SECTION

III

OPERATING INSTRUCTIONS

3-1

m

=~=::

OU~~~/~~2~:

"If"

_---

........

1

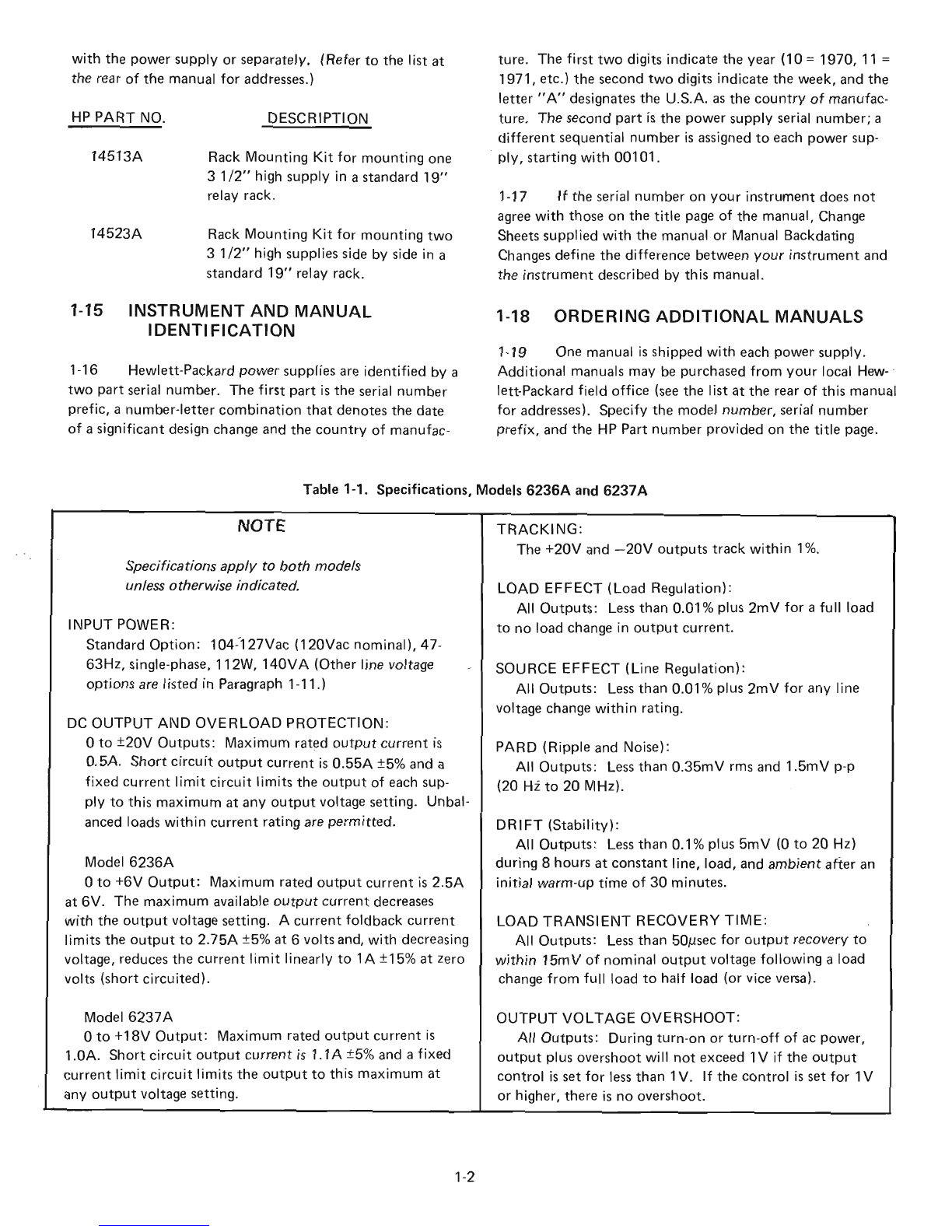

Figure 3-1. Controls and Indicators

TURN-ON CHECKOUT PROCEDURE

a.

Connect

line

cord

to

power

source

and

turn

LINE

switch

G)

on.

LINE ON

indicator

®will light.

b.

Set

METER

switch

®

to

the

+6V

position

and,

with

no

load

connected,

vary

+6V

VOLTAGE-control

@over

its range

and

check

that

the

voltmeter

responds

to

the

con-

trol

setting

and

the

ammeter

indicates

zero.

c.

Set

the

+6V

VOLTAG E

control

for

a

6-volt

meter

indication

and

short

the

+6V

output

terminal

to

COM

(common)

terminal

®

with

an

insulated

test

lead.

The

ammeter

should

indicate

a

short-circuit

output

current

of

approximately

1.0A

(1.1A

in

the

6237A).

Remove

the

short

from

the

output

terminals.

d.

