5

4/24/2017 870-MLFPK

LP Tank Enclosure Specifications

2 Openings for each top and bottom - 180oapart

From LP tank base to bottom of opening - Max. 1" (25.4mm)

From floor to base of LP tank - Min. 2" (50.8mm)

The cylinder valve shall be readily accessible for hand operation. A door on the enclosure to gain access to the

cylinder valves is acceptable, provided it is non-locking and can be opened without the use of tools. Designs using

a cover to gain access to the cylinder and cylinder valve shall be provided with handles or equivalent at a

minimum of 180 degrees apart to facilitate lifting of the cover.

The enclosure for the LP-gas cylinder shall isolate the cylinder from the burner compartment to provide:

oShielding from radiation;

oA flame barrier; and

oProtection from foreign material.

There shall be a minimum clearance of 2 in (50.8mm) between the floor of the non-disposable LP-gas cylinder

enclosure and the ground.

The design of the enclosure shall be such that:

oA non-disposable LP-gas cylinder can be connected, disconnected, and the connections inspected and

tested outside the cylinder enclosure; and

oThose connections which could be disturbed when installing the cylinder in the enclosure can be leak

tested inside the enclosure.

Propane Cylinder:

A worn cylinder may be hazardous and should be checked by your propane supplier. Never use a cylinder with a damaged

valve. Use only a propane supply cylinder constructed and marked in accordance with the specifications for LP gas

cylinders of the National Standard of Canada, CAN/CSA B339, Cylinders, Spheres and Tubes for Transportation of

Dangerous Goods; and Commission, as applicable or the Specifications for LP-Gas Cylinders of the U.S. Department of

Transportation (D.O.T.). This appliance has been designed for use with a 20lb or 30lb size propane cylinder only (not

supplied).

The propane cylinder must be provided with a cylinder connection device compatible with the connection for outdoor

appliances. The propane cylinder must be provided with a shut-off valve terminating in a propane cylinder valve type

QCC1, and a safety relief device having direct communication with the vapor space of the cylinder. The cylinder supply

system must be arranged for vapor withdrawal and the cylinder shall include a collar to protect the cylinder valve. The

cylinder shall incorporate listed OPD (overfill protection device). Do not store a spare LP-gas cylinder under or near this

appliance. Never fill the cylinder beyond 80 percent full.

