Maintenance

The Hozelock Cyprio range of

Aquaforce pumps have been designed

to allow fast and easy maintenance. To

prolong the life of your pump and

keep your pump in peak condition,

you should follow these maintenance

guidelines.

Caution: Always unplug or disconnect

ALL appliances in the pond from the

electricity supply before putting your

hands in the water or starting

maintenance.

1. When the pump is newly installed,

you should check your pump daily that

it is performing correctly.

2. If you notice a drop in performance

(low flow) you should clean the

strainer cage. Cleaning intervals will

vary depending on the condition of

your pond’s water. This could be as

often as weekly in the summer

months. To clean the strainer cage,

open the clips and remove the pump.

The cage can then be wiped clean of

debris blocking the strainer holes and

washed in clean water. You should

also check that the pump chamber &

rotor are not blocked with debris.

3. At least once a year you should

completely disassemble the pump

including the rotor assembly as

described below and wash all

components in clean, fresh water.

Replace worn or broken parts.

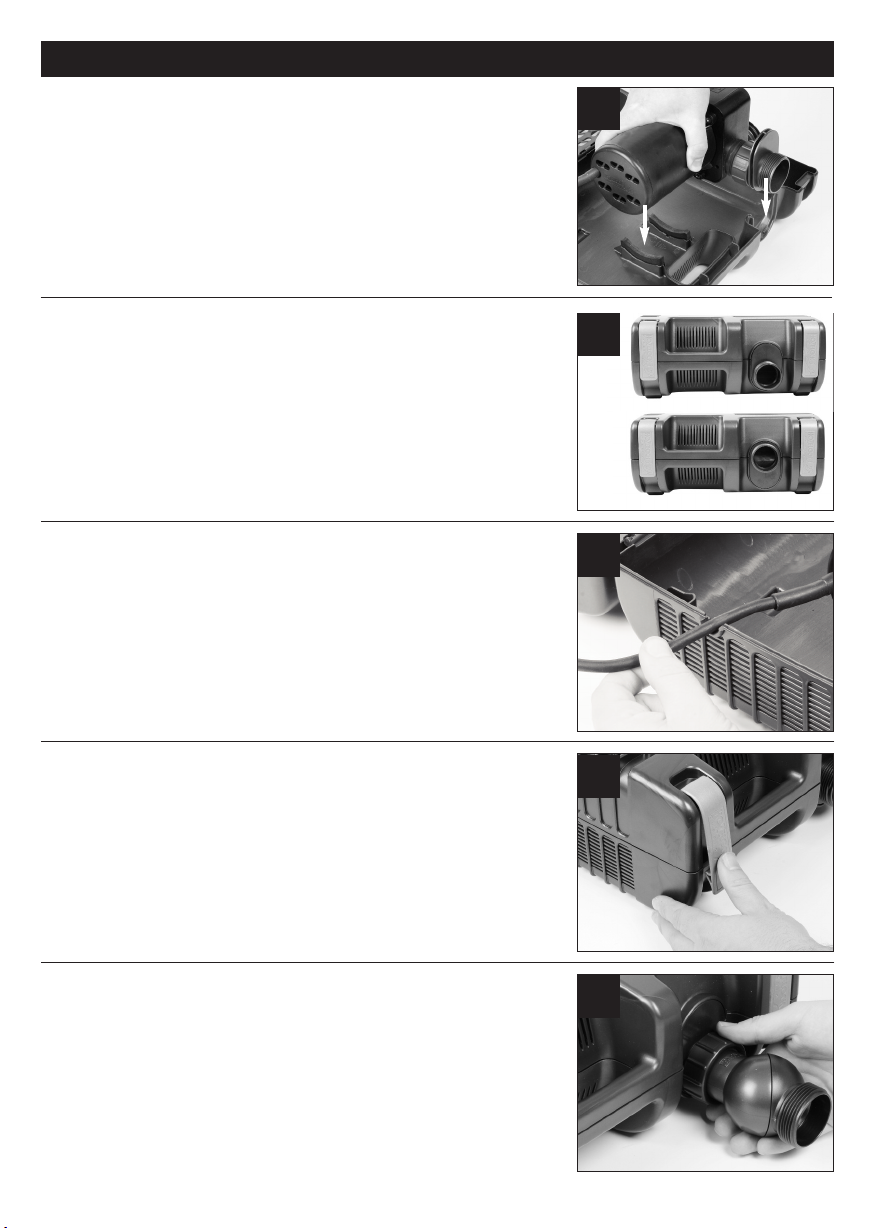

Pump Dismantling & Assembly

(6000 & 8000) - Fig 22

1. Switch off the pump and remove

the strainer cage as described above

and remove the pump.

2. Ensure the pump is cool before

dismantling it.

3. Unscrew the 3 posidrive screws in

the chamber.

4. ently pull the pump chamber (d)

squarely away from the motor body

(a).

5. Pull the rotor assembly (c) out of

the motor body. Important! Take

extra care so as to not drop the

rotor assembly.

6. Wash out all of the components in

clean water. Do not use detergents

or other chemical cleaners.

