OPERATING PROCEDURES

MP35.4572

02NOV98

JACK RETRACTION

1. The operator must be sure that there are no objects under

the vehicle and that all people are clear of the vehicle.

2. Turn the ignition switch to the "ON" or "ACC" position. Press

the "HYDRAULIC START" button. The "HYDRAULIC OPER-

ATION" indicator light will glow steady.

3. Press the "JACK STORE" (STORE) button. The "JACK

STORE" indicator light will start to flash. As the two front jacks

retract to the horizontal position, the respective "JACK DOWN"

indicator light on the touch panel will go out. When both front

"JACK DOWN" lights are out, the two "REAR SUSPENSION

WARNING LIGHTS" will go out. The automatic rear suspen-

sion control will now function. The dash mounted "JACK DOWN"

warning light will go out. The "WARNING MANUAL MODE"

indicator light will be "OFF". The coach may now be moved.

The "JACK STORE" indicator light will continue to flash.

4. The system will continue to "retract" for six minutes, then

automatically shut off. If a "JACK DOWN" indicator light stays

on the system will continue to retract for thirty (30) minutes

then shut off regardless of warning lights.

IMPORTANT:

Do not interrupt power to the system until the

system automatically shuts off.

5. If the jacks cannot be retracted by this procedure, see "MANUAL

JACK RETRACTION" section.

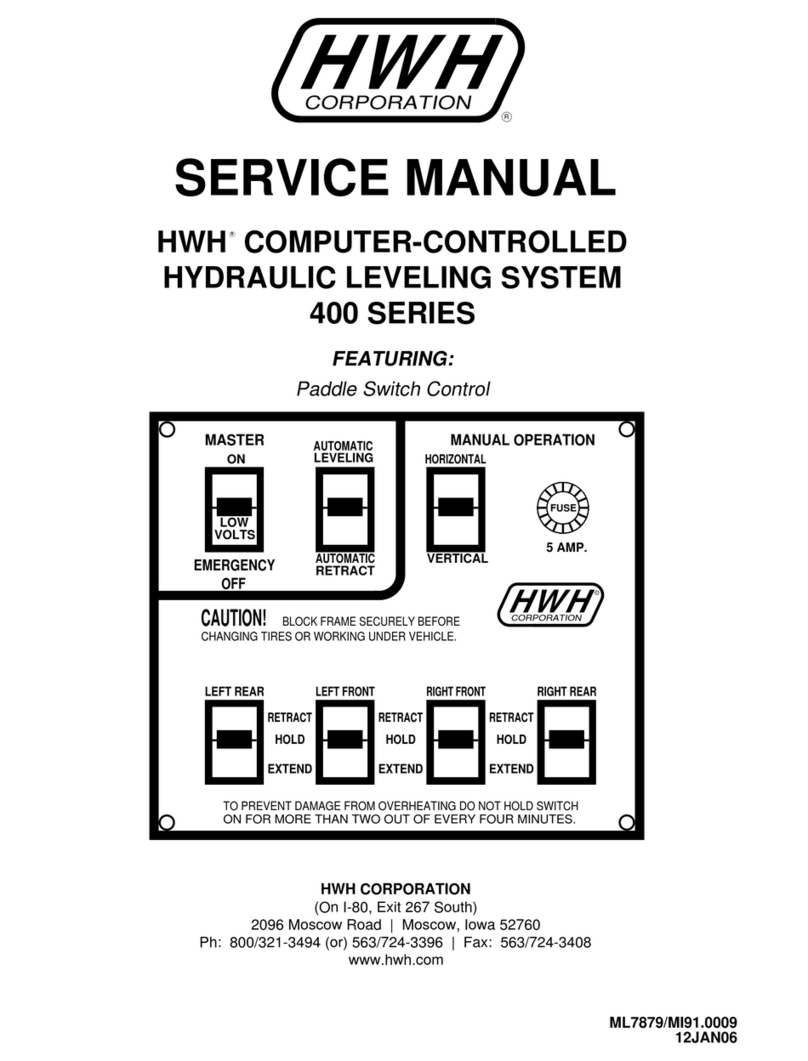

MANUAL HYDRAULIC OPERATION

1. Place the transmission in the recommended position for

parking and set the parking brake. Turn the ignition to the "ACC"

or "ON" position.

2. Press the "HYDRAULIC START" button. This will place the

system in the hydraulic/air operation mode. The "HYDRAULIC

OPERATION" indicator light will glow steady.