Set

the

METER

switch

to

the

+20V

position

and,

with

no

load

connected,

vary

±20V

VOLTAGE

control

®

over its range

and

check

that

the

voltmeter

responds

to

the

control

setting

and

the

ammeter

indicates

zero.

3-2

The

following

steps

describe

the

use

of

the

Model

6236A

or

6237

A

front

panel

controls

and

indicators

illus-

trated

in Figure 3-1

and

serve as a

brief

check

that

the

sup-

ply

is

operational.

This

checkout

procedure

or

the

more

detailed

performance

test

of

Paragraph 5-6

should

be follow-

ed

when

the

instrument

is

received

and

before

it

is

connect-

ed

to

any

load

equipment.

Proceed

to

the

more

detailed

procedures

beginning in Paragraph 5-6 if

any

difficulties

are

encountered.

--

CAUTION--

e.

Set

the

±20V

VOLTAGE

control

for

a

20-volt

meter

indication

and

short

the

+20V

output

terminal

to

the

com-

mon

terminal

with

an

insulated

test

lead.

The

ammeter

should

indicate

a

short-circuit

output

current

of

O.55A

±5%.

Remove

the

short

from

the

output

terminals.

f.

Repeat

steps

(d)

and

(e),

but

substitute

the

-20V

position

of

the

METER

switch

and

the

-20V

output

ter-

minal.

