968XTP Maximum Security Switch - Installation Instructions

For the latest U.S. warranty information, please go to: www.honeywell.com/security/hsc/resources/wa or

Please contact your local authorized Honeywell representative for product warranty information.

2006 Honeywell International Inc. Honeywell is a registered trademark of Honeywell International Inc.

All other trademarks are the properties of their respective owners. All rights reserved. Assembled in Mexico.

Protected under

US Patent 6,963,281.

Ê5-051-649-00F4Š

P/N 5-051-649-00F 9/11 Rev A

Door

Frame 2” (51 mm)

Minimum

3/16”

(4.8 mm)

OPEN

Door

Frame

7/16”

11.1 mm

Align

Edges

Area to be

protected

Area to be

protected

3/16”

4.8 mm

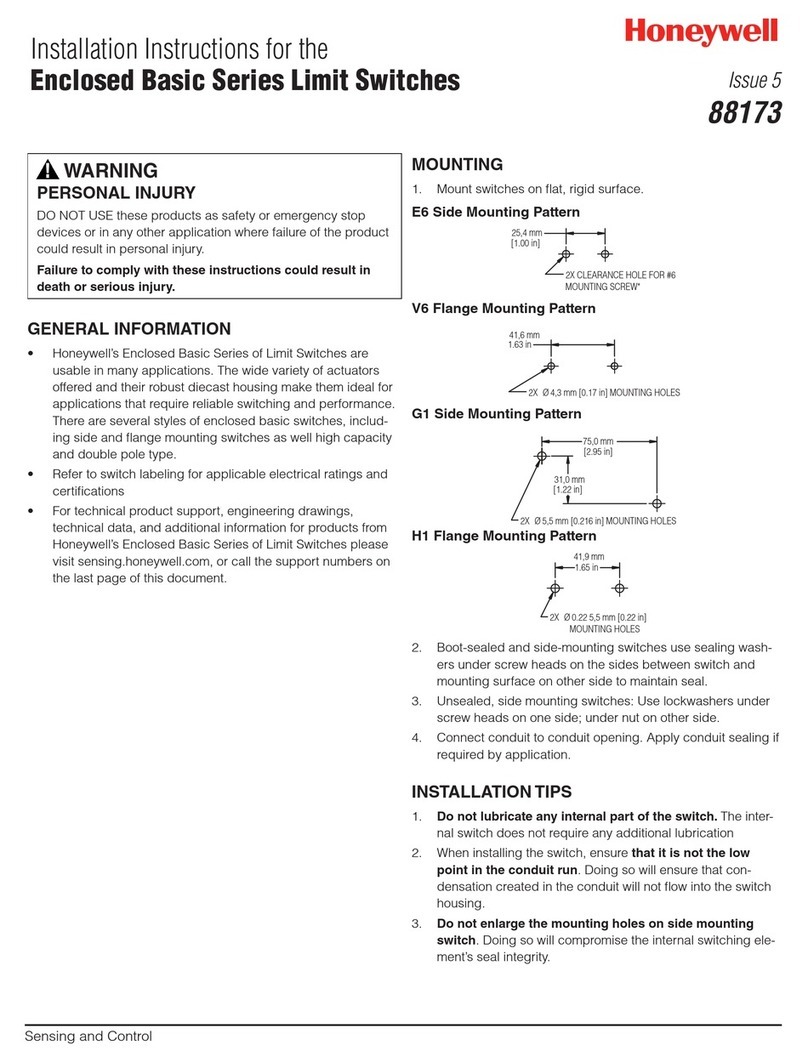

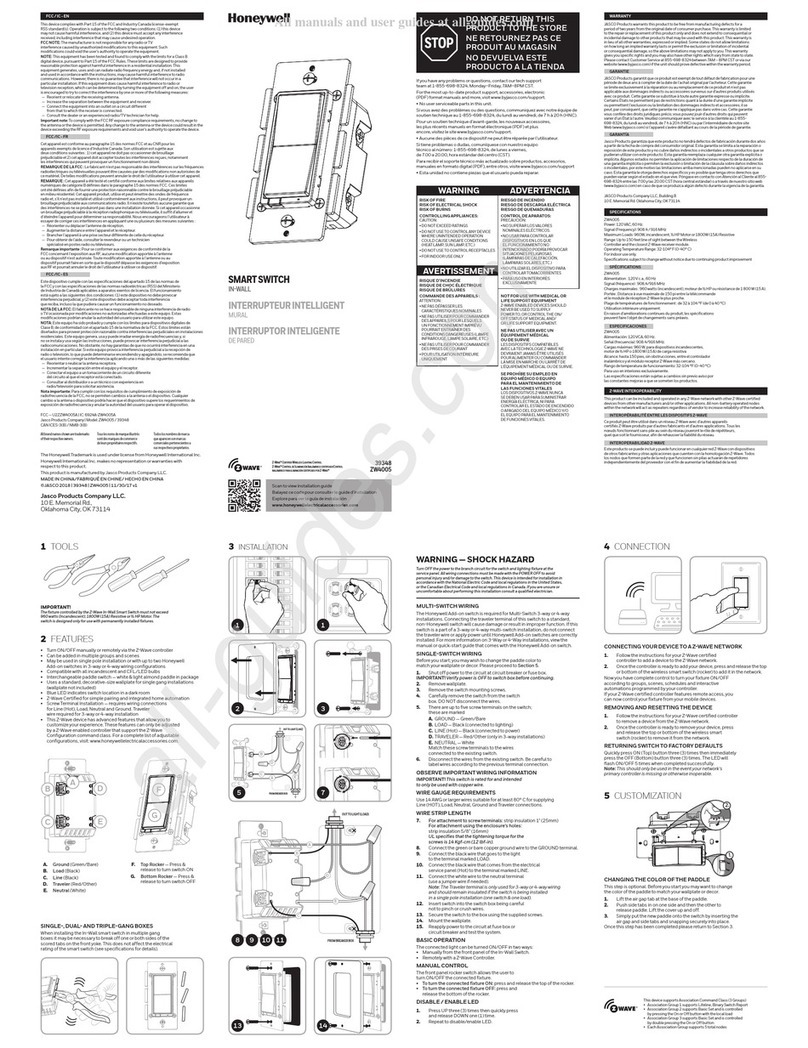

Outswinging Door Instructions

General Guidelines

• Mount the magnet

assembly to the

door, mount the

switch assembly to

the frame.

Step 1 - Install the Magnet

• Place the magnet

2” (51 mm)

[minimum] from

the side of the

door frame and

3/16” (4.8 mm)

from the top.

• Mark the two

mounting holes

and drill pilot

holes for #8

(4.1 mm) screws

[provided].

• Mount the

magnet on the

door using two #8

(4.1 mm) screws

with the Honeywell label surface facing down and the arrow

pointing away from the door.