3. Press the "HYDRAULIC START" button a second time. The

"HYDRAULIC OPERATION" light will start to flash. The left

front jack will lower to the vertical position, then the right front

jack will lower to the vertical position. As the jacks lower to the

vertical position, their respective "JACK DOWN" indicator light

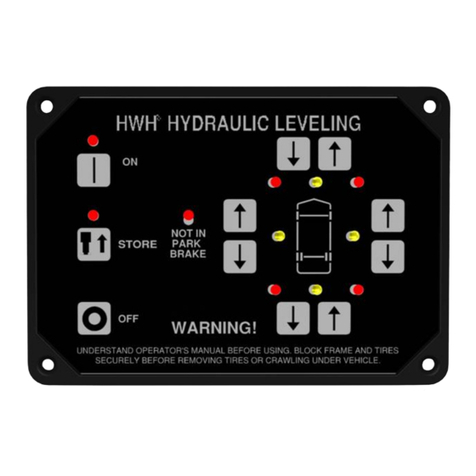

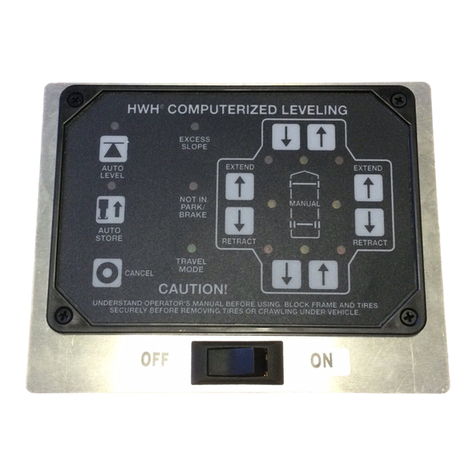

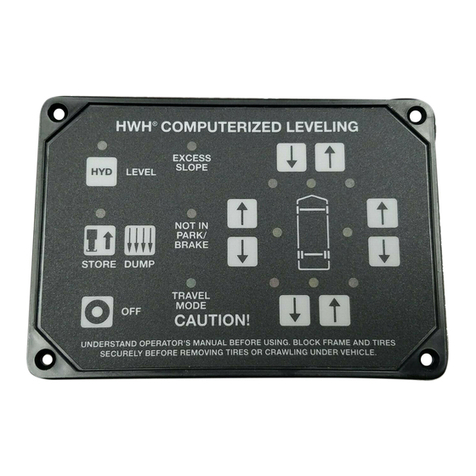

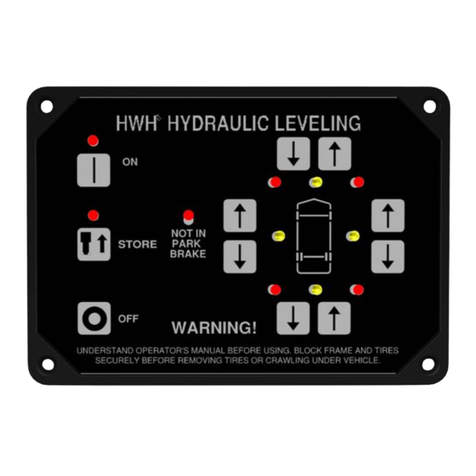

4. The vehicle may be leveled using the manual raise and lower

buttons on the right half of the panel. (Refer to the Control Ident-

ification and Function page.) If a yellow "LEVEL SENSING"

indicator light is "ON", that side or end of the vehicle is low.

Right to left leveling is done with the rear suspension air bags.

If the front yellow light is on, it is best to lower the rear of the

vehicle first. If the front light remains on, extend the two (2)

front jacks until the front yellow light goes out. If not used for

leveling, the two front jacks may be extended to the ground to

help stabilize the coach.

IMPORTANT:

Do not continue to push the front raise button

for more than ten (10) seconds after the jacks are fully extended.

5. Turn the ignition switch to the "OFF" position.

MANUAL AIR OPERATION

1. The manual "REAR SUSPENSION CONTROL" (manual

air operation) will operate any time the ignition switch is in the

"ACC" or "ON" position. This function can be used to level the

coach without the front jacks being lowered to the vertical pos-

ition.

2. Press "REAR SUSPENSION CONTROL" (AIR) button. "REAR

SUSPENSION CONTROL" indicator light will come "ON" steady.

The "WARNING MANUAL MODE" indicator light (in dash) will

come "ON". The two (2) red "REAR SUSPENSION WARN-

ING LIGHTS" on the touch panel will come "ON".

NOTE:

At this point, the automatic rear axle position control

will not function.

3. Use the up and down arrow on the right side of the touch

panel to inflate or deflate the rear suspension air bags. Only

the right, left, and rear raise and lower buttons will operate at

this time. Level the coach according to the yellow "LEVEL

SENSING" indicator lights.

4. Pushing the "OFF" button will return the coach to the auto-

matic rear axle position control. Turn the ignition switch to the

"OFF" position.

will come "ON". The dash mounted "JACK DOWN" warning

light and the "WARNING MANUAL MODE" light will come "ON".

The pump will shut off and the "HYDRAULIC OPERATION"

light will glow steady. At this time, the operator should check

to make sure the jacks are vertical and place pads under the

jacks if the ground will not support the vehicle.