R7515C MacroCel™ CONTROLLER

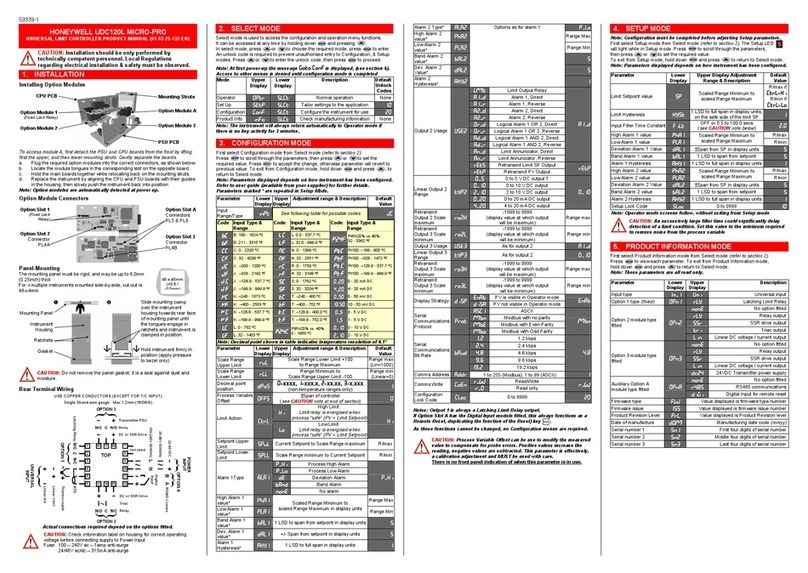

2. Connect C-NAP bus wiring to C-NAP terminal block on

Mount MacroCel Card Cage Assembly

MacroCel per job drawings (Fig. 5).

MacroCel

NOTES:

3 7

4 5

+ +

CNAP

OUT IN

7

6

TB9

C-NAP

TERMINAL

BLOCK

7 7

RED

YEL

YEL

RED

0.16 MAX

INTERFACE

BOARD

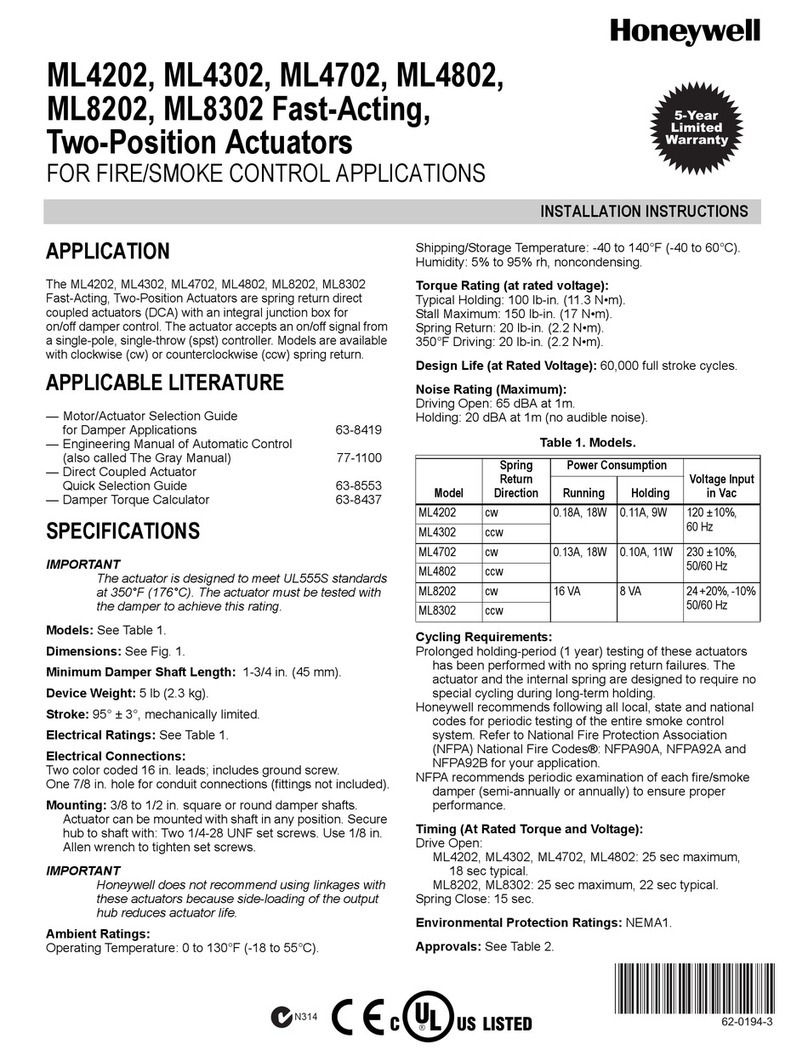

1. Lower edge of Assembly is supported by two supports

on the Subpanel (Fig.8). Do not force Assembly into

supports.If supports interfere with mounting Assembly,

gain proper clearance by using pliers to bend supports

outward slightly.

