ADEMCO 5817CBXT

Wireless Commercial/Household Transmitter

Installation and Setup Guide

GENERAL INFORMATION

The 5817CBXT is a universal contact-monitoring transmitter that can be

used with household and commercial fire and burglary-initiating devices

such as door/window contacts, motion and glassbreak detectors,

sprinkler water flow switches, tamper switches, post indicator valves,

manual pull stations, and remote duct detectors. The 5817CBXT has

three unique input loops (zones).

Loop 1: Supervised and typically used for high-priority alarm reporting

such as commercial fire or burglary. It requires a 470K ohm

end-of-line resistor (PN EOLR 470K) to be placed across the

sensor. Short circuit reports as loop 1; open circuit reports as

loop 4 (tamper). Response time is approx. 320mS.

Loop 2: Built-in, normally closed reed switch (used in conjunction with

a magnet).

Loop 3: Normally closed household burglary loop. Response time is

approx. 320mS.

Loop 4: Tamper loop (automatically enrolled) contains two tamper

switches. A built-in cover tamper switch is activated when the

cover is removed. A unit tamper switch is activated if the unit

is separated from its mounting plate.

ENROLLING

The 5817CBXT has a built-in serial number that must be enrolled in the

control panel prior to its usage in the alarm system. Assign loops 1-3 to

individual zones respectively. Refer to the control panel's installation

instructions for specific programming procedure.

When programming the 5817CBXT transmitter, set as Input Type "RF"

(i.e., supervised RF) (mandatory for UL installations).

NOTE: DIP switch 1 must be set to OFF during enrollment.

MOUNTING

•Signal strength may vary from location to location. Before mounting

the transmitter permanently, conduct Go/No Go tests (see control's

instructions) to verify adequate signal strength from this location.

•When a satisfactory location is found,remove the battery and

proceed with installation.

IMPORTANT: Do not mount the transmitter on or near metal

objects, as this may affect transmission range. It is also good

practice to avoid locating the transmitter near wiring such as AC,

telephone, HVAC, computer data cables, etc.

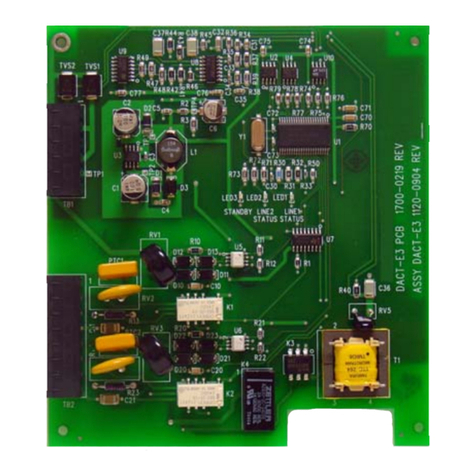

1. Remove the tamper switch hold down tab from the mounting plate

and set it aside. It will be needed if not using the mounting plate.

2. Remove the transmitter's cover using the flat blade of a small

screwdriver in the pry-off slot and twisting. To replace the cover,

engage the hooks along the top edge and snap shut.

3. Disengage the mounting plate from the case back by inserting the

blade of a small screwdriver into the mounting plate release hole

(see Figure 3) and pushing the locking tab out (see Figure 1). Slide

the mounting plate downward along the case back.

4. For Concealed Wiring: Feed the wires through the concealed wiring

entry hole at the bottom corner of the mounting plate (and/or case

back).

For Surface Wiring: Remove the knockout slot in the case back

(near loop 3 terminal block).

Do not connect the wiring to the terminal block(s) yet.

5. If Using the Mounting Plate (for easy removal later for servicing):

a. Install the mounting plate in the location determined, with its case-

holding posts pointing up. Use two flat head dry-wall screws.

NOTE: To ensure proper operation of the unit's back tamper, the

screws must be anchored to a wall stud or other solid wood

material.

b. Attach the case back to the mounting plate by sliding the

keyhole slots in the case back down onto the mounting

plate's holding posts. The locking tab clicks as the case

back locks in place.

