INSTALLATION INSTRUCTIONS

I-80 GEAR-DRIVEN ROTORS

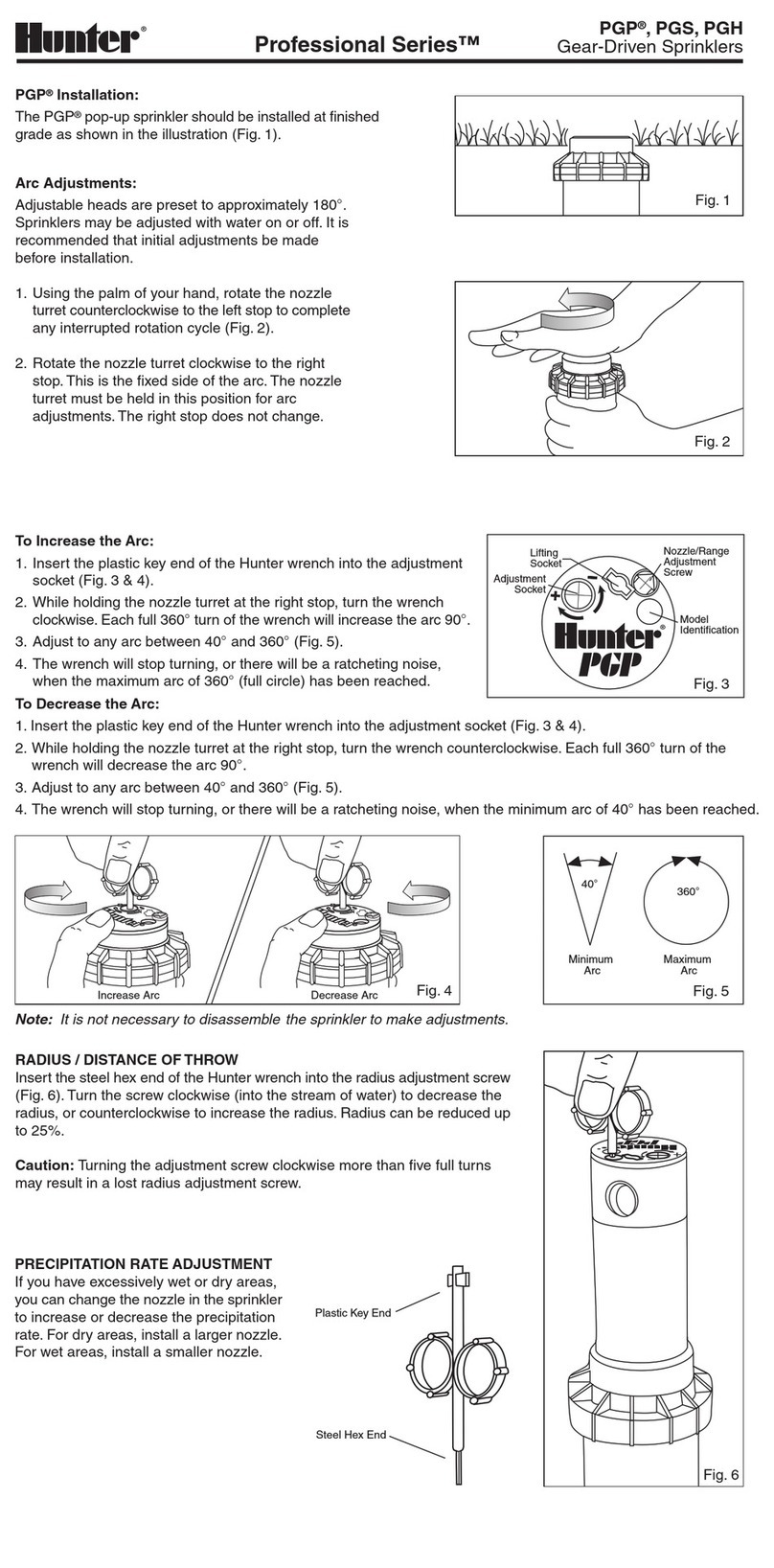

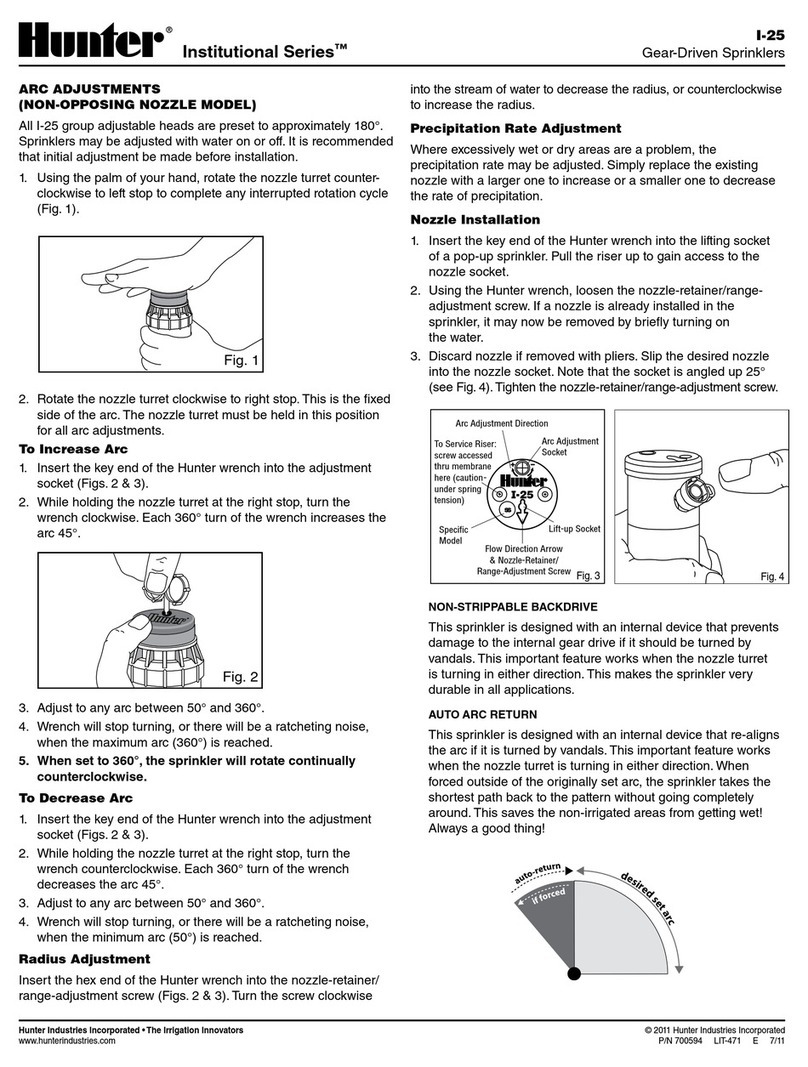

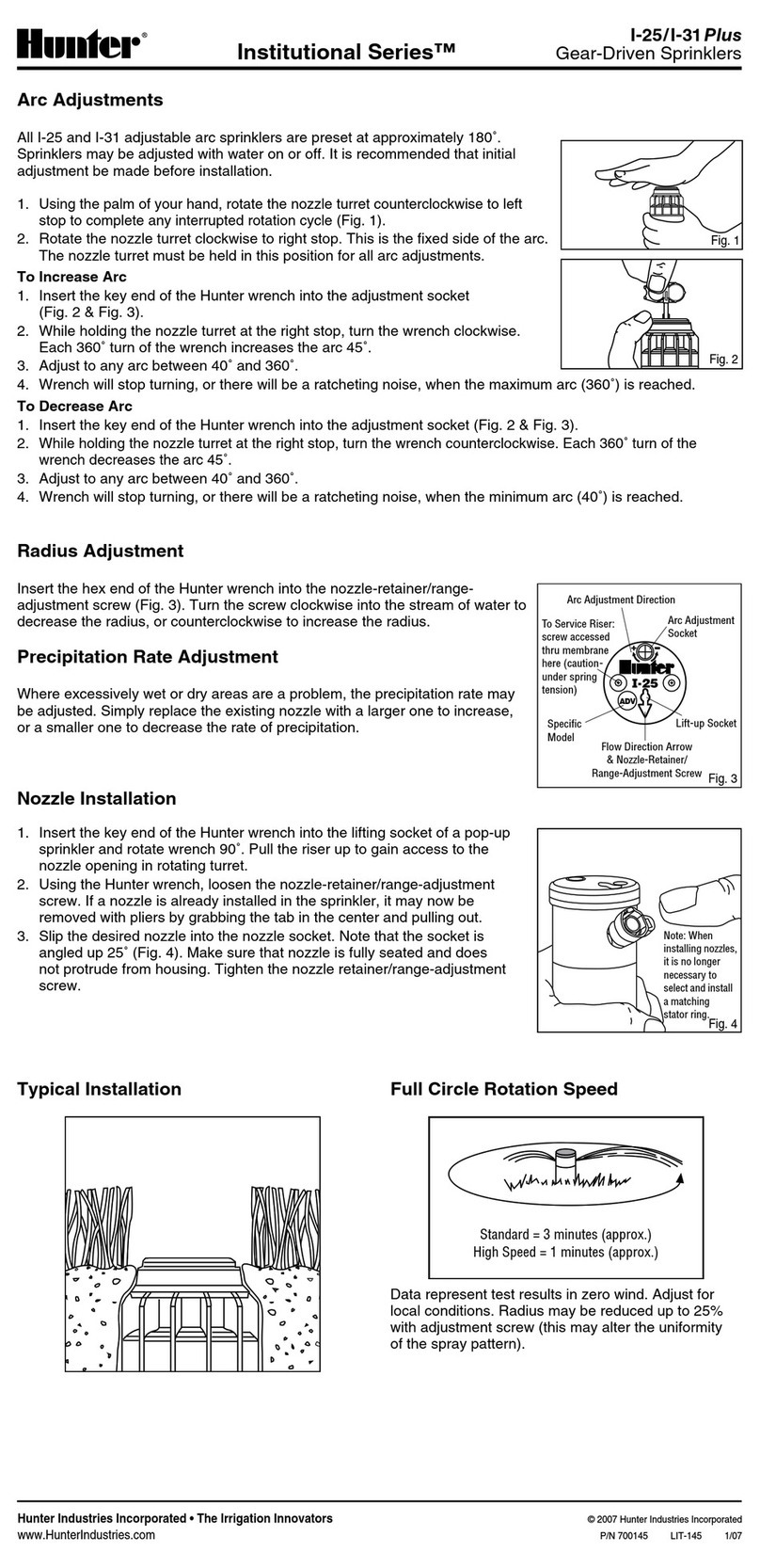

I-80 Arc Adjustments

Adjustments (not for “ON” opposing-nozzle models)

All I-80 adjustable arc rotors are preset to approximately

180°. Sprinklers can be adjusted with water on or o. It is

recommended that initial arc adjustments be made before

installation.

➊ Use your hand to rotate the nozzle turret counterclockwise

to the le stop to complete any interrupted rotation cycle.

② Next, rotate the nozzle turret clockwise to the right stop.

This is the xed side of the arc. The nozzle turret must be

held in this position for all arc adjustments.

➌ The ratchet feature allows the right xed stop to be moved

when water is o. Pull the riser up, grab the riser below

adjustment ring, and rotate the right xed arc stop to the

desired landscape alignment.