2. Two mounting tab screws are factory installed (started)

to aid in mounting the Assembly.

++

C5693

Fig. 5. Connecting C-NAP bus wiring to C-NAP terminal

block on MacroCel.

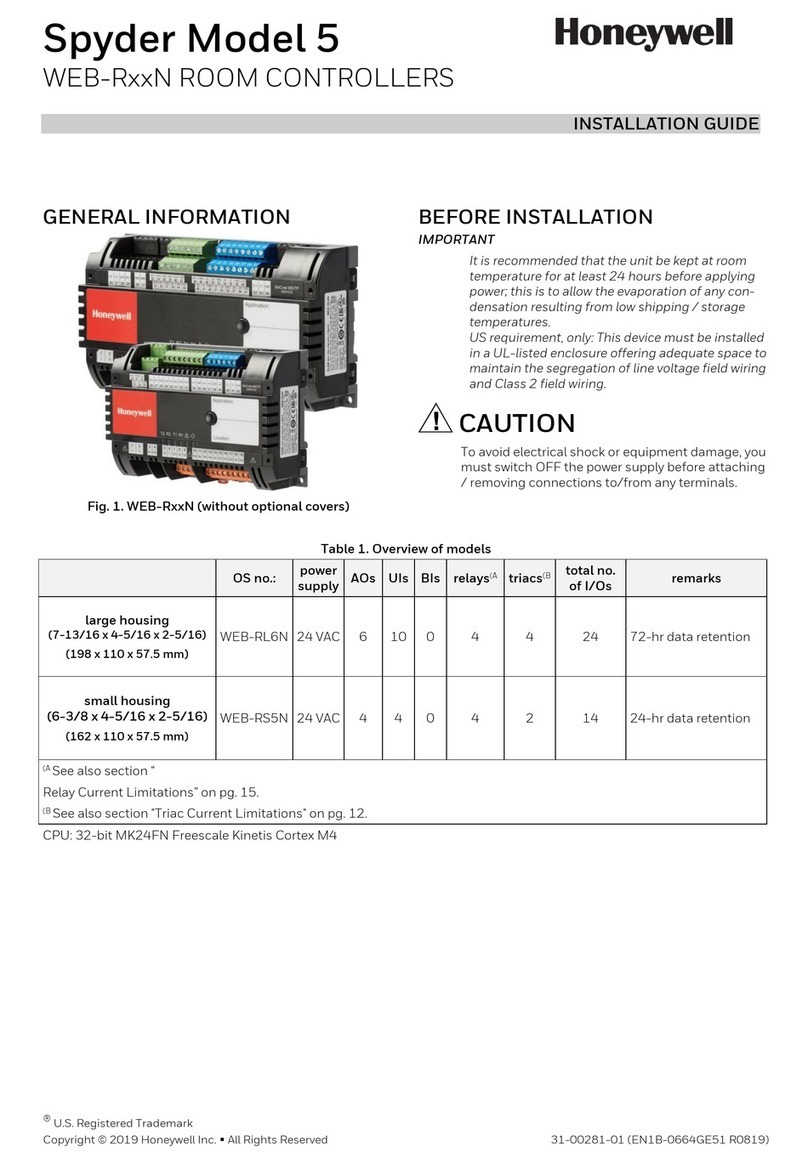

3. When required, activate the EOLR on the MacroCel

Subpanel Interface Board by placing the shorting bar in

Position 1-2 (Fig. 6A). Deactivate the EOLR by placing

the shorting bar in Position 2-3 (Fig. 6B).

A A

SHORTING BAR 1

1

1 & 2 IN 1 & 2 IN

2 2

SHORTING BAR

2 & 3 OUT 2 & 3 OUT

3

3

EOL EOL

A. EOLR "IN" B. EOLR "OUT"

C5687

Fig. 6. MacroCel subpanel interface board EOLR

positions for activation (IN) and deactivation (OUT).

4. Connect line voltage to AC Input Block. Leave power to

MacroCel subpanel OFF until system is checked by a

Honeywell Representative.

