TFP316

Page 4 of 4

NATIONAL FIRE PROTECTION ASSOCIATION and NFPA are registered trademarks of National Fire Protection Association;

MONEL and INCONEL are registered trademarks of Special Metals Corporation;

TEFLON is a registered trademark of DuPont

1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

© 2020 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision date and are subject to change without notice.

Care and

Maintenance

TYCO Model ESFR-17 Early Suppres-

sion, Fast Response 16.8K Upright

Sprinklers must be maintained and ser-

viced in accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and notify all personnel who may be

affected by this action.

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or other-

wise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers before,

during, and after installation. Sprin-

klers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprin-

kler that has a cracked bulb or that has

lost liquid from its bulb. See Installation

section for additional information.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the National Fire Protection Associ-

ation, such as NFPA 25, in addition to

the standards of any authorities having

jurisdiction. Contact the installing con-

tractor or product manufacturer with

any questions.

Automatic sprinkler systems are

recommended to be inspected,

tested, and maintained by a qualified

Inspection Service in accordance with

local requirements and/or national

codes.

Installation

TYCO Model ESFR-17 Early Suppres-

sion, Fast Response 16.8K Upright

Sprinklers must be installed in accor-

dance with this section.

General Instructions

Avoid damage to the fusible Link

Assembly during installation by using

the Frame arms only to handle the

sprinkler and by using the appropri-

ate sprinkler wrench. Do not apply

pressure to the fusible Link Assembly.

Failure to do so can lead to an unstable

link assembly and premature activation

of the sprinkler. Damaged sprinklers

must be replaced.

A leak-tight 3/4 in. NPT sprinkler joint

should be obtained by applying a min-

imum-to-maximum torque of 10 to 20

lb-ft (13,4 to 26,8 N∙m). Higher levels

of torque can distort the sprinkler inlet

with consequent leakage or impairment

of the sprinkler.

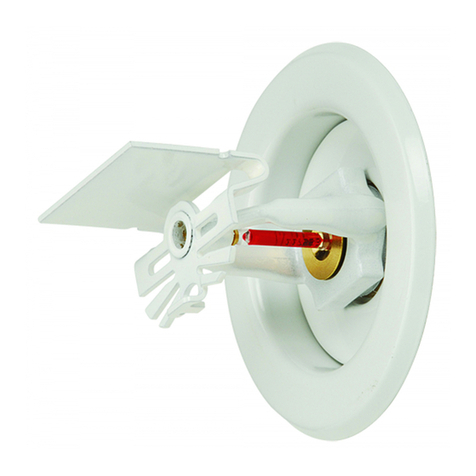

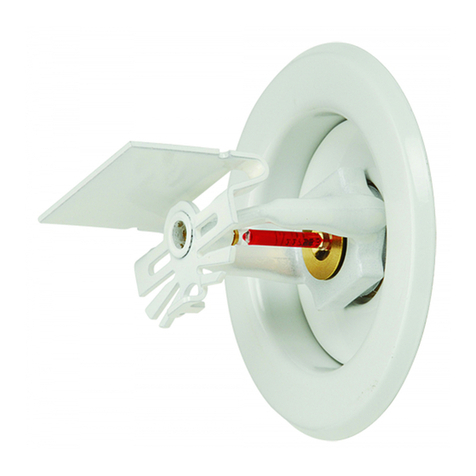

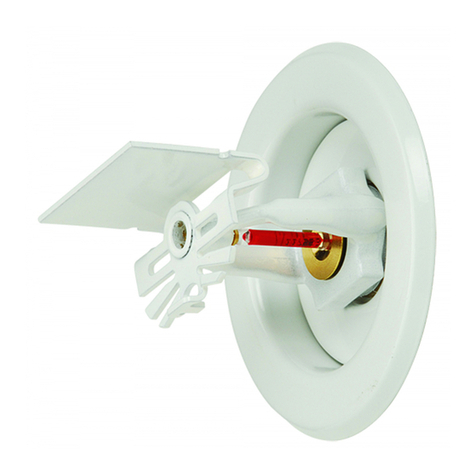

Note: Install the Model ESFR-17 Upright

Sprinkler in the Upright position (see Figure

2).

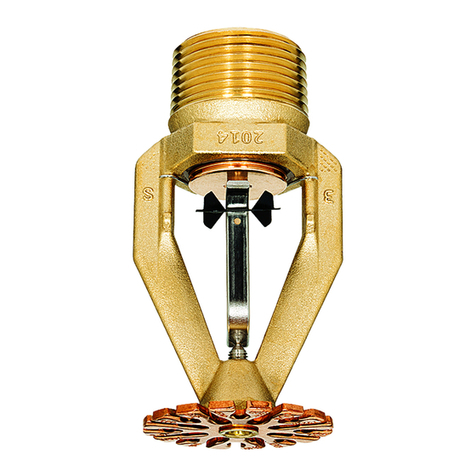

Step 1. With pipe thread sealant

applied, hand-tighten the sprinkler into

the sprinkler fitting. Do not apply pres-

sure to the Link Assembly, and handle

the Model ESFR-17 Sprinkler only by

the Frame arms.

Step 2. Wrench-tighten the Model

ESFR-17 Upright Sprinkler using only

the W-Type 21 Sprinkler Wrench (see

Figure 2) and by fully engaging (seating)

the wrench on the sprinkler wrench

flats (see Figure 1).

Step 3. After installation, inspect the

Link Assembly of each Model ESFR-17

Sprinkler for damage. In particular,

verify that the Link Assembly and Hook

are positioned as illustrated in Figure

1, and that the Link Assembly is not

bent, creased, or forced out of normal

position in any way. Replace damaged

sprinklers.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indicate

the full product name and part number

(P/N).

Sprinkler Assemblies

Specify: Model ESFR-17 Early Sup-

pression, Fast Response 16.8K Upright

Sprinklers (TY7126), (specify tempera-

ture rating), with Natural Brass finish,

P/N (specify):

165° F (74°C) ..................58 - 447-1-165

212°F (100°C) .................58-447-1-214

Special Order

Sprinkler Assemblies with

ISO 7-1 Thread Connection

Specify: Model ESFR-17 Early Sup-

pression, Fast Response 16.8K Upright

Sprinklers (TY7126) with ISO 7-1

thread connection, (specify tempera-

ture rating), with Natural Brass finish,

P/N (specify):

165° F (74°C) ..................58-448-1-165

212°F (100°C) .................58-448-1-214

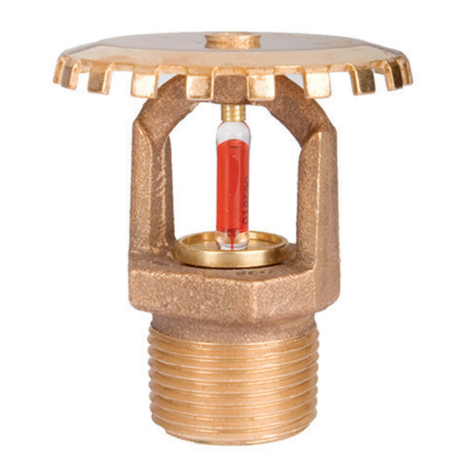

Sprinkler Wrench

Specify: W-Type 21 Sprinkler Wrench,

P/N 56-001-0-686

WRENCH

RECESS

"FITTING SIDE"

FITTING

FIGURE 2

W-T YPE 21

SPRINKLER WRENCH