4

SECTION I - GENERAL DESCRIPTION AND CONSTRUCTION

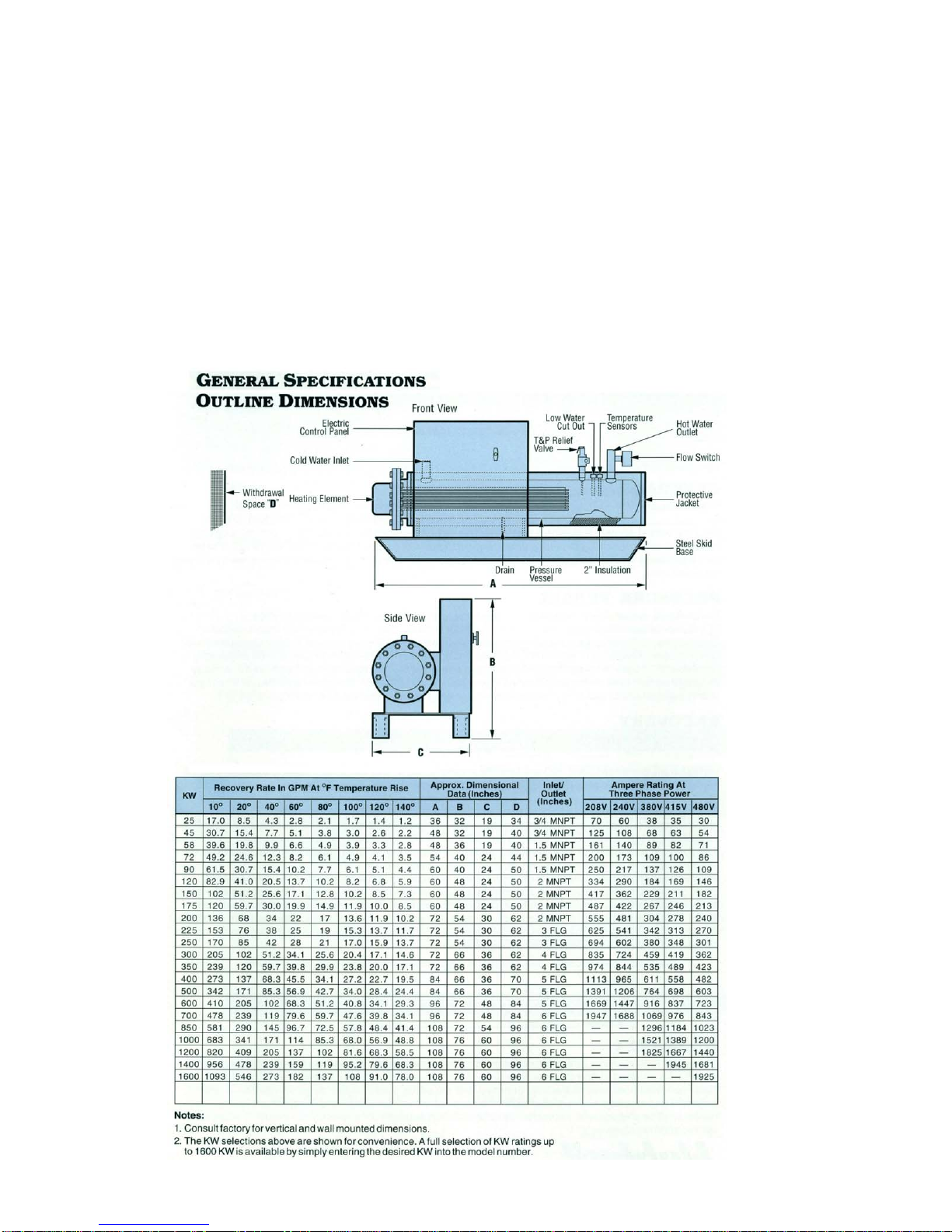

GENERAL DESCRIPTION

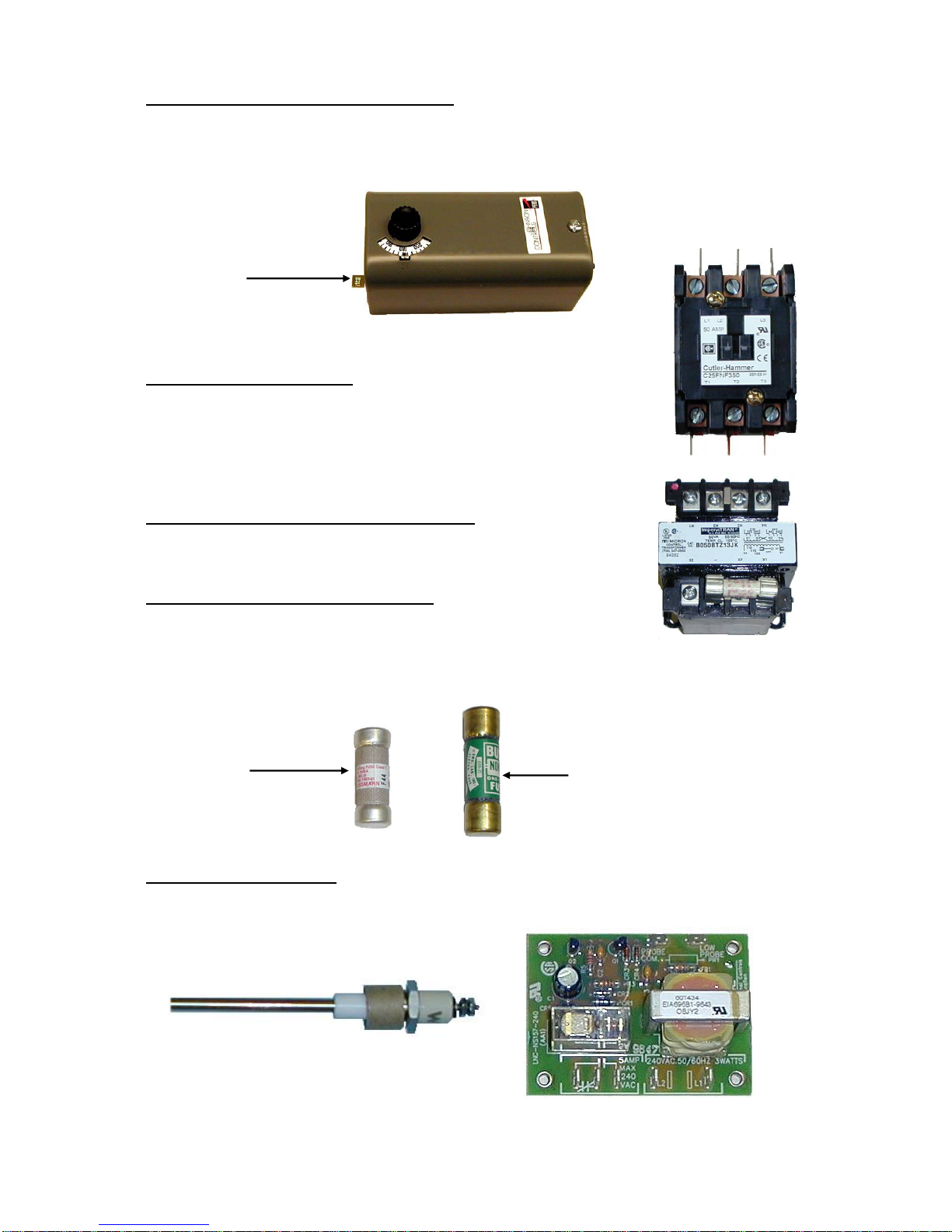

This book describes a packaged electric heater that is a stationary, self-contained unit. The

complete assembly consists of the pressure vessel, immersion electric heating element,

thermostat, safety relief valve, safety high temperature cut out, magnetic contactor(s), power

circuit fusing, fused low voltage control circuit transformer, and any other required electrical

operating control. Optional equipment may be supplied with your unit. Please consult the

product drawing for details specific to your assembly. The unit is factory assembled, insulated,

jacketed, wired, tested, and ready for electrical and plumbing service connections.

CONSTRUCTION

PRESSURE VESSEL

Standard Vessel Construction:

The standard pressure vessel is constructed of all welded carbon steel, then hot dip galvanized

for added corrosion resistance. Units over 58 kW are designed and built in accordance with

ASME Section IV and stamped, certified, and registered with the National Board of Boiler and

Pressure Vessel Inspectors. The maximum allowable working pressure is stamped on the

nameplate. The standard working pressure is 150 psi (225 psi TP).

Optional Non-Ferrous Vessel Materials:

1. Copper-Silicon – A copper-silicon alloy offers tremendous longevity due to its ability to

withstand the cycling effects induced from changes in water temperature and pressure.

This material is suitable for storage of hot potable water in a variety of commercial and

industrial applications.

2. 90/10 Copper-Nickel – A 90% copper and 10% nickel alloy similar to copper-silicon, but

with added strength and corrosion resistance. Typically used in applications with

corrosive environments (salt water) or critical applications.

3. Stainless Steel – Stainless steel (type 304, 316, or 316L) is well suited for high purity

applications requiring a corrosion resistant tank with minimal leaching of impurities into

the water. Well suited for process, RO, and DI water systems in the pharmaceutical, food,

and electronic industries.

4. Other materials are available upon request.

Optional Working Pressures:

The pressure vessel may be supplied with optional working pressures (standard working

pressure is 150 psi). See drawing for details.