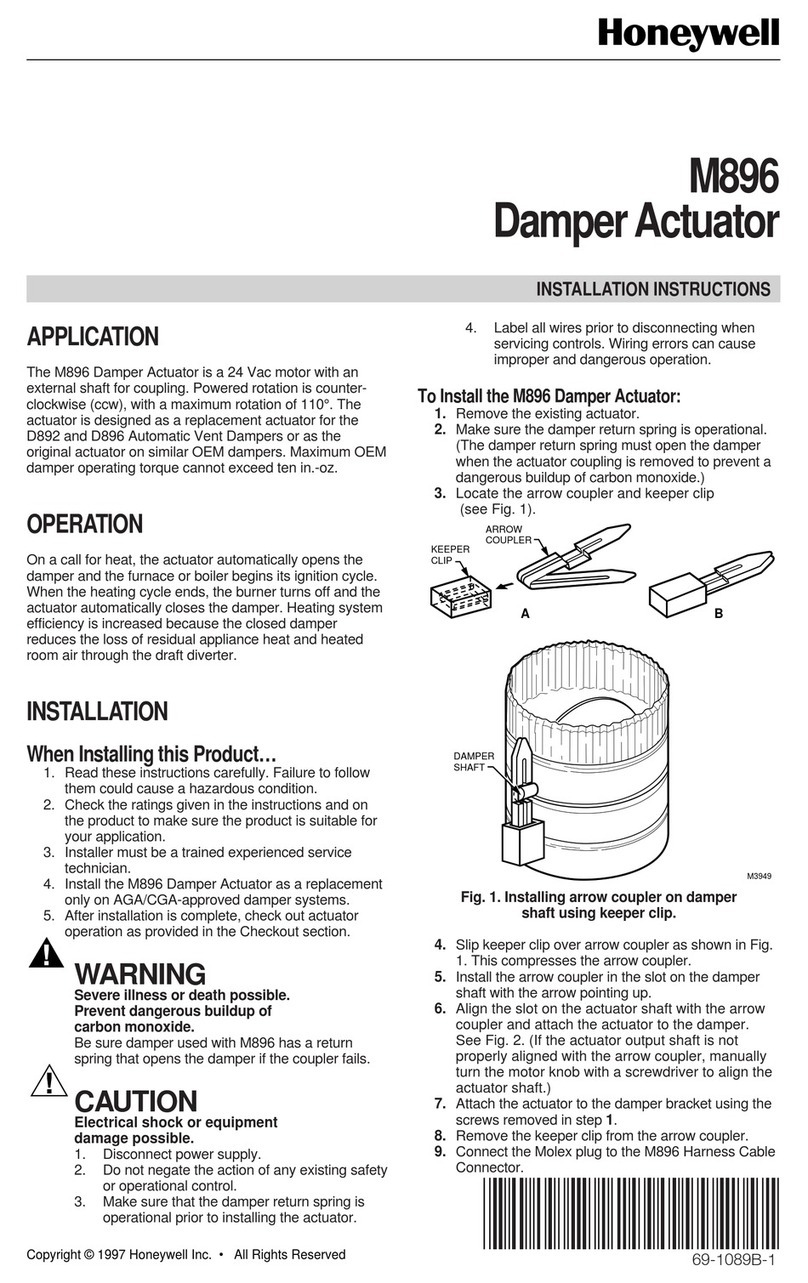

5. Mount optional Tamper Switch on cabinet and wire per

job drawings (Fig.7).

PREINSTALLED

MOUNTING TAB

SCREW (2) MacroCel

SUBPANEL

INTEGRAL

SUPPORT

C5689

Fig. 8. Subpanel supports and preinstalled mounting

tab screws.

Mount the Assembly as follows:

1. Position mounting surface of Assembly flat against

Subpanel, aligning sides of Assembly with sides of

mounting silhouette and top of Assembly approximately

1 in. (25 mm) above top of mounting silhouette.

2. Slide Assembly down, simultaneously engaging lower

supports and preinstalled mounting tab screws.

3. Tighten screws to secure Assembly to Subpanel.

4. Connect input/output board ribbon cables and power

cable to Interface Board in sequential order as they

protrude from the Assembly. Connect farthest-left

ribbon cable connector to J1 on the Interface Board,

farthest right ribbon cable connector to J7 (Fig. 3).

LOCK

WASHERS

FROM

TAMPER

SWITCH

PLUNGER

DOOR

LATCH

TAMPER

SWITCH

LOCKNUT

RING

PLUNGER

SCREW

AFTER INSTALLATION

1. Mount cabinet Door.

SCREWS

2. If applicable, adjust Tamper Switch screw (at end of

FROM

door switch plunger) so Tamper Switch activates when

DOOR

LATCH

door opens.

3. Close and lock Door.

C6039

Fig. 7. Mounting optional tamper switch.

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited-Honeywell Limitée

Honeywell Plaza 155 Gordon Baker Road

P.O. Box 524 North York, Ontario

Minneapolis MN 55408-0524 M2H 3N7

Printed in U.S.A. on recycled

paper containing at least 10%

95-7456—1 T.M. 2-98

post-consumer paper fibers.

www.honeywell.com

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your

use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and

against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the

literature by you.