S89E,F DIRECT SPARK IGNITION CONTROL MODULE

68-0066—4 4

instructions, and service procedures for their appliance. If the

manufacturer instructions are not available, use the general

guidelines that follow.

Mount the S89

Select a convenient location on the burner or furnace chassis

or cabinet, protected from moisture due to splashing, dripping,

or condensation. Allow room to easily reach the S89 terminals

for wiring and servicing. Do not exceed the ratings given in the

Specifications section.

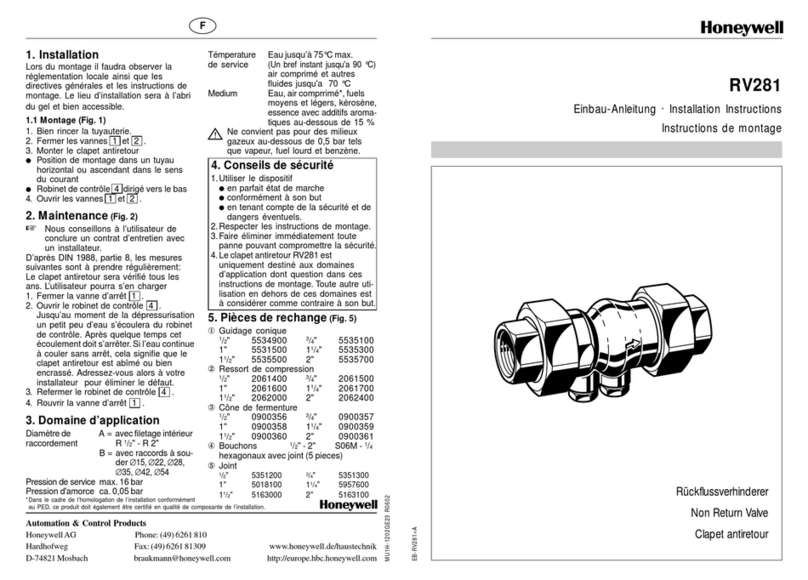

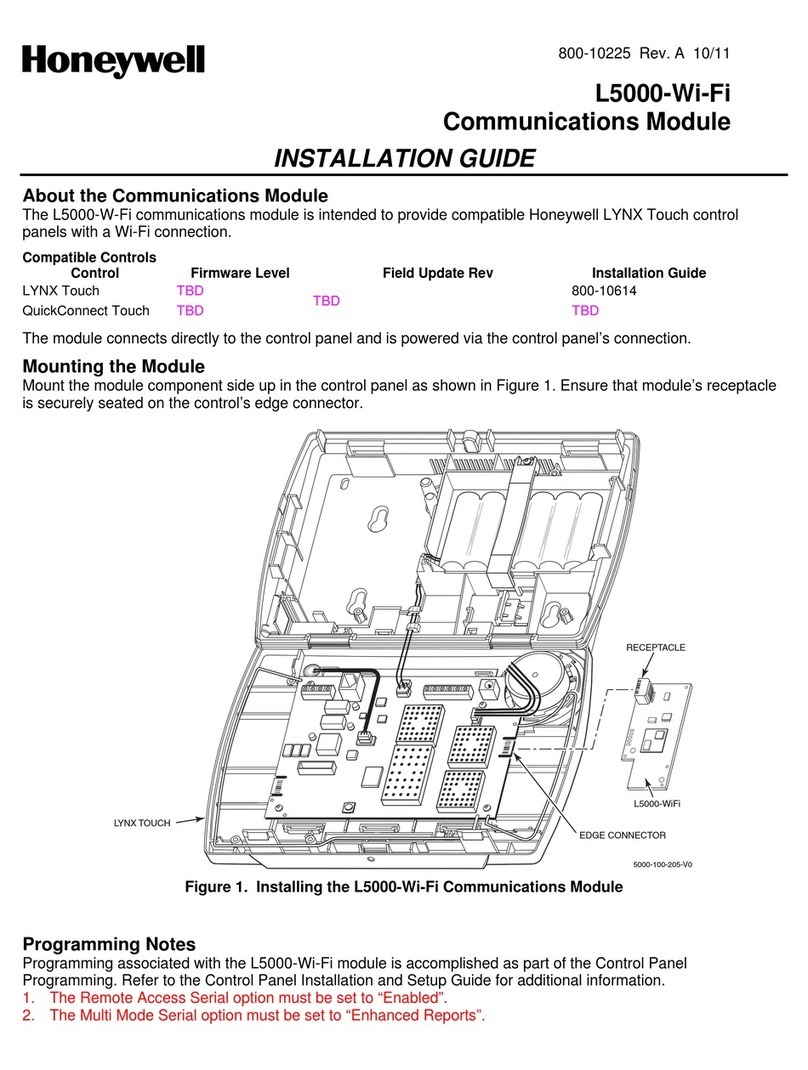

The S89 may be mounted in any position. See Fig. 1 for

mounting dimensions. Mount with 1 in. (25 mm) long, no. 6-32

machine screws or no. 8 sheet metal screws. Fasten securely.

Mount Auxiliary Controls

Mount the spark generator, igniter, flame sensor, thermostat,

transformer, gas control, and any other auxiliary controls

according the control manufacturer instructions.

WIRING

CAUTION

Equipment Damage Hazard.

Can cause equipment malfunction or damage.

1. The sensor leadwire must be no more than 3 ft

(0.9m) long. Do not allow the wire to touch

grounded metal surfaces.

2. A common ground is required for the S89, the spark

ignitor and the main burner. The 24V (GND)

terminal internally grounds one side of the

transformer. Auxiliary controls or limits must be in

the ungrounded leg.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect the power supply before beginning wiring.

More than one disconnect may be required.

Use wiring diagrams and instructions provided by the

appliance manufacturer, if available. Otherwise, follow the

general procedures and diagrams outlined below.

All wiring must comply with all applicable electrical codes and

ordinances.

1. Make sure the transformer has adequate power (VA)

rating. See Table 1 in Specifications section.

2. If you are replacing an S89 that was used with an

external valve on delay timer, you must disconnect the

external timer and use an S89F to provide the delay

function. External timers cannot be used with either

S89E or S89F controllers because the safety circuit in

the controls may repeatedly set the timer to zero,

preventing burner start. Always disconnect the external

timer when using an S89E or F. To disconnect the timer:

a. Turn off power.

b. Cut the two leadwires at the external timer.

c. Strip the ends of the wires 1/2 in. (13 mm) and

connect with a solderless connector.

d. Restore power.

