OPERATING PROCEDURES

AUTOMATIC AIR OPERATION

the ignition is in the "ON" or "ACC" position, the four red

will begin. The system will attempt to level the vehicle by

SYSTEM ACTIVE LIGHT will start flashing and air leveling

3. Press the "AIR" button a second time. The LEVELING

vehicle should not be moved when these lights are on.

that the height control valves have been locked out. The

WARNING lights on the panel will come on. This indicates

LEVELING SYSTEM ACTIVE LIGHT will glow steady. When

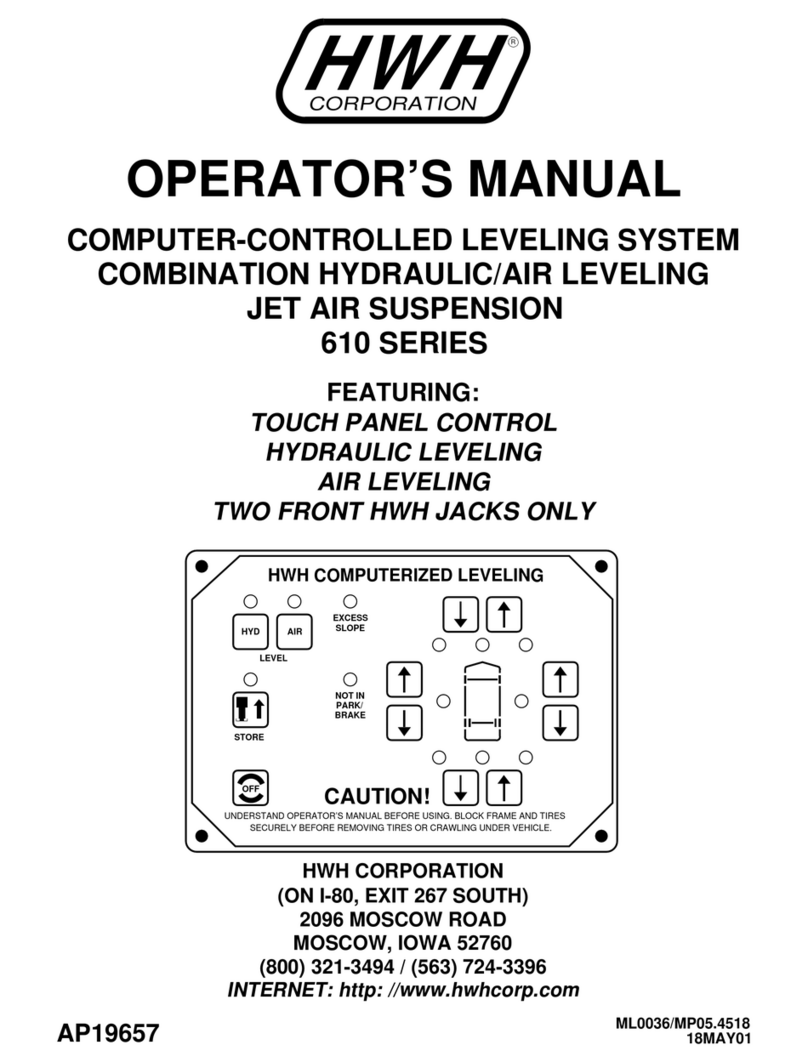

2. Press the "AIR" button once to enter the air mode. The

"NOT IN PARK/BRAKE" light will be on while the "AIR"

the panel will not turn on if the park brake is not set. The

With the ignition key in the "ON" or "ACC" position,

required for leveling.

will level with the engine shut off, however more time will be

This will provide a better air supply for leveling. The vehicle

Leaving the engine running during leveling is recommended.

turned on if the ignition is in the "ON" or "ACC" position.

and set the park brake. The air leveling system can only be

1. Place the transmission in the proper position for parking

ignition can be moved to the "OFF" position and the operation

use the "AIR" button. Once the operation is started, the

The ignition must be in the "ON" or "ACC" position to

button is being pushed.

NOTE:

NOTE:

leveling is complete.

When all four yellow LEVEL SENSING lights are out the

the vehicle will be raised by adding air to the air bags.

achieved by lowering the vehicle, the low side and/or end of

exhausting air from the air bags. If a level position is not

4. When all four yellow level lights are out, the LEVELING

SYSTEM ACTIVE LIGHT will stop flashing and start pulsating

dimly. The Leveling System is now in the SLEEP MODE.

NOTE: After the ignition and all room extension KEY

SWITCHES are turned OFF, the CAN Network stays active

for 10 minutes before shutting down. Leveling System touch

will continue.

Only one or two yellow LEVEL SENSING lightsNOTE:

may be ON at one time.

The vehicle’s engine/ignition may now be turned OFF.

panel lights will stay ON during this time and go out when

the CAN Network shuts down.

5. 30 minutes after the Leveling System enters the SLEEP

MODE, the computer will monitor the LEVELING SENSING

UNIT. If no leveling is needed, the computer will continue

to monitor the LEVELING SENSING UNIT every 30 minutes.

6. If the vehicle needs to be releveled, the CAN Network will

become active. The Leveling System touch panel lights will

come ON during the leveling procedure. The LEVELING

SYSTEM ACTIVE LIGHT will flash. One or two yellow

LEVELING LIGHTS will be ON. When the yellow LEVELING

LIGHTS are all out, the LEVELING SYSTEM ACTIVE LIGHT

will stop flashing and start pulsating dimly. The Leveling

System will remain in the SLEEP MODE with the computer

monitoring the LEVELING SENSING UNIT every 30 minutes,

releveling the vehicle as needed.

ignition is in the "ON" position.

STOP" button is pushed or the park brake is released, if the

7. The SLEEP MODE will continue until the "EMERGENCY

relevels the vehicle.

touch panel lights OFF. This happens every time the system

after releveling the vehicle and then shut down, turning the

The CAN Network will stay active for 10 minutes

NOTE:

is active until the vehicle is leveled with all yellow LEVEL

The "EXCESS SLOPE" light will be on whenever the network

will go out. The "EXCESS SLOPE" light will be on whenever

SLOPE" light will come on. The LEVEL LIGHT indicator light

minutes, if a LEVEL SENSING light is still on, the "EXCESS

vehicle for approximately 15 to 20 minutes. After the 15 to 20

The system will attempt to level the

the network is active.

indicator lights off.

EXCESS SLOPE:

If the Leveling System is in the SLEEP MODE

when the Network shuts down, the computer will stay ON.

The Leveling System touch panel lights will all be OFF,

but the Leveling System will still be in the SLEEP MODE.

NOTE:

TAG AXLE DUMP

The tag axle dump-switch is supplied by Monaco. This is a

IMPORTANT:

Refer to Monaco for the proper use of the Tag

Dump feature.

The Tag Dump switch will work only with the ignition switch in

the "ON" position and the leveling system panel off.

NOTE:

If the Tag Dump switch is in the dump position and the

ignition key is turned on (with the leveling system panel off) the

tag axle air bags will go into the dump mode.

two position switch with one position for "TRAVEL" and one

position for "TAG DUMP".

11AUG03

MP35.206C