Check your equipment....

Take suitable anti-static precautions, such as wearing a grounded

wrist strap, when following ALL instructions. Remove all packaging

from the kit and ensure that it has not been damaged in transit (and

that no items are missing - see checklist on the left) before

proceeding any further. If no damage is evident, proceed using the

instructions below. In the unlikely event that damage has occurred

or items are missing, DO NOT PROCEED, contact your supplier

and refer to the panel’s Installation, Commissioning &

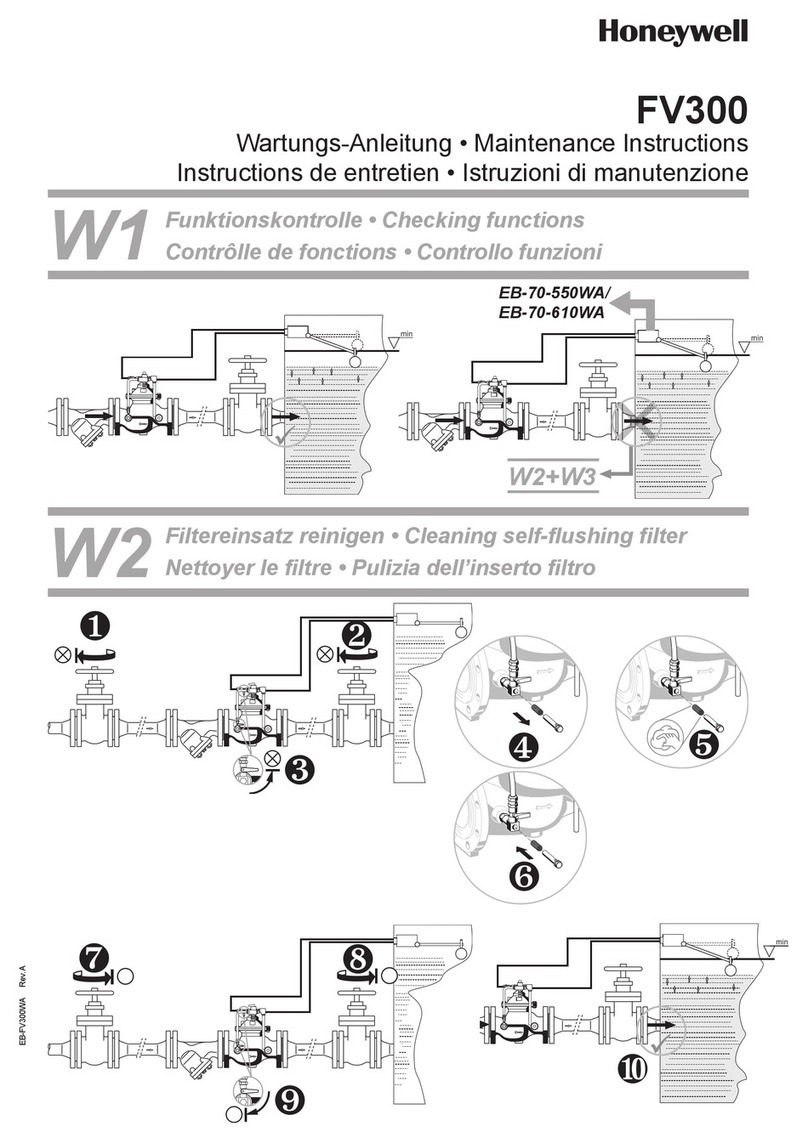

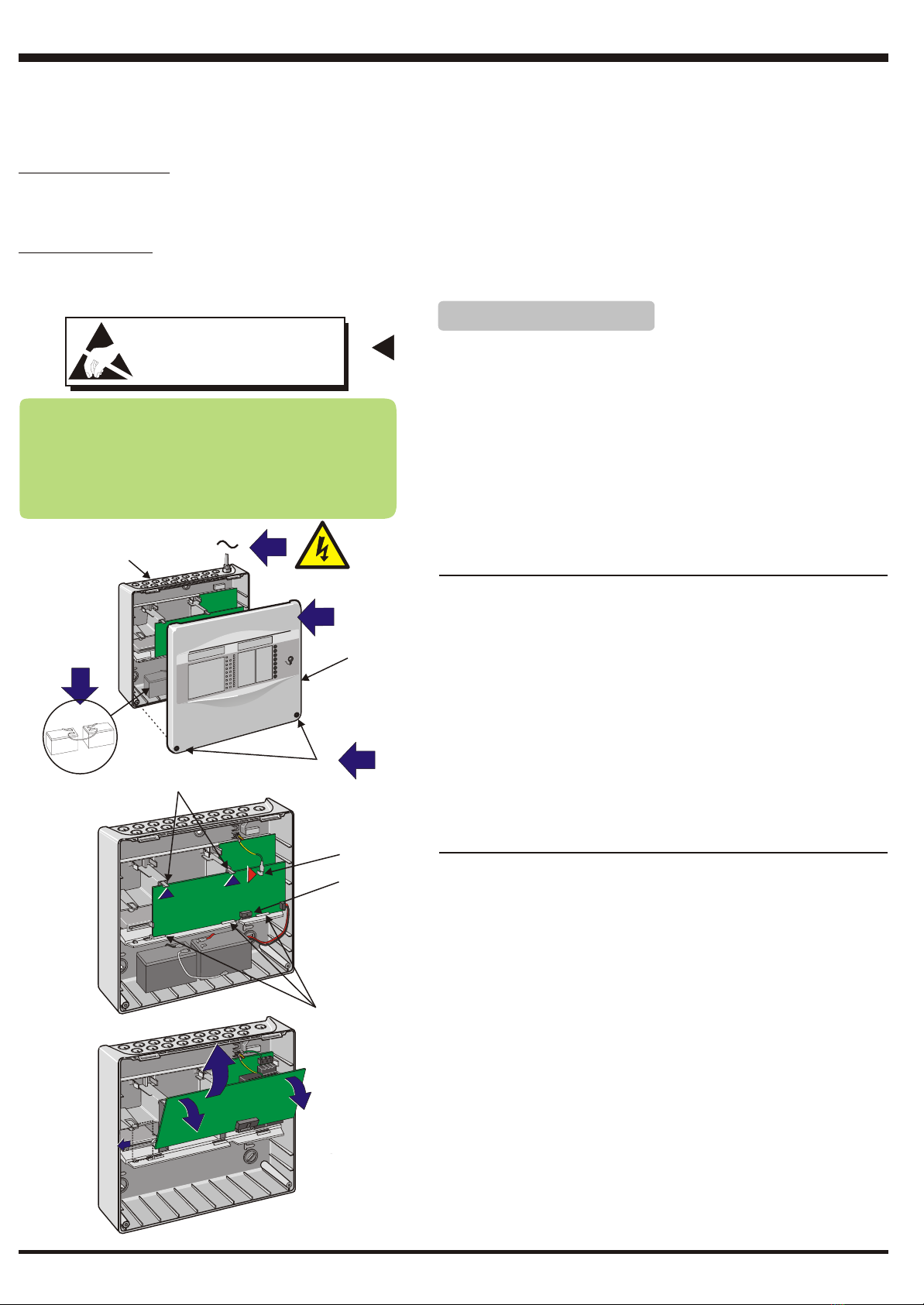

To fit/replace the 4-Way Sounder PCB, configure it (see page 3), then

proceed as follows:

