19MAY99

OPERATING PROCEDURES

MP35.322C

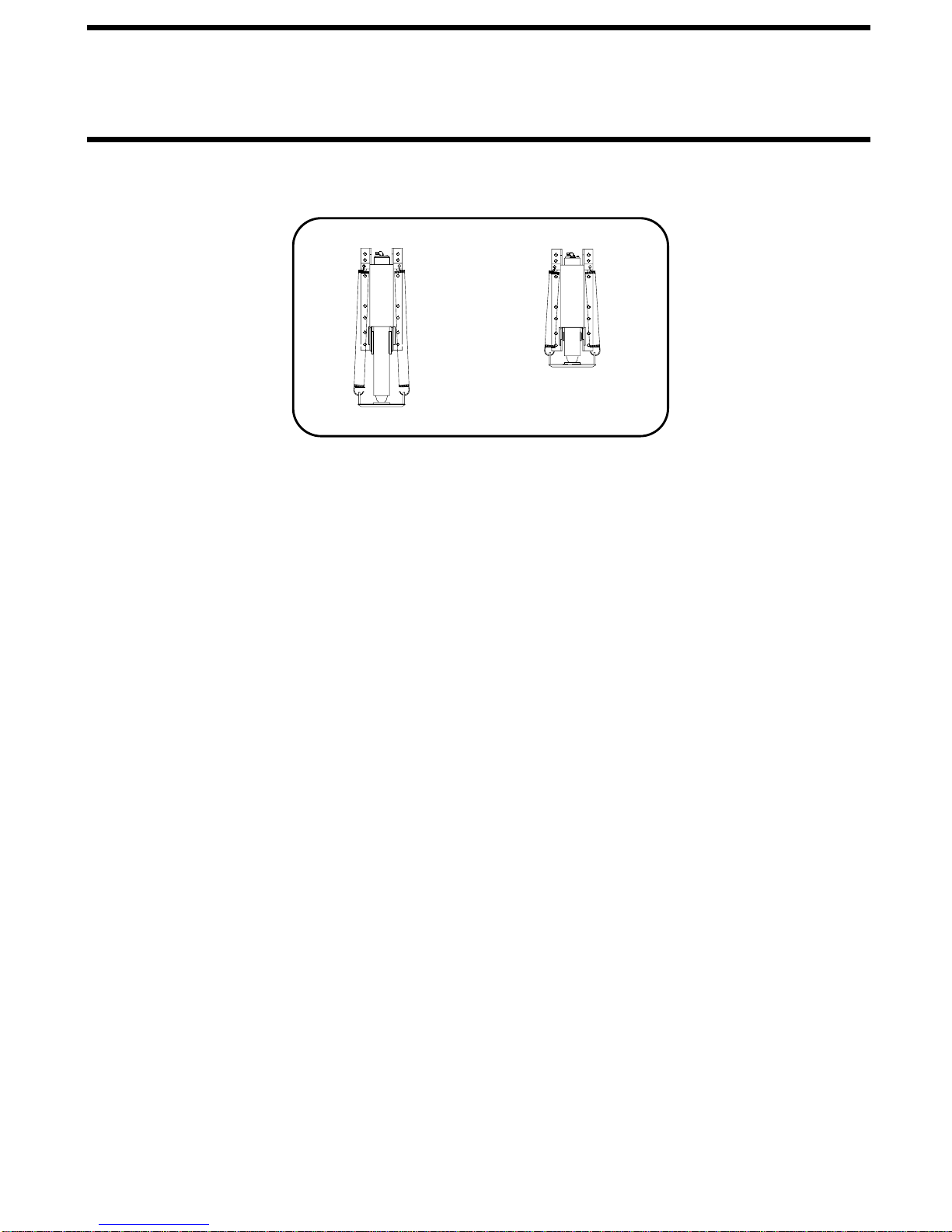

GENERATOR SLIDE EXTEND PROCEDURE

CAUTION:

