• the product has an accessory that is not from the

manufacturer or not approved by the manufacturer.

• the product is not repaired at an approved service

center or by an approved authority.

Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of injury or

death for the operator or bystanders if the

instructions in the manual are not obeyed.

CAUTION: Used if there is a risk of damage

to the product, other materials or the

adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary in

a given situation.

General safety instructions

WARNING: Read the warning instructions

that follow before you use the engine.

• The engine is dangerous if you are not careful or if

you use the engine incorrectly. There is a risk of

injury or death, or damage to the engine. Before you

use the engine, you must read and understand the

contents of this operator’s manual.

• You must read and understand the operator’s

manual for the product that uses this engine. There

can be more safety instructions for start, stop,

operation and maintenance.

• Save all warnings and instructions.

• Do not let a person operate the engine unless they

read and understand the contents of the operator's

manual.

• Do not let a child operate the engine.

• Do not do modifications to the engine.

Safety instructions for operation

WARNING: Read the warning instructions

that follow before you use the engine.

• Make sure that you know how to stop the engine

quickly in an emergency.

• The exhaust fumes from the engine contain carbon

monoxide which is an odorless, poisonous and very

dangerous gas.

• Do not use a combustion engine product indoors or

in areas that do not have sufficient airflow.

• Do not use the engine in areas where fire or

explosions can occur.

Safety devices on the product

WARNING: Read the warning instructions

that follow before you use the product.

• Do not use a product with defective safety devices.

• Do a check of the safety devices regularly. If the

safety devices are defective, speak to your

Husqvarna service agent.

