SECTION 1.00

GENERAL SAFETY PRECAUTIONS - READ

AND FOLLOW INSTRUCTIONS

Carefully read and understand all safety messages in this

manual before using the equipment. The manuals provided

with the equalization pump must also be read for safety.

The maintenance procedures are to be

followed to keep the equipment in good working condition.

PERSONAL PROTECTION

Hydra-Stop recommends that installers wear required per-

sonal protective equipment including but not limited to:

• Hard Hat

• Safety Shoes

• Safety Glasses

• Ear Protection

• Gloves

Avoid wearing jewelry, such as rings, wristwatches, neck-

laces, or bracelets. If working near traffic, select ear protec-

tion that allows you to hear the traffic for safety.

KEEP SPECTATORS AWAY FROM INSTALLATION

AREA

Keep all spectators and other workers away from machines

and work area(s) while in operation.

CLEAR WORK AREA

Clear the work area of all objects that might interfere with

the proper operation of any tools. Avoid placing tools or

other objects where they can fall into the pit.

DO NOT WORK IN AN UNSUPPORTED TRENCH

Do not work in trench with unstable sides, which could

cave in. Specific requirements for shoring or sloping trench

walls are available from several sources including federal

and state offices. Be sure to contact suitable authorities for

these requirements before working in the trench. A mini-

mum 5’x 5’excavation is recommended.

Locate the existing pipe joints or fittings in the area and use

the appropriate restraint methods if necessary.

CHECK LAWS AND REGULATIONS

Know and obey all Federal, State, and local laws and regu-

lations that apply to your work situation.

HANDLING THE EQUIPMENT

To avoid back injury, use proper lifting techniques. Follow

all equipment instructions when lifting heavy loads.

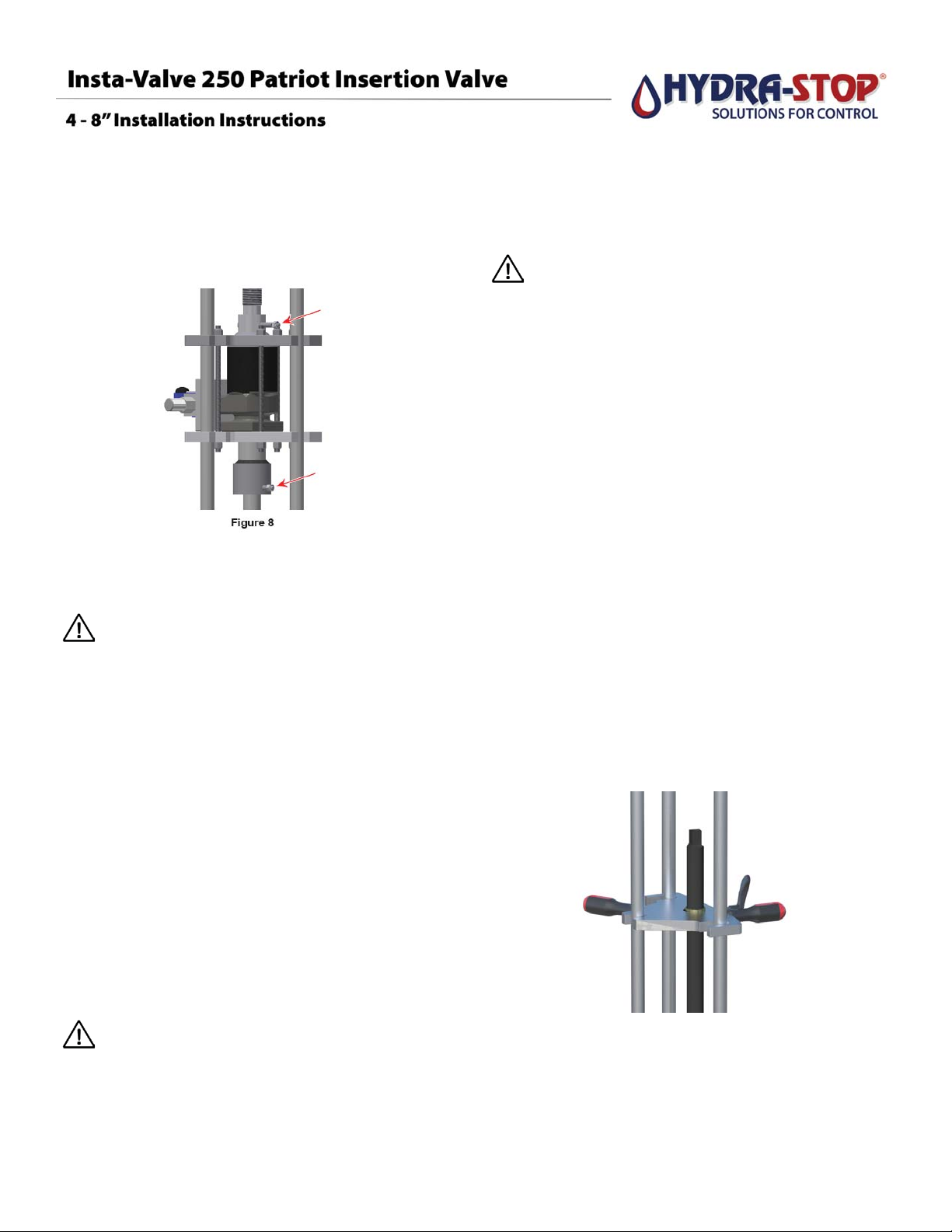

CHECK HARDWARE AND EQUIPMENT

Make sure that all air or hydraulic line couplings are tight-

ened and secured to eliminate the chance of

accidental uncoupling. Use hose connection retaining

devices such as locking rings, clips, pins, chains, or cables.