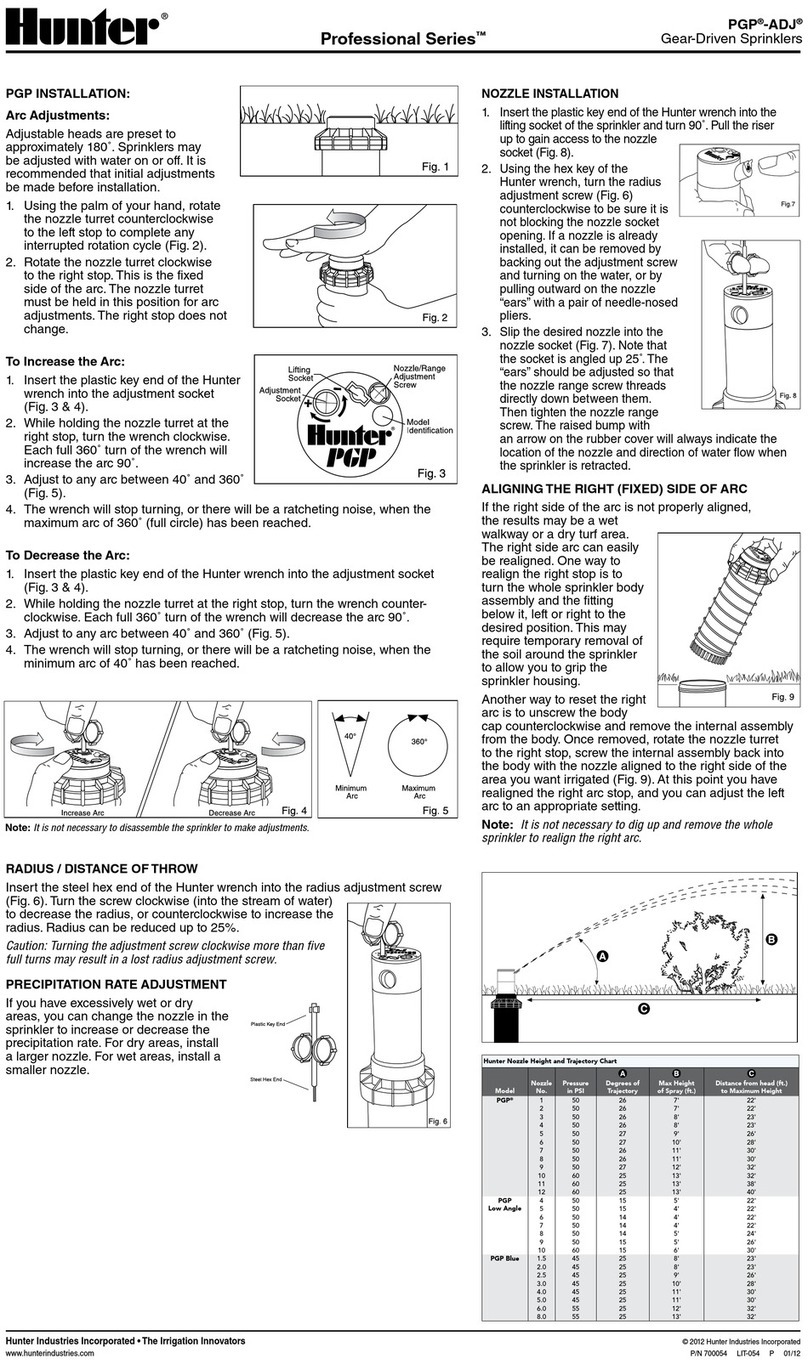

To Increase Arc

➊Slide the adjustment wrench

PN 382800SP onto the gray

adjustment ring below the nozzle

turret (Figure 1).

②While holding the nozzle turret

at the right stop, turn the wrench

counterclockwise.

➌Adjust to any arc between 60° and 360°. The wrench will

stop turning when the maximum arc (360°) is reached.

When set to 360°, the sprinkler will rotate continually

counterclockwise.

