3 / 51

C O N T E N T S

1. INTRODUCTION 4

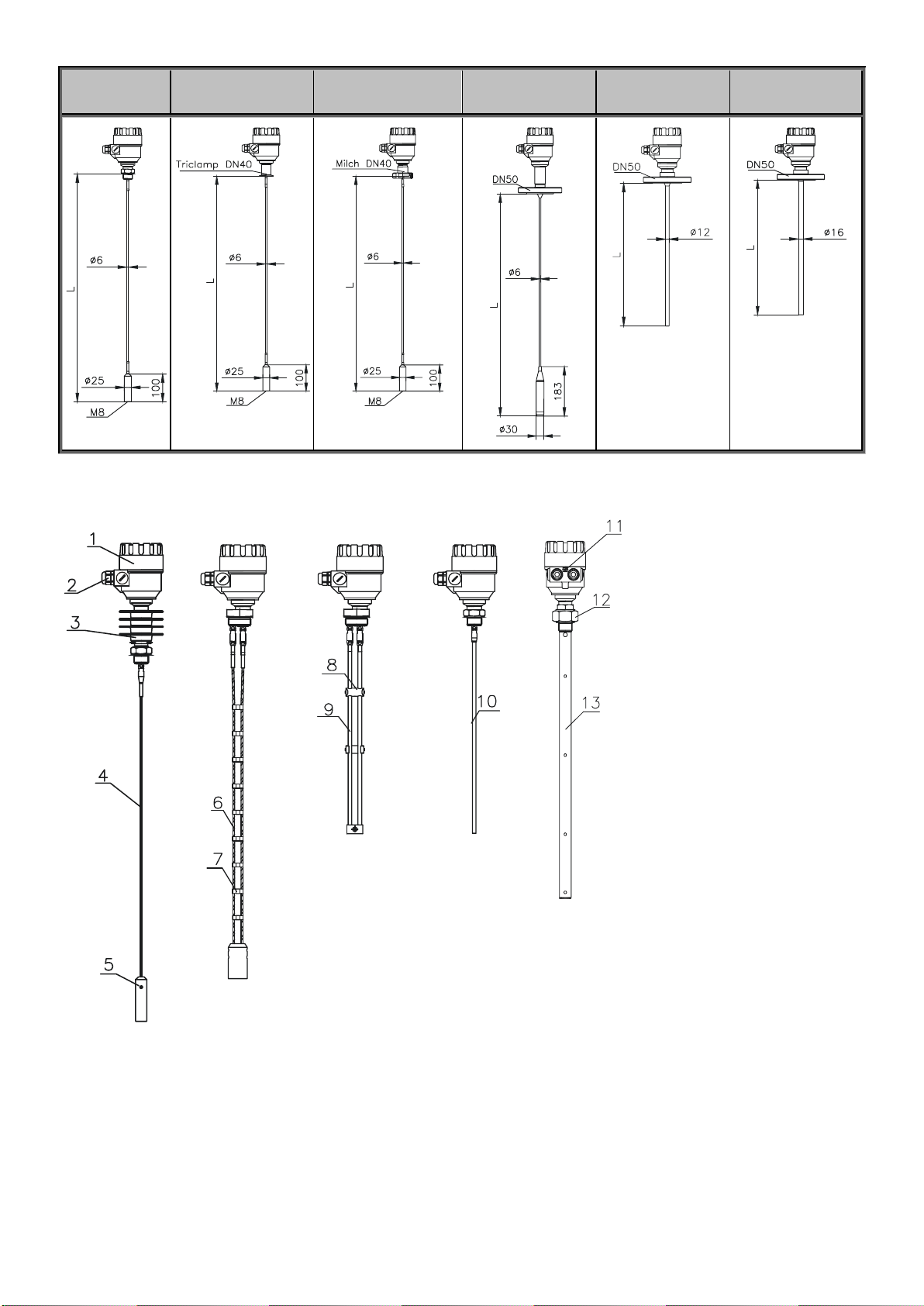

2. ORDER CODE 5

3. TECHNICAL DATA 5

3.1 ATEX, Explosion protection, Ex markings, Ex limit data 6

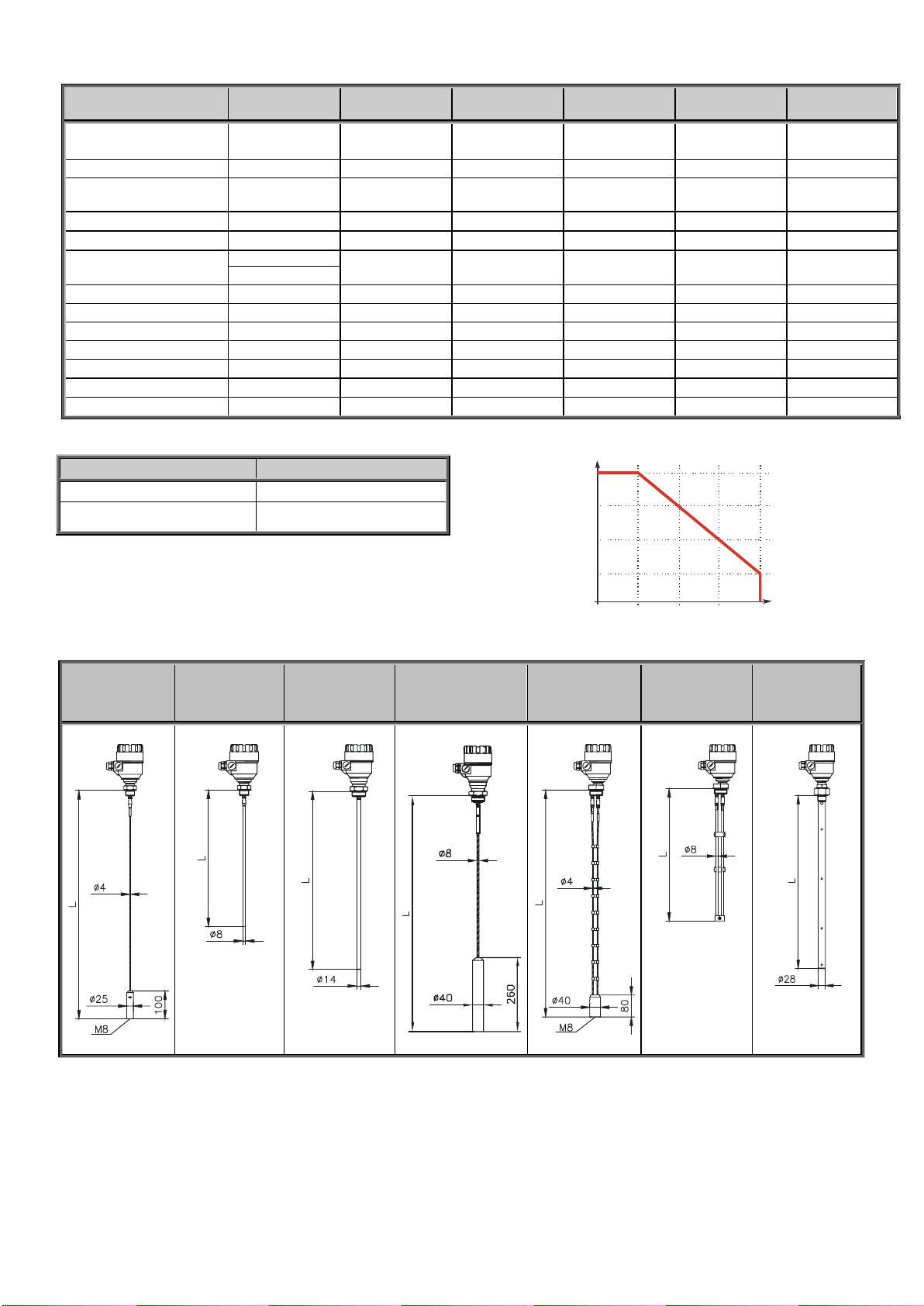

3.2 Technical data of the probes 6

3.3 Accessories 10

3.4 Safety regulations for the Ex approved units 10

3.5 Maintenance and repair 10

4. MECHANICAL INSTALLATION 11

4.1 Handling and storage 11

4.2 Mounting on the tank 12

4.2.1 Installation instructions: general notes 12

4.2.2 Specific installation instructions: instrument - solid applications 15

4.3 Wiring 16

4.3.1 BUS ( HART®) communication 19

4.4 Power-on and start-up 19

4.5 Available user interfaces 19

5. PROGRAMMING 20

5.1 Programming with HyView software 20

5.1.1 HyView: installation and operation. 20

5.1.2 Summary of Parameter functions In HyView 24

5.1.3 Configuration: configuration examples 29

5.2 Programming with VGF-DISPLAY display unit 35

5.2.1 VGF-DISPLAY display unit 35

5.2.2 VF04’s behaviour in manual programming mode 36

5.2.3 Manual programming requires a VGF-DISPLAY module 36

5.3 Programming with HART® handheld (HHC) Communicator 37

5.3.1 Characters available for alpha-numerical data functions in HyView and on the HART®console 41

5.4 VF04 2-wire T.D.R. meter characteristics 41

5.4.1 Instrument operating logic when the reflection is lost 42

5.4.2 Gain and voltage amplitude 43

5.4.3 Typical signal trends 45

5.4.4 Automatic adjustment 46

5.4.5 Level measurement when more than one phase or layer in the tank 47

5.5 Troubleshooting 48

APPENDIX 1. ATEX SAFETY GUIDELINES 50