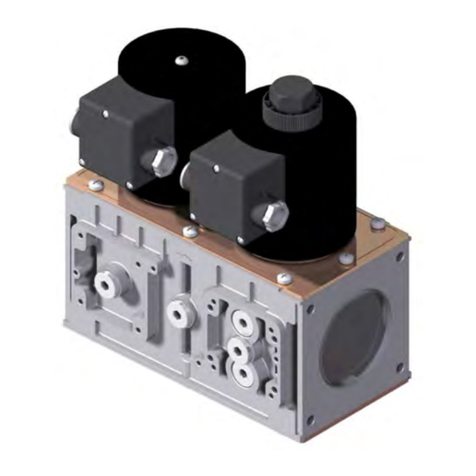

SV2 SERIES VALVES PREMIX ACCESSORIES

32-00180—01 2

–Protect pulse lines against damage and keep the lines free

from any contact to potential vibrating surfaces.

• In all cases, avoid creating a siphon-like shape.

• A wide variety of pulse line slopes and shapes may be

needed to fit into a particular appliance; best engineering

practice would be ‘1/2 bubble’ on a level (¼ inch of drop per

1 foot of run or about 6mm drop per 0.31m of run). However,

practical limitations may require some deviation from it.

Please consult Honeywell Thermal Solutions with your

particular geometrical arrangement if at doubt.

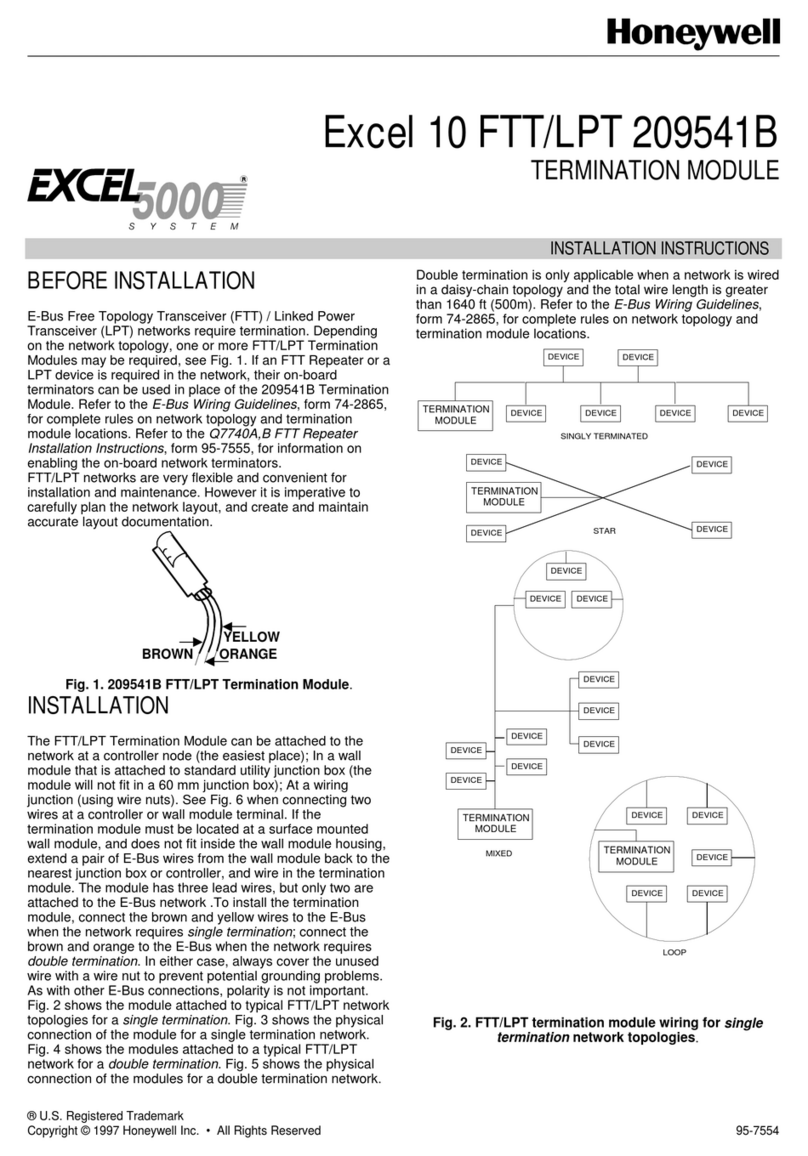

Fig. 1. V2MU mixing unit pulse line connections.