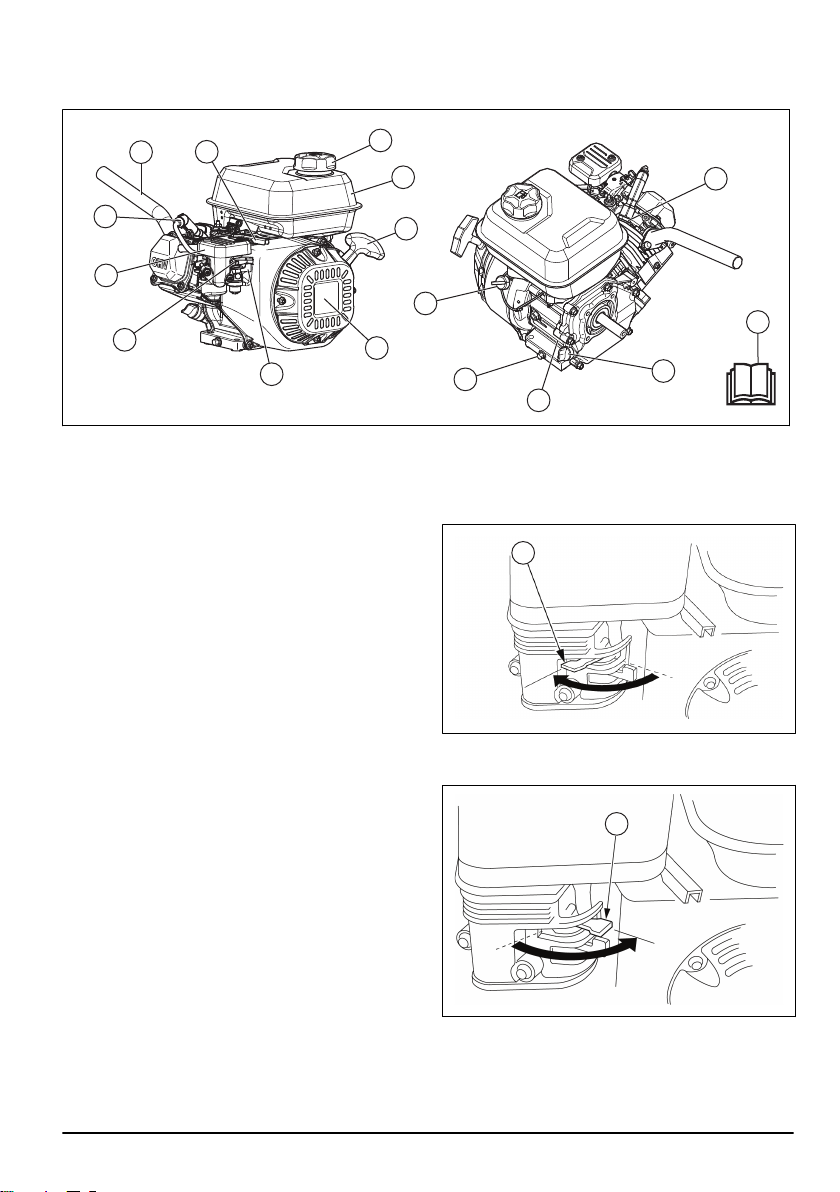

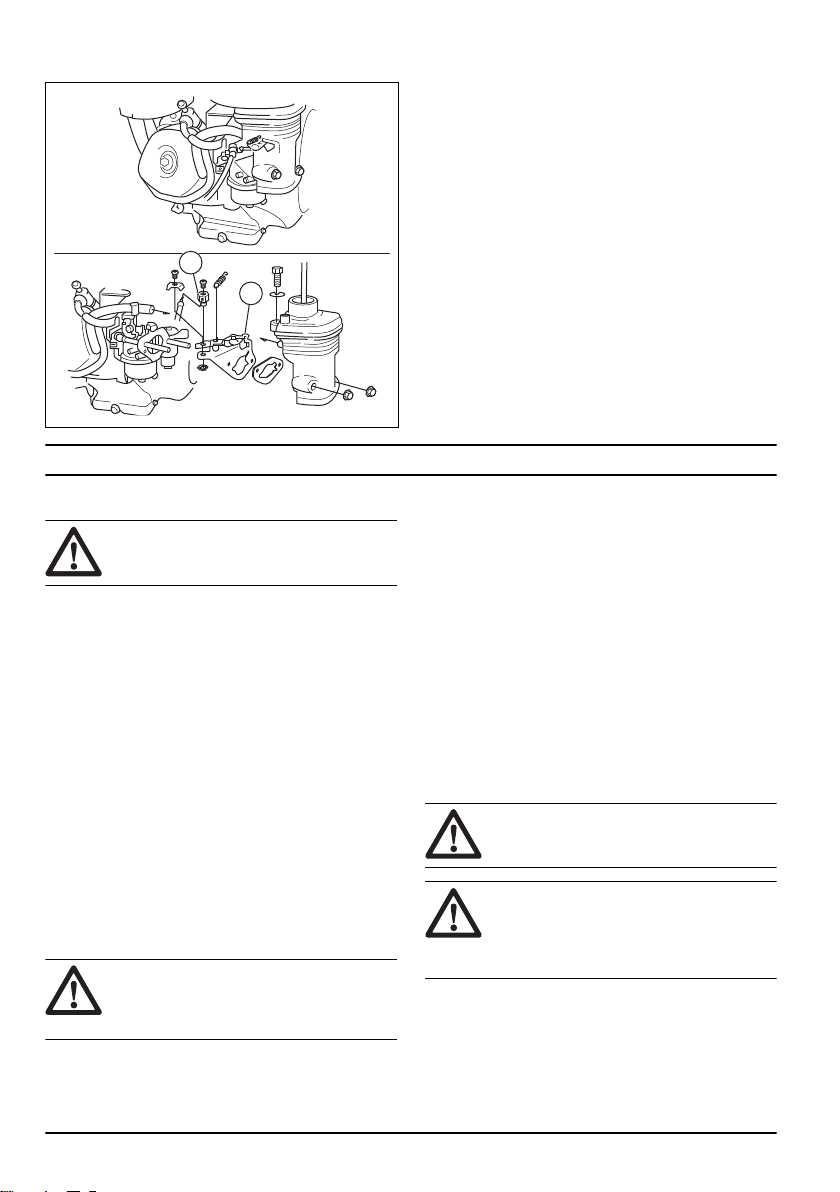

Engine ON/OFF switch

The engine can only start when the engine ON/OFF

switch is set to "ON". The engine stops when you set the

engine ON/OFF switch to "OFF".