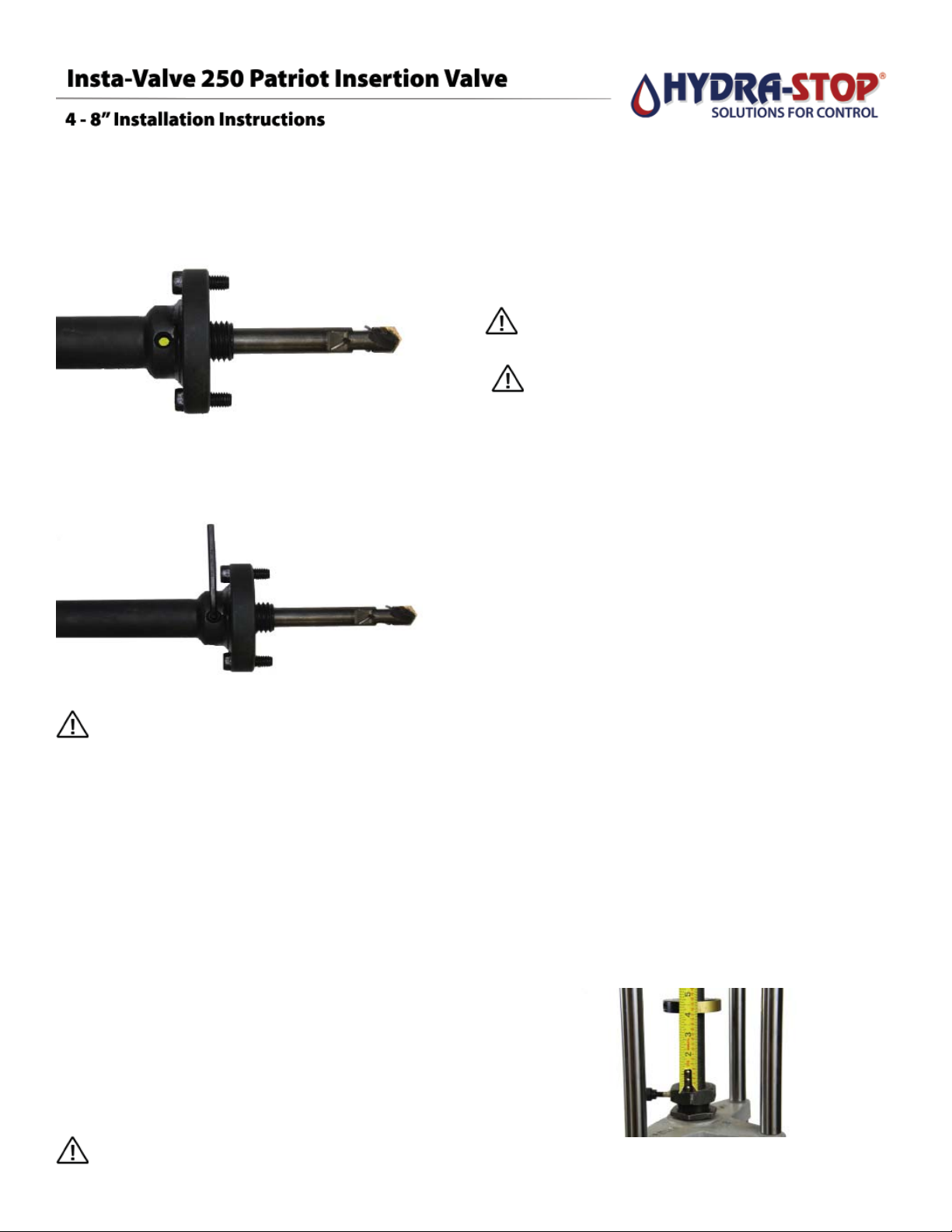

Identify all equipment and tools necessary for the size of IV

250 you intend to install. Please refer to the attached tool

list (See Appendix A). Inspect equipment to verify it is in

good working condition and free of wear and damage prior

to use. Never start an operation if the equipment is not in

proper working order. Contact Hydra-Stop if equipment is

not in working order.

DO NOT EXCEED LOAD RATING ON ANY LIFT-

ING EQUIPMENT

This includes but is not limited to lifting magnets, eyebolts

and straps. Lifting magnets provided with Hydra-Stop

equipment are labeled with a load rating. 12” knife gate

lifting assists and ¾” eye bolts should ONLY be used for

lifting 12” and 8” temporary gate valves respectively.

WARNING: Failure to follow any of the above safety

instructions or those that follow in this manual, could result

in serious injury. Any operation involving work on pipe

containing liquids or gases under pressure is potentially

hazardous. It is necessary, therefore, that correct proce-

dures be followed in the use and maintenance of this equip-

ment to maintain a safe working environment.

No person should use this equipment who is not fully

trained in the procedures stated in this manual, and who

is not fully aware of the potential hazards connected with

work on pipe containing liquids or gases under

pressure.

The purchaser of this equipment is responsible for the

manner in which this equipment is used, maintained and the

training, competence and safety of the operators.

Should any difficulty arise at any time in the use of this

equipment, please contact HYDRA-STOP at 708-389-5111

immediately.

GENERAL SAFETY WARNINGS