7. Ensure the o-ring (b) is on it’s seat

(fig 29). Replace the rotor assembly

into the motor body, ensuring that

the holes in the plate behind the

impeller locate onto the pins on the

motor body. Refit the pump

chamber and screws and return the

pump to the strainer cage.

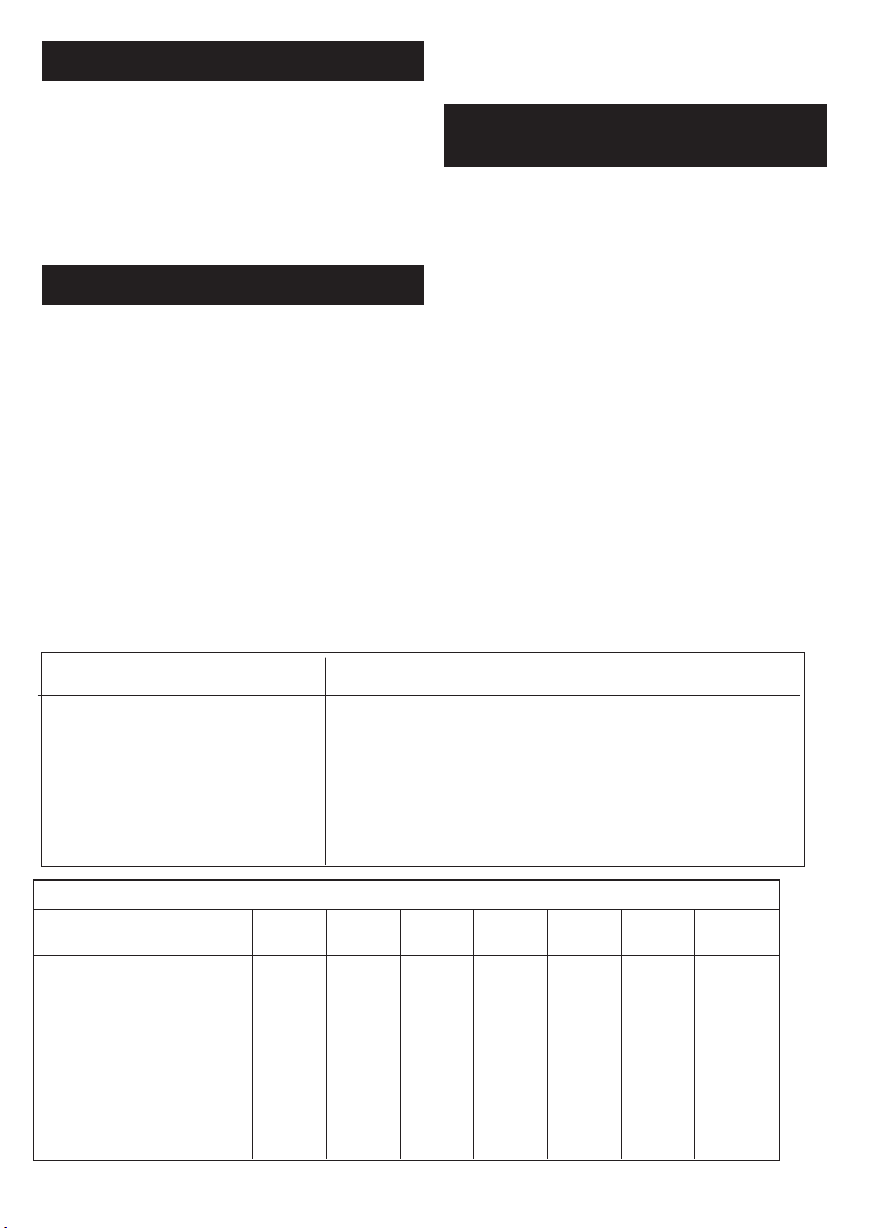

Pump Dismantling & Assembly

(12000 & 15000) - Fig 23

1. Switch off the pump and remove

the strainer cage as described above

and remove the pump.

2. Ensure the pump is cool before

dismantling it.

3. Unscrew the 4 posidrive screws in

the chamber.

4. Rotate the pump chamber (d) as

far as it will go and gently pull the

chamber squarely away from the

motor body (a).

5. Pull the rotor assembly (c) out of

the motor body.

Important! Take extra care so as to

not drop the rotor assembly.

6. Wash out all of the components in

clean water. Do not use detergents

or other chemical cleaners.

7. Ensure the o-ring (b) is on it’s seat

(fig 24). Replace the rotor assembly

into the motor body, ensuring that

the holes in the plate behind the

impeller locate onto the pins on the

motor body. Refit the pump

chamber and screws and return the

pump to the strainer cage.

4. If you live in a hard water area

(water with high levels of calcium or

limescale content), the pump, rotor

assembly and steel can should be

cleaned at regular intervals. The

cleaning interval required will vary

depending on the hardness of your

water, so you should inspect for signs

of calcium build up regularly.

To clean off calcium or limescale

deposits a small nylon bristled brush

(such as a toothbrush) may be used.

Dismantle the pump as described

above and remove the rotor. Clean the

limescale deposits from the rotor using

fresh clean water

If excessive calcium deposits build up,

the thermal overload protection may

be activated (See INTRODUCTION).

d

c

b

a

d

c

b

a

24

22

23

6000/8000

12000/15000