To do a check of the engine ON/OFF switch

1. Start the engine. Refer to

To start the engine on

page 9

.

2. Set the engine ON/OFF switch to "OFF". The engine

stops.

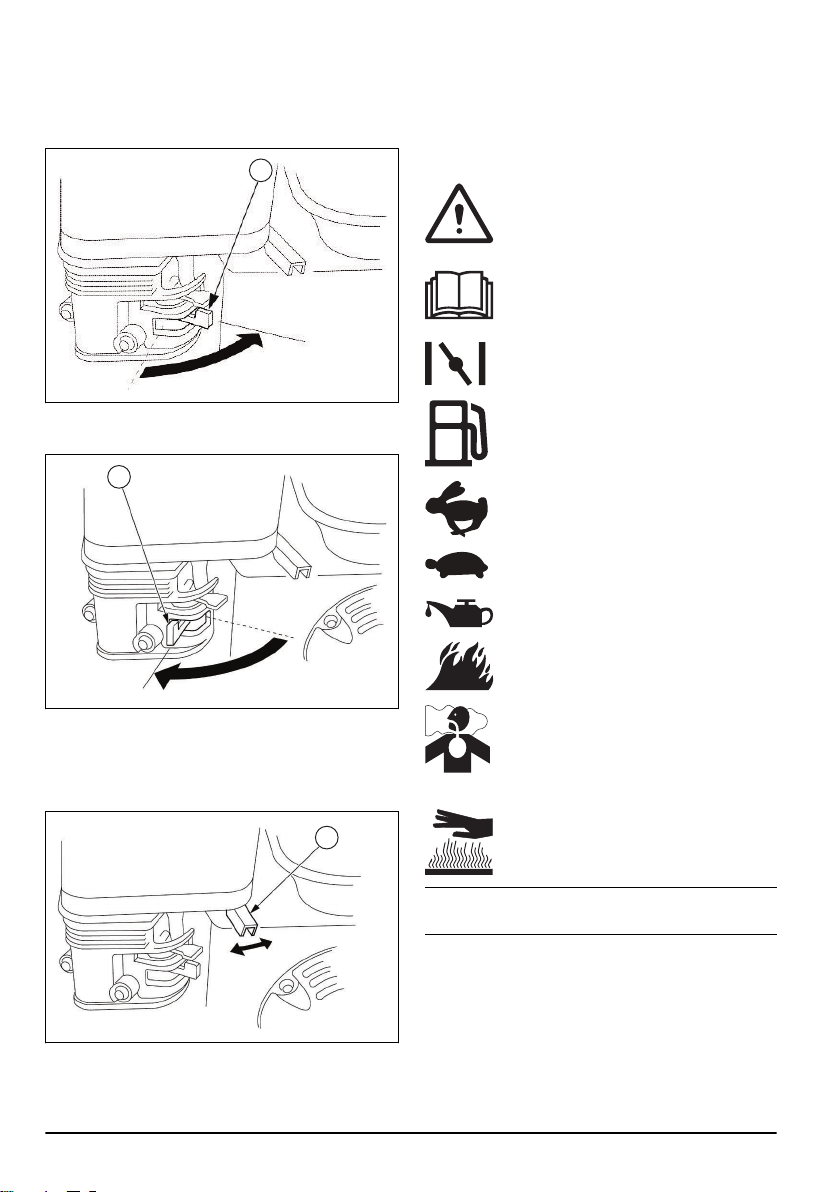

Muffler

The muffler keeps the noise levels to a minimum and

sends the exhaust fumes away from the operator.

Do not use the product if the muffler is missing or

defective. A defective muffler increases the noise level

and the risk of fire.

WARNING: The muffler becomes very hot

during and after use and when the engine

operates at idle speed. Be careful near

flammable materials and/or fumes to prevent

fire.

To do a check of the muffler

• Examine the muffler regularly to make sure that it is

attached correctly and not damaged.

Fuel safety

WARNING: Read the warning instructions

that follow before you use the product.

• Fuel is flammable and the fumes are explosive. Be

careful with fuel to prevent injury, fire and explosion.

1537 - 001 - 20.08.2020 5