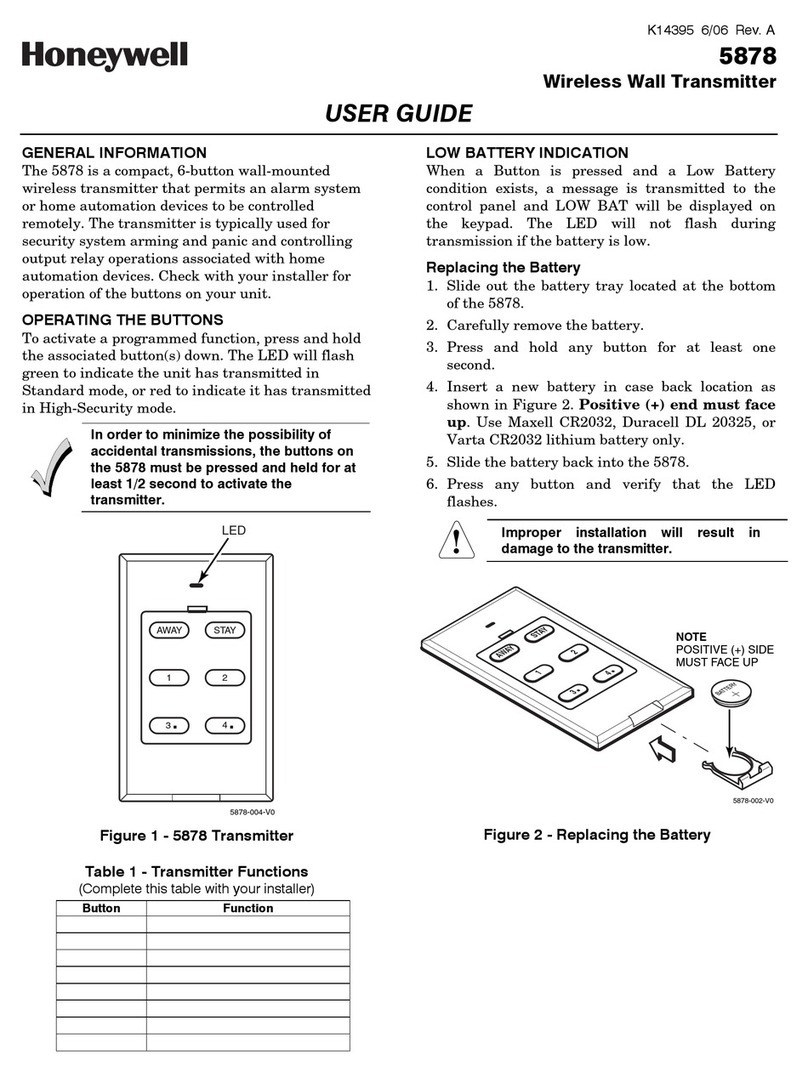

If Not Using the Mounting Plate:

a. Make note of the location of the tamper switch hold-

in Fig. 1 for the proper placing of the hold-down tab in Fig. 2.

b. Remove the PC board from the case back. Slide a small flat

bladed screwdriver between the case back and PC board near the

board hold-down clip and carefully pry the board out.

c. In the area that was marked, install the hold-down tab with a 5/8”

flat head dry-wall screw. The tab must be aligned with the

corresponding slot in the case back as shown in Figure 2. The tab

as well as the case back must be anchored to a wall stud or other

solid wood material.

d. Mount the case back to the wall using two flat head dry-wall

screws, anchoring it to a wall stud or other solid wood material.

e. Reinstall the PC board into the case back, position the board onto

the two retaining studs on one side of the case back and snap the

board into place. The hold-down tab must mate with the

corresponding cutout in the case back after case back is installed.

