6 OF 24

021564 K17

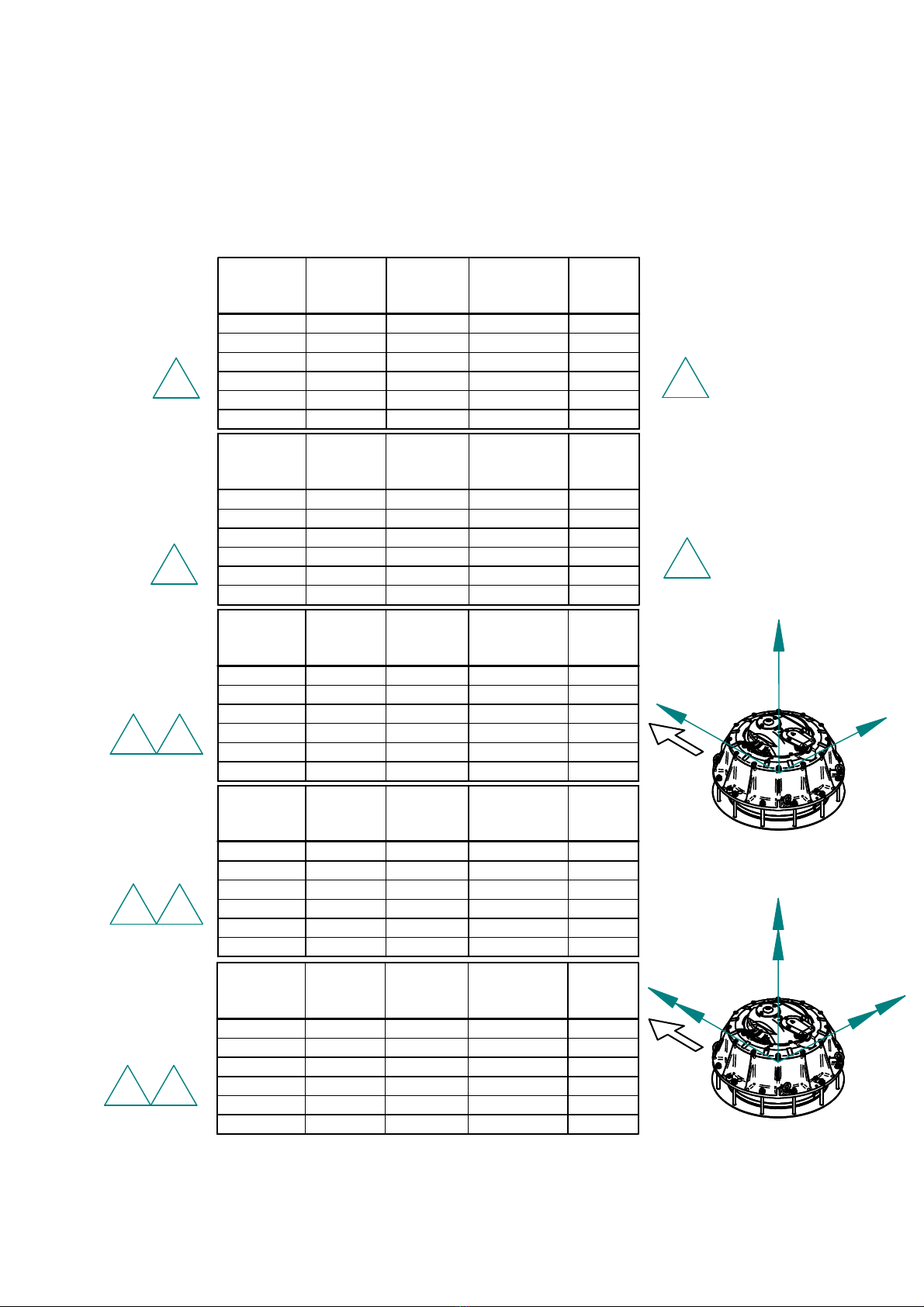

