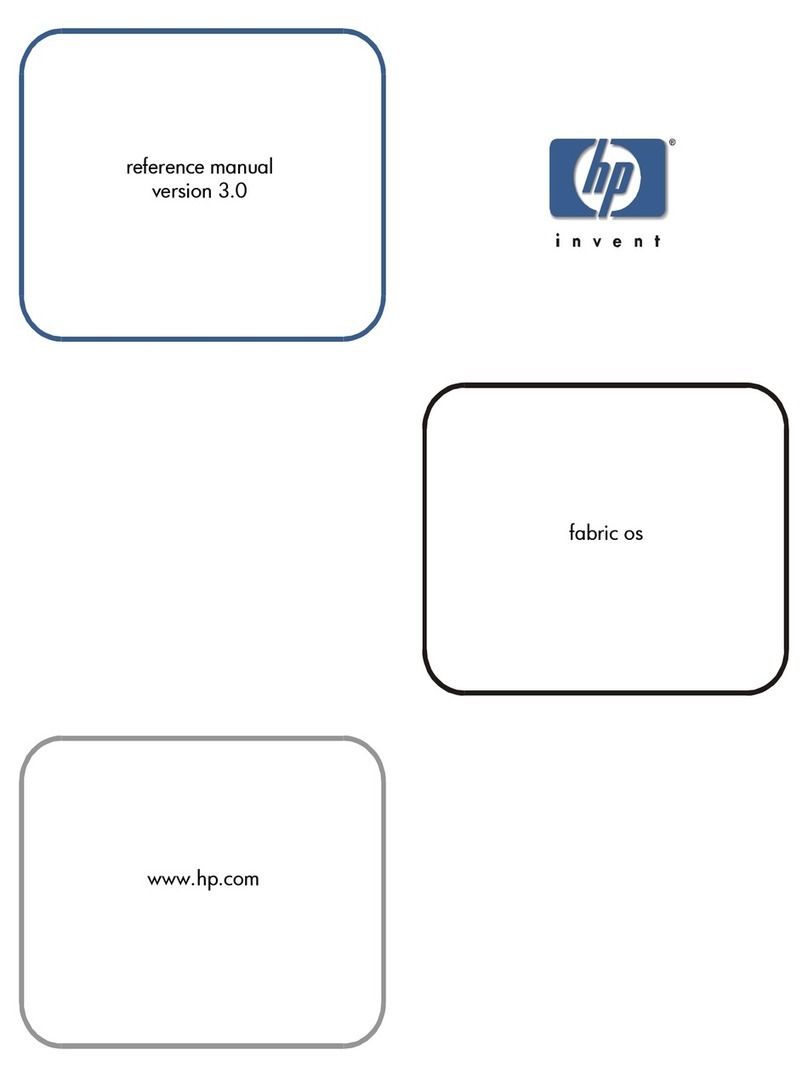

HP C737990900 Product manual

Other HP Storage manuals

HP

HP AJ765A - StorageWorks RDX Removable Disk Backup... User manual

HP

HP StorageWorks 8B - FC Entry Switch User manual

HP

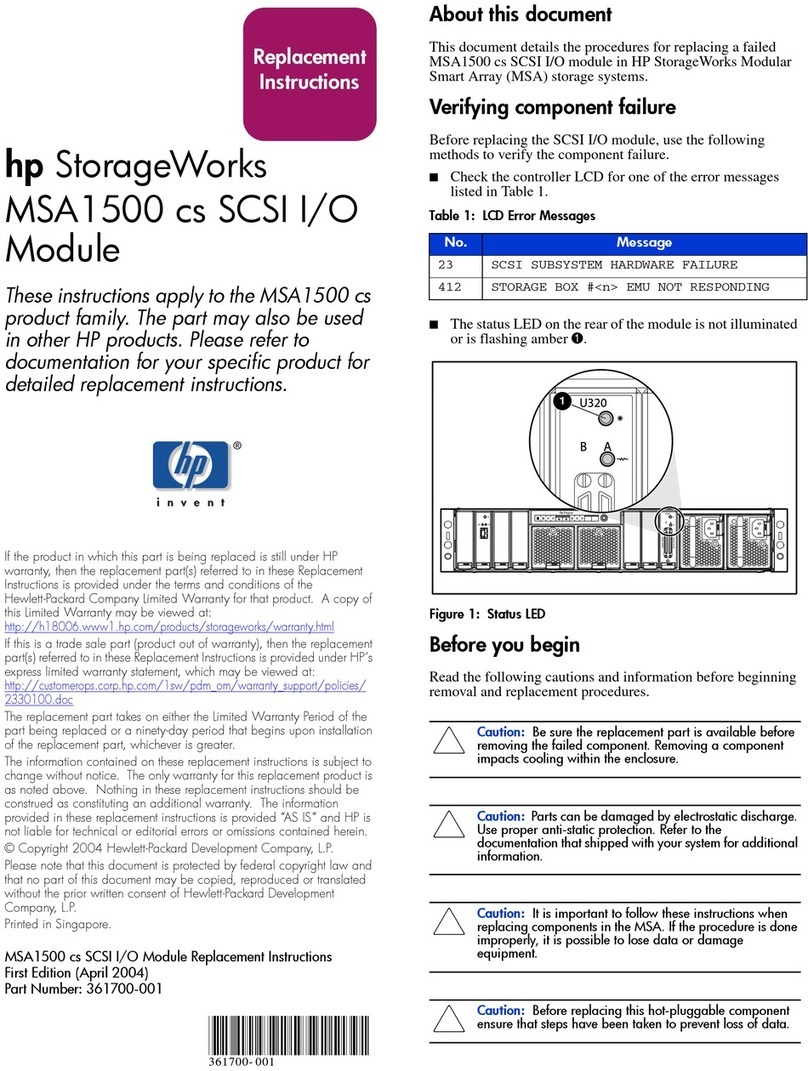

HP StorageWorks 1500cs - Modular Smart Array User manual

HP

HP StorageWorks 8000 - NAS User manual

HP

HP StorageWorks 1/8 G2 User manual

HP

HP Surestore 1200ex - Optical Jukebox User manual

HP

HP STORAGEWORKS XP24000 User manual

HP

HP StoreAll 9000 User instructions

HP

HP StoreEasy 3830 User manual

HP

HP P9000 User manual

HP

HP Pocket Playlist User manual

HP

HP AD510A - StorageWorks Modular Smart Array 1500 cs 2U Fibre Channel SAN Attach Controller Shelf Hard... Guide

HP

HP AD510A - StorageWorks Modular Smart Array 1500 cs 2U Fibre Channel SAN Attach Controller Shelf Hard... Guide

