Always wash any contaminated clothing.

Seek medical attention if spray gets in your eyes or you

develop any symptoms after spraying.

Do not spray near food or food preparation areas. When

spraying crops, pay particular attention to the chemical

manufacturers advice on time before crops can be eaten.

Do not spray any solvent e.g. White spirit.

Spray only thin watery solutions; thicker mixtures will clog

the nozzle.

Powdered chemicals can be sprayed successfully if they

are completely soluble in water. If they are not, or the

solution tends to settle, spraying can still be successful if

the mixture is continually agitated.

If the material to be sprayed contains sediment, strain the

liquid into the sprayer bottle.

Do not over pressurize the bottle. The pressure release

valve is designed to release excess pressure, and must not

be tampered with, or forced to remain closed.

Winter use – drain liquid from all parts and loosen pump

assembly.

Annual maintenance – At least once per year thoroughly

clean the whole sprayer and apply silicone grease to all

moving parts & seals. Test with water, and if any washer or

seal has perished it must be replaced.

Notes

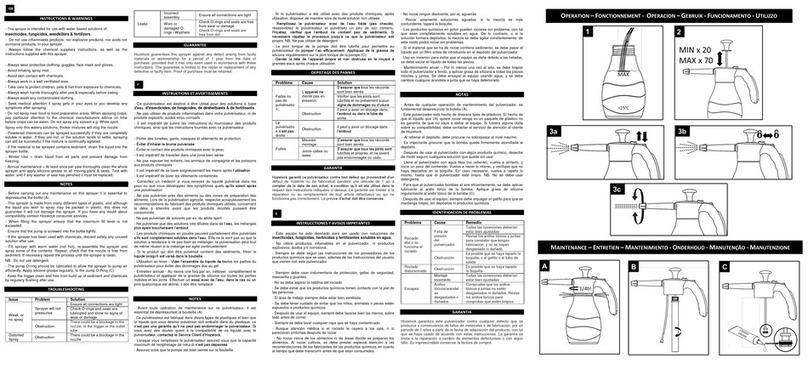

A Ensure the hose fully covers the barbed details on both

the lance, and outlet connector. Make sure all nuts are

hand tight before use.

B This sprayer is made from many types of plastic, and

although the liquid you wish to spray may also be packed

in plastic, this does not guarantee it will not damage

the sprayer. If you have any doubt about compatibility,

contact Hozelock consumer services. When filling the

sprayer, or using the dosing cup, always use the large

filling aperture, and ensure that the maximum fill level is

not exceeded.

C Ensure that the pump and dosing cup is screwed into the

bottle tightly before pressurising and locked in position.

D Beforeoperatingthepump,operatethepressure

releasevalvemanuallybyliftingtheknobtoensure

itisfreetomove,thenreleasethehandlebyrotating

anticlockwise,pressurisebottleandthenlockbackin

position.

E After using the sprayer, manually operate the pressure

release valve as above, to depressurise.

F If the sprayer has been used with chemicals discard any

unused solution in an environmentally friendly manner.

G Fill bottle with warm (not hot) water, reassemble the

sprayer, and spray some of the contents. Repeat, and

check that the nozzle is free from sediment. If necessary,

repeat the process until the sprayer is clean. NB: Do not

use detergent.

H The pump assembly and pressure release valve o rings

should be lubricated to allow the sprayer to pump air

efficiently. Access the seals by unscrewing the plunger

retaining ring. Apply silicone grease regularly to the pump,

piston and release valve o ring seals (A).

I The nozzle cap (B) and swirl grooves (C) should be kept

clean and free of obstructions. The ‘O’ ring seal (D) should

be lubricated with silicone grease to allow the spray

pattern to be easily changed.

J Keepthetriggercleanandfreefrombuildupof

sedimentbyregularlyflushingafteruse,ifnecessary

removeandcleantheshuttleinthetrigger(A)usinga

coinorsimilar.

K To clean or replace the angled adaptor washer, unscrew

the retaining nut (B), pull off the hose and unscrew the

angled adaptor.

LEnsure that the dosing cup last used indicator is set

correctly after using the sprayer. To change the setting,

remove the dosing cup then align the arrow with the

required symbol by lifting and turning the nut.

M For storage the hose can be coiled inside the base.

N If required the hose maybe clipped into the top trim for

storage.

O When using the weed killer cone, ensure that the angled

head assembly with the red fan spray nozzle is fitted

and the nozzle aligned correctly. The red nozzle is not

adjustable.

P The telescopic lance can be adjusted in length by firstly

loosening the lance nut, and retightening as required.

Guarantee

• Hozelock guarantees this sprayer against any defect arising

from faulty materials or workmanship for a period of 5 years

from the date of purchase, provided that it has only been

used in accordance with these instructions. The guarantee

is limited to the repair or replacement of any defective or

faulty item. Proof of purchase must be retained.

• Hozelock extended guarantee covers the bottle and pump

mechanism only. It specifically excludes all ‘O’-rings & seals.

These have a 12-month guarantee, are wearing parts and

are available as spares from the retailer or from Hozelock

direct.

Troubleshooting

Issue Problem Solution

Weak or

no spray Sprayer

will not

pressurise

Ensure all connections are

tight and the dosing cup is

fitted

Loss of

pressure

Check ‘O’-rings and seals are

lubricated and show no signs

of wear or damage – replace

if required

(see notes H, I, J, and K)

Obstruction There could be a blockage in

the nozzle, the trigger or the

outlet hose

Distorted

Spray Obstruction There could be debris in the

nozzle