PARTS

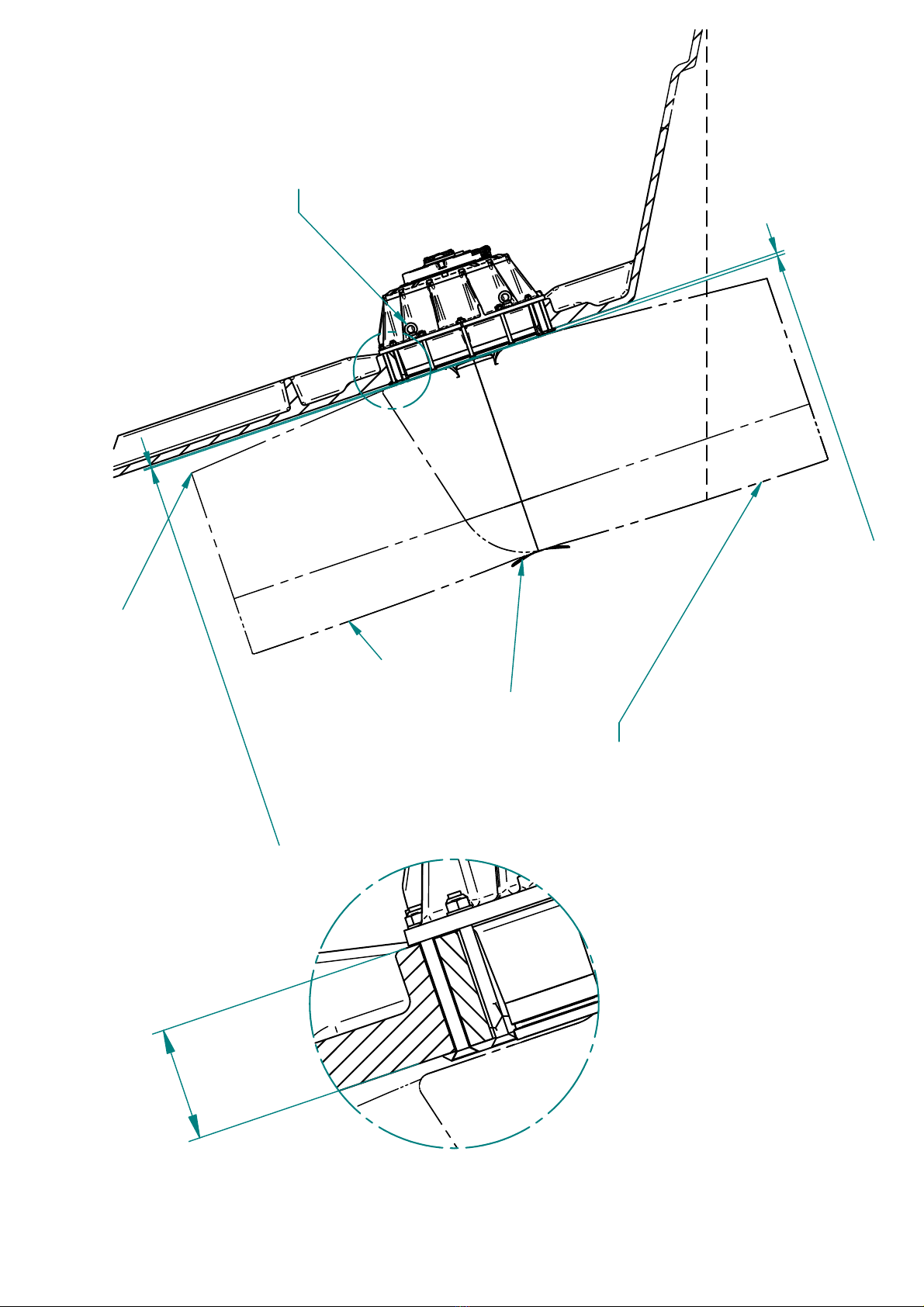