To Decrease Arc

➊Slide the adjustment wrench PN 382800SP onto the gray

adjustment ring below the nozzle turret.

②If the arc is set to less than 360°, hold the nozzle turret at

the right stop and turn the wrench clockwise.

➌If the arc is set to 360°, turn the wrench clockwise. Then

proceed with #2 above to complete the adjustment.

④Adjust to any arc between 60° and 360°. The wrench will

stop turning when the minimum arc (50°) is reached.

Radius Adjustment

Individual I-80 nozzles cannot be adjusted to reduce the radius.

To change the radius, install a larger or smaller nozzle.

Primary Nozzle Removal and Installation

➊ Insert the hex-key end of the Hunter wrench into the

primary nozzle “arrow” located on the top of

the rubber cover.

② Raise the nozzle-retainer screw by turning

counterclockwise. Raise the screw until the

screw clears nozzle opening.

➌ Using small needle-nose pliers, rmly insert

tip of pliers into the opening below the nozzle

(Figure 2). This action will collapse the nozzle’s

retaining hook (Figure 3). While gripping the

nozzle, pull outward to remove.

④ Slip the desired nozzle rmly into the nozzle

socket. Lower the nozzle-retainer screw to retain

the nozzle.

Short-Range/Mid-Range Nozzle Removal and

Installation

➊ Reference the I-80 and I-80-ON performance charts to

determine the correct nozzle part number and color.

② Use nozzle installation and removal tool PN

803700SP to service all short-range and

mid-range nozzles.

➌ When facing directly toward the nozzles,

short-range nozzles are on the le and mid-

range nozzles are on the right. To remove a

nozzle, rmly align and press the tool against it

while turning counterclockwise (Figure 4).

④To install the nozzle, engage the tool to the

nozzle. Then carefully align the nozzle to the

housing. Use care to prevent cross-threading

and turn clockwise (Figure 5).

➎ Each short-range and mid-range nozzle

has an alignment pointer. Turn the nozzle

clockwise until the pointer is facing the 12:00

position (Figure 6).

Stator Adjustments

All I-80 rotors with nozzles #10 through #20

have an automatic self-adjusting stator to control

rotation speed (Figure 7).

All I-80 rotors with nozzles #23 through #52 have a

manually adjustable stator to control rotation speed

(Figure 8).

When the primary nozzle size is changed, the stator

must be changed or adjusted to match the nozzle in

use. To make stator adjustments, rst remove the

riser assembly using the instructions below.

➊Remove the screen at the base of the riser by

grabbing, turning counterclockwise, and

liing away.

②Remove the stator assembly and adjust by

turning the black stator plate until the arrow

aligns with the nozzle in use (Figure 9).

➌Install the stator assembly with the black stator plate facing

the screen. Insert the screen and turn clockwise to lock.

Pop-Up and Riser-Mount Models

All I-80 rotors also have a traditional body cap that must be

unscrewed to gain riser assembly access. To facilitate easy riser

assembly removal, all I-80 rotors also include a removable snap

ring on the body cap. To access the riser assembly using the

snap ring, use tool 984400SP.

➊Insert the tool into the snap ring’s access

point (Figure 10). Press downward, slightly

twist the tool’s handle, and pull upward to

remove the snap ring (Figure 11).

②Engage the pull-up socket in the riser’s

logo cap using the Hunter wrench or

T-handle tool PN 319100SP. Pull upward to

remove the riser.

➌To install the riser assembly, insert the

riser into the body. First, install the snap

ring’s le side. Then press downward in a

counterclockwise direction.

Turf Cup Models

All I-80 rotors with turf cups have a removable

snap ring on the body cap to facilitate easy riser

assembly removal. To gain access to the snap ring,

the turf cup must be removed rst.

Figure 2

Figure 3

Figure 4

Figure 6

Figure 5

Figure 7

Figure 8

Figure 9

Figure 1

Figure 10

Figure 11