CAUTION: CARBON MONOXIDE GAS AND ITS DETECTION

This carbon monoxide detector is designed for indoor use only. Do not

expose it to rain or moisture. Do not drop the detector or subject it to

other physical shock. Do not open or tamper with the detector as this

may cause it to malfunction. The detector will not protect against the

risk of carbon monoxide poisoning if not properly installed.

NOTE: The detector will only indicate the presence of carbon

monoxide gas in the vicinity of the detector itself. Carbon monoxide

gas may be present in other areas.

THIS CARBON MONOXIDE DETECTOR IS NOT:

•Designed to detect smoke, fire or any gas other than carbon

monoxide

•A substitute for the proper servicing of fuel-burning appliances or

the sweeping of chimneys

•To be used on an intermittent basis, or as a portable alarm for the

spillage of combustion products from fuel-burning appliances or

chimneys

Carbon monoxide gas is a highly poisonous gas which is released

when fuels are burned. It is invisible, has no smell and is therefore

impossible to detect with the human senses. Under normal conditions

in a room where fuel burning appliances are well maintained and

correctly ventilated, the amount of carbon monoxide released into the

room by such appliances should not be dangerous.

SYMPTOMS OF CARBON MONOXIDE POISONING: Carbon

monoxide bonds to the hemoglobin in the blood and reduces the

amount of oxygen being circulated in the body. The following

symptoms are related to carbon monoxide poisoning and should be

discussed with all members of the household:

•Mild exposure: Slight headache, nausea, vomiting, fatigue (often

described as “flu-like” symptoms).

•Medium exposure: Sever throbbing headache, drowsiness,

confusion, fast heart rate.

•Extreme exposure: Unconsciousness, convulsions, cardio

respiratory failure, death.

Many causes of reported carbon monoxide poisoning indicate that

while victims are aware that they are not well, they become so

disoriented that they are unable to save themselves by either exiting

the building or calling for assistance.

Also, young children and pets may be the first to be affected.

WARNING: IMPORTANT INFORMATION FOR THE USER

Actuation of your CO alarm indicates the presence of carbon

monoxide (CO), which can cause injury or death.

Individuals with medical problems may consider using warning

devices which provide audible and visual signals for carbon monoxide

concentrations under 30ppm.

What to do if the carbon monoxide detector goes into alarm:

1. Push the Hush/Test button. If the detector reactivates or the

detector does not silence, continue with Step 2.

2. Immediately move to fresh air, outdoors or by an open window.

Check that all persons are accounted for. Do not reenter the

premises nor move away from the open door/window until

emergency service responders have arrived.

3. Call your local fire department from a phone in an area where the

air is safe.

4. If your detector reactivates within a 24-hour period, repeat steps

1 - 3 and call a qualified appliance technician to investigate

possible sources of CO from fuel burning equipment and

appliances, and check for proper operation of this equipment. If

problems are identified during this inspection, have the

equipment serviced immediately. Note any combustion equipment

not inspected by the technician and consult the manufacturer’s

instructions, or contact the manufacturers directly, for more

information about CO safety and this equipment. Make sure that

motor vehicles are not, and have not been, operating in an

attached garage or adjacent to the residence.

IMPORTANT: This detector should be tested and maintained

regularly following National Fire Protection Association (NFPA) 720

requirements. (Generally, this detector should be fully tested at least

once per month.)

MAINTENANCE

Occasionally clean the outside casing with a cloth. Ensure that the

holes on the front of the alarm are not blocked with dirt and dust.

Do not paint, and do not use cleaning agents, bleach, or polish

on the detector.

DETECTOR REPLACEMENT

This detector is manufactured with a long-life carbon monoxide

sensor. Over time the sensor will lose sensitivity, and will need to be

replaced with a new carbon monoxide detector. This detector’s

lifespan is approximately six years from the date of manufacture.

The user should periodically check the detector’s replacement date.

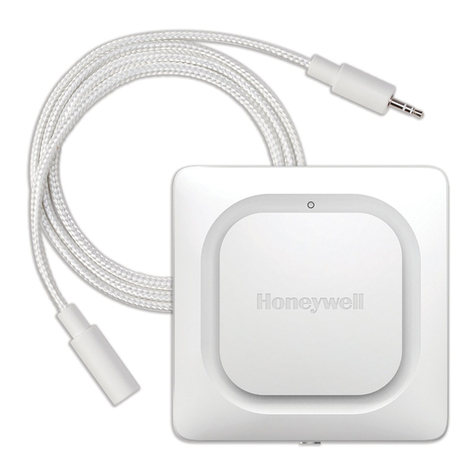

Remove the detector from its base and check the replacement date

label on the underside of the detector. The label indicates the date

that the detector should be replaced.

NOTE: When the detector is removed from its base, a message is sent

to the central station. If the system is armed, a tamper alarm

message is sent; if disarmed, a trouble message is sent.

The detector will also indicate a trouble condition when it has

reached the end of its useful life. If this occurs, it is time to replace

the detector.

NOTE: Before replacing the detector, notify your central station that

maintenance is being performed and the system will be temporarily

out of service. Disable the zone or system undergoing maintenance to

prevent any unwanted alarms. Dispose of detector in accordance with

any local regulations.

CAUTION

It should be noted that installation, operation, testing and

maintenance of the 5800CO is different than smoke detectors. Per

NFPA 720 section 5.3.7.2 the detector shall not be connected to a zone

that signals a fire condition (i.e. smoke detector zones). Therefore, the

5800CO detector must be programmed as a non-fire zone. See the

control panel’s Installation Instructions for the appropriate carbon

monoxide zone type to be programmed.

SPECIFICATIONS

Power Source: One 3-volt CR123A Lithium Battery (included).

(Replace with Duracell DL123A, Panasonic CR123A or ADEMCO

466.)

Audible Signal (temp 4 tone): 85 dBA min. in alarm (at 10ft)

Height: 2.3 inches (58 mm)

Diameter: 5.3 inches (135 mm) with mounting base

Weight: 7 oz. (241 g) without battery

Operating Ambient Temperature Range:

32° to 100°F (0° to 37.8°C)

Operating Humidity Range:

15% to 95% Relative Humidity, non-condensing

Agency Listings: UL standard 2075

Patent Numbers: 7,120,795

Please see insert for Limitations of Carbon Monoxide Detectors.

FOR WARRANTY INFORMATION AND FOR DETAILS REGARDING

THE LIMITATIONS OF THE ENTIRE ALARM SYSTEM, GO TO:

www.honeywell.com/security/hsc/resources/wa

ÊK14631V22Š

K14631V2 4/14 Rev. A