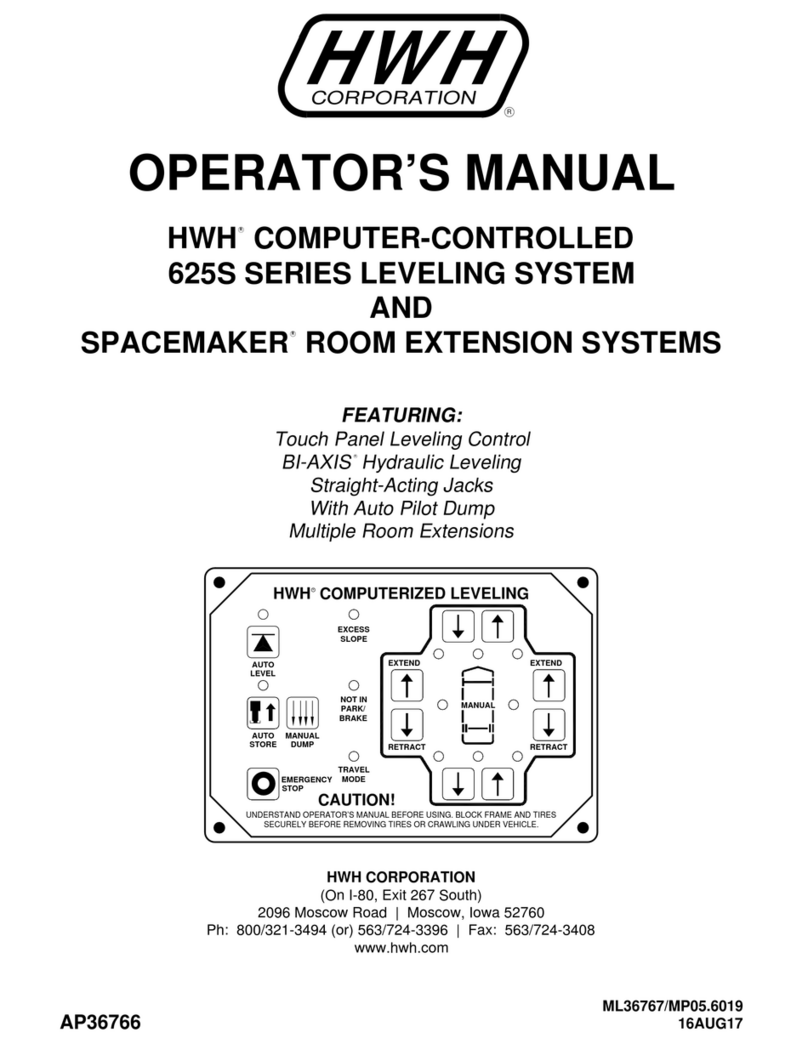

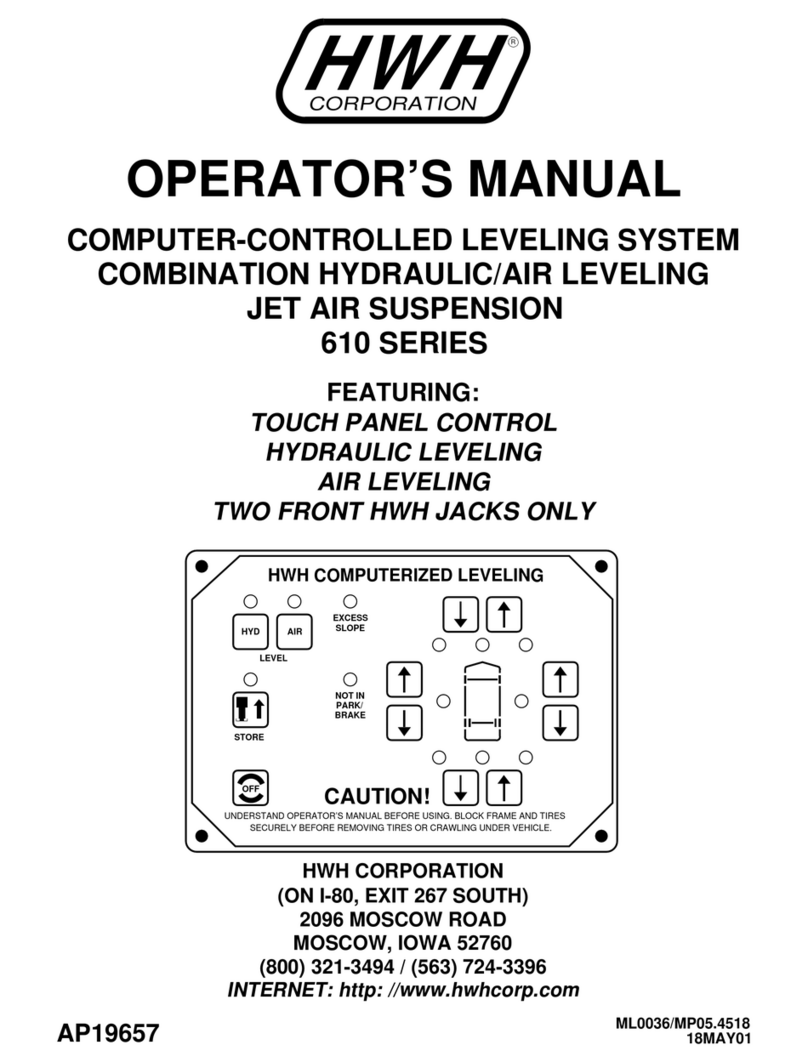

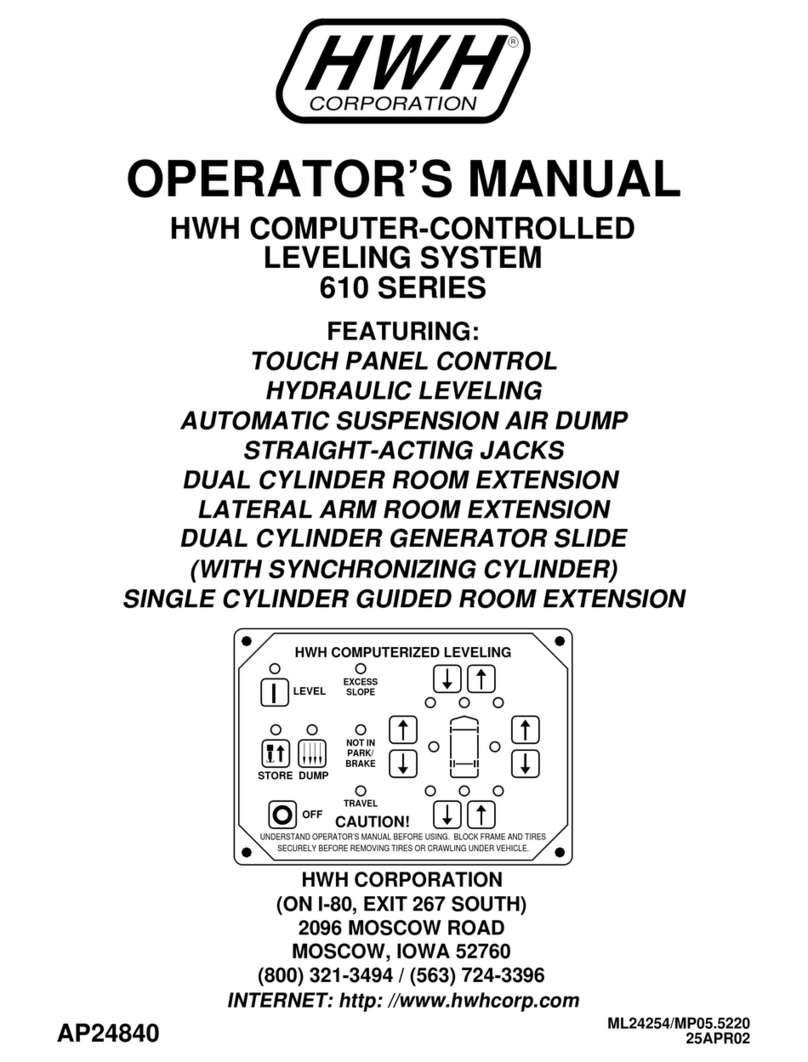

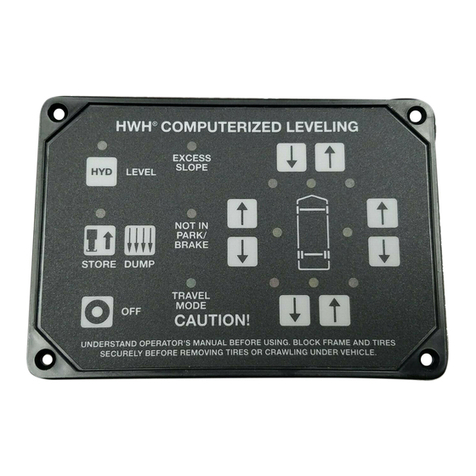

OPERATING PROCEDURES

MP35.4507

28APR98

GENERAL INSTRUCTIONS

If parking on soft ground or asphalt paving, pads should be

placed under the jacks for hydraulic leveling.

Press the "OFF" button at any time to stop the operation of the

system

may return to travel height.

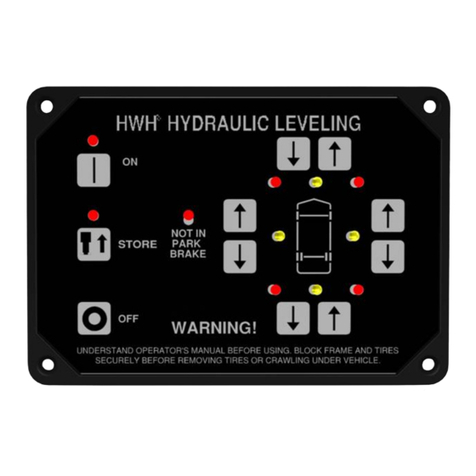

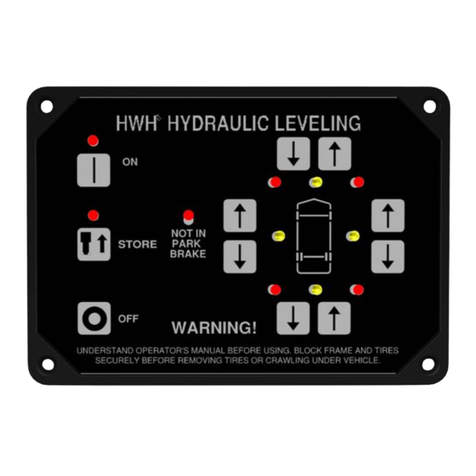

If the ignition is in the "ON" position and the park brake is not

set, the "NOT IN PARK/BRAKE" light will come on, and the

system will not turn on when either the "AIR" or "HYD" button

is pressed. If the ignition is in the "ON" position, either air or

hydraulic leveling will be stopped anytime the park brake is

released. The system will shut off and the vehicle suspension

system will return to travel height.

Air and hydraulic leveling can not be used simultaneously.

The "DUMP" and "RAISE" buttons will function with the system

and park brake off if the ignition is in the "ON" position. See

AIR DUMP AND RAISE FUNCTIONS.

The MASTER WARNING light and buzzer will be on if a jack

is extended two inches or more or if an air bag has low air

pressure if the ignition is in the "ON" position.

CAUTION:

DO NOT MOVE THE VEHICLE IF A

PREPARATION FOR TRAVEL

Start the vehicle’s engine and allow air pressure to build to

recommended level for traveling.

Visually check that the jacks are in the STORE/TRAVEL position.

Also check that the vehicle’s suspension is at the proper height

for travel.

