3 / 27

CONTENTS

1. INTRODUCTION ...................................................................................................................................................................................................4

2. ORDER CODES ....................................................................................................................................................................................................4

3. TECHNICAL DATA ...............................................................................................................................................................................................5

3.1. Explosion Protection, Designation, Limit Values ..........................................................................................................................................7

3.2. Accessories...................................................................................................................................................................................................7

3.3. Conditions for Safe Use................................................................................................................................................................................7

3.4. Maintenance and Repair...............................................................................................................................................................................7

4. INSTALLING .........................................................................................................................................................................................................8

4.1. Handling and Storage ...................................................................................................................................................................................8

4.2. Mounting on Containers................................................................................................................................................................................8

4.2.1. General mounting instructions .................................................................................................................................................................8

4.2.2. Installing the Device for Measuring Solids.............................................................................................................................................10

4.3. Wiring..........................................................................................................................................................................................................11

4.3.1. BUS (HART®) communication ...............................................................................................................................................................12

4.4. Switching On and Commissioning..............................................................................................................................................................12

4.5. Available User Interfaces............................................................................................................................................................................12

5. PROGRAMMING.................................................................................................................................................................................................13

5.1. Programming with HyView..........................................................................................................................................................................13

5.1.1. Installing and Running HyView ..............................................................................................................................................................13

5.1.2. Programming and Configuring the Device.............................................................................................................................................13

5.1.3. Programming Example 1 (Using HyView):.............................................................................................................................................18

5.2. Programming with the VGF-DISPLAY: Display Unit...................................................................................................................................19

5.2.1. VGF-DISPLAY: Display Unit ..................................................................................................................................................................19

5.2.2. The Behavior of the VF05 while Programmed Manually .......................................................................................................................19

5.3. Properties of VF05 Two-Wire Microwave Level Transmitter ......................................................................................................................21

5.3.1. Level Measurement –Level reflection, Threshold Line and Automatic Gain Adjustment .....................................................................21

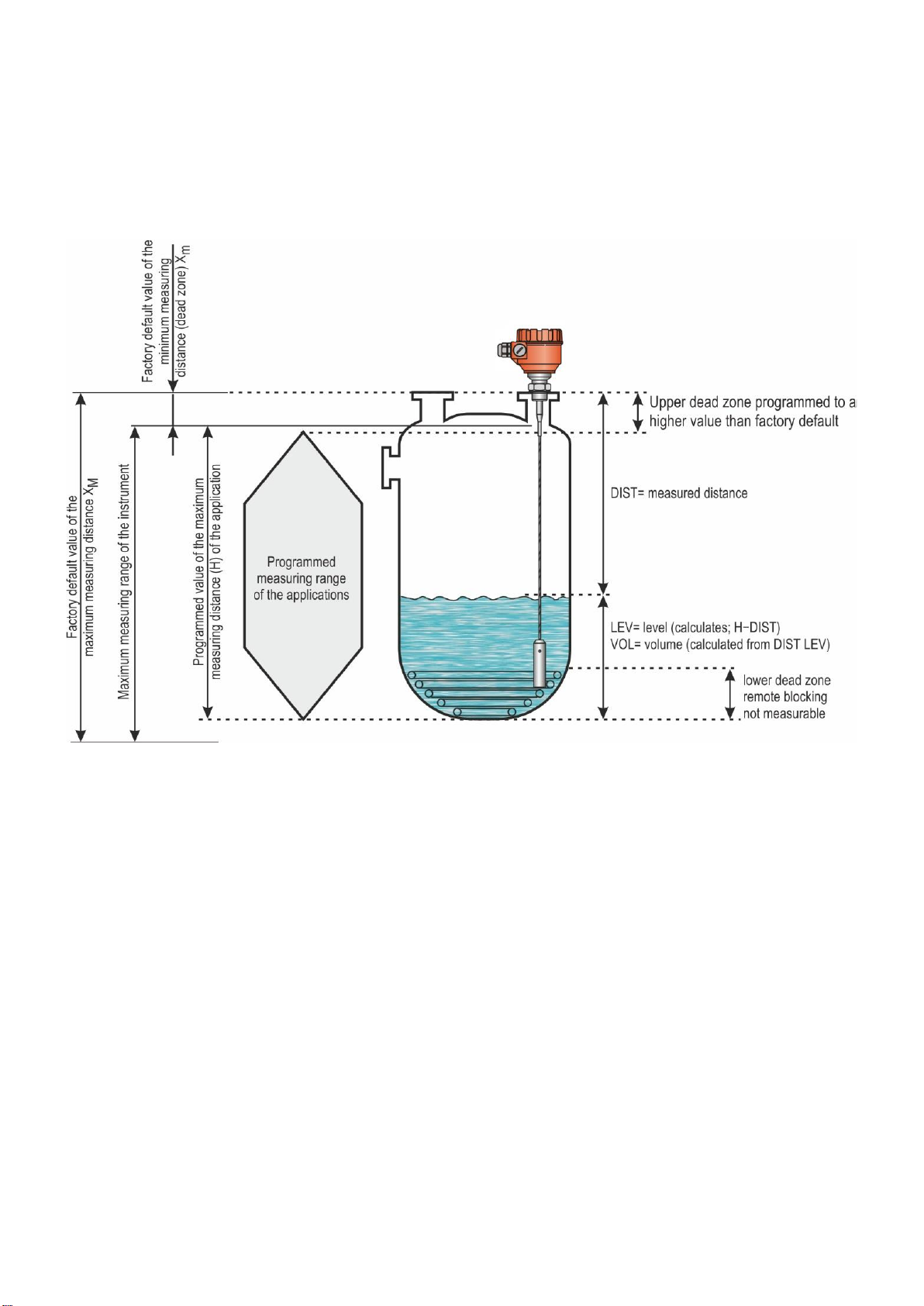

5.3.2. To illustrate the five possible configurations, the following fluid level measurement settings are assumed .........................................22

5.3.3. Echo Loss Handling ...............................................................................................................................................................................22

5.3.4. Typical Signal Forms..............................................................................................................................................................................24

5.4. Troubleshooting ..........................................................................................................................................................................................25