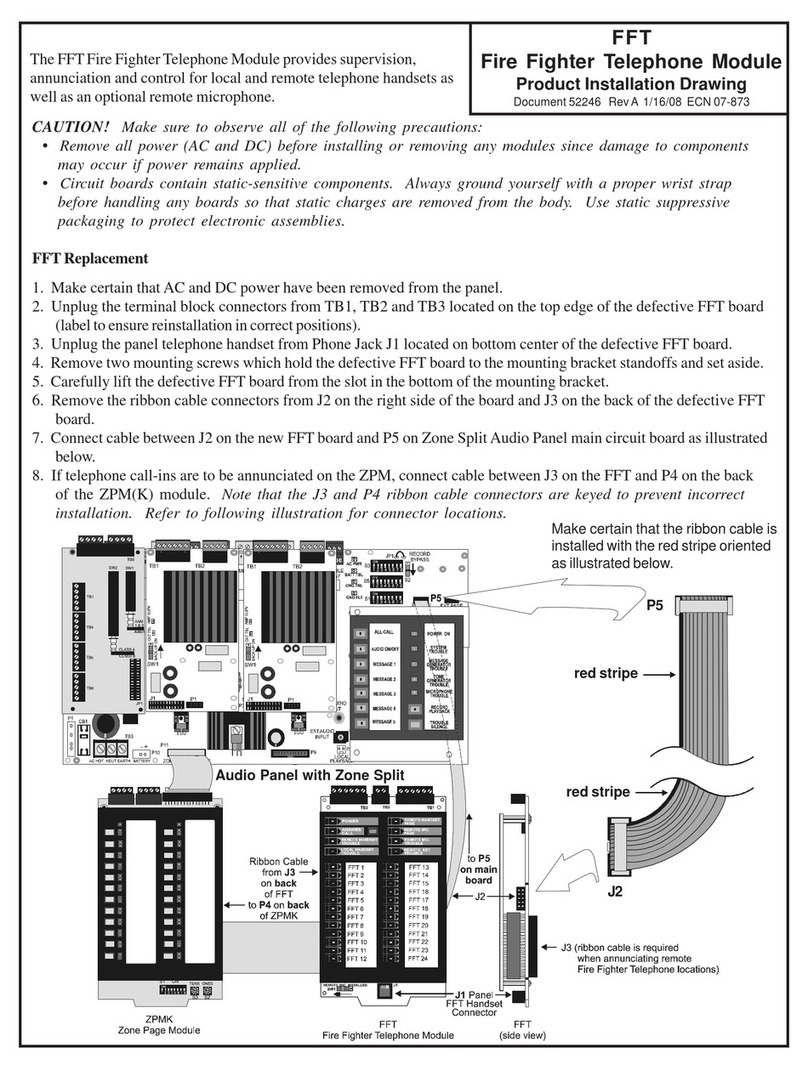

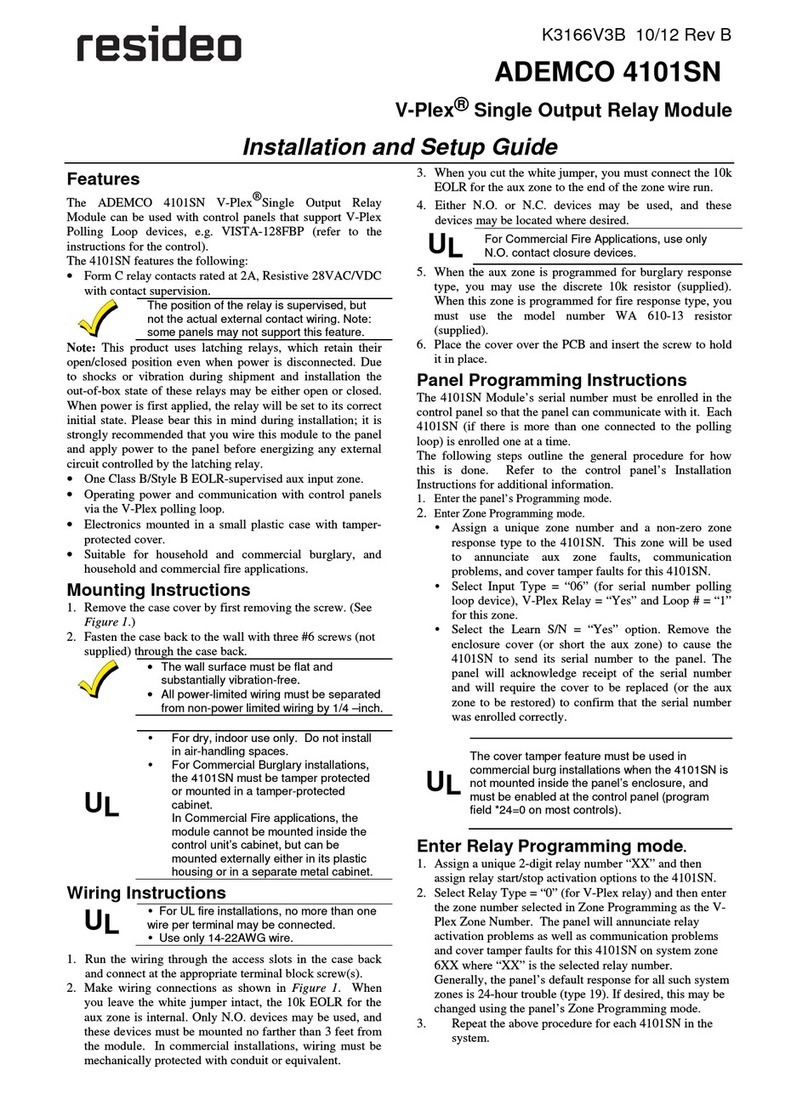

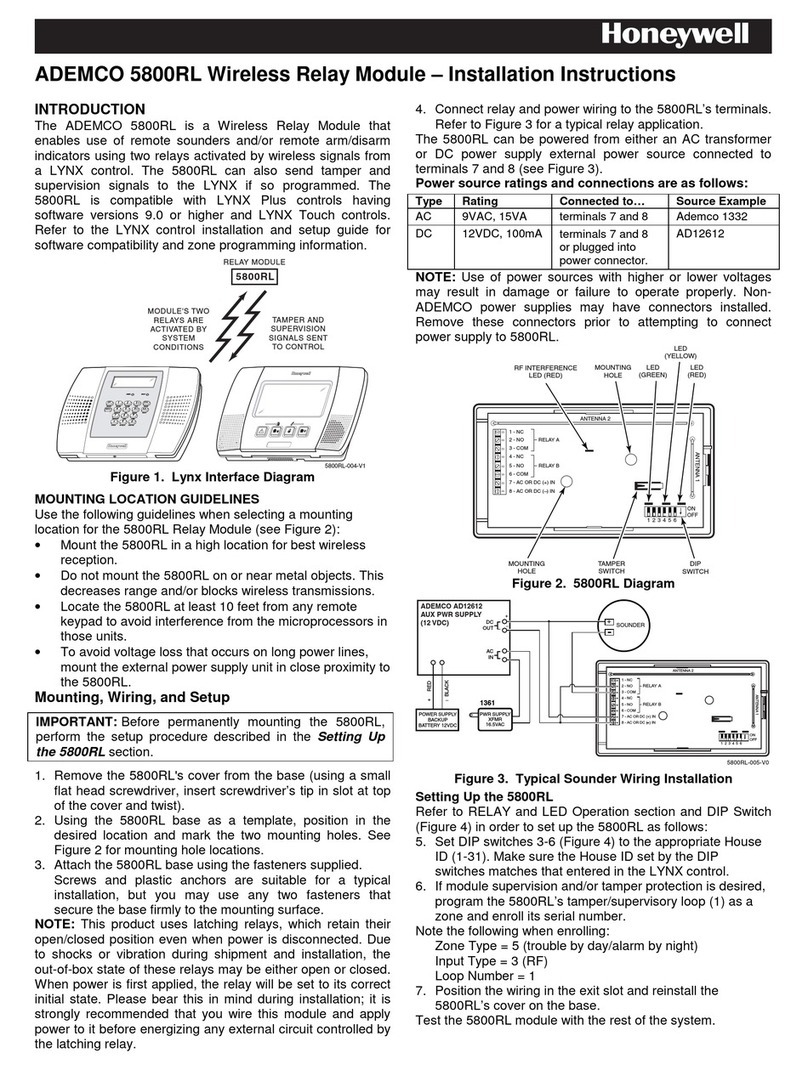

3. Wire system components and S89 as shown in Fig. 2

and 3. Refer to appliance manufacturer instructions for

connections to other auxiliary controls.

4. Make sure the L1 (Hot) and L2 (Ground) leads are

connected to the right leads. If they are reversed, the

S89 will not detect the flame and will go into safety

lockout.

5. Connect spark igniter, flame sensor, main burner, and

S89 to a common ground. Use thermoplastic insulated

wire with a minimum rating of 221°F (105°C) for the

ground wire. Connect the ground wire as follows:

a. Connect one end of the ground wire to the

quick-connect GND (burner) terminal on the S89,

using a 1/4 in. (6 mm) quick-connect (AMP 41772 or

equivalent).

b. Strip the other end of the wire and fasten it under the

igniter bracket mounting screw.

c. If necessary, install a shield to protect the wire from

radiant heat generated by the burner.

d. The burner serves as the common ground. If

metal-to-metal contact between the burner and the

appliance cabinet is poor, run a lead from the burner

to the cabinet. The cabinet must be earth-grounded.

START-UP AND CHECKOUT

If this is a replacement application, refer to the specific

instructions provided by the heating appliance manufacturer

(if available). Also, since the auxiliary controls used on any

system may differ, refer to the control manufacturer

instructions for start-up and checkout procedures for other

system components.

Perform Gas Leak Test

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. Never use a flame to check for gas leaks, only a

soap and water solution.

2. Test for gas leaks whenever work is done on a gas

system.

3. Soap and water must not touch the S89.

With the main burner in operation, paint the pipe joints and

gas control gasket edges with a rich soap and water solution.

Bubbles indicate a gas leak. To stop the leak, tighten joints

and screws, or replace the gas control. Never use a flame to

check for gas leaks.