valve and refer to the general documentation or consult us. In the event of a

malfunction, please contact us.

Dismantling the mechanism is a simple but delicate operation that requires the use of appropriate tools and to follow

the valve's maintenance manual.

Please contact us for these instructions or to request maintenance operations at our premises or on site.

Note: The valve must be out of service before any work is carried out and disassembly of the components with the pre-

tensioned spring must be carried out according to the instructions in the maintenance manual.

All users of DEFINOX valves must periodically check the condition of the equipment installed, specially concerning

the parts playing a "safety" role (at a fixed frequency depending on the use and cleaning applied).

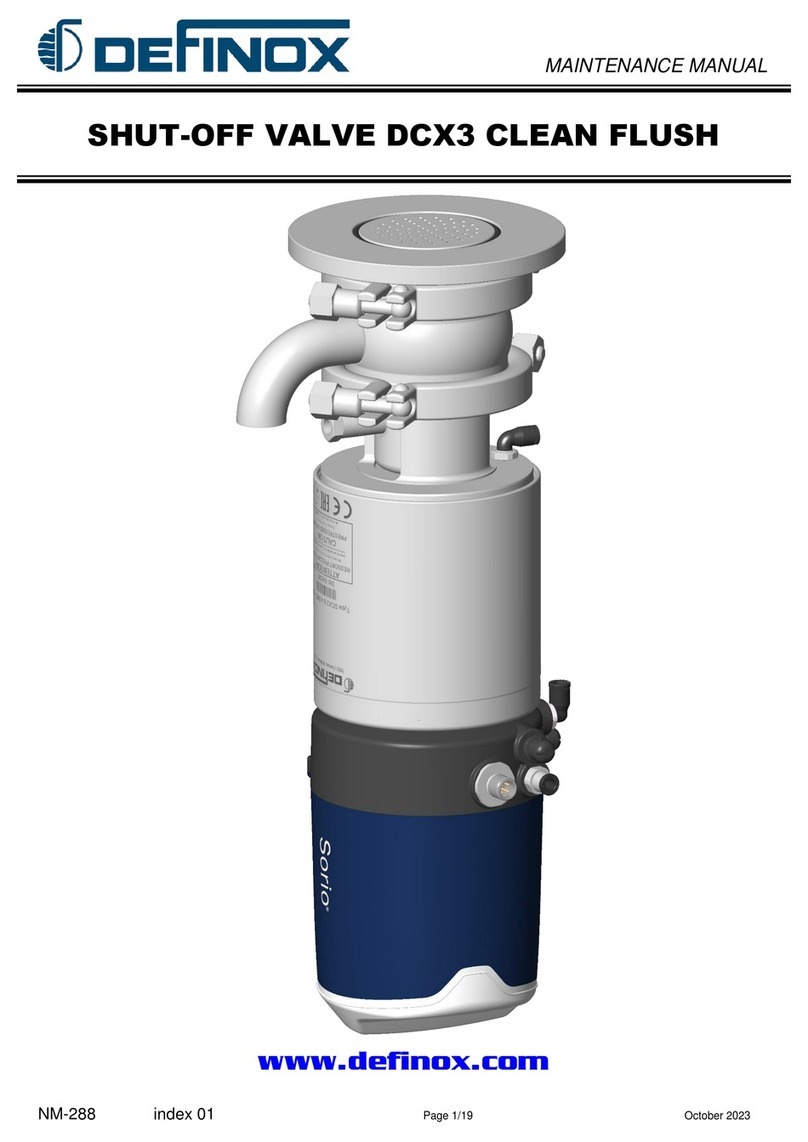

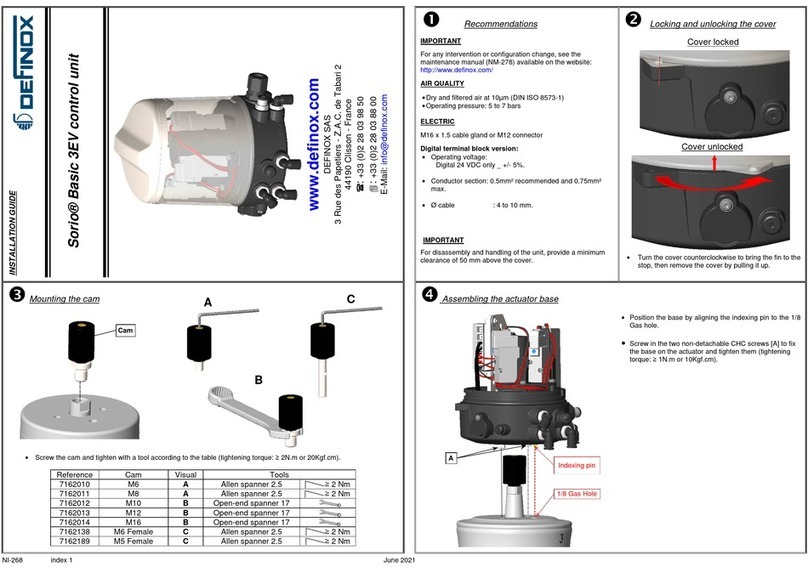

INSTALLATION GUIDE

AUTOMATIC SHUT-OFF

VALVE DCX4 HP

www.definox.com

DEFINOX SAS

3 Rue des Papetiers - Z.A.C. de Tabari 2

44190 Clisson - France

:+33 (0)2 28 03 98 50

:+33 (0)2 28 03 88 00