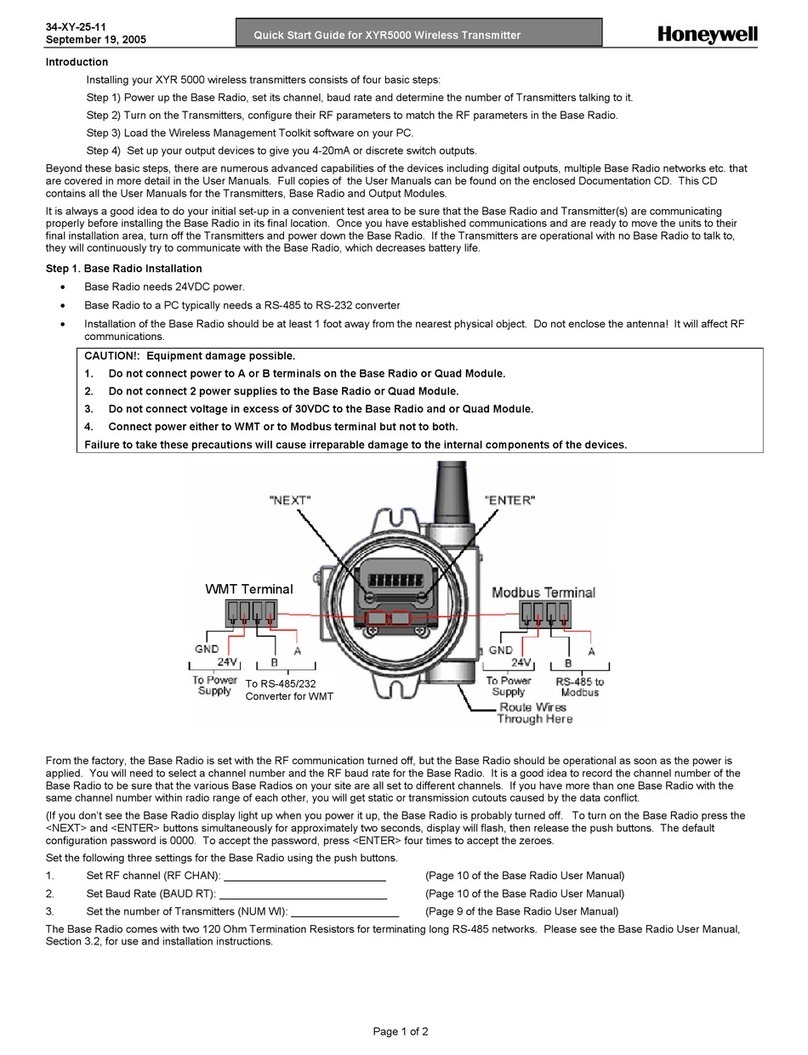

5817CB-004-V0

MOUNTING

PLATE

HOLE CASE

HOLDING

POSTS

CONCEALED

WIRING

ENTRY

HOLE

MOUNTING

PLATE HOLE

TAMPER

SWITCH

HOLD

DOWN

LOCKING

TAB

HOLD-DOWN

TAB

Figure 1. Mounting Plate

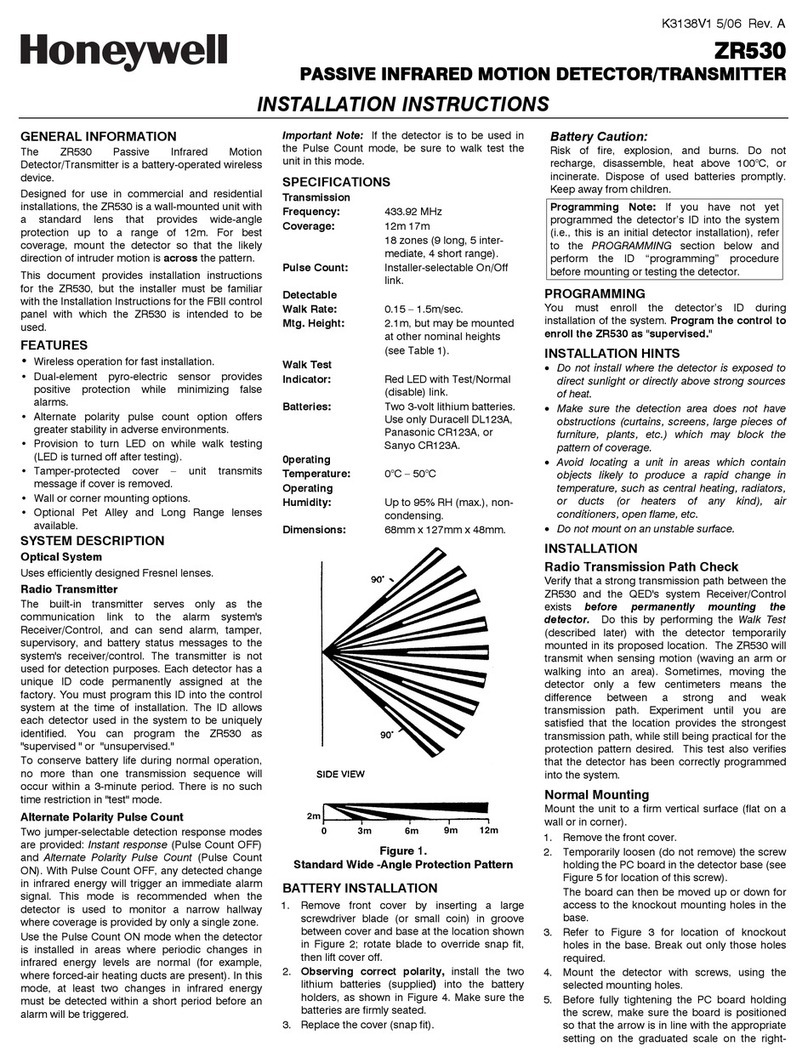

5817CB-001-V0

TAMPER SWITCH

HOLD-DOWN TAB

CASE

BACK

CONCEALED

WIRING

ENTRY HOLE

MOUNTING