Before traveling, the MASTER WARNING light and buzzer

must be off.

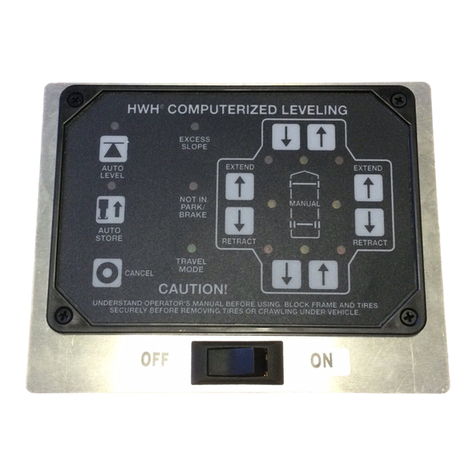

HYDRAULIC OPERATION

"ON" or "ACC" position. When the leveling system is off and

the ignition is in the "ON" position, the vehicles suspension

can return to travel height.

1. Place the transmission in the recommended position for

parking the vehicle and set the park brake.

2. At this time, the operator may want to check the jacks and

place pads under the jacks if the ground will not support the

vehicle on the jacks.

3. Turn the ignition to the "ACC" position.

4. Press the "HYD" button to enter the hydraulic operation mode.

The HYDRAULIC OPERATION indicator light will glow steady.

5. Press the "HYD" button a second time. The HYDRAULIC

OPERATION indicator light will start to flash. The system will

begin to dump air from the vehicle’s suspension. After approx-

imately 25 seconds the system will automatically extend the

jacks to level the vehicle and then extend any remaining jacks

until they touch the ground. After the system has finished

leveling and stabilizing, and has completed the air dump cycle,

it will automatically shut off.

The panel will stay on 45 seconds regardless of the time taken

to level the vehicle.

EXCESS SLOPE SITUATION: In the event that the jacks are

unable to level the vehicle, the "EXCESS SLOPE" indicator

light will come on. The pump will shut off. One or two yellow

LEVELING indicator lights will remain on. The HYDRAULIC

OPERATION indicator light will continue to flash for 2 minutes,

then the system will shut off. The system will not stabilize the

vehicle if the "EXCESS SLOPE" light comes on. Store the

jacks according to the JACK RETRACTION Section. Move

the vehicle to a more level position or level the vehicle as close

as possible according to the MANUAL HYDRAULIC OPERATION

6. Turn the ignition switch to the "OFF" position.

CAUTION:

Section.

AUTOMATIC HYDRAULIC LEVELING

NOTE:

If the ignition switch is "ON" the vehicle’s air suspension

NOTE:

Hydraulic leveling can be used with the ignition in the

NOTE:

Air will continue to dump during the leveling process.

DO NOT MOVE THE VEHICLE WHILE THE

LEVELING JACKS ARE STILL IN CONTACT WITH THE

GROUND OR IN THE EXTEND POSITION. THIS VEHICLE

IS EQUIPPED WITH STRAIGHT-ACTING JACKS. MOVING

THE VEHICLE WITH THE LEVELING JACKS EXTENDED

CAN CAUSE SEVERE DAMAGE TO THE JACKS AND OR

THE VEHICLE AND CREATE A DRIVING HAZARD. DO NOT

RELY SOLELY UPON WARNING LIGHTS. IT IS THE OPER-

ATOR’S RESPONSIBILITY TO CHECK THAT ALL JACKS ARE

FULLY RETRACTED INTO THE STORE POSITION.

IT IS THE OPERATOR’S RESPONSIBILITY TO

CHECK THAT THE VEHICLE IS AT THE PROPER RIDE HEIGHT

Check that the room extension is fully retracted.

The "TRAVEL" light on the leveling panel must be on.

EXTENSION IS EXTENDED.

WARNING LIGHT OR BUZZER IS ON, OR IF THE ROOM

CAUTION:

BEFORE TRAVELING.

Read room operating procedures before operating any rooms.