EN1R-9175 0908RA-NE 2

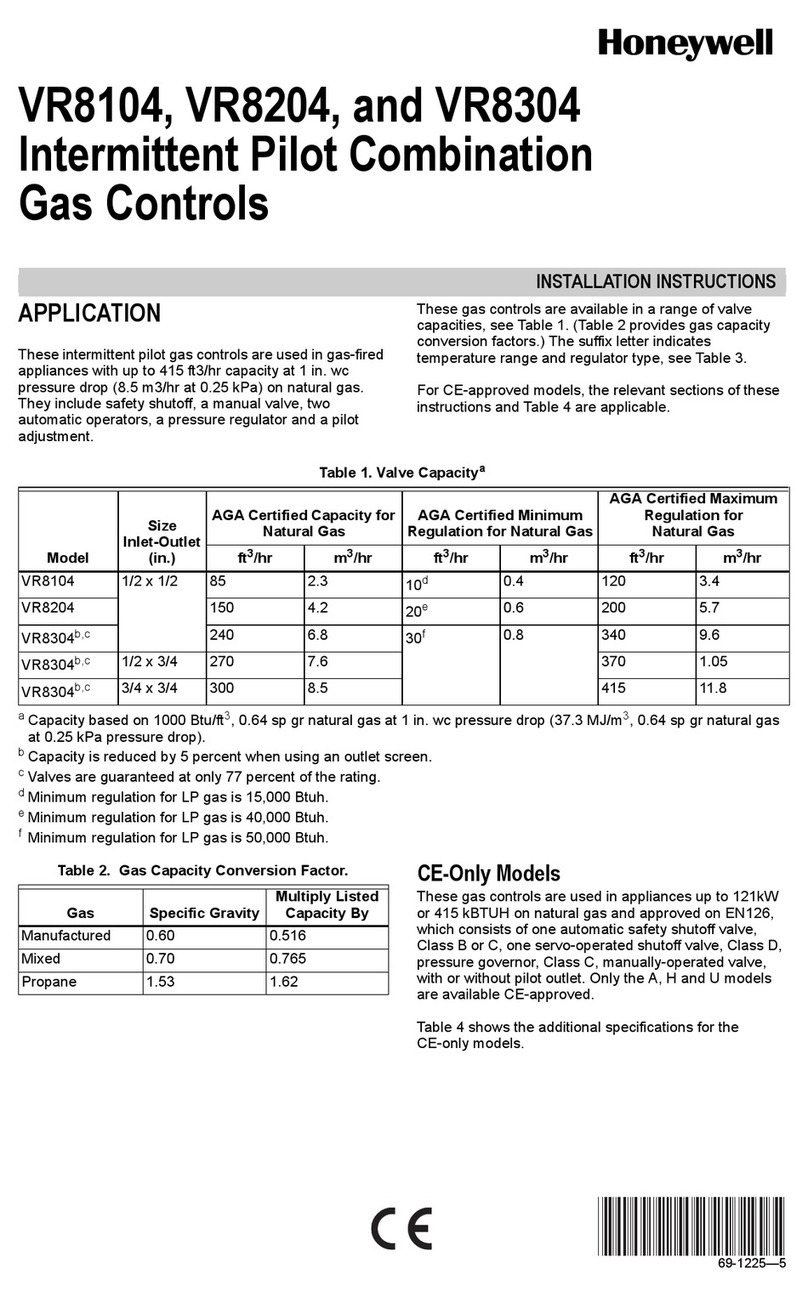

Table 2. Electrical rating

Do not exceed the maximum current value.