HOLES (2)

INSTALL

IN LINE

WITH

CUT-OUT

IN CASE

BACK

Figure 2. Case Back

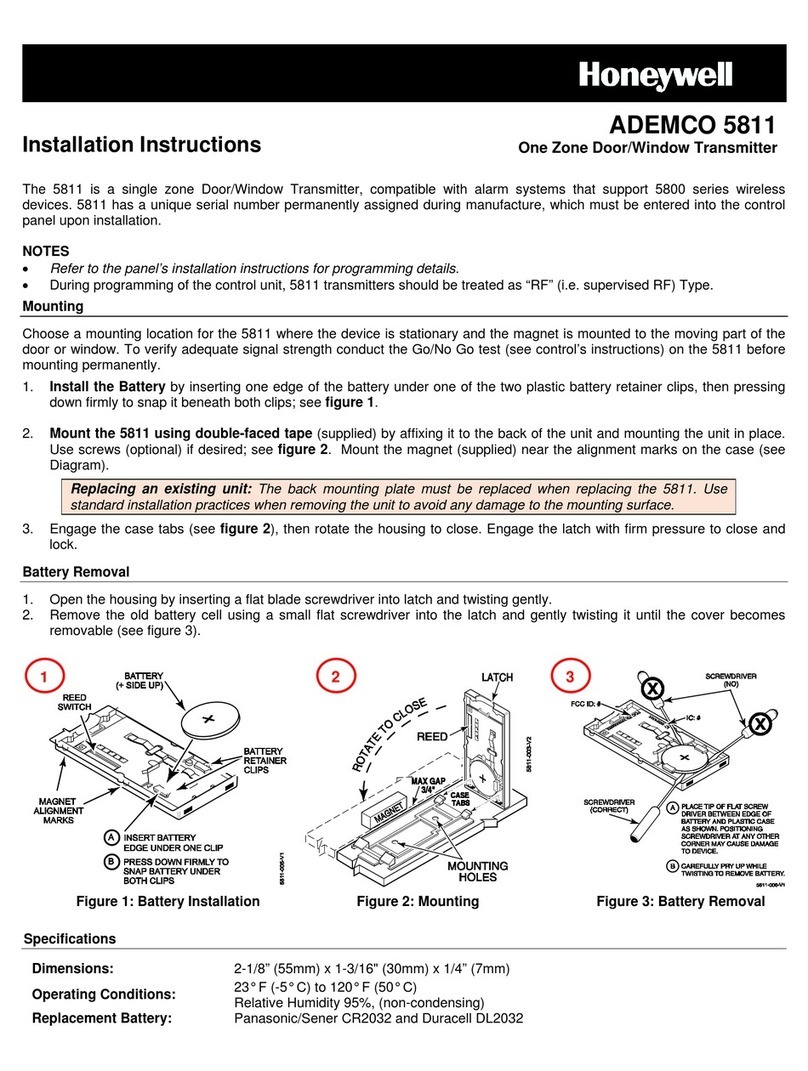

6. Set the DIP switch (after the control panel has enrolled the

transmitter loops) for the desired primary loop characteristics, as

described in the Primary Loop Options Table.

Notes:

•The DIP switch may be set by the installer only. It is not a user

function.