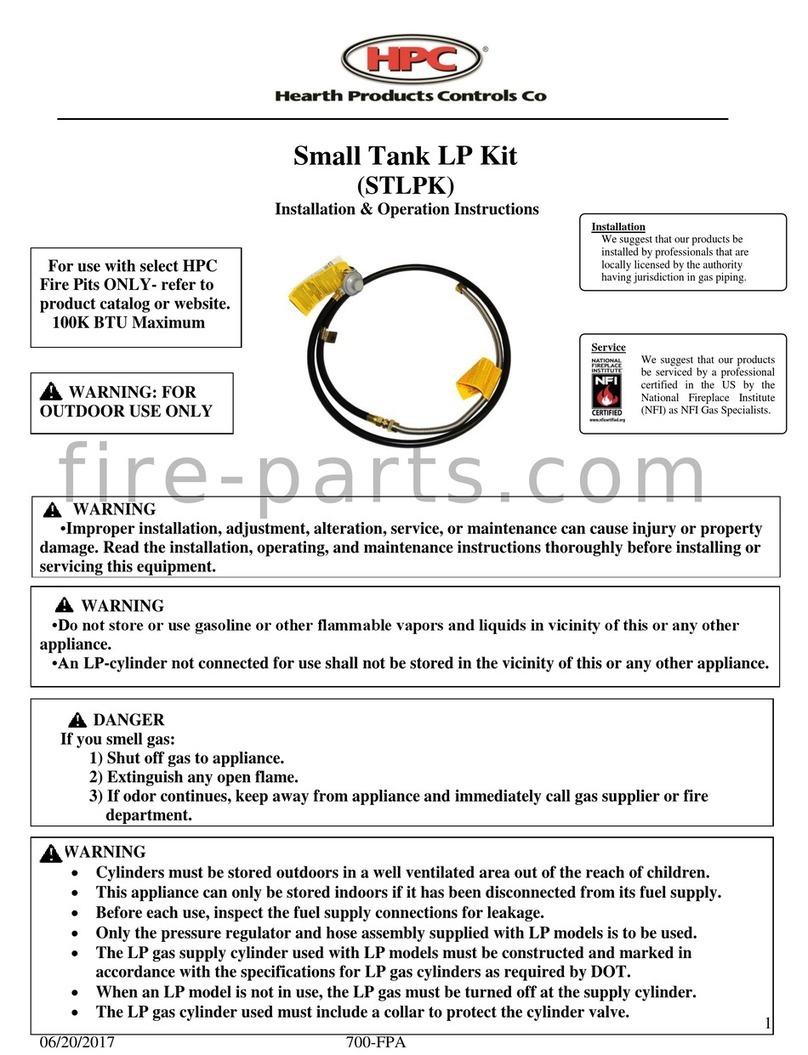

Use only the pressure regulator and hose assembly provided with this appliance. Replacement pressure regulators and hose

assemblies must be specified by the manufacturer. The regulator supplies a pressure of 11 inches water column to the

appliance and has a QCC1 type fitting. Cylinders to be used with this unit must be supplied with a QCC1 cylinder valve. A

QCC1 cylinder has a positive seating connection, which will not allow gas to flow until a positive seal has been achieved. It

is also equipped with an excess flow device. In order to attain full flow to the appliance, the valve must be in the off

position when the cylinder valve is turned on.

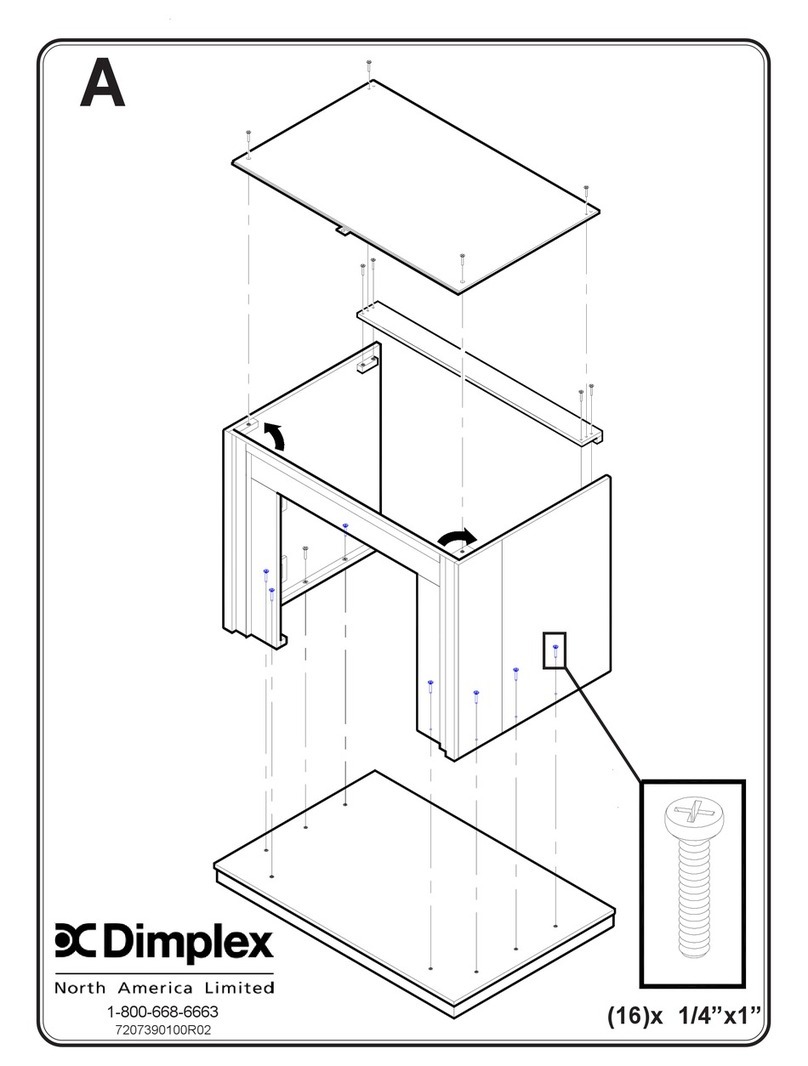

Securing the LP tank:

1. Fasten the L-bracket to the bottom of the propane tank using the nut and bolt supplied. Ensure the nut is tight and will not

loosen.

2. Select location for the propane tank and screw the bracket to the mounting surface. For concrete surface, use a concrete

anchor (not supplied). Ensure that screw is tight so that the cylinder cannot move.

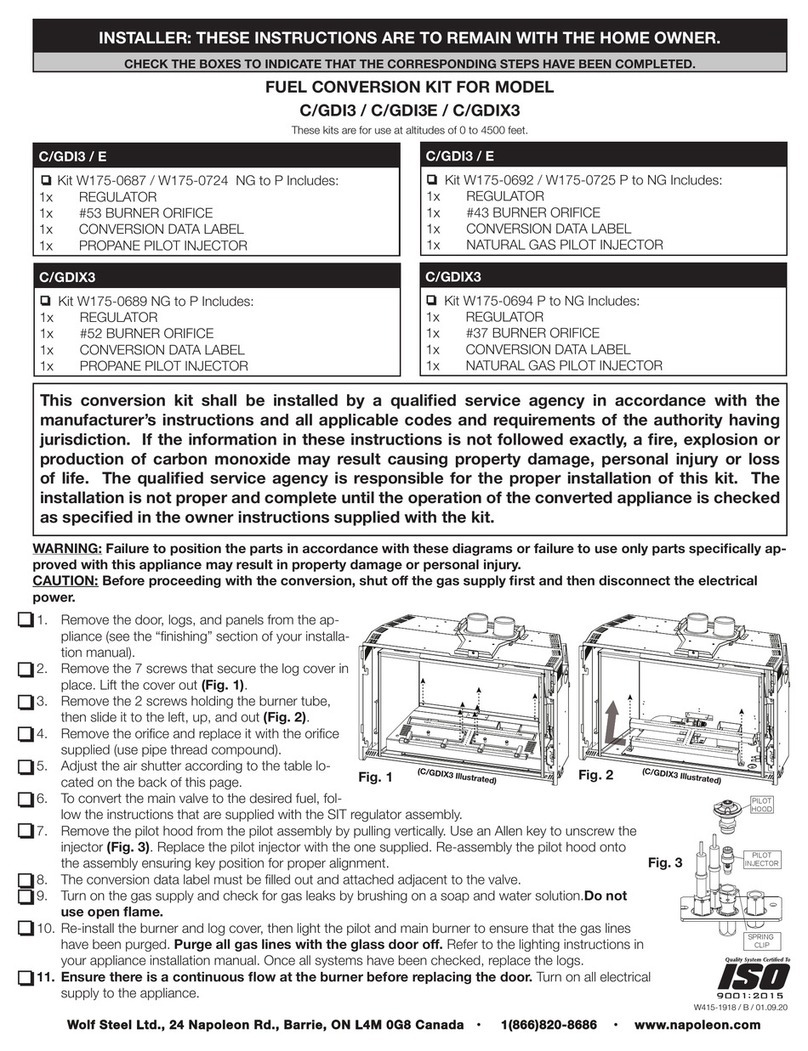

Cylinder Connection:

Ensure the gas regulator has no kinks and is smooth. Remove the cap or plug from the cylinder fuel valve. Insert the black QCC1

regulator nipple onto the QCC1 fuel valve and tighten until snug. Do not use tools. Leak test all joints prior to using the gas

appliance. A leak test must be performed annually and each time a cylinder is hooked up or if a part of the gas system is replaced.

Follow the instructions for natural gas hook-up if the appliance is to be connected directly to a house propane gas supply line.