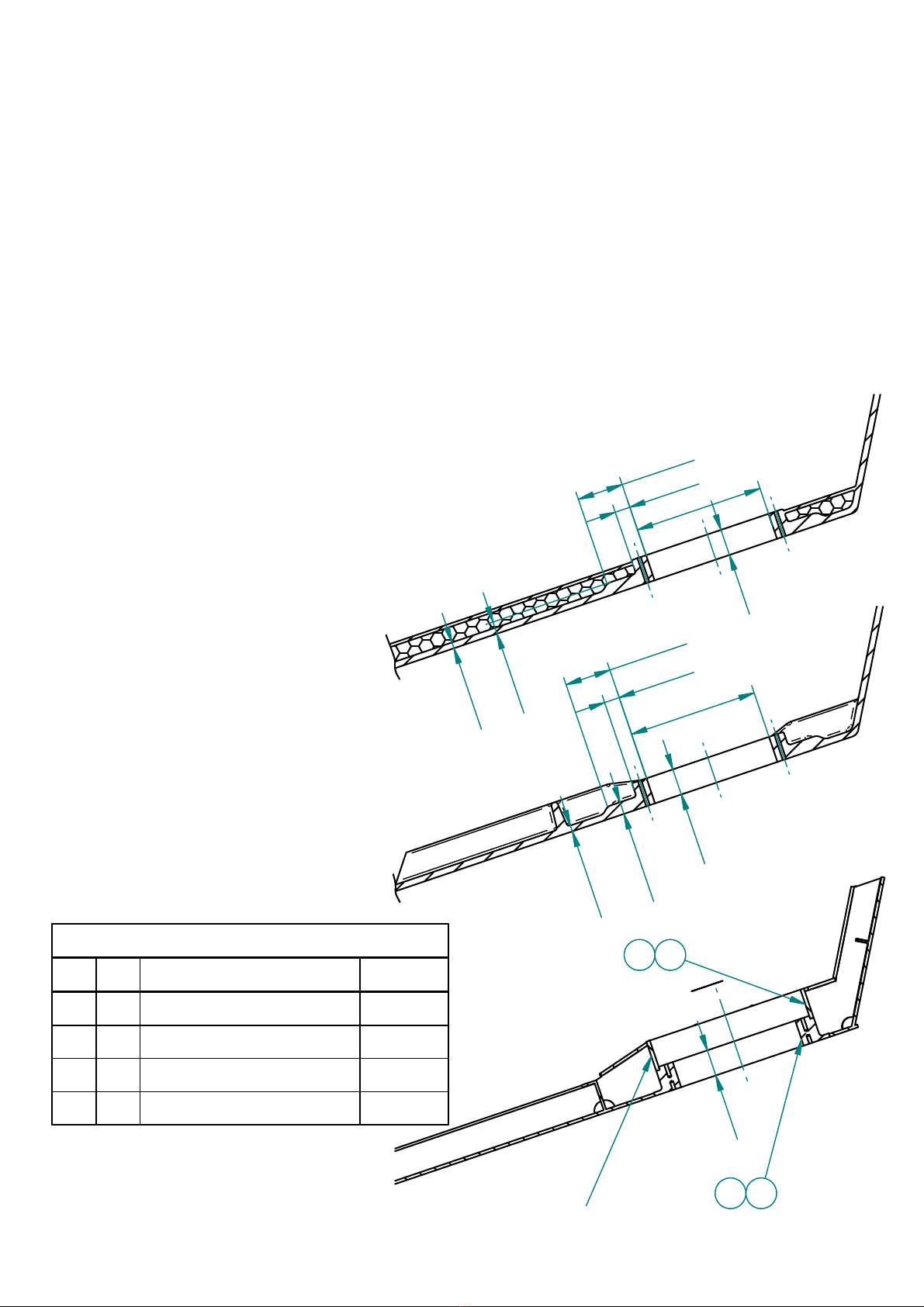

ITEM QTY PART NAME PART NO.