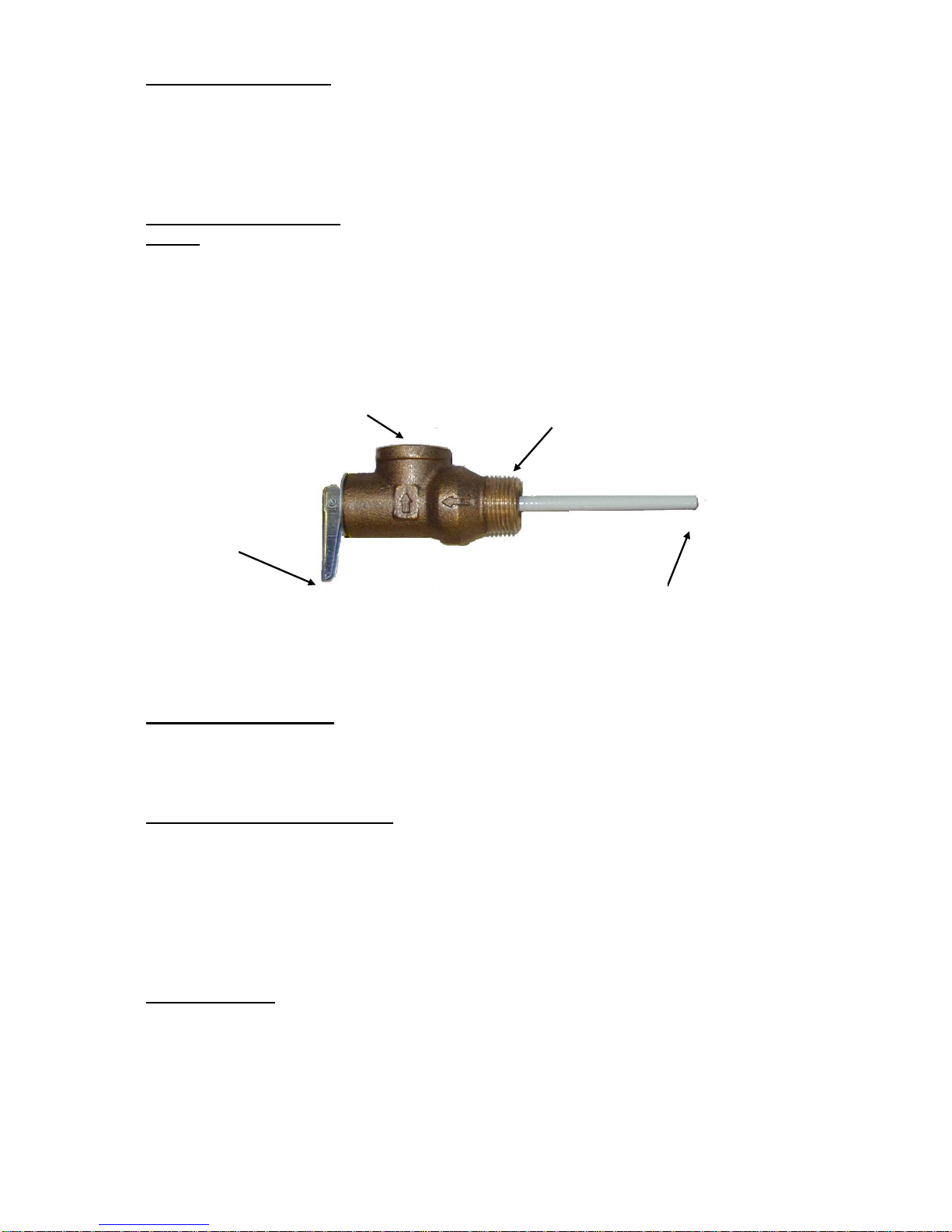

VESSEL CONNECTIONS

The heater is supplied with separate cold water and hot water connections. A connection is

provided for mounting a combination safety temperature and pressure relief valve. An overflow

line should be utilized from the relief valve outlet to a floor drain. See drawing for locations and

sizes.

OUTER SHELL, INSULATION, AND SUPPORTS

The pressure vessel is encapsulated in 2-inches of high-density fiberglass insulation. The

protective shell is constructed of galvaneel and is coated with a durable silver hammertone

finish. The horizontal configuration is supported on heavy-duty steel I-beam supports. Also

available in a vertical configuration or wall hung for off the floor installation.

HEATING ELEMENT

The heater is supplied with a flanged electric immersion heating element assembly, composed

of copper, incoloy, or stainless steel sheathed elements that are brazed or welded into a ANSI

steel flange. The heating element is fastened to a corresponding tank flange using a gasket and

hex head steel bolts and nuts. Specialized heating element construction may be included. These

options include: special watt density ratings, passivation, electropolishing, or special materials.

See drawing for voltage, power ratings, and special options.