HP

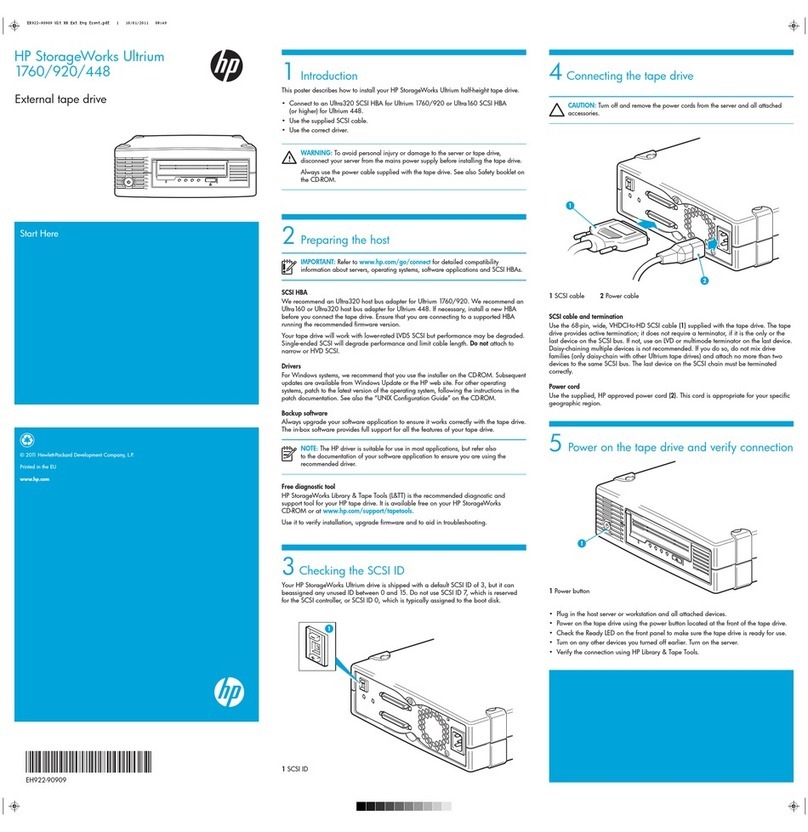

HP StorageWorks Ultrium 1760 Instruction Manual

HP

HP Storevirtual 4000 Instruction Manual

HP

HP LTO Ultrium Product manual

HP

HP AJ765A - StorageWorks RDX Removable Disk Backup... Instruction Manual

HP

HP M8501 User manual

HP

HP P9000 Quick setup guide

HP

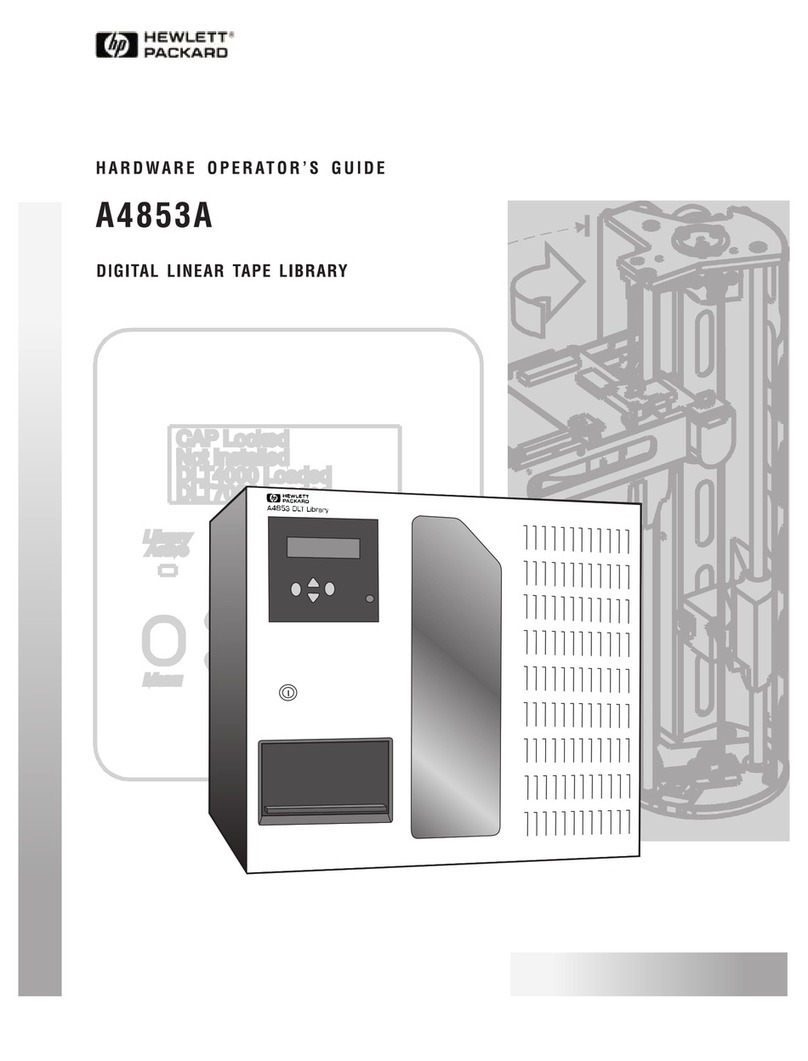

HP Surestore Tape Library Model 3/30 Manual

Popular Storage manuals by other brands

Panasonic

Panasonic LKM-F931-1 instruction manual

Tabernus

Tabernus Enterprise Erase E2400 user guide

Rocstor

Rocstor COMMANDER 3F series user manual

Western Digital

Western Digital Ultrastar Data60 installation guide

Dell

Dell PowerVault MD3600f Series Getting started

CFI

CFI TERA STOR SATA RAID IV user manual