4

All Valves

1. With the valve in the open position, verify that

flow passes through the valve.

2. With the valve in the closed position, verify

that no flow passes through the valve.

3. Test the diaphragm seal and the seat seal for

leakage by performing an inboard helium leak

test to a rate of 1 10–9 std cm3/s.

4. Test the seat seal for leakage at the

application pressure.

Manually Actuated (Round Handle) Valves

1. Turn the handle to the open position, then

the closed position to test for proper three-

quarters turn operation.

Manually Actuated (Integral

Lockout Handle) Valves

1. Turn the handle to the open, then the closed

position to test for proper three-quarters turn

operation.

2. With the valve in the closed position, pull

up on the handle to test for proper locking

function.

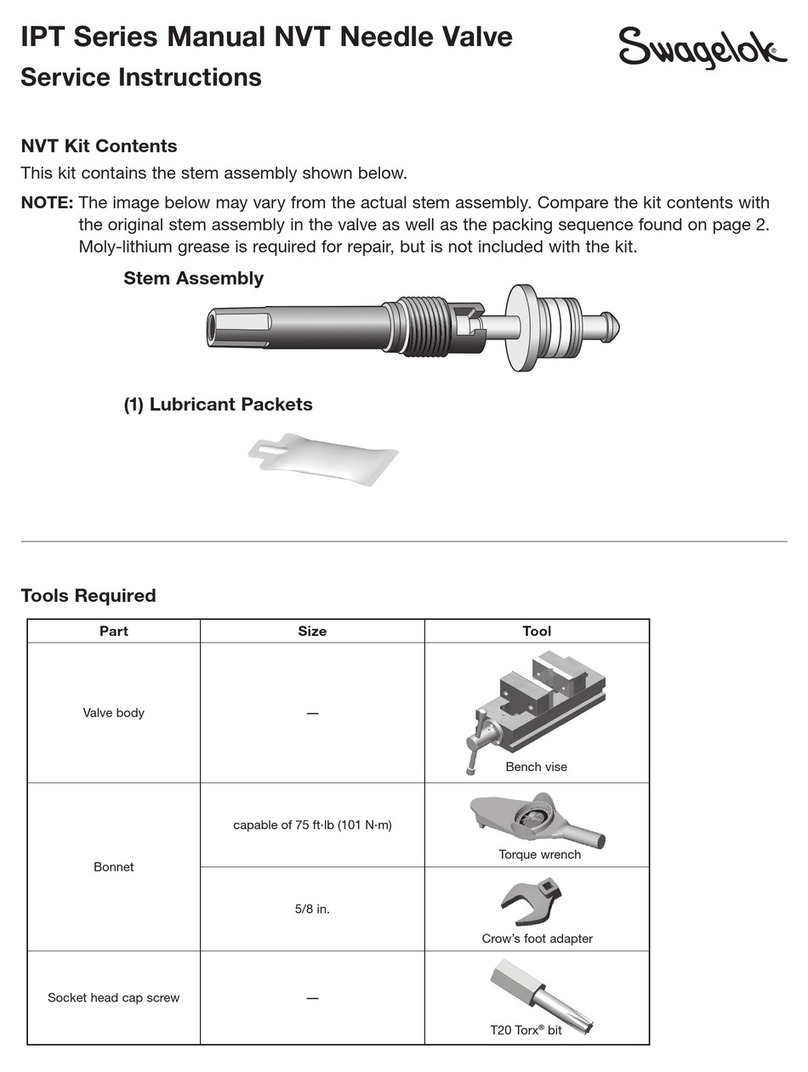

Welding

location

Purge Gas Flow

Welding

location

Purge Gas Flow

Testing

Welding (All Valve Types)

CAUTION

Disassembly of the valve is not required

for inline welding if proper precautions are

taken. If the valve is disassembled, cover

the sealing surfaces to protect them from

nicks and weld spatter.

WARNING

Welding should be done by qualified

personnel as outlined in Section IX of the

ASME Boiler Code.

1. If necessary, use a heat sink to prevent

excessive heating of internal components.

2. Actuate the valve to the OPEN position.

3. Connect the purge gas supply so that the gas

exits out of the valve port being welded.

CAUTION

Use a high quality purge gas to maintain

cleanliness and reduce welding

discoloration.

4. Perform the weld.

5. With the valve in the open position, purge the

valve and system of contamination.

6. Test the valve for proper operation and

leak-tight integrity. See Testing.