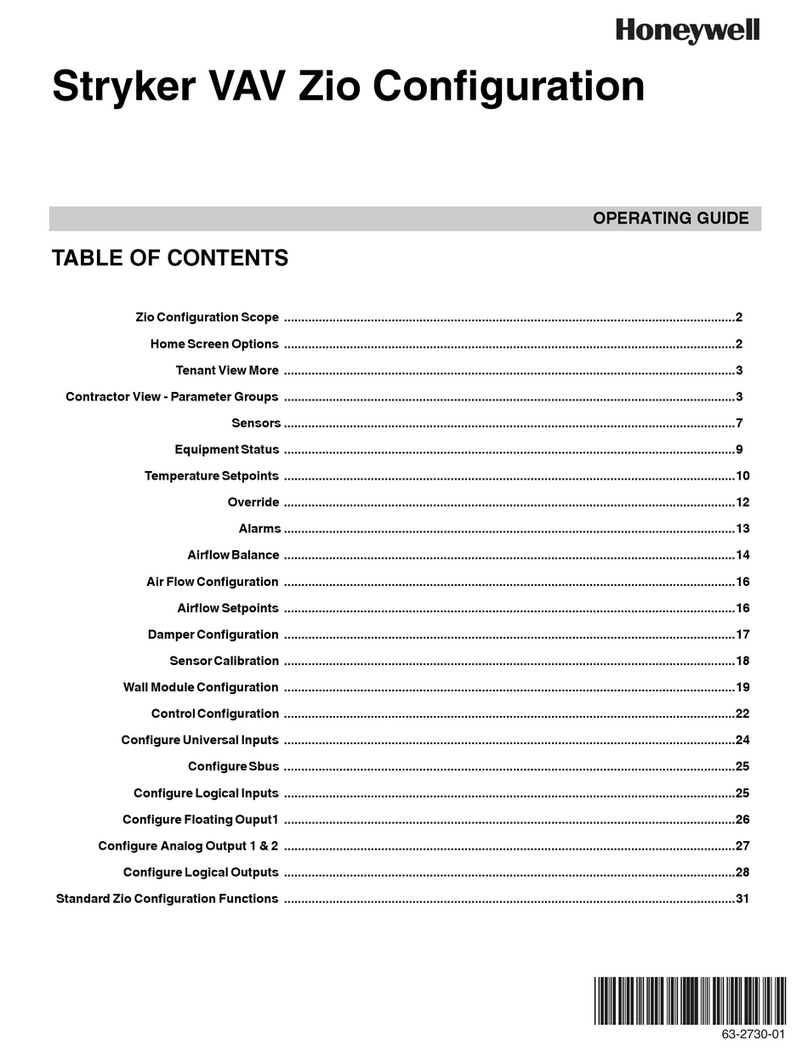

Modulation characteristics

Values are based on increasing current with start at zero.

When current is decreasing from its maximum value the

outlet pressure will be higher.

NOTE:

Good and reliable performance of the Moduplus®is not

only dependent on the Moduplus®itself, but also upon the

reliability of the modulating control and sensor used.

ADJUSTMENT, CHECKOUT AND

MAINTENANCE

Adjustments should be made by qualified persons

only.

If the appliance manufacturer supplies checkout

and/or service and maintenance instructions,

carefully follow them. If such instructions are not

provided, then follow the procedure as outlined

below.

Adjustments should be made within the specified

pressure ranges.

Allow time for pressure to stabilize before making

adjustments.

It is recommended that the Moduplus®is operated

a few times to ensure correct setting.

Remove cap before adjustment.

Take care that after any adjustment cap is mounted.

In applications with pressure feedback mount the

cap.

Do not dismount parts of the Moduplus®.

Dismounting can cause malfunction of the

Moduplus®.

The maximum pressure setting must first be adjusted to

ensure that burner will safely light up, then the minimum

pressure setting can be adjusted.

Any adjustment of maximum pressure setting influences

minimum pressure setting, thus a min. pressure setting

should always be re-adjusted after.