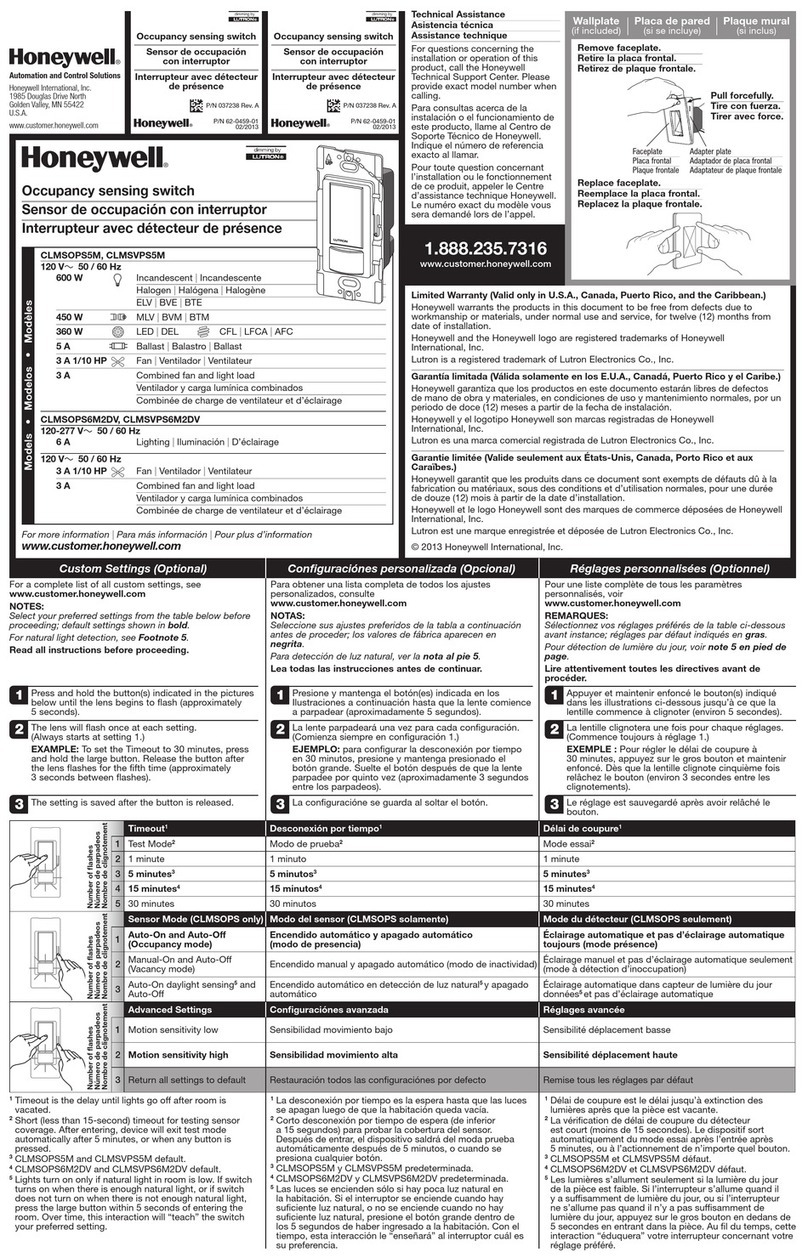

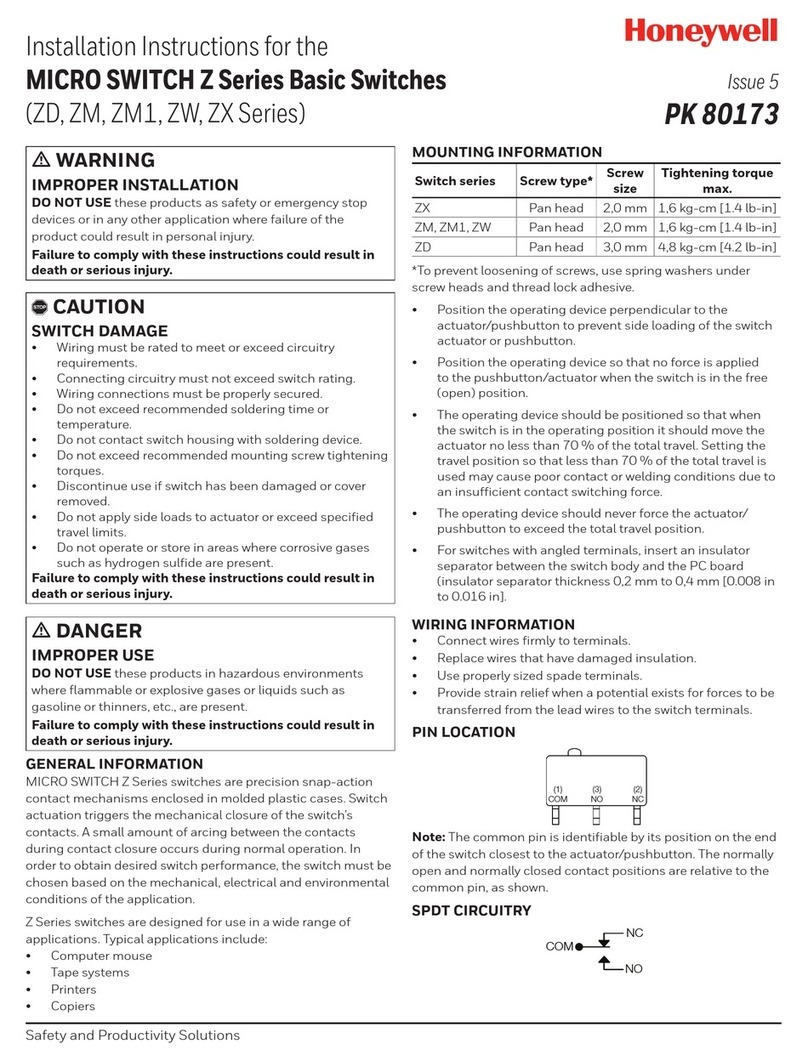

Step 2 - Install the Tamper Plate

• Line up the edge of the tamper plate to the edge of the magnet.

Make sure the

arrows on the

tamper plate

are pointing

toward the

door.

• Measure the

gap distance

7/16” ±1/16”

(11.1 mm ±1.6

mm).

• Mark the

mounting holes

and drill pilot

holes for two

#6 (3.5mm)

and four #8

(4.1 mm)

screws [provided].

• Mount the tamper plate in place using two #6 (3.5 mm) screws.

Step 3 - Install the Switch

• Verify that the

arrow on the

switch assembly

is facing the arrow

on the magnet

assembly.

• Mount the switch

assembly to the

tamper plate

using four #8

(4.1 mm) screws

[provided].

• See

Supplemental

Information for

wiring

instructions.

