Chapter 1Introduction

Page 6 Definitions of Terms

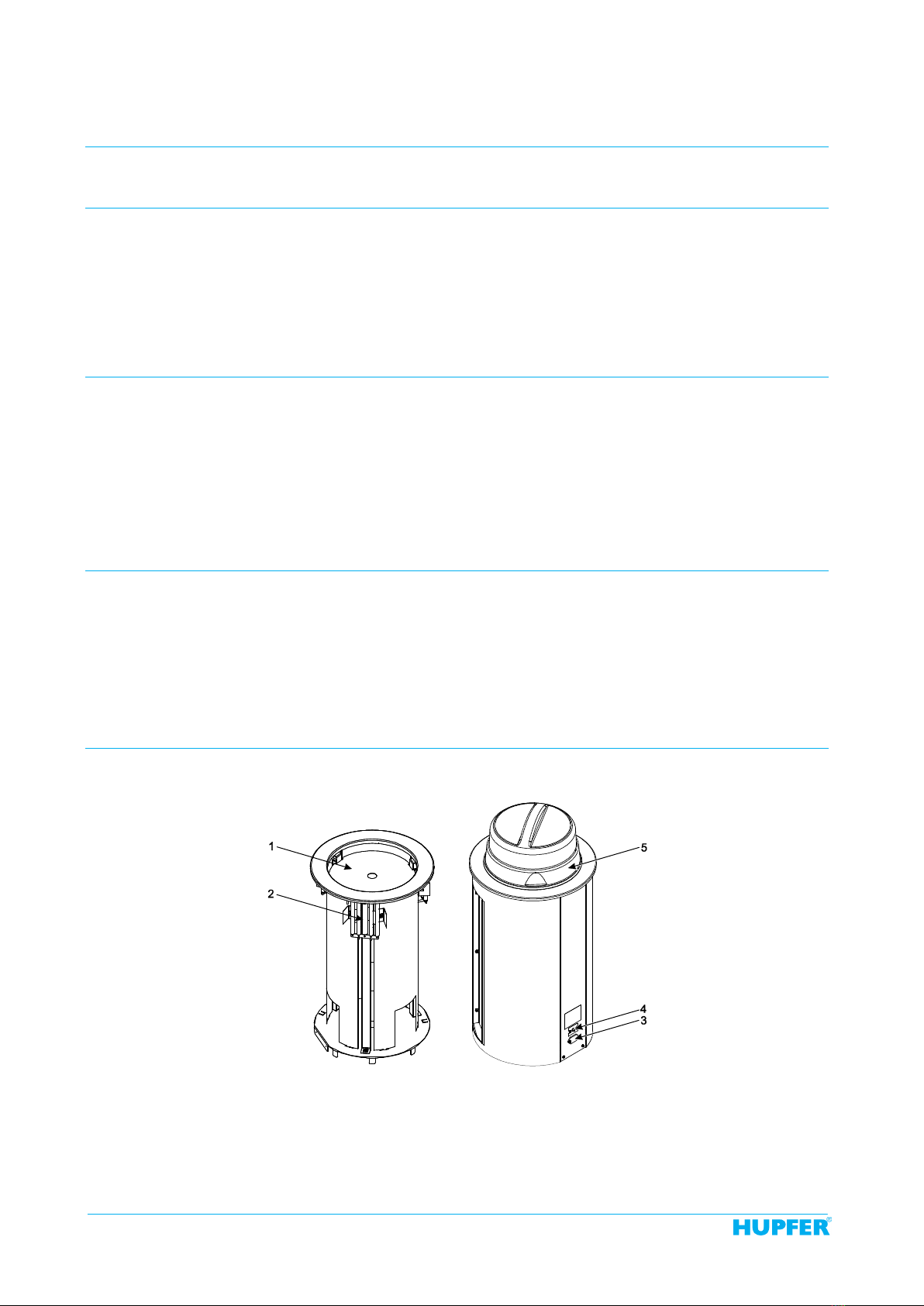

Cup Dispenser

EBR/70-120 | EBR/100-150 | EBRH/70-120 | EBRH/100-150 91285809_A0

1.4 Definitions of Terms

Term Definition

Authorised specialist An authorised specialist is a specialist that has been trained by the manufacturer, an

authorised service dealer or a company assigned by the manufacturer.

Cover A bell-shaped cover for keeping food warm on plates and dishes.

Cook&Chill Kitchens "Cook and Chill": Kitchens where warm food after being cooked is chilled as quickly as

possible.

Cook&Serve Kitchens "Cook and Serve": Kitchens where warm food is served immediately after being

cooked or kept warm until it is consumed.

Element formation Also: contact corrosion. Occurs when different noble metals are in close contact with

each other. This happens when a corrosive medium is between both metals, as for

example water or even air humidity.

Specialist A specialist is a person who can evaluate work assigned and can individually recog-

nise any possible dangers due to professional training, specialist knowledge and

experience as well as knowledge of the respective guidelines.

Lift A movement, for example a vertical movement of the stacking platform from bottom to

top.

Control Compare with certain conditions and/or characteristics such as damage, leaks, filling

levels, heat.

Convection Physical properties or mass transfer (e.g. heat or cold) through currents in gases and

liquids.

Corrosion The chemical reaction of a metallic material with its surroundings, e.g. rust.

Machine safety The term of machine safety means all the measures used to avert injury to persons.

The basis for this are national as well as EC-wide valid directives and laws for protect-

ing users of technical devices and systems.

Passive layer A non-metallic protective layer on a metallic material that prevents or slows down

material corrosion.

Check Compare with certain values such as weight, torque, content, temperature.

Qualified person,

qualified staff Qualified personnel are persons who due to their professional training, experience and

instruction as well as their knowledge of the respective standards, guidelines, accident

prevention regulations and operating conditions have been authorised by a person

responsible for system safety to carry out required activities and can recognise and

prevent any possible danger (definition of specialists according to IEC 364).

Schuko® The abbreviation of the German term "Protective contact" that indicates a system of

domestic plugs and sockets equipped with protective earthed contacts used in most of

Europe.

Instructed persons An instructed person is a person who has been instructed on the possible risks result-

ing from improper behaviour when carrying out the assigned task as well as on the

necessary protective equipment and protective measures and trained for this task if

necessary.

1.5 Orientation Guide

The front

"The front" means the side of the appliance where it is loaded.

The rear

The side named "the rear" means the opposite side of the front side (the front).

The right

The side named "the right" means the side at the right hand side of the front side (the front).

The left

The side named "the left" means the side at the left hand side of the front side (the front).