HONEYWELL

HONEYWELLHONEYWELL

HONEYWELL

CLASS “A” COMBINATION VALVES

VQ400M-Series

EN2R9081-C

October 2009

2

CONTENTS

VQ400M SERIES ........................................................... 1

CLASS “A” COMBINATION VALVES ......................... 1

APPLICATION................................................................ 1

Contents......................................................................... 2

FEATURES .................................................................... 2

DESCRIPTION............................................................... 3

SPECIFICATION............................................................ 3

Models ........................................................................ 3

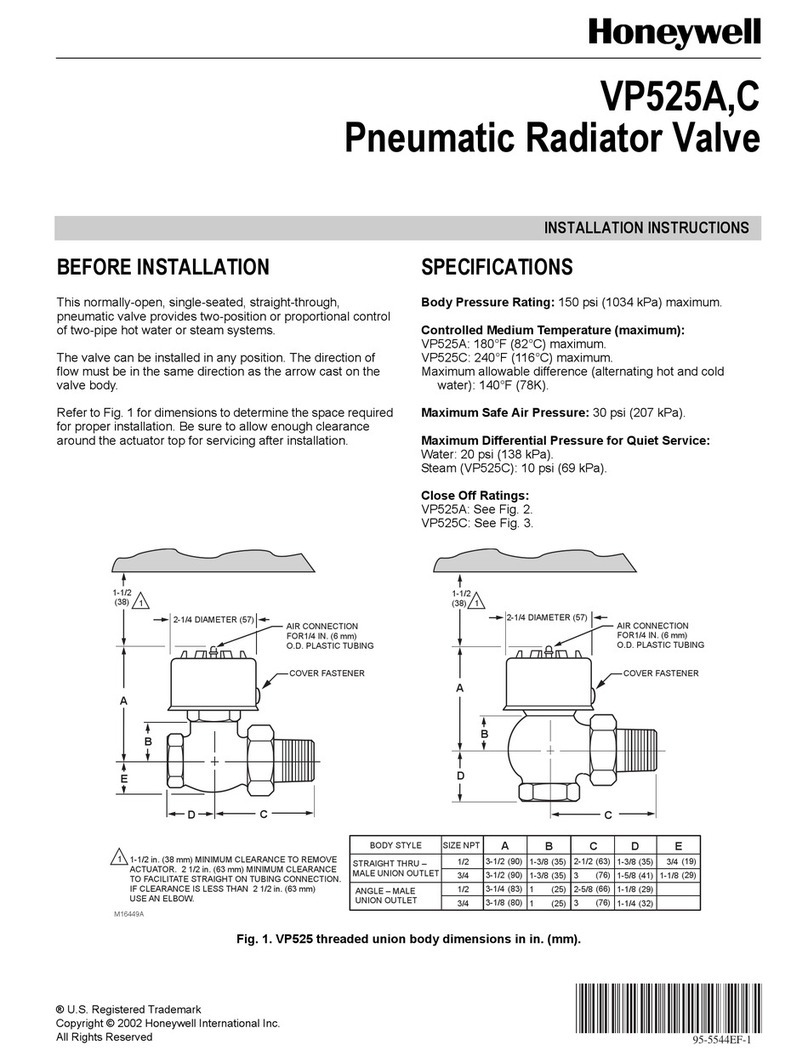

Dimensions................................................................. 3

Pipe sizes.................................................................... 4

Capacity...................................................................... 4

Connections................................................................ 4

Torsion and bending stress......................................... 4

Supply voltages........................................................... 4

Electrical equipment.................................................... 4

Electrical connections ................................................. 5

Ambient temperature range ........................................ 5

Coil insulation solenoid valves.................................... 5

Enclosure.................................................................... 5

Body material.............................................................. 5

Closing spring ............................................................. 5

Valve plunger.............................................................. 5

Seals and gaskets....................................................... 5

Power consumption .................................................... 5

PERFORMANCE CHARACTERISTICS......................... 6

Opening time............................................................... 6

Closing time................................................................ 6

Maximum working frequency ...................................... 6

Duty cycle ................................................................... 6

Operational voltage range........................................... 6

Designed life time ....................................................... 6

CAPACITY CURVES...................................................... 7

INSTALLATION.............................................................. 8

IMPORTANT............................................................... 8

WARNING................................................................... 8

Maintenance and service............................................ 8

Mounting position........................................................ 8

Mounting location........................................................ 8

Main gas connection flanged valves........................... 9

WARNING!.................................................................. 9

Electrical connection................................................... 9

WARNING................................................................... 9

Wiring.......................................................................... 9

ADJUSTMENTS AND FINAL CHECKOUT .................. 11

CAUTION.................................................................. 11

2nd main valve fast opening....................................... 11

2nd main valve slow opening..................................... 11

IMPORTANT............................................................. 11

Final checkout of the installation............................... 12

OPTION INSTALLATION ............................................. 13

WARNING................................................................. 13

CONSTRUCTION AND WORKING PRINCIPLES........ 13

ORDERING INFORMATION ........................................ 14

NOTE........................................................................ 14

Replacement of parts.................................................... 15

Warning..................................................................... 15

Recommended accessories ......................................... 15

APPROVALS................................................................ 17

Declaration of Conformity.......................................... 17

FEATURES

•Class “A” safety combination valve for

control of gaseous fluids in gas consuming

appliances in accordance with international

standards.

•Main body with two gas valves with single

seat.

•Possibility of installing internal by-pass

valve to achieve high-low flame control.

•Possibility of installing internal or external

pilot valve.

•Possibility of installing vent valve.

•Possibility of installing flanged minimum

and maximum pressure switches.

•Possibility of installing valve Proving

System (VPS).

•Possibility of mounting Closed Position

Indication switch (CPI) at bottom of safety

valve V1 and / or valve V2.

•Closing time: < 1 second.

•Coils field replaceable.

•Coils suitable for permanent energizing.

•Fine mesh screen between inlet flange and

main body (optional).

•Various pressure tap points at main body

available

•Second main valve, either with adjustable

flow regulator (fast), or characterized

opening mechanism (slow) with adjustable

maximum flow rate and step pressure.

•Rectifier boards field replaceable.

•PG11 cable strain relief standard at

VQ400M.

•Plug connector according to ISO 4400 /

DIN EN 175301-803 optional for VQ400M.