Hussmann DM LOW HEIGHT Series User manual

Other Hussmann Display Case manuals

Hussmann

Hussmann Austral H1 User manual

Hussmann

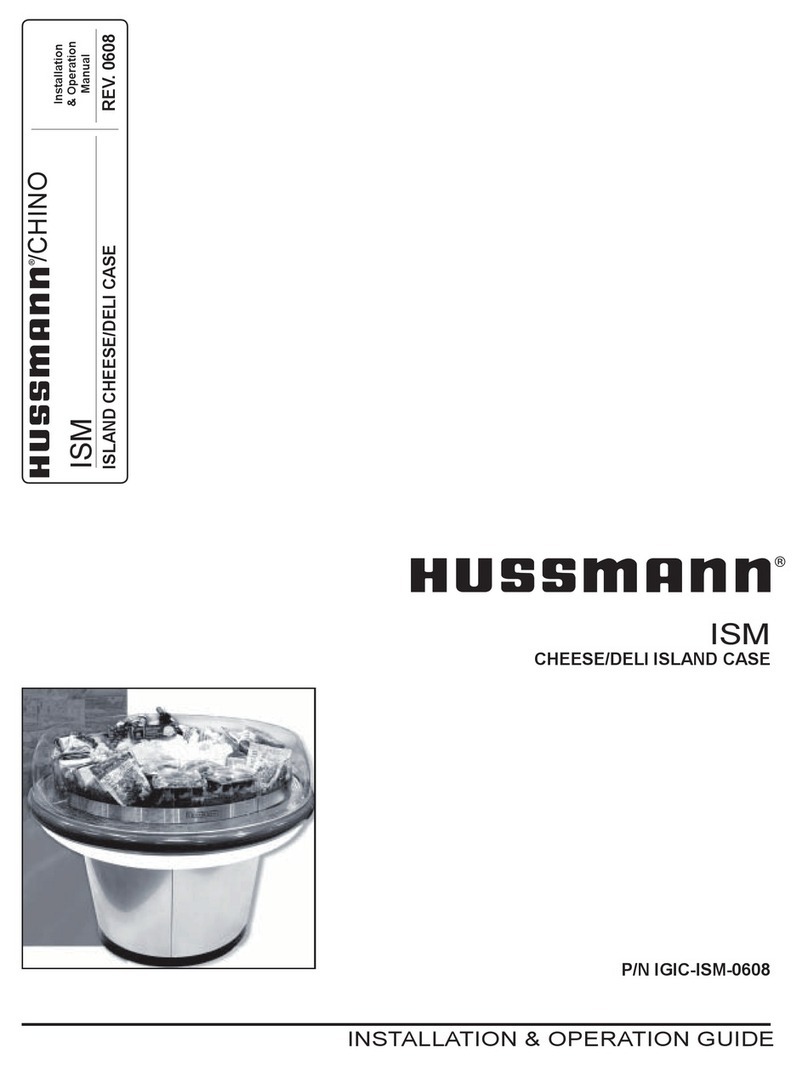

Hussmann ISM Operating instructions

Hussmann

Hussmann ISLA Original operating instructions

Hussmann

Hussmann DCCG-8 Quick guide

Hussmann

Hussmann PMM20F3R User manual

Hussmann

Hussmann GSVM 4060D User manual

Hussmann

Hussmann Q3SSM6R User manual

Hussmann

Hussmann AB Operating instructions

Hussmann

Hussmann Q3-DV Original operating instructions

Hussmann

Hussmann Chino DBP Series Original operating instructions

Popular Display Case manuals by other brands

Costan

Costan WHALE 2000 G LG300 User instructions

Costan

Costan IMPALA User instructions

True Manufacturing Company

True Manufacturing Company TCGD-50 installation manual

Bartscher

Bartscher 100L instruction manual

Steelcase

Steelcase Opus Assembly instructions

Hatco

Hatco Glo-Ray GRHD-2P Replacement parts list