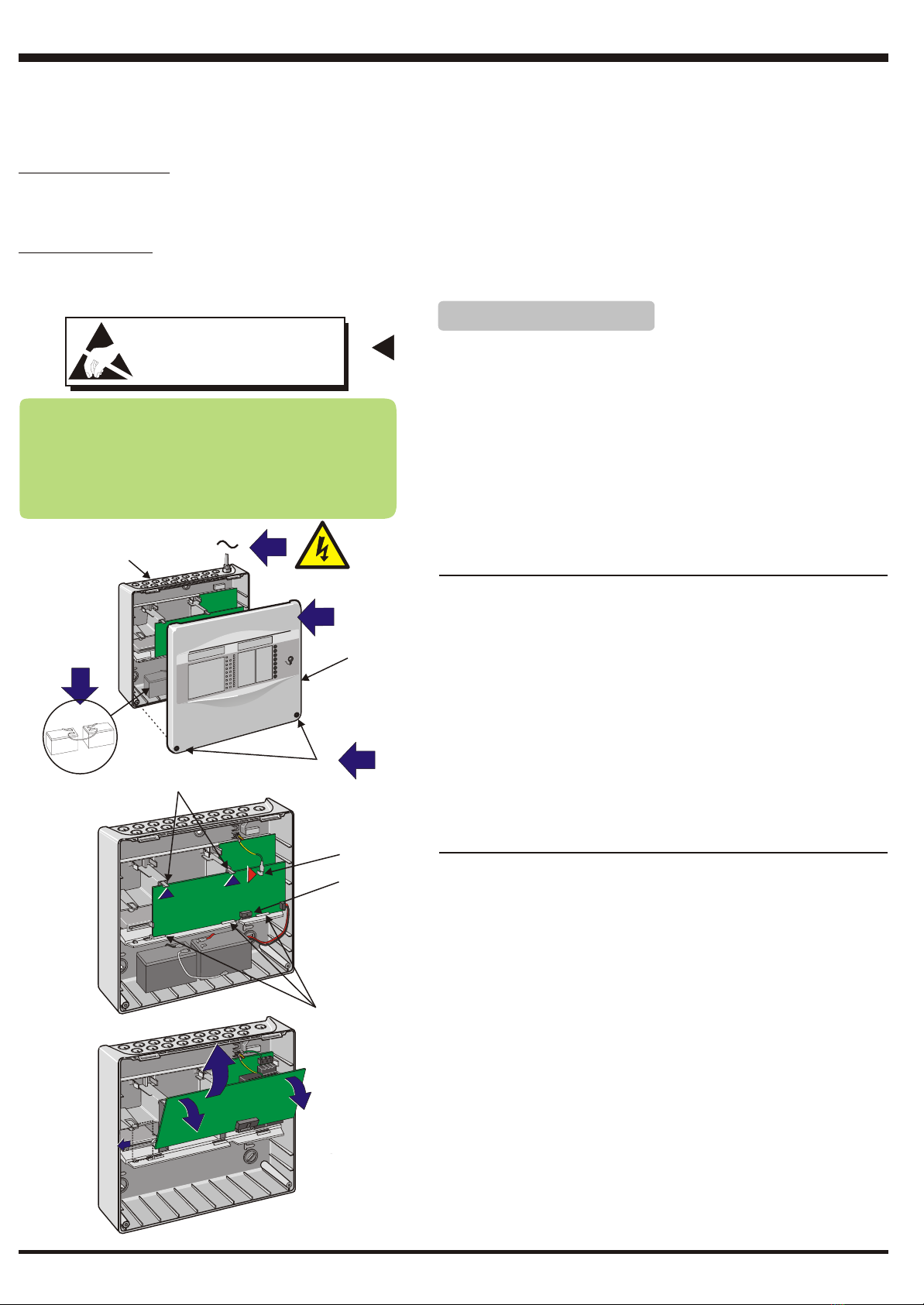

1Only carry out this procedure when mains power to the panel has been

isolated.