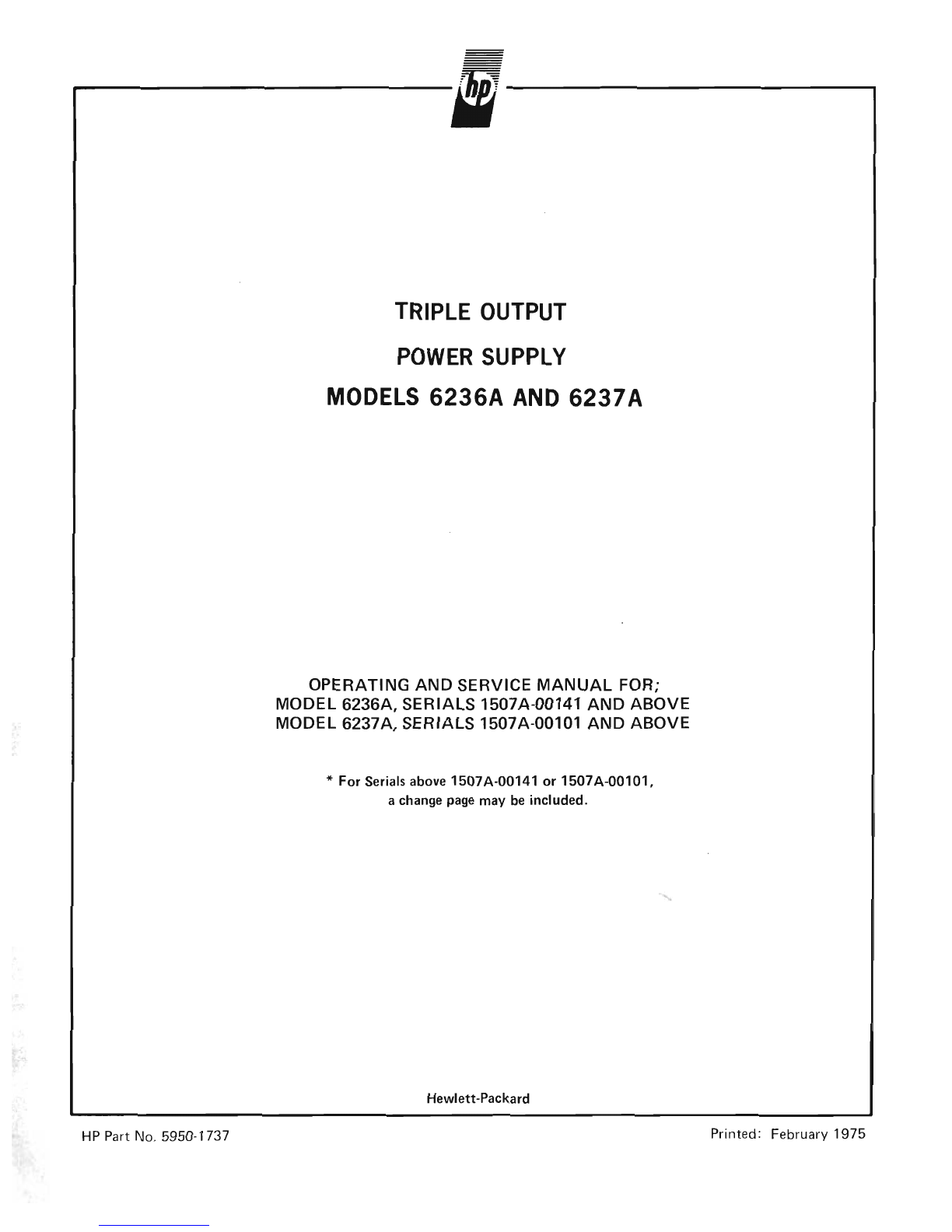

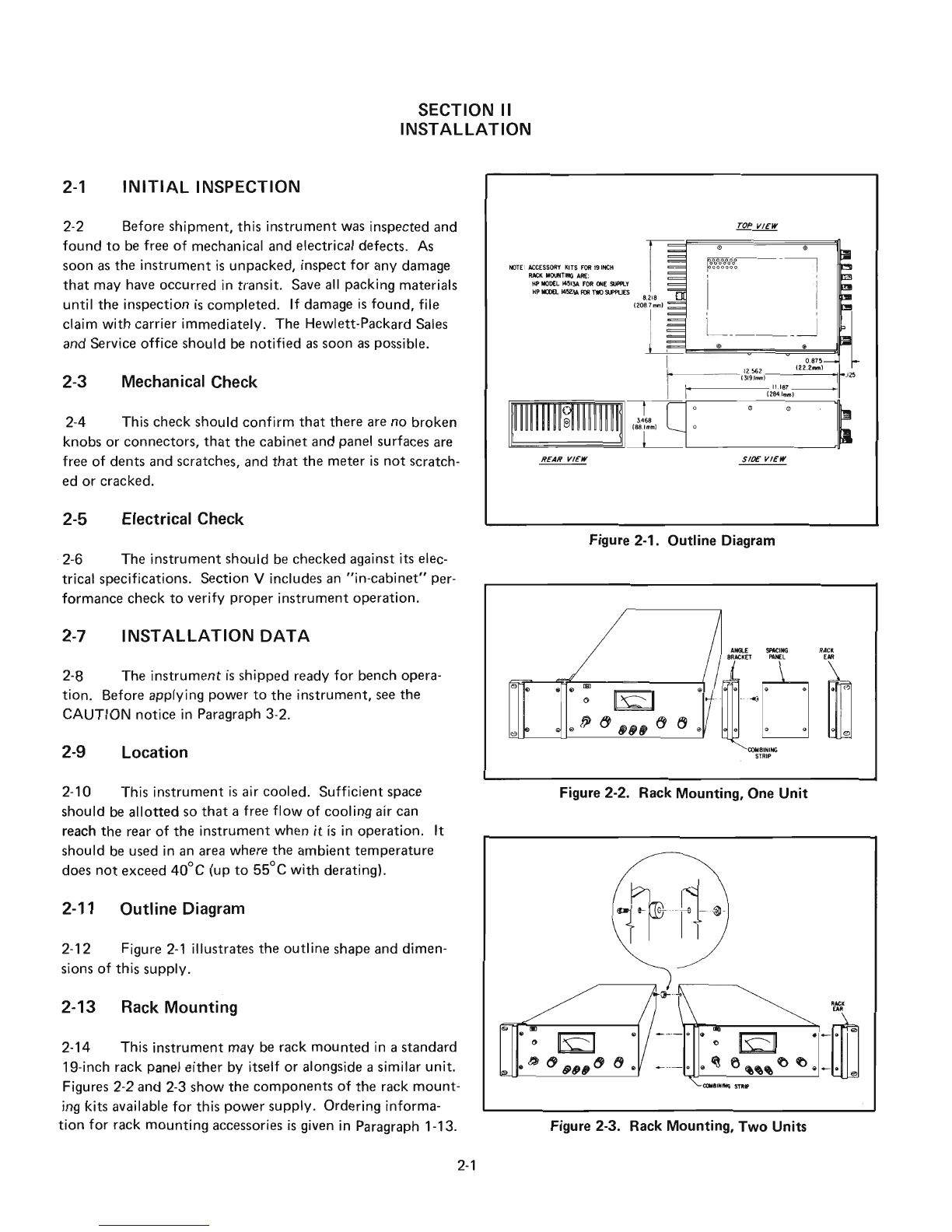

Figure 3-2. Line Voltage Selector (Set for

120

Vac)

Before applying power to the supply, make certain

that its line voltage selector switch

(53)

is

set

for

the line voltage to be used. This switch

is

mounted

on the circuit board behind the voltmeter and

is

visible through the perforations in the top cover.

The positions

of

the two white marks on the switch

indicate the switch setting

(see

Figure 3-2).

If

the

switch setting does

not

correspond to the intended

power source, proceed to

Paragraph

3-4 before

applying power.

.r--

240----,

(

r-

220

----,

0_

0

L-,OO--.J

'---120

---J

t

FRONT

OF

SUPPLY

NOTE

For the Model 6237A, substitute. +18V

for +6Vin the following steps.

3-1

3-3

If

this

brief

checkout

procedure

or

later

use

of

the

supply

reveals apossible

malfunction,

see

Section

V

of

this

manual

for

detailed

test,

troubleshooting,

and

adjustment

procedures.