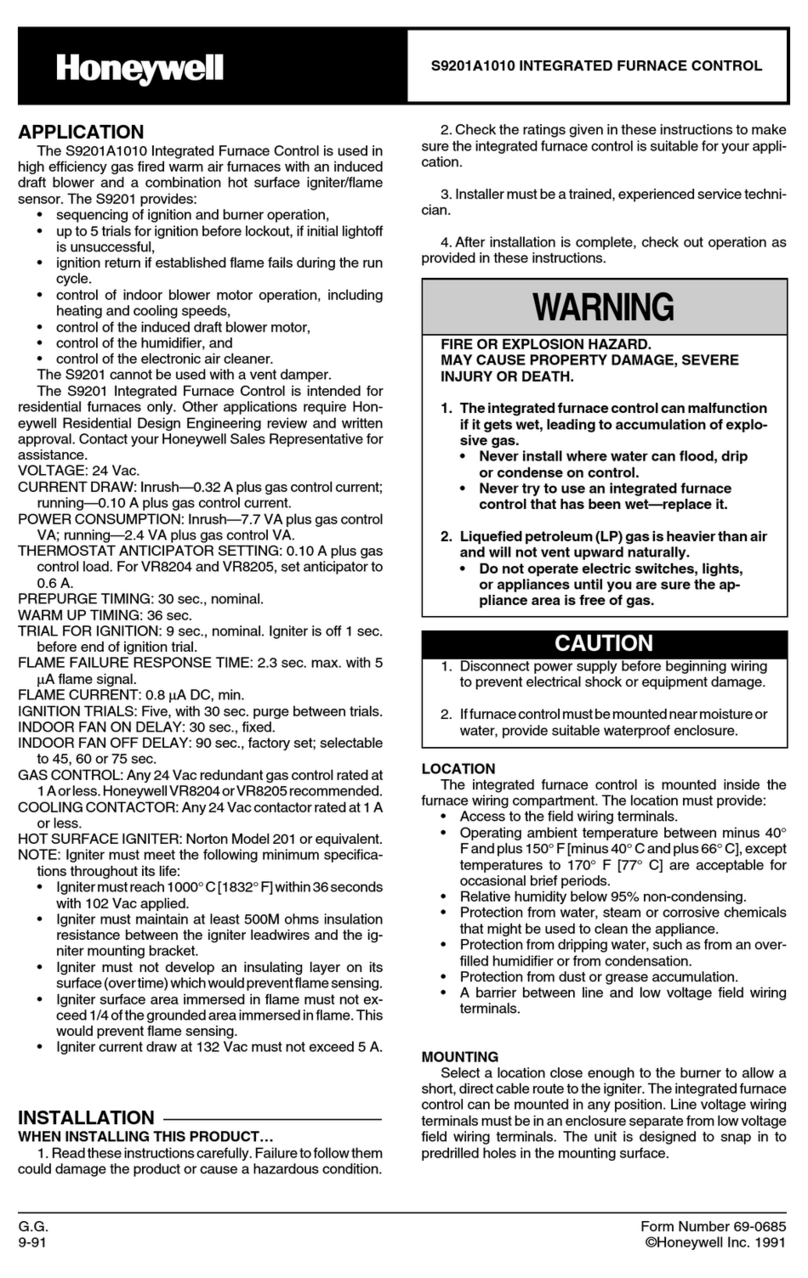

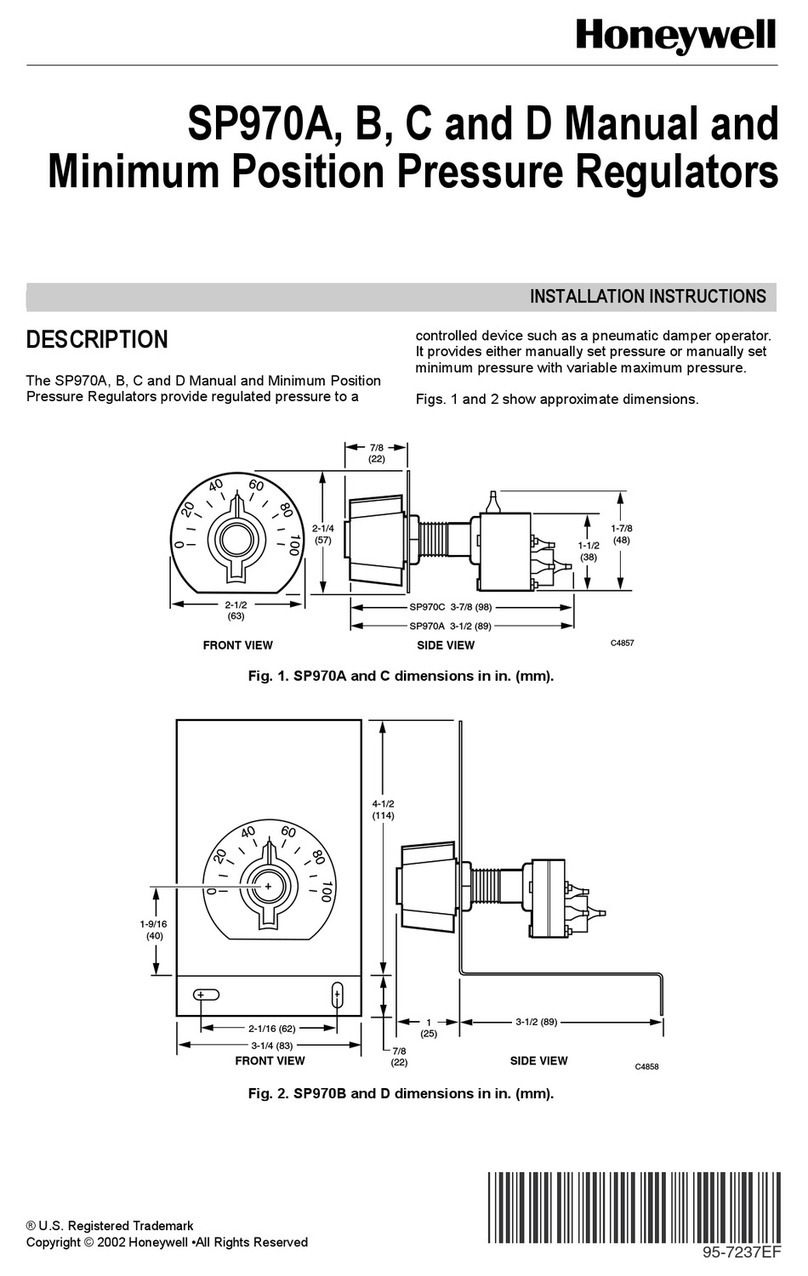

Adjusting the maximum pressure setting (see fig 1.)

Methode 1:

•Disconnect pressure feedback connection (if applicable).

•Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

•Disconnect electrical connection of Moduplus®.

•Energize operator, set control in operation and wait until

an outlet pressure is recorded on pressure gauge.