• (Refer to Fig. 1) To avoid condensate from back draft

entering any pulse line of the Fuel/Air Ratio Module,

downwards pointing pressure ports on the V2MU mixing

unit or any other device shall not be used.

• Partial blockage of the air intake of the V2MU mixing unit

can potentially influence the air pressure signal to the valve.

–Proper measures shall be taken to avoid the (partial) air

intake blockage of the V2MU mixing unit. Inspection

of the V2MU air intake shall be part of the annual

maintenance of the appliance.

Air Pre-Filter

The air pre-filter is included with every premix valve and is

available as a field replacement part as well. The air pre-

filter MUST be installed in every premix system, regardless

of whether the Heat Exchanger is used. The filter is designed

to remove fine dust particles from the air stream to the valve

FARMOD, which can collect at the internal FARMOD orifice

entrances, affecting flow resistance to the internal sensors

and eventually cause nuisance lockouts.

The filter must be mounted between the V2MU mixing unit

and the valve FARMOD in the air pulse line. When the Heat

Exchanger is used, it must also be mounted between the

V2MU mixing unit and the valve FARMOD, with the Heat

Exchanger first and the filter second.

IMPORTANT

• The filter should be mounted as close to the valve FARMOD

as possible.

• Replacement of the filter shall be included in the annual

appliance maintenance procedures.

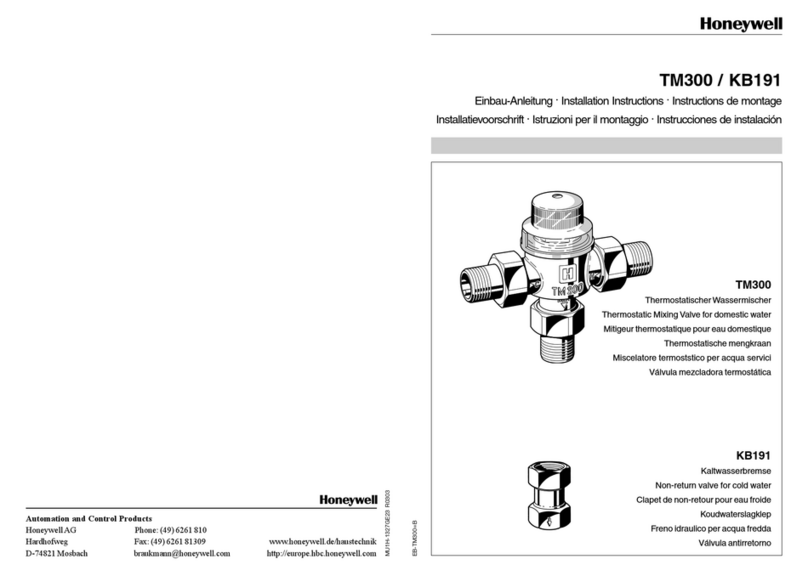

Fig. 2. Pre-Filter installation.

Outdoor Air Installations

WARNING

Direct water ingress (e.g. from mist, rain or pressure

wash) into the pulse lines should be avoided or

prevented

IMPORTANT:

• When the valve is installed in an area with a temperature

continuously lower than the combustion air intake

temperature, a risk of condensate formation in the air pulse

line is present, which can affect the fuel/air ratio control,

depending on the appliance and permanently damage the

FARMOD and the system.

• In this case it is strongly recommended to install the

Honeywell SV2 Series HEATEXCHANGER-000 kit for a

complete condensation/dehumidification solution to avoid

permanent damage to the FARMOD and the system.

• When using the Honeywell HEATEXCHANGER-000 kit, the

valve + FARMOD may be installed above or below the mixing

unit + Heat Exchanger, but above is preferred.

• If the potential for condensation exists and the full

Honeywell dehumidification system is not used, Honeywell

cannot provide any guidance regarding the valve/FARMOD

position versus the mixing unit as this configuration has not

been designed or tested.

• To prevent condensation formation due to back draft, it is

recommended to purge the application after each burner

operation.

• If there is never a risk of condensation, meaning the ambient

room temperature is above the combustion air dew point at

all times, the SV2 Series Heat Exchanger kit is not needed.

In this case the valve + FARMOD can be mounted above or

below the mixing unit.

NOTE: The Heat Exchanger and the filter must be mounted

between the V2MU mixing unit and the FARMOD,

with the Heat Exchanger first and the filter mounted

as close to the FARMOD as possible

INSTALLATION SEQUENCE

WARNING

Explosion or Fire Hazard Can cause severe injury,

death, or property damage.