1 1 SU553, SU563 -

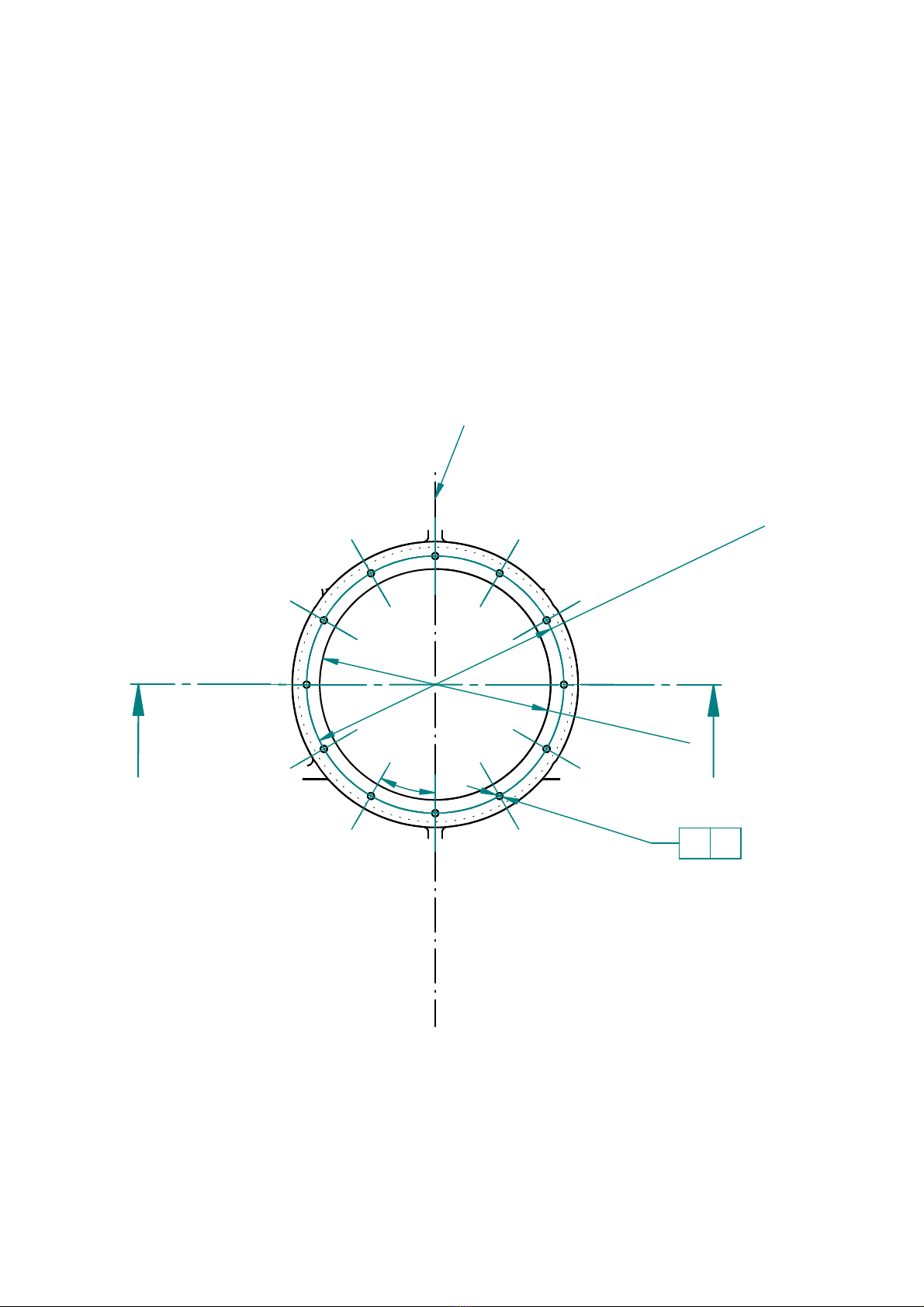

2 1 OUTER FLANGE 021218

3 1 MOUNTING KIT SU553 FOR GRP HULL 021548

4 1 MOUNTING KIT SU553 FOR ALU/STEEL

HULL

022200

SEE HCS5 CONNECTION DIAGRAM FOR THE

SPECIFIC VESSEL PROJECT

MOUNTING KIT SU553 FOR GRP 021548

ITEM QTY PART NAME PART NO.

5 1 CHOCKFAST FOAM 021418

6 1 CHOCKFAST HOSE 1m 021417

7 1 CABLE SU550 Power & Servo bus 3m 021446

8 12 BOLT M10x120 MF6S A4 021423

9 12 Washer M10 A4 011016

10 12 NUT M10 LM A4 011017

IMPORTANT WARNING

THE ILLUSTRATIONS SHOWN IN THIS INSTALLATION MANUAL ARE

TYPICAL HULL REINFORCEMENT STRUCTURES AND MATERIALS, AND

ARE INTENDED AS A GENERAL GUIDE ONLY.

EACH VESSEL'S REINFORCEMENT STRUCTURE MUST BE CONSIDERED A

UNIQUE DESIGN DUE TO VARIETY OF FORCES DISTRIBUTED TO THE

HULL RESULTING FROM VARIOUS INDIVIDUAL VESSEL PARAMETER.

THESE PARAMETERS INCLUDE, LONGITUDINAL AND TRANSVERSE

LOCATION,

THE MAXIMUM OPERATIONAL SPEED OF THE VESSEL, THE VESSEL

DISPLACEMENT, CENTER OF GRAVITY, TRANSVERSE AND

LONGITUDINAL METACENTER, HULL FORM, PURPOSE AND USAGE,

ROLLING AND PITCHING TENDENCIES AND FORCES, AS WELL AS

ADJACENT EQUIPMENT, STRUCTURES AND UNDERWATER

APPENDAGES.

THE POSSIBLITITY OF THE FIN STRIKING AN UNDERWATER OBJECT

AND THE POSSIBILITY OF THE VESSEL RUNNING AGROUND MUST ALSO

BE CONSIDERED WHEN DESIGNING HULL STRUCTURES.

3

MOUNTING KIT SU553 FOR ALU/STEEL HULL 022200

ITEM QTY PART NAME PART NO.

5 1 CHOCKFAST FOAM 021418

6 1 CHOCKFAST HOSE 1m 021417

7 1 CABLE SU550 Power & Servo bus 3m 021446

11 12 BOLT M10x25 MF6S A4 022199

12 12 BOLT M10x50 MC6S A4 022198

9 12 WASHER M10 A4 011016

4

14

15