•Due to FCC regulation 15.231(a)(4), this switch may not be set to

ON unless loop 1 is used to indicate a type of emergency

involving fire, security, or safety of life.

PRIMARY LOOP OPTIONS

SWITCH

SET TO DIP SWITCH POSITION

ON

REPEATING TRANSMISSION (every 4 sec.)

UPON PRIMARY LOOP 1 FAULT

Use for high priority alarm, such as fire.

OFF

SINGLE TRANSMISSION

PER PRIMARY LOOP CHANGE-OF-STATE

Notes:

•In order for the control panel to enroll the transmitter, DIP

switch 1 must be set to OFF (see Figure 3).

•the Auxiliary loops are not affected by the DIP switch settings.

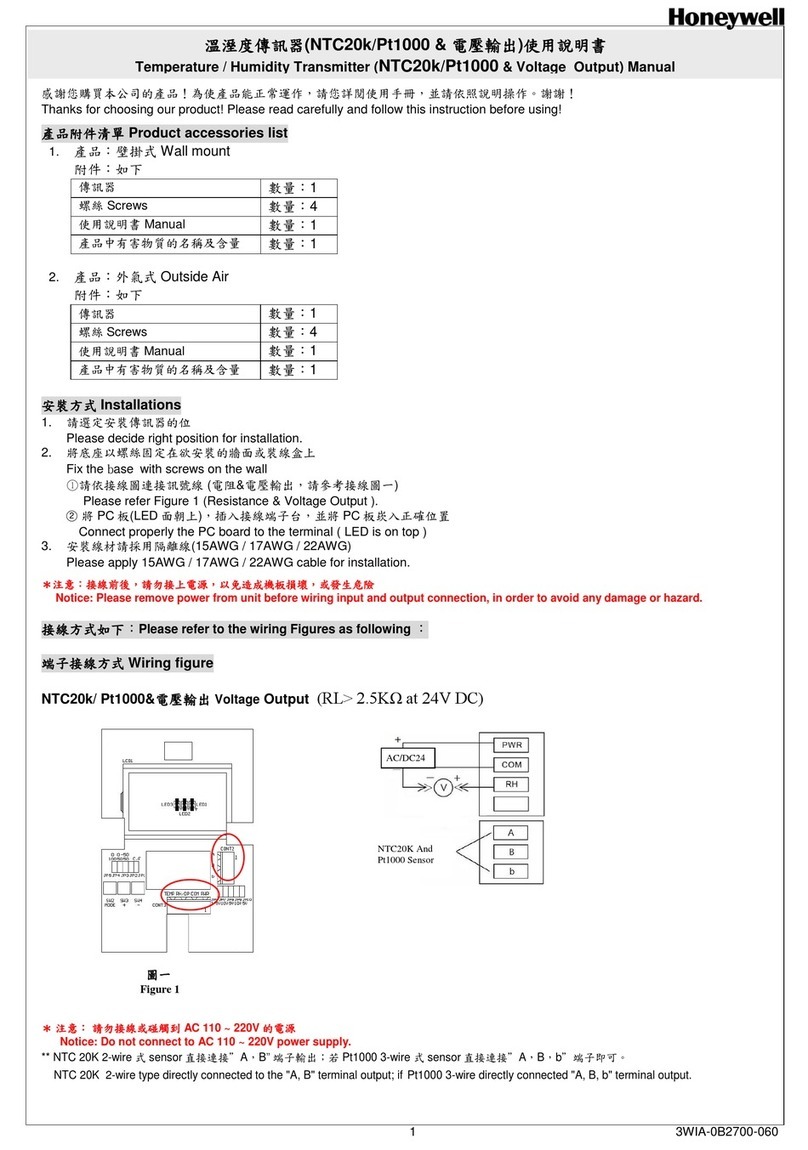

WIRING CONNECTIONS

Connect the loop wiring to the unit's terminals before installing the

battery (see Figure 3).

NOTES:

•Primary loop 1 is a supervised loop and must have an end-of-line

(EOL) resistor (470K ohms, supplied) placed across the last sensor.

Additionally, for Primary loop 1, a contact device may not be installed

more than 20 feet from the transmitter.

•For UL household burglary and fire installations, the loop 3 contact

device (if used) may not be more than 3 feet from the transmitter.