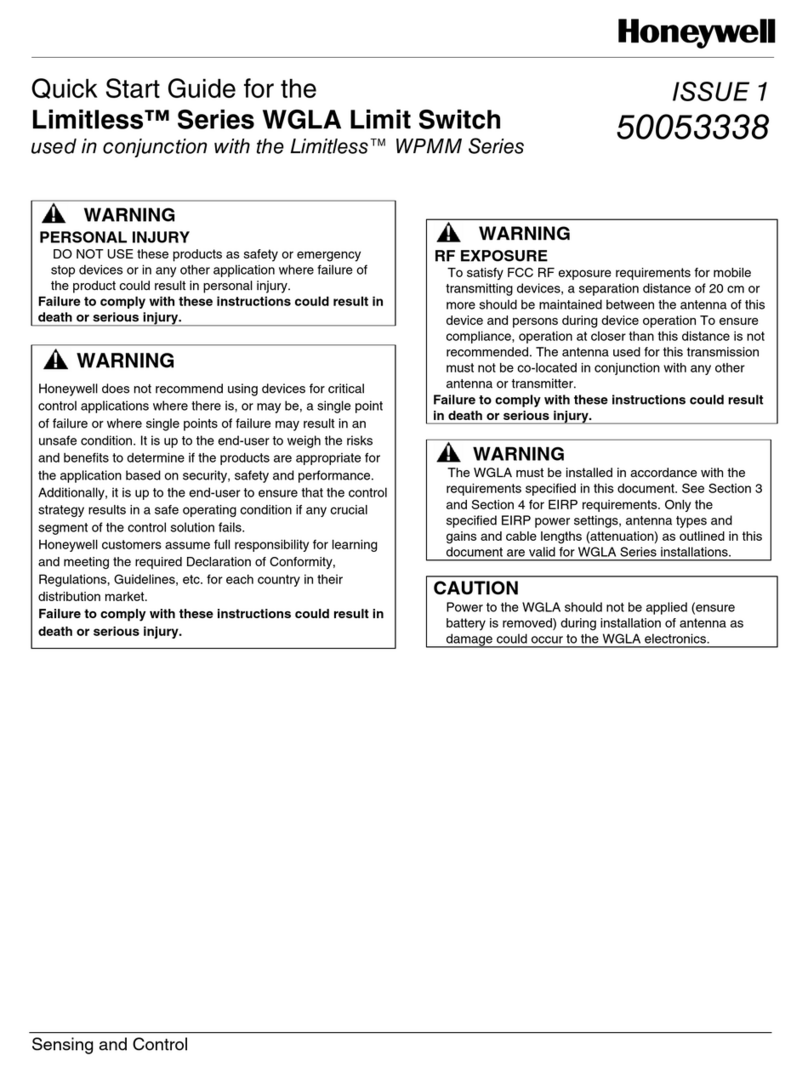

Supplemental Information

Wiring

• The normal condition of the 968XTP is when it is reporting secure,

energized by the magnet.

• The two white tamper wires will be closed when the tamper switch

is in secure condition.

• The tamper contacts should be connected to a 24 hour circuit to

trigger an alarm any time the switch module is tampered with.

• Maximum contact ratings depend on the voltage put through the

switch. They are 250 mA at 12 V or less and 125 mA at 24 V. The

tamper circuit can handle a maximum of 1 Amp.

Black Common

Green Normally Closed (NC)

Red Normally Open (NO)

White Tamper NC

White Tamper NC

Notes

• To minimize tamper potential, the 968XTP should be installed inside the

perimeter being protected.

• The switch assembly / magnet combination is designed to have a

nominal gap of 0.45” (11.4 mm). The system will go into alarm

condition if the gap is approximately 0.63” (16.0 mm) and greater,

or approximately 0.27” (6.9 mm) or less. To account for system

tolerances, a 7/16” ±1/16” (11.1 mm ±1.6 mm) gap has been specified

in these instructions. The minimum make gap is 0.53” (13.5 mm).

• Approvals/listings: cULus listed

EN 50131-1:2006 and EN 50131-2-6:2008 Security Grade 3

Environmental Class II; Certified by VdS.

Suitable for connection to an EN 60950 Class II

Limited Power Source in European Installations.

For any additional information, please refer to our Website,

www.honeywell.com/security/emea/hscdownload or contact:

Honeywell Security Group

Quality Assurance Dept.

Newhouse Industrial Estate

Motherwell

Lanarkshire ML1 5SB

United Kingdom

Green

Red

Black

White

White

NC

NO

COM

Tamper NC

Tamper NC

Tel: +44(0)1698 738200

Email: UK64Sales@Honeywell.com

Door

Frame

DOOR

7/16”

(11.1 mm)

Align edges

#8

(4.1 mm)

Screw

#6

(3.5 mm)

Screw

#8

(4.1 mm)

Screw

Door

Frame

DOOR