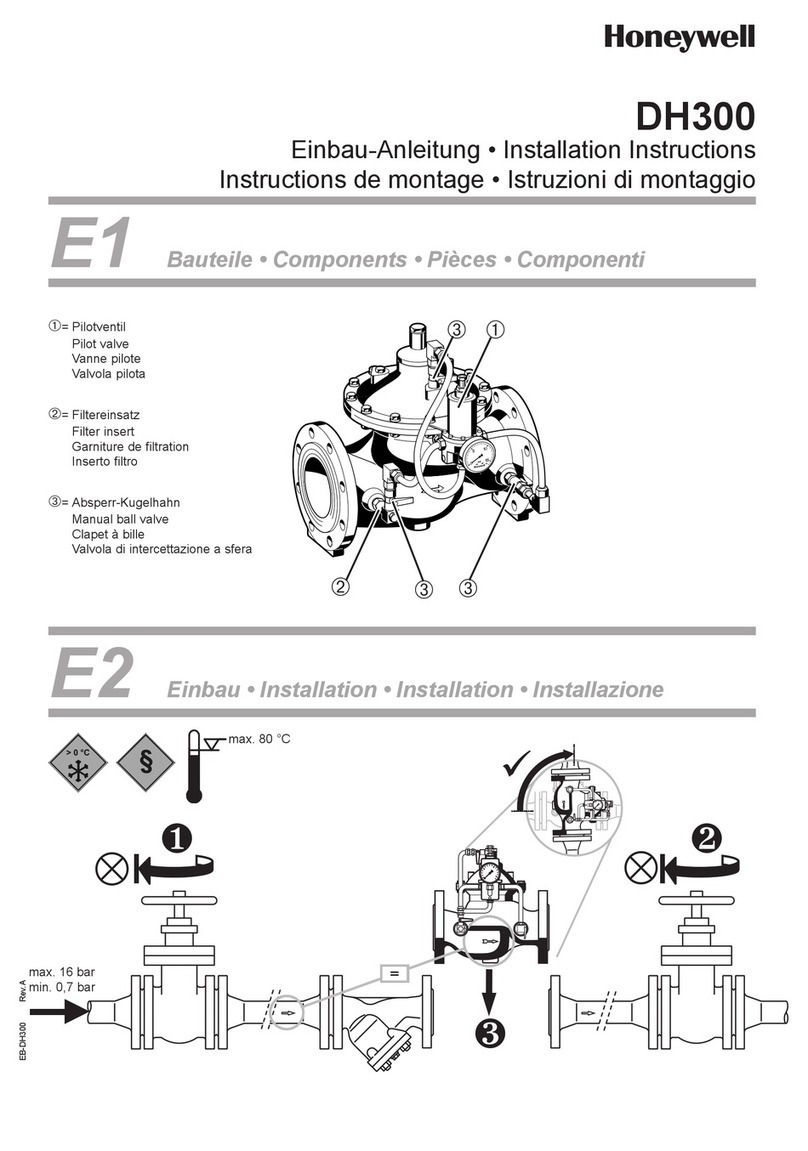

2Use a 4mm hex key to release the two socket-headed screws (A) that

secure the cover (B) to the back box (C).

3Carefully withdraw the cover from the back box. Store cover safely.

4Ensure the batteries (D) are disconnected.

5If replacing the 4-Way Sounder PCB, temporarily disconnect all

external cables to the Main PCB.

Procedure for Fitting/Replacing the 4-Way Sounder

PCB

Your 4-Way Sounder PCB Kit, PN: 020-772 should

contain:

4-Way Sounder PCB PN: 124-372

16-way Ribbon Cable (x1) PN: 082-252-002

Nylon Spacers (x2) PN: 423-262

Nylon locking rivets (x2) PN: 423-261

Fitting/Replacing the 4-Way Sounder PCB

1

6Disconnect the earth lead from the right-angled, blade connector (E)

located at the top right-hand corner of the Main PCB.

7Carefully push up the two PCB-retaining clips (F) until the top edge of

the Main PCB is free to move - the bottom edge of the PCB is still

located by the three tabs (G).

Note: If a 2-Way Relay PCB is fitted, slide it to the left to disengage

socket connector SK2 on the Main PCB. Once disengaged, there

is no need to remove the 2-Way Relay PCB from the panel.

8Leave the ribbon cable connected at connector SK4 (H) on the Main

PCB, disconnect the ribbon cable at socket connector SK2 on the PSU

PCB.

DO NOT forget to reconnect this cable before re-fitting the main

PCB.

9Gently pull the top of the Main PCB away from the back box and lift the

PCB clear of the back box and store safely.

Removing the Main PCB

AA

CC

BB

Main

PCB

Main

PCB

1

0

1

1

3

3

2

2

4

4DD

Main PCB

EE

GG

FF

HH

For clarity,

batteries are

not shown.

For clarity,

batteries are

not shown.

99

77

OBSERVE PRECAUTIONS FOR

HANDLING ELECTROSTATIC

SENSITIVE DEVICES

OBSERVE PRECAUTIONS FOR

HANDLING ELECTROSTATIC

SENSITIVE DEVICES

ATTENTIONATTENTION

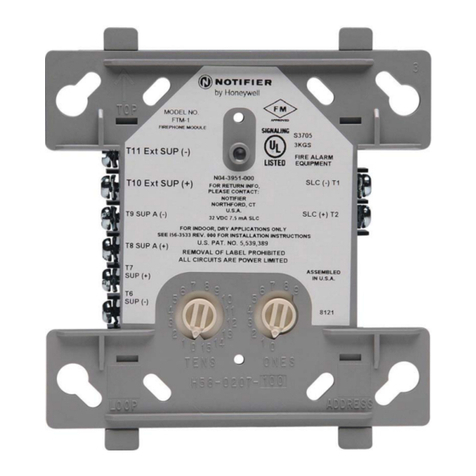

The 4-Way Sounder PCB (kit PN: 020-772) supports four configurable monitored outputs and two configurable digital

inputs. Various preset combinations of input and output functions are selected via a DIP switch. Up to two,

independently-configurable 4-Way Sounder PCBs may be fitted in the fire control panel. Provision is made for

connecting an SST LED box.

Output options are: sounder, ÜE transmission circuit, SST extinguishing system (three output circuits are used: one

for SST output and two for SST inputs), fault routing or fire routing. To connect an SST, a Routing Termination kit (PN:

020-773) and LED Display Box (English version PN: 020-769-001 or German version 020-769) are also required. The 4-

Way Sounder PCB detects partial open and short circuits on the output circuits, to meet EN54-13 requirements.

Input options are: fire transmission confirmed, fault transmission confirmed, class change or day mode.

Depending upon its output load, the PCB can be powered from the panel or from an external dc power supply, as set by a

jumper link.

997-536-000-2, Issue 2 July 2009