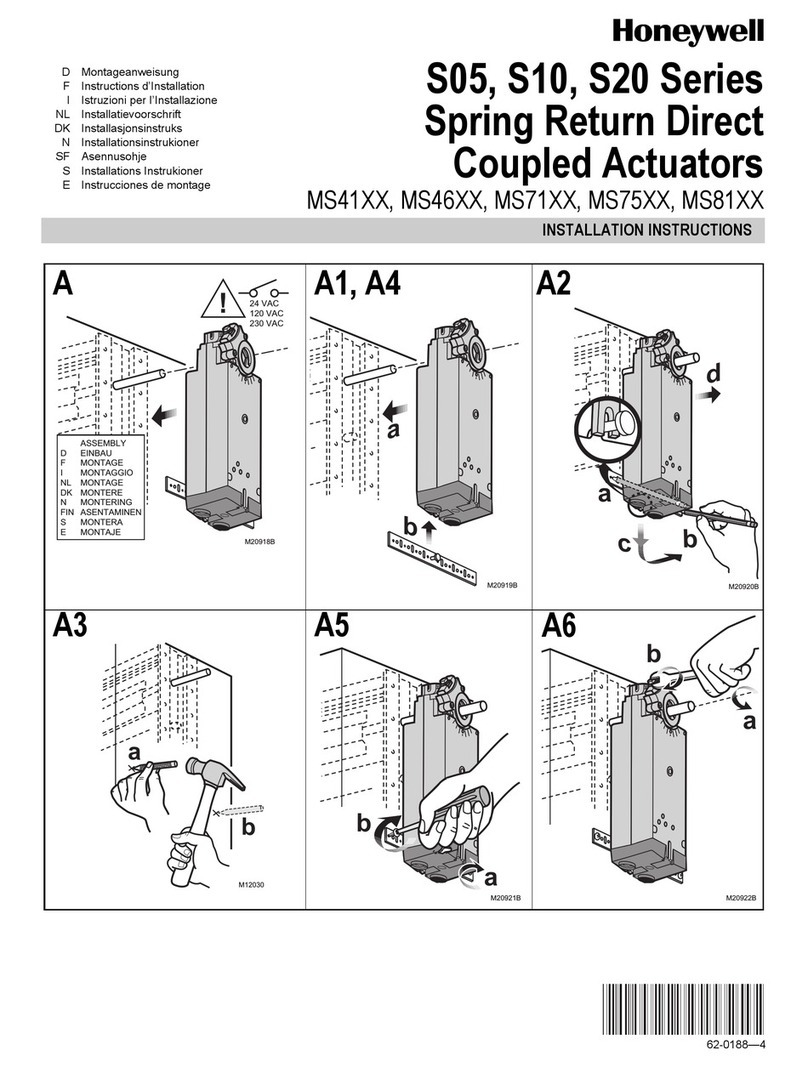

•Push shaft gently downwards by means of a suitable pin

through the hole on the top of the Moduplus®to the

bottom and hold it on.

•If maximum rate pressure needs adjustment then use an

8 mm wrench to turn adjustment screw for maximum

pressure setting clockwise to increase or counter-

clockwise to decrease pressure, until the desired

maximum outlet pressure is obtained. Release shaft.

•Check minimum pressure setting and readjust if

necessary.(according instructions below)

•Mount cap and reconnect pressure feedback connection

(if applicable).

•If minimum and maximum pressures are set, wire the

Moduplus®in circuit.

•Close pressure tap screw

Methode 2:

•Disconnect pressure feedback connection (if applicable).

•Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

•Make sure that the appliance is in operation and the

Moduplus®coil is energized with maximum current.

•If maximum rate pressure needs adjustment then use an

8 mm wrench to turn adjustment screw for maximum

pressure setting clockwise to increase or counter-

clockwise to decrease pressure, until the desired

maximum outlet pressure is obtained.

•Disconnect electrical connection of Moduplus®

•Check minimum pressure setting and readjust if

necessary. (according instructions below)

•Mount cap and reconnect pressure feedback connection

(if applicable).

•If minimum and maximum pressures are set, wire the

Moduplus®in circuit.

•Close pressure tap screw

Adjusting minimum pressure setting (see fig. 1.)

•Disconnect pressure feedback connection (if applicable).

•Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

•Disconnect electrical connection of Moduplus®.

•Energize operator, set control in operation and wait until

an outlet pressure is recorded on pressure gauge.

•If minimum rate pressure needs adjustment then use a 5

mm wrench to turn adjustment screw for minimum

pressure setting clockwise to increase or counter-

clockwise to decrease pressure, until the desired

minimum outlet pressure is obtained.

•Check if main burner lights easily and reliable at minimum

pressure.

•Mount cap and reconnect pressure feedback connection

(if applicable).

•Close pressure tap screw

Adjusting intermediate pressure setting

Some controls are able to provide modulating control as well

as a fixed setting.

In case this intermediate pressure setting should be set, it is

Coil Modulation

current dc (mA) Resistance at

20 °C (Ω)

Voltage

(Vdc) Color

12 blue 55 ... 310 31,5 ... 36,5

15 white 45 ... 250 42 ... 46

17 grey 30 ... 165 82 ... 88

28 green 30 ... 165 107,5 ... 117,5