OPERATING PROCEDURES

SET UP PROCEDURE

1. Trailer must be unhitched from the tow vehicle before level-

ing. The HWH front jacks may be used to lift the trailer for

unhitching. If auxiliary jacks are used to unhitch the trailer,

they should be retracted before the leveling system is used

for leveling.

If parking on soft ground or asphalt paving, wood blocks or

unhitching.

pads should be placed under the jacks.

result if raise arrows are operated for an extended period of

time.

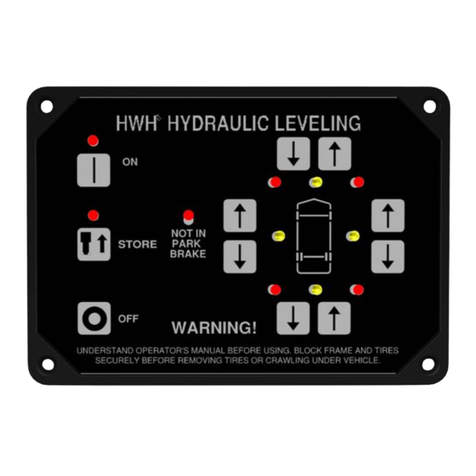

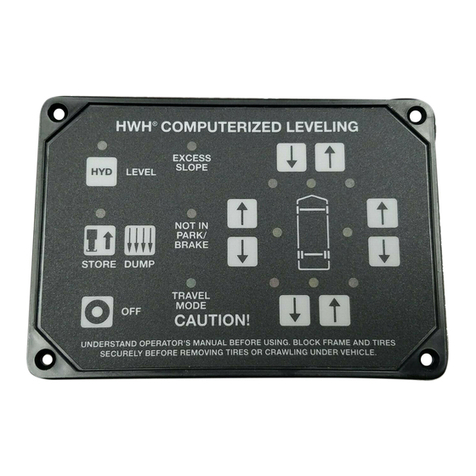

2. The touch panel must be on for the system to function.

3. Lower the front of the trailer until the front yellow level indi-

cator lights come on. This is done by pushing the front RETRACT

button. The red jacks down warning lights will light when the

4. A lit yellow LEVEL light indicates that the side, end or corner

of the trailer is low. Pushing the up arrow for corresponding yellow

level lights will extend that jack or jack pair to level the vehicle.

Extend jacks as needed to put out all the yellow lights. Always

give a side yellow level light priority when leveling the trailer.

If the ground is too uneven, the jacks may not have engough

stroke to level the trailer. The trailer may have to be moved.

5. After the trailer is level, the jacks not used for leveling may

be extended until they touch the ground. This provides addi-

6. Push the "OFF" button on the touch panel to turn the system

7. The jack stop rods should be adjusted immediately after

the leveling and stabilizing procedure is finished.

is supported by the front jacks.

CAUTION:

WHILE SETTING STOP RODS AVOID

AREAS WHERE BODY MAY BE CRUSHED BY SUDDEN

DROPPING OR SLIDING OF TRAILER.

A. Remove retaining pin to allow stop rod to drop down to

the foot of the jack.

B. Lift stop rod as needed (up to 4") to align the hole in the

guide with the nearest available hole in the stop rod. Insert

the retaining pin through the holes in the guide and stop rod.

Latch the keeper wire for the retaining pin.

a month or whenever the trailer is used. To keep the system

in operating condition.

STOP ROD

RETAINING PIN

STOP ROD POSITION

GUIDE

MP35.3055

21JUL98

ROOM EXTENSION PROCEDURES

read this section carefully.

If the vehicle is equipped with kick-down jacks, the wheels MUST

be blocked securely. Do NOT operate any room extension

until the leveling and stabilizing procedure is complete. Do

If the vehicle is equipped with a room extension

IMPORTANT:

NOT retract the leveling system until all room extensions are

retracted. NEVER operate the leveling system when any

Refer to the vehicle owner’s manual for proper operation of

room extensions are extended.

room extensions.

IMPORTANT:

Do not use a room extension support when the

vehicle is supported by the leveling system.

jacks are extended 2 inches or more.

tional stability against wind and activity in the trailer.

off.

NOTE:

Refer to the trailer manufacturer owner’s manual for

IMPORTANT:

Overheating and excessive current drain will

NOTE:

The jack stop rods should be set anytime the trailer

NOTE:

The leveling system should be cycled at least once