Honeywell Aquatrol W964F User manual

Other Honeywell Server manuals

Honeywell

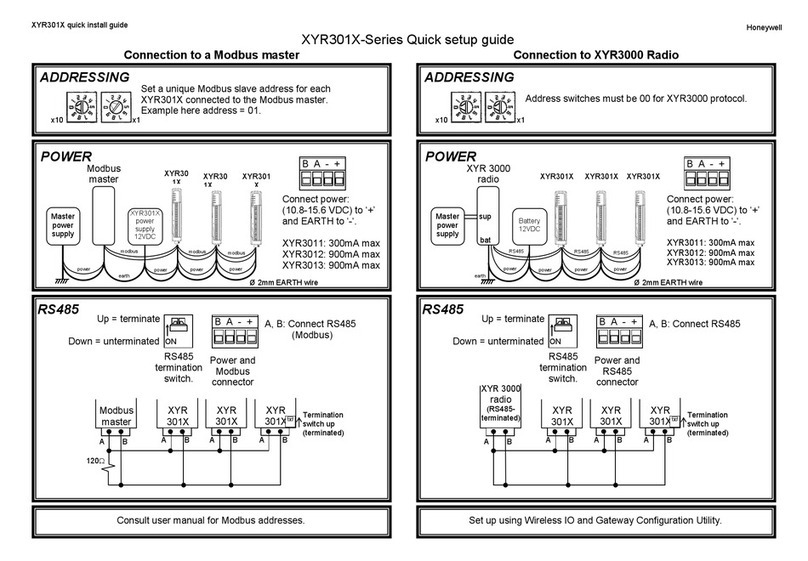

Honeywell XYR301E User manual

Honeywell

Honeywell XYR3011 User manual

Honeywell

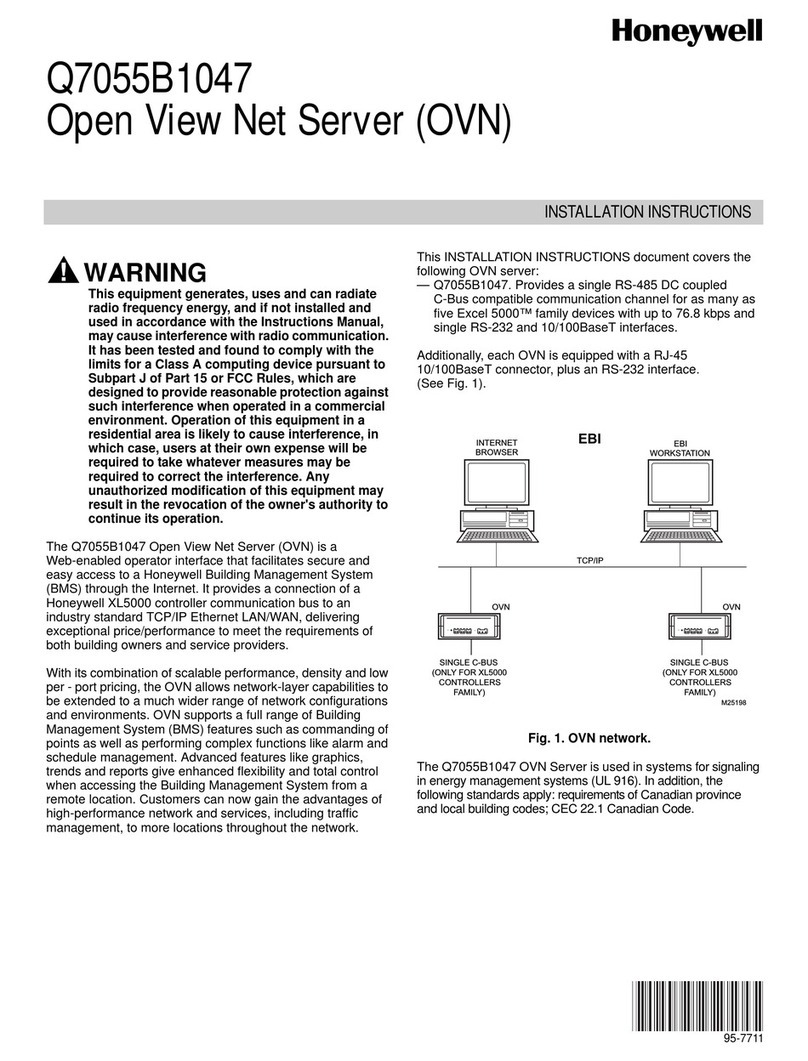

Honeywell Q7055B1047 User manual

Honeywell

Honeywell T610 Technical manual

Honeywell

Honeywell HAS-QNH User manual

Honeywell

Honeywell HUS-D4-E-Pro User manual

Honeywell

Honeywell AutomationServer User manual

Honeywell

Honeywell MZ-PCSV74 Technical manual

Honeywell

Honeywell HP ProLiant DL360P Gen8 User manual

Honeywell

Honeywell LANSRLU1 Setup guide