CAUTION:

KEEP PEOPLE AND OBSTRUCTIONS

2. Turn the ignition switch to "ACCESSORY".

NOTE:

OPERATING THE ROOM OR GENER-

ATOR SLIDE WITH ANY ROOM-LOCKING DEVICES LOCK-

ED OR THE MANUAL-RETRACT WINCH ATTACHED CAN

CAUSE PERSONAL INJURY AND VEHICLE DAMAGE. IT

IS THE OPERATOR’S RESPONSIBILITY TO ENSURE THAT

ALL ROOM-LOCKING DEVICES AND THE MANUAL-RETRACT

Make sure there is adequate clearance to fully extend

the room or generator slide.

WINCH ARE DISENGAGED BEFORE OPERATING THE ROOM.

GENERATOR SLIDE RETRACT PROCEDURE

CAUTION:

1. Turn the ignition switch to "ACCESSORY".

KEEP PEOPLE AND OBSTRUCTIONS

1. Removing any locking devices from the generator slide.

CLEAR OF GENERATOR SLIDE WHEN OPERATING.

NOTE:

To operate the generator slide the ignition key must

be in the "ON" or "ACC" position. The leveling system does

not have to be on and the vehicle does not have to be level.

Running the generator slide will interrupt leveling procedures.

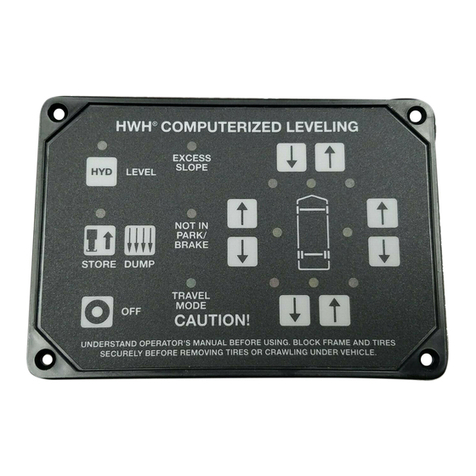

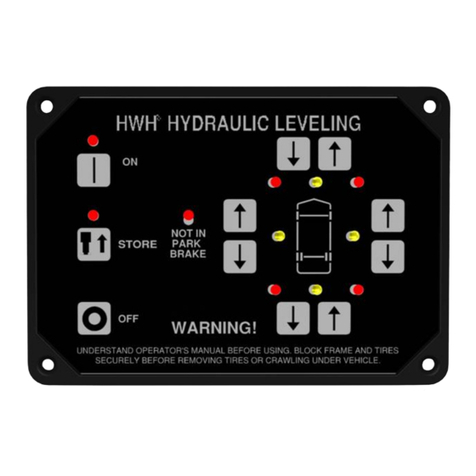

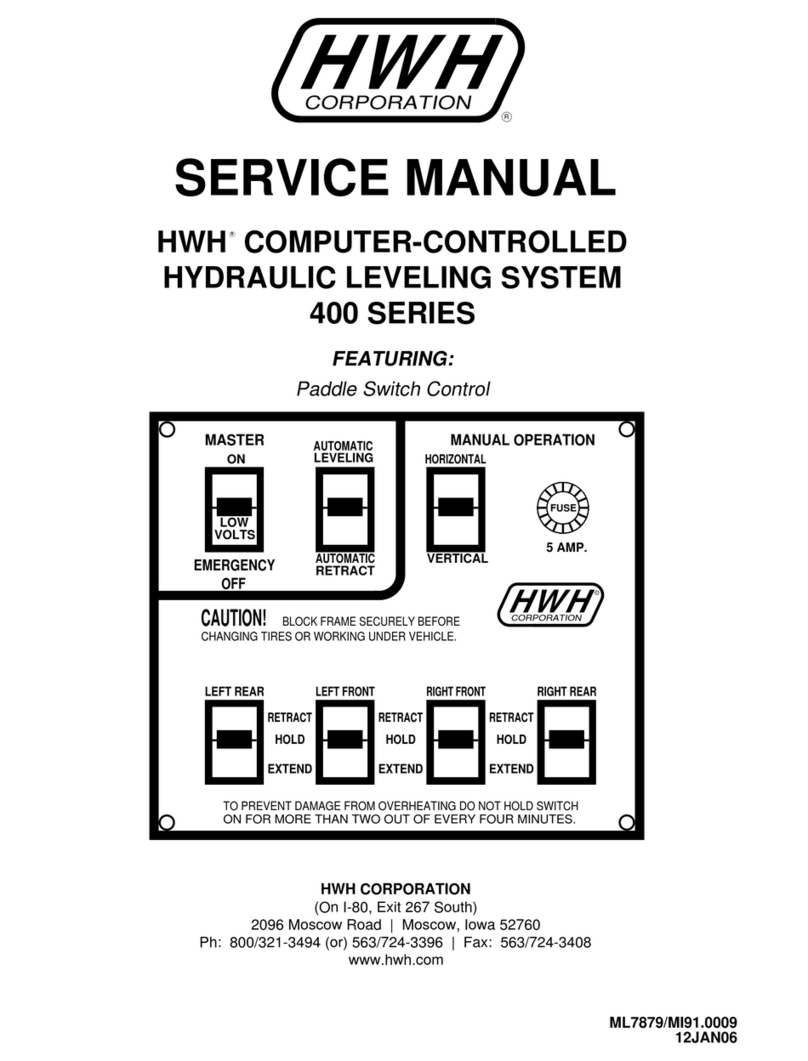

3. Push the GENERATOR SLIDE MASTER SWITCH to the

"ON" position. Refer to the CONTROL IDENTIFICATION page.

4. To extend the generator slide, press and hold the GENER-

ATOR SLIDE CONTROL SWITCH in the "EXTEND" position.

When the slide is fully extended, release the CONTROL SWITCH.

IMPORTANT:

Do not hold the CONTROL SWITCH in the

"EXTEND" position for more than ten seconds after the slide

is fully extended or stops moving.

IF EITHER SIDE OF THE

SLIDE STOPS MOVING, RELEASE THE CONTROL SWITCH

IMMEDIATELY.

NOTE:

Releasing the CONTROL SWITCH will halt the oper-

ation of the generator slide.

5. Push the GENERATOR SLIDE MASTER SWITCH to the

"OFF" position.

6. Turn off the ignition switch.

CLEAR OF THE GENERATOR SLIDE WHEN OPERATING.

2. Push the GENERATOR SLIDE MASTER SWITCH to the

"ON" position.

NOTE:

To retract the generator slide the ignition key must be

in the "ON" or "ACC" position.

3. To retract the generator slide press and hold the CONTROL

SWITCH in the "RETRACT" position. When the generator is fully

retracted, release the CONTROL SWITCH.

NOTE:

The generator slide can be retracted after the leveling

system is put in the STORE mode. This will interrupt the STORE

mode until the CONTROL SWITCH is released. The leveling

system will continue to STORE after the switch is released.

IMPORTANT:

Do not hold the GENERATOR SLIDE CONTROL

SWITCH in the "RETRACT" position for more than ten sec-

onds after the room or slide is fully retracted or stops moving.

IF EITHER SIDE OF THE GENERATOR SLIDE STOPS

MOVING, RELEASE THE CONTROL SWITCH IMMEDI-

ATELY.

NOTE:

Releasing the CONTROL SWITCH will halt the opera-

tion of the generator slide.

4. Push the GENERATOR SLIDE MASTER SWITCH to the

"OFF" position.

5. Turn the ignition switch off.

6. If the generator slide will not retract see the MANUAL ROOM

RETRACT PROCEDURE.

IMPORTANT:

